Patents

Literature

117results about How to "Guaranteed paint effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

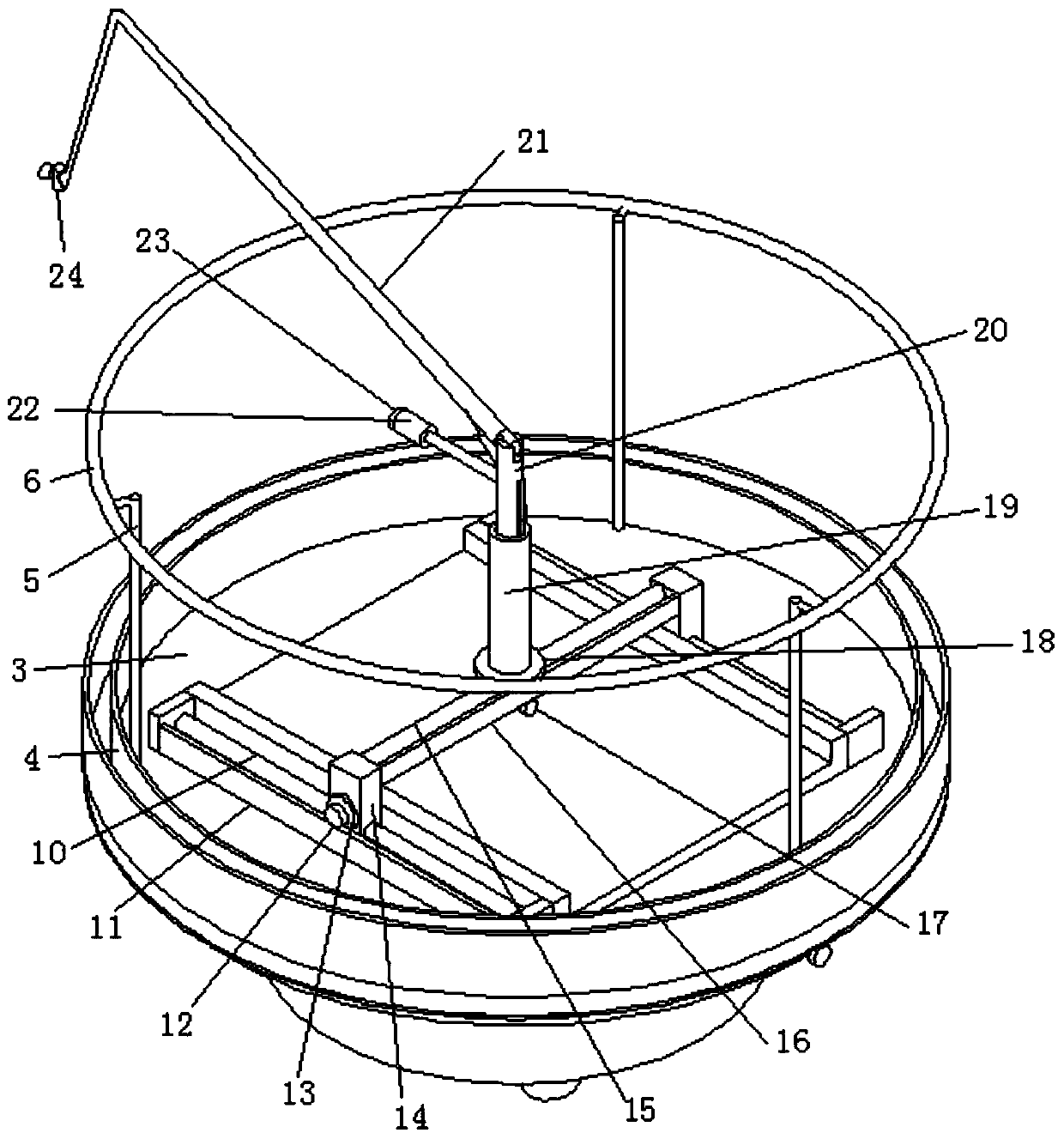

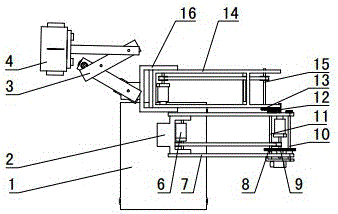

