Liquid medicine stirring apparatus for gene engineering

A technology of liquid medicine and stirring device, which is applied in the field of genetic engineering, can solve the problems of small stirring range, increased workload, and improve stirring efficiency, so as to achieve the effect of improving the effect of stirring and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

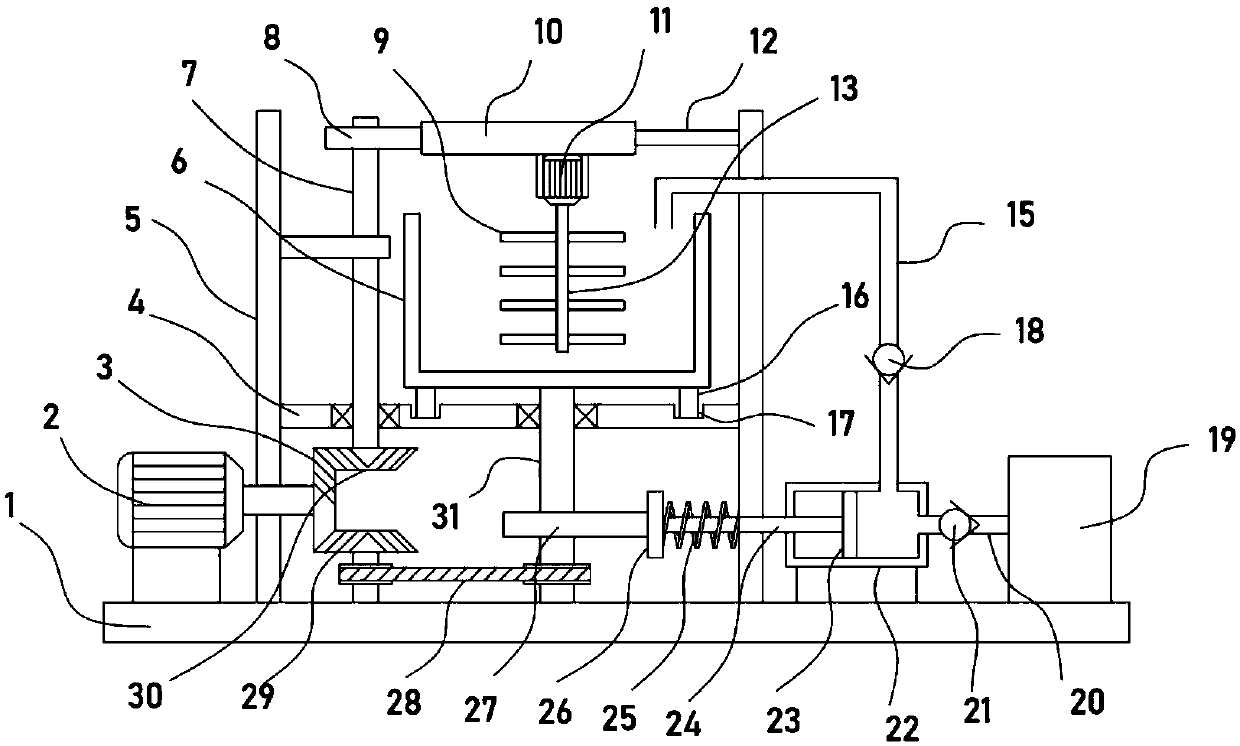

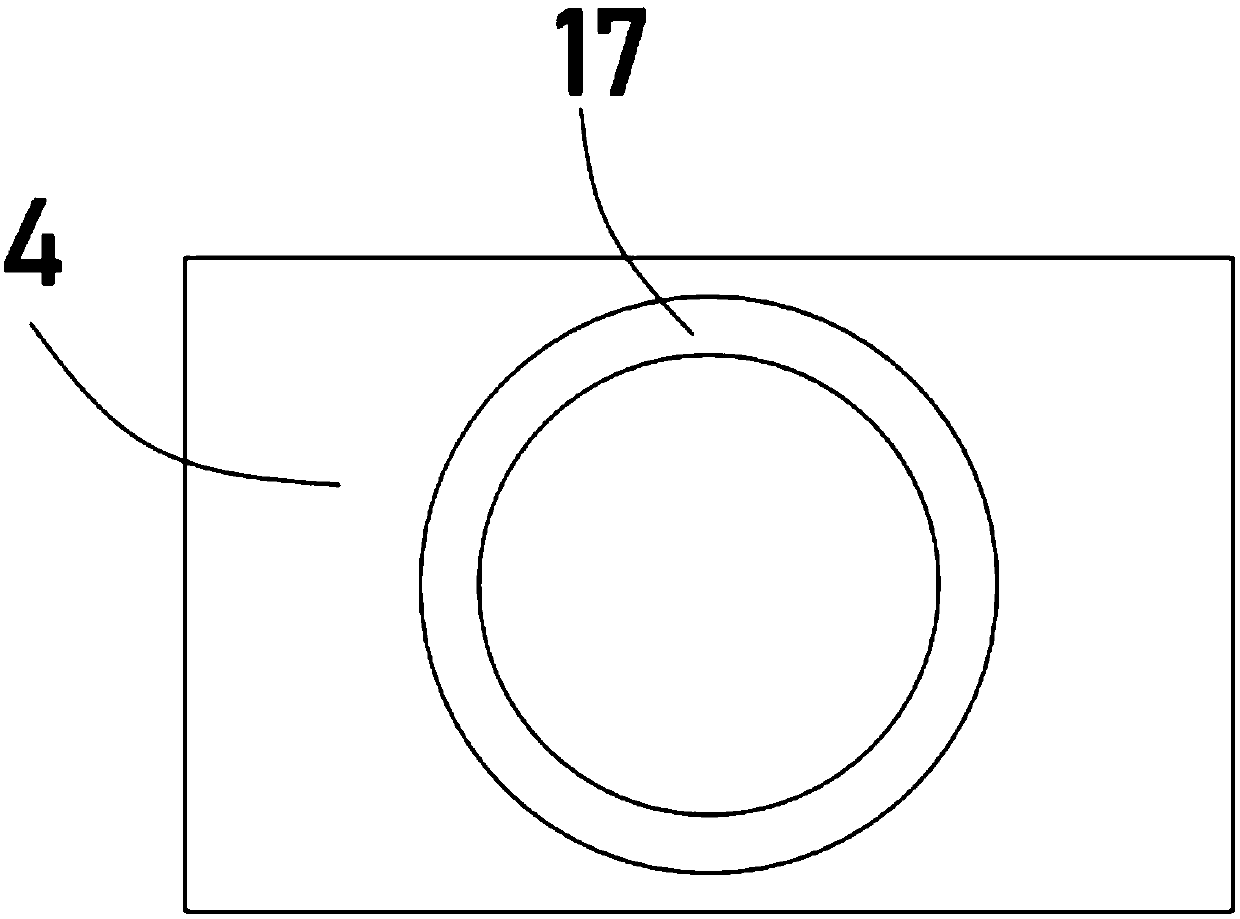

[0021] see Figure 1-3 , a genetic engineering liquid medicine mixing device, comprising a bearing plate 1, a support frame 5 is fixedly installed on the support plate 1, a horizontal plate 4 is horizontally fixed on the support frame 5, and a stirring device for holding liquid medicine is installed on the horizontal plate 4 Groove 6, stirring tank 6 top is provided with stirring motor 11, and the output shaft coaxial of stirring motor 11 is fixedly installed with the stirring shaft 13 that extends to stirring tank 6, and stirring shaft 13 surface is evenly fixed with some pairs of stirring blades 9, by setting The stirring motor 11 drives the stirring shaft 13, and the stirring shaft 13 drives the stirring blade 9 on it to stir and mix the liquid drug components in the stirring tank 6.

[0022] A rotating shaft 31 pivotally connected to the horizontal plate 4 is vertically provided at the bottom of the stirring tank 6 , and the rotating shaft 31 is driven to rotate by a drivi...

