Lignin porous microspheres based on W/O/W type multiple emulsion solvent volatilization and preparation method and application thereof

A technology of porous microspheres and lignin, applied in the fields of botanical equipment and methods, applications, chemical instruments and methods, etc., can solve the problems of not conforming to the concept of green chemistry, not realizing the maximum utilization of lignin, and low proportion, etc. Achieve the effect of improving solubility, good biocompatibility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

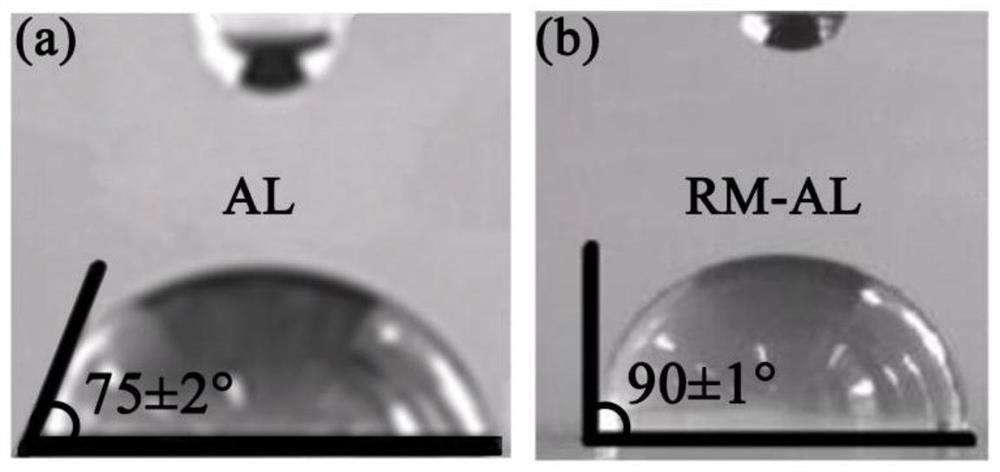

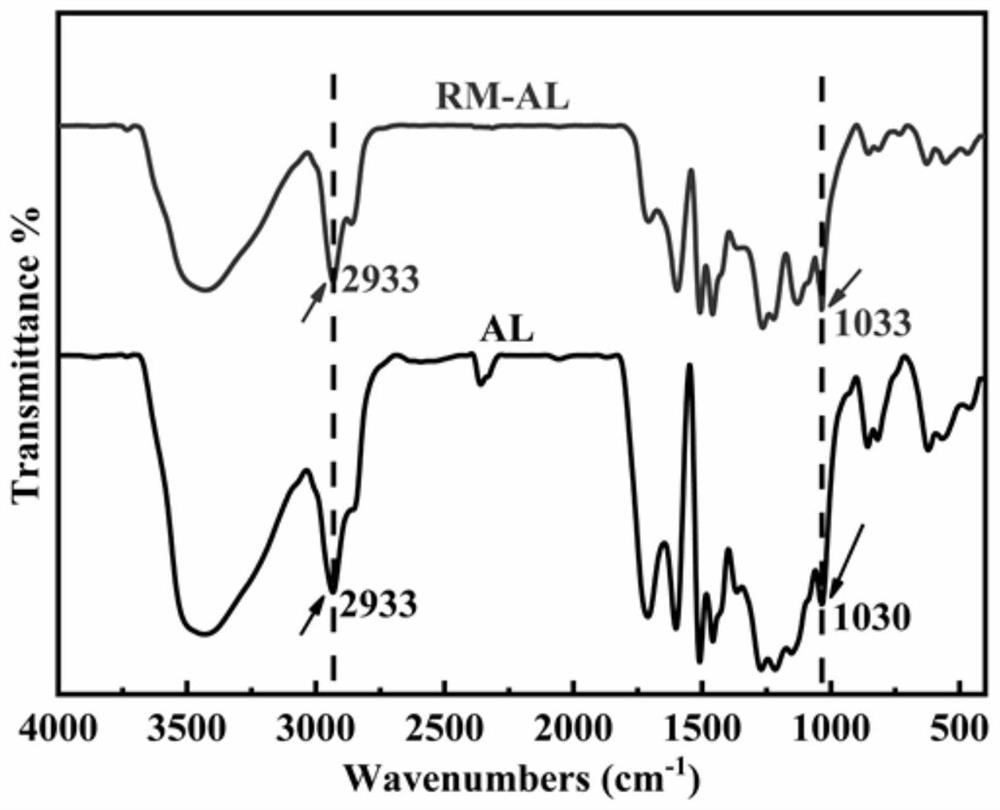

[0046] (1) Preparation of hydrophobic lignin: 10 g of dried wood pulp black liquor of acid-separated lignin powder was dissolved in 100 g of acetone solution containing 2 g of dodecyl vinyl ether, at room temperature N 2 Under the atmosphere, the cobalt source was irradiated continuously until the absorbed dose was 60 kGy, and the radiation dose rate was 5 kGy / h. Finally, the obtained mixed solution is rotary-evaporated and dried to obtain hydrophobically modified lignin powder.