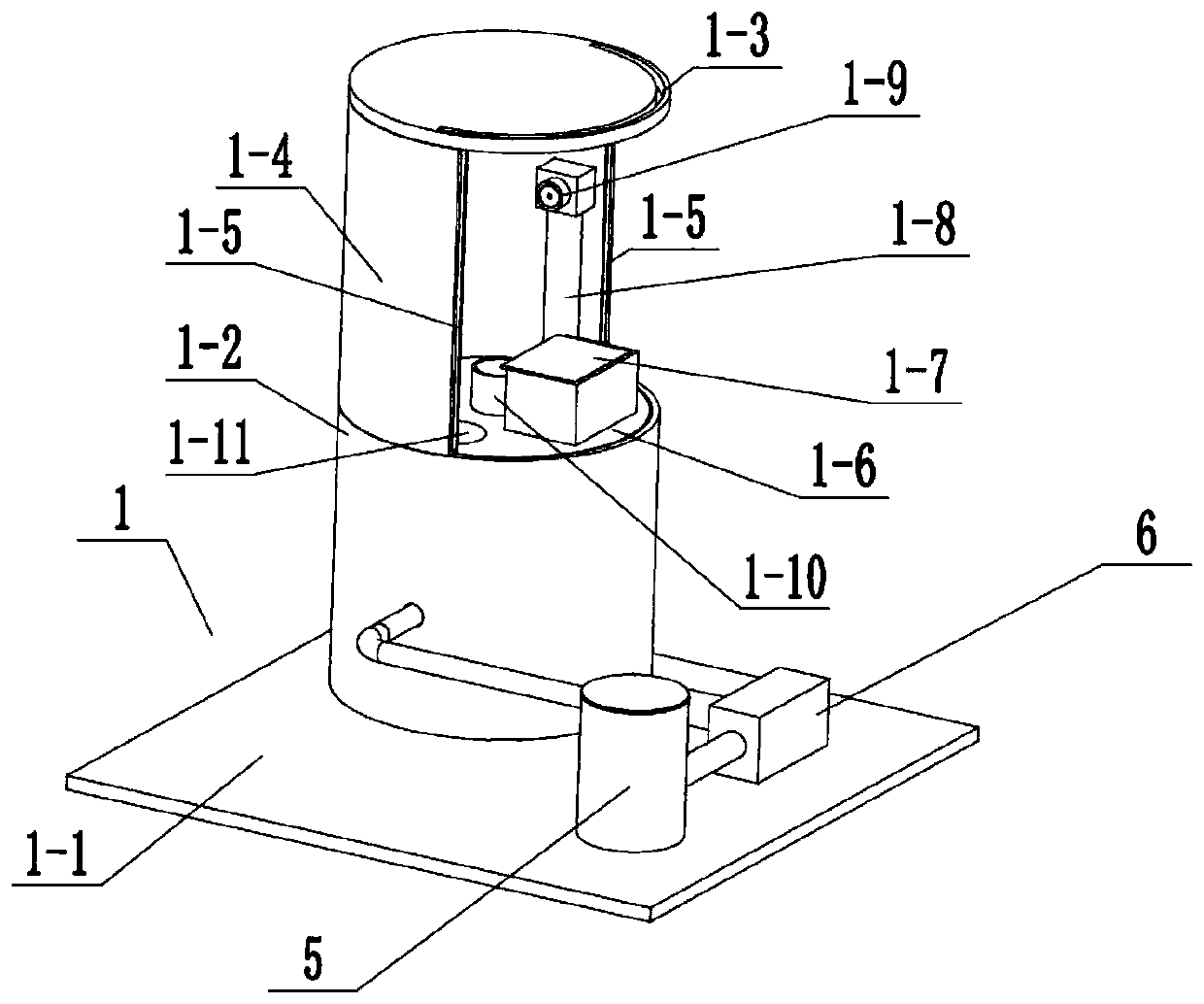

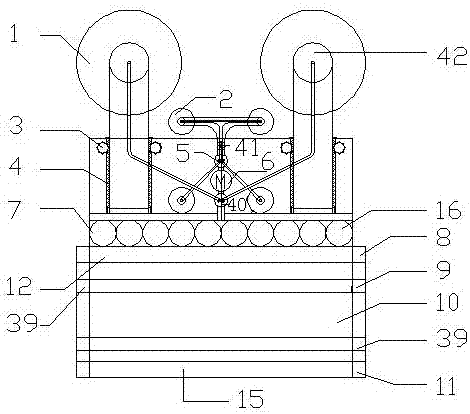

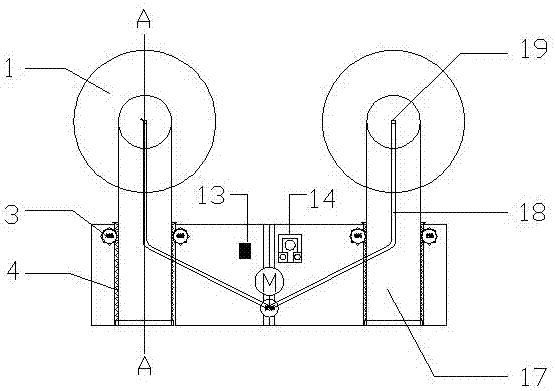

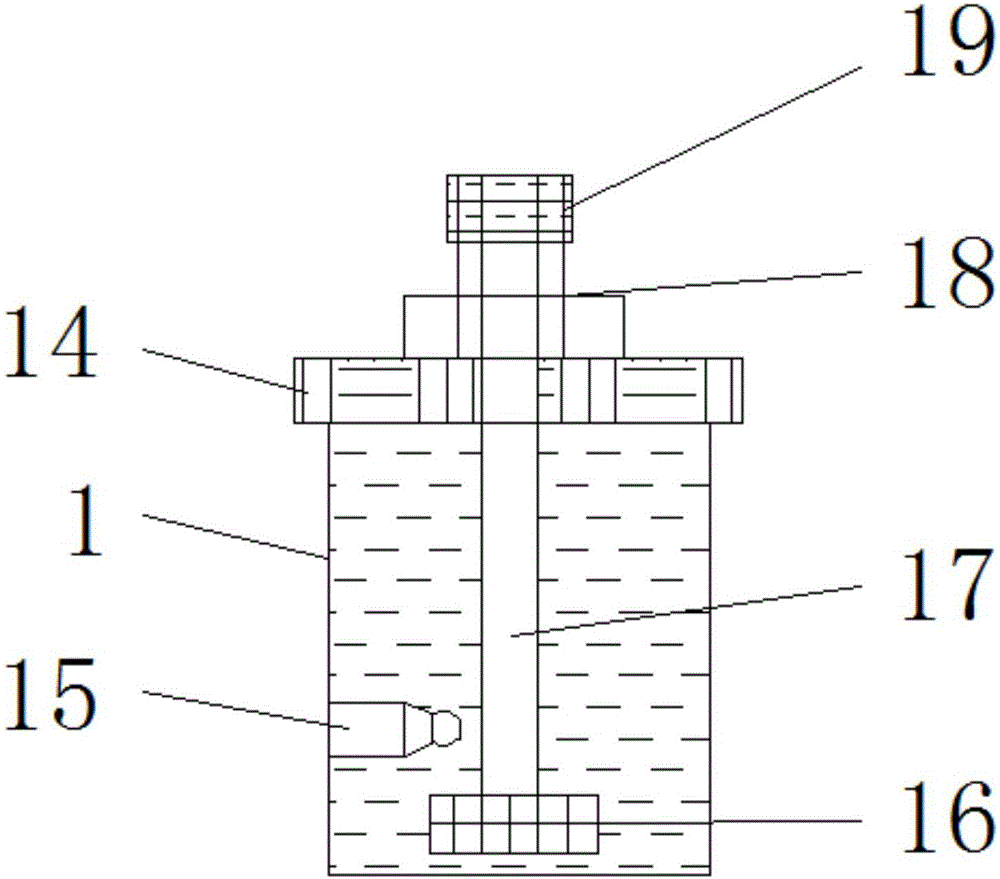

Motor shell paint spaying device with controllable spraying range

InactiveCN108480087AUniform coatingGuaranteed paint effectSpraying apparatusManufacturing dynamo-electric machinesCircular discEngineering