Embodiment 2

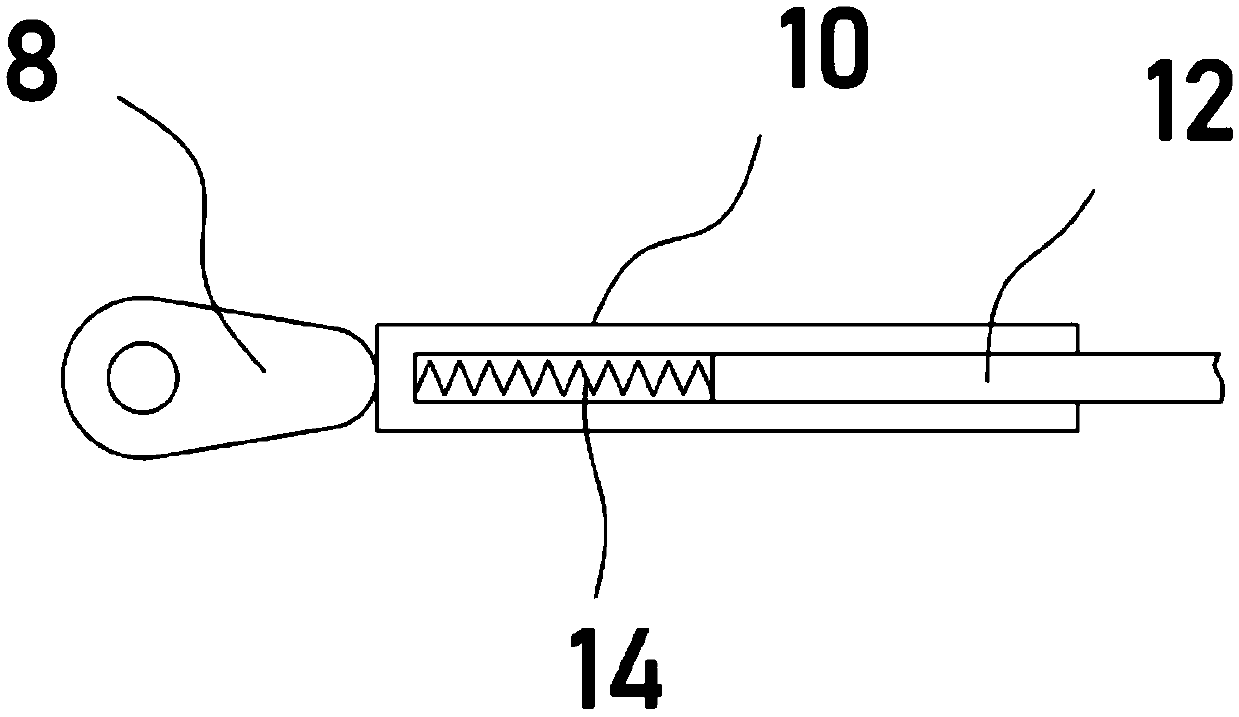

[0026] In order to fully stir the liquid drug components in different positions of the stirring tank 6, on the basis of Embodiment 1, in addition, the bevel gear II30 is coaxially fixed with a vertically arranged driven shaft 7, and the driven shaft 7 A cam I8 is fixed, and the cam I8 abuts against a horizontally arranged casing 10. The stirring motor 11 is fixed on the bottom of the casing 10, and a guide rod 12 fixedly connected with the support frame 5 is slidably installed in the casing 10. Inside the casing 10 There is a return spring 14 whose two ends are respectively fixed on the guide rod 12 and the bushing 10 .

[0027] Through the above settings, the incomplete bevel gear 3 meshes with the bevel gear II30 to drive the driven shaft 7 to rotate together with the cam I8, and the cam I8 realizes lateral reciprocating motion under the elastic force of the return spring 14 by abutting the sleeve 10, and the guide rod 12 plays a role Guiding effect, now the stirring shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com