[0047] (2) Preparation of lignin particle dispersion: disperse 2 g of the hydrophobically modified lignin in step (1) in 100 g of water, adjust the pH to 11 with 1 mol / L NaOH solution, filter and remove impurities to obtain a hydrophobically modified lignin solution , and then use 1 mol / L HCl solution to adjust the pH of the system to 3, so that lignin is precipitated to form a lignin particle dispersion.

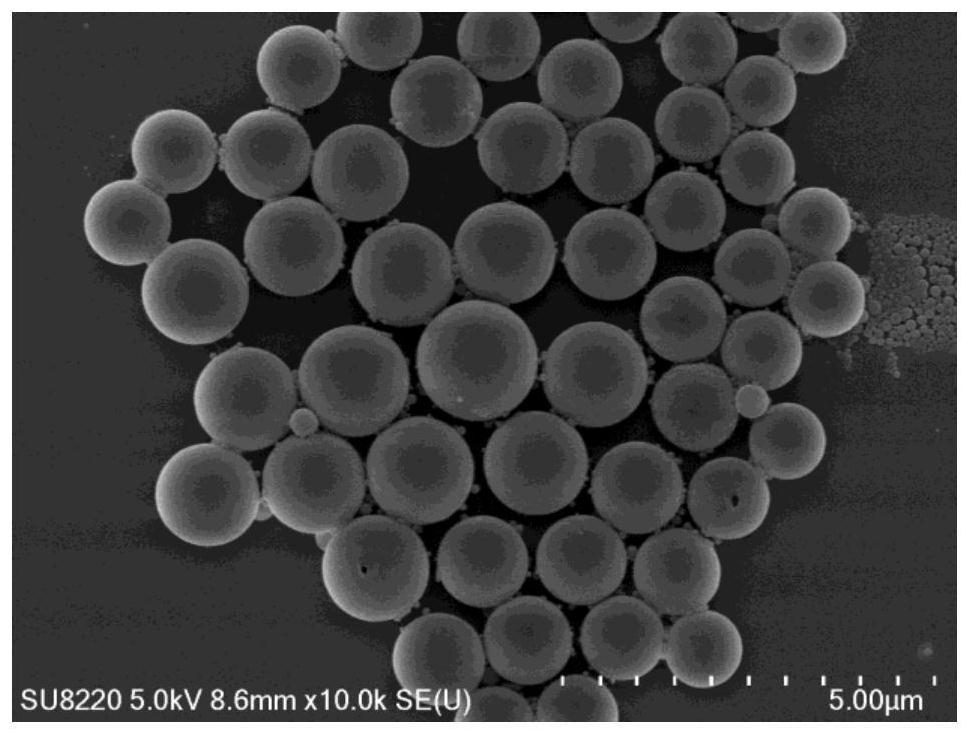

[0048] (3) Preparation of W / O / W type double emulsion: first, add 2.5g deionized water to 7.5g...

Embodiment 2

[0051] (1) Preparation of hydrophobic lignin: 10 g of dried bamboo pulp black liquor acid-separated lignin powder was dissolved in 100 g of acetone solution containing 0.5 g of methyl acrylate, and at room temperature N 2 Under the atmosphere, the cobalt source was irradiated continuously until the absorbed dose was 40 kGy, and the radiation dose rate was 2 kGy / h. Finally, the obtained mixed solution is rotary-evaporated and dried to obtain hydrophobically modified lignin powder.

[0052] (2) Preparation of lignin particle dispersion: disperse 5 g of the hydrophobically modified lignin in step (1) in 100 g of water, adjust the pH to 12 with 1 mol / L NaOH solution, filter and remove impurities to obtain a hydrophobically modified lignin solution , and then adjust the pH of the system to 5 with 1 mol / L acetic acid solution to precipitate lignin to form a lignin particle dispersion.

[0053] (3) Preparation of W / O / W type double emulsion: firstly, 2.5g deionized water was added to...

Embodiment 3

[0056] (1) Preparation of hydrophobic lignin: Dissolve 10 g of dry enzymatically hydrolyzed lignin powder in 100 g of acetone solution containing 1 g of vinyltrimethoxysilane, and at room temperature N 2 Under the atmosphere, the cobalt source was irradiated continuously until the absorbed dose was 30 kGy, and the radiation dose rate was 0.5 kGy / h. Finally, the obtained mixed solution is rotary-evaporated and dried to obtain hydrophobically modified lignin powder.

[0057] (2) Preparation of lignin particle dispersion: disperse 10 g of the hydrophobically modified lignin in step (1) in 100 g of water, adjust the pH to 10 with 1 mol / L ammonia water, filter and remove impurities to obtain a hydrophobically modified lignin solution, Then use 1mol / L H 2 SO 4 The pH of the solution was adjusted to 3, and the lignin was precipitated to form a lignin particle dispersion.

[0058] (3) Preparation of W / O / W type double emulsion: First, add 2.5g deionized water to 7.5g of ethyl acetat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com