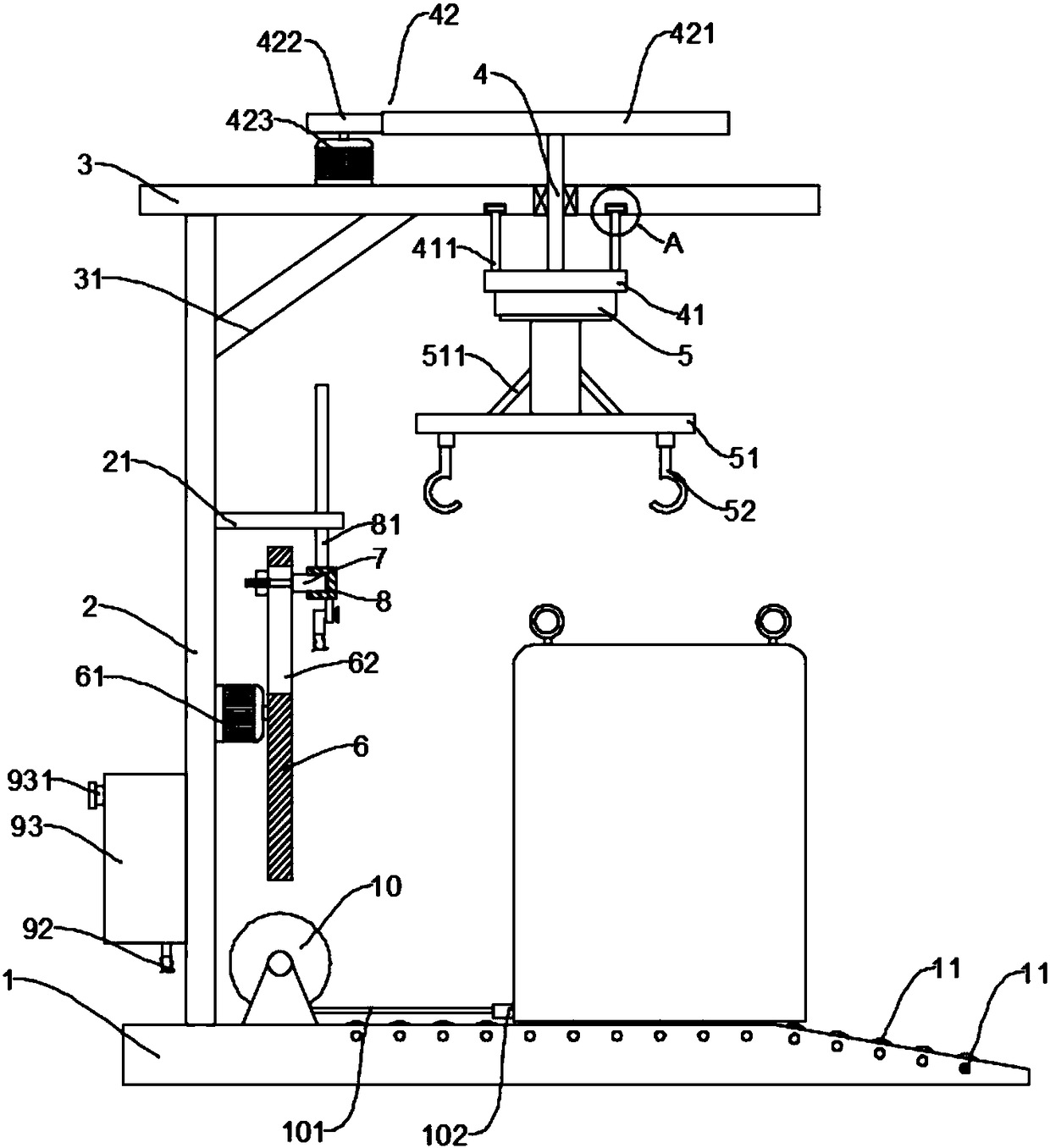

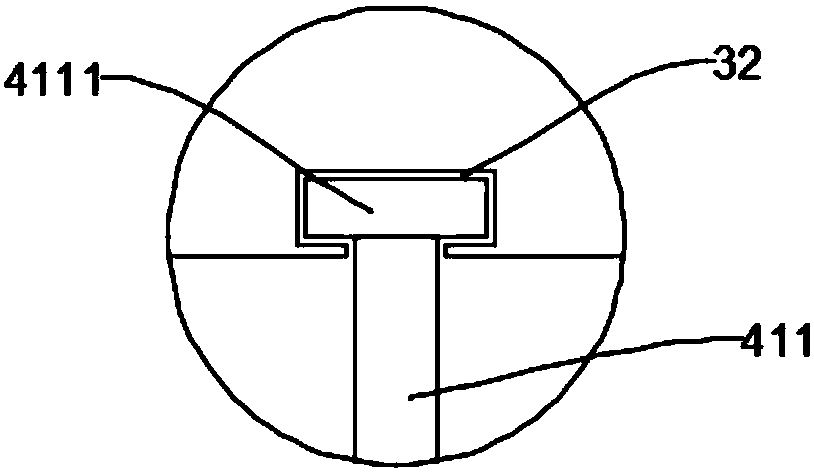

