Preparation equipment for producing chemical divinylbenzene catalyst

A divinylbenzene and catalyst technology, applied in chemical instruments and methods, chemical/physical processes, mixers with rotating stirring devices, etc., can solve the inconvenience of carrying and moving, cannot be cleaned quickly, and cannot realize multiple roots Stirring shaft synchronous reverse stirring mixing and stirring structure linkage work and other issues, to achieve the effect of easy carrying and transferring, convenient carrying and transferring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

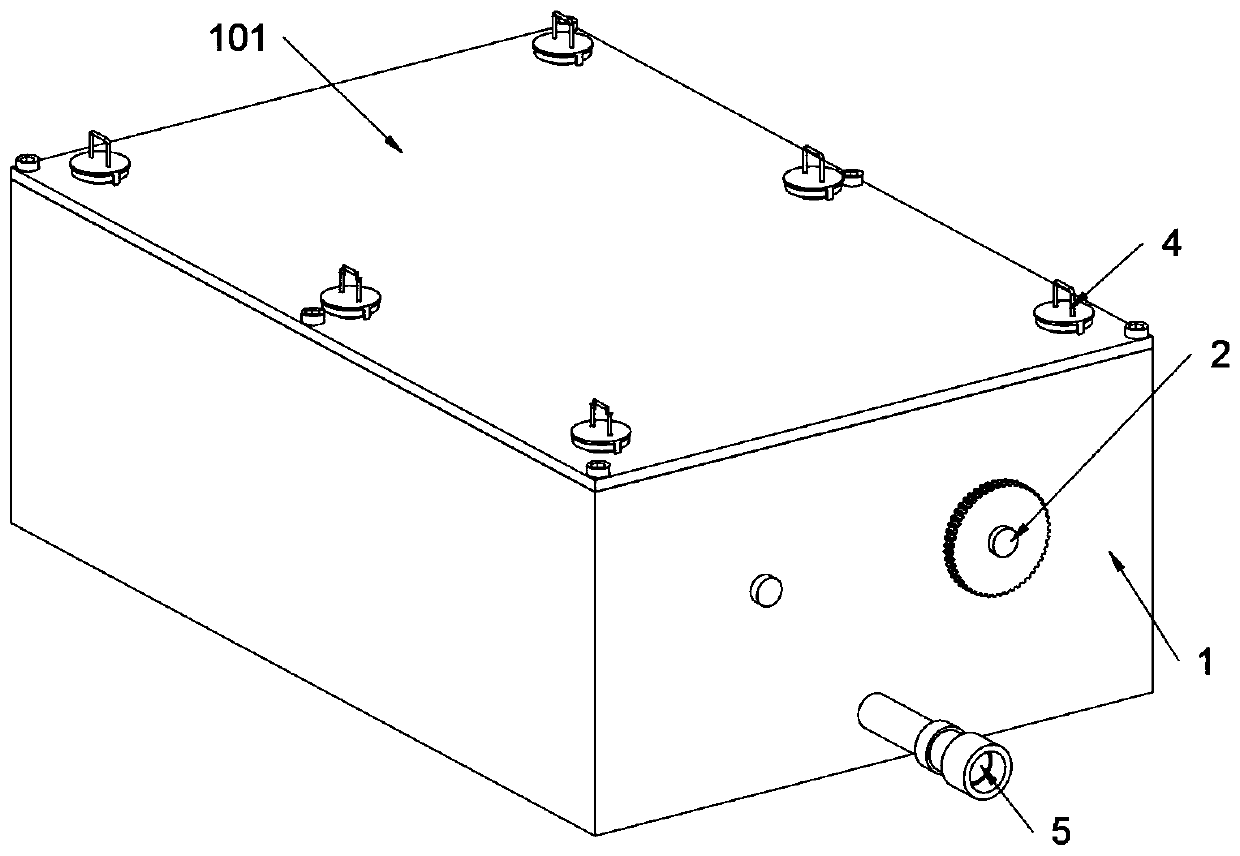

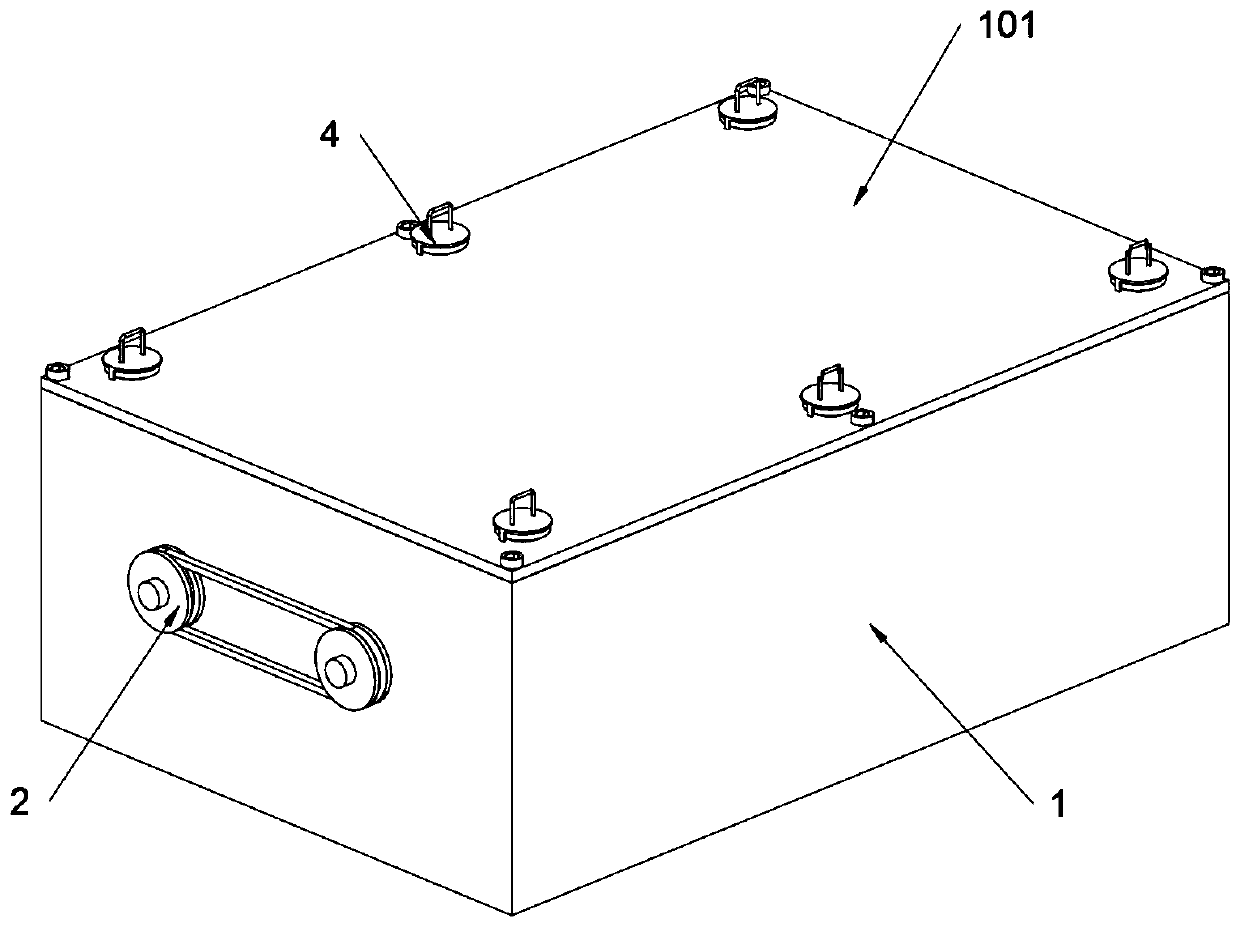

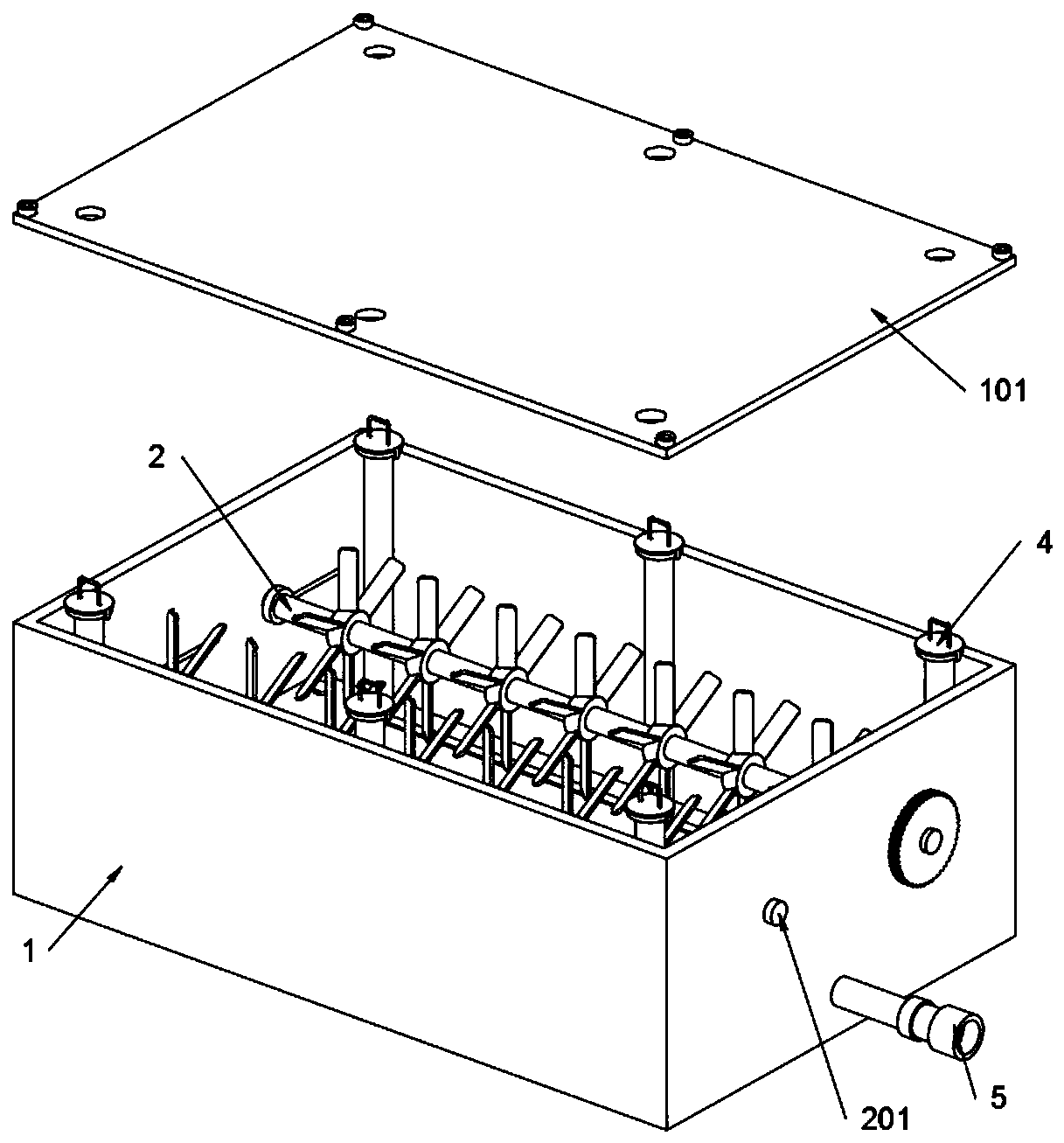

[0036] as attached figure 1 To attach Figure 9 Shown:

[0037] The invention provides preparation equipment for the production of chemical divinylbenzene catalysts, including a barrel body 1; the barrel body 1 is filled with liquid, and the barrel body 1 is rotatably connected with a mixing structure 2, and the barrel body 1 is also provided with a second Two mixing structures 3; two groups of three sampling structures 4 for each group are plugged into the barrel body 1, and a drain pipe structure 5 is threaded on the barrel body 1; refer to as Figure 8 and Figure 9 , the discharge pipe structure 5 includes a main pipe 501, a filter screen 502, a sleeve 503, a cylindrical rod 504 and a scraper 505, the main pipe 501 is screwed on the barrel body 1, and the head end of the main pipe 501 is equipped with a filter screen 502 ; Sleeve 503 is rotatably connected on the main body pipe 501, and a cylindrical rod 504 is welded on the sleeve pipe 503; a scraper 505 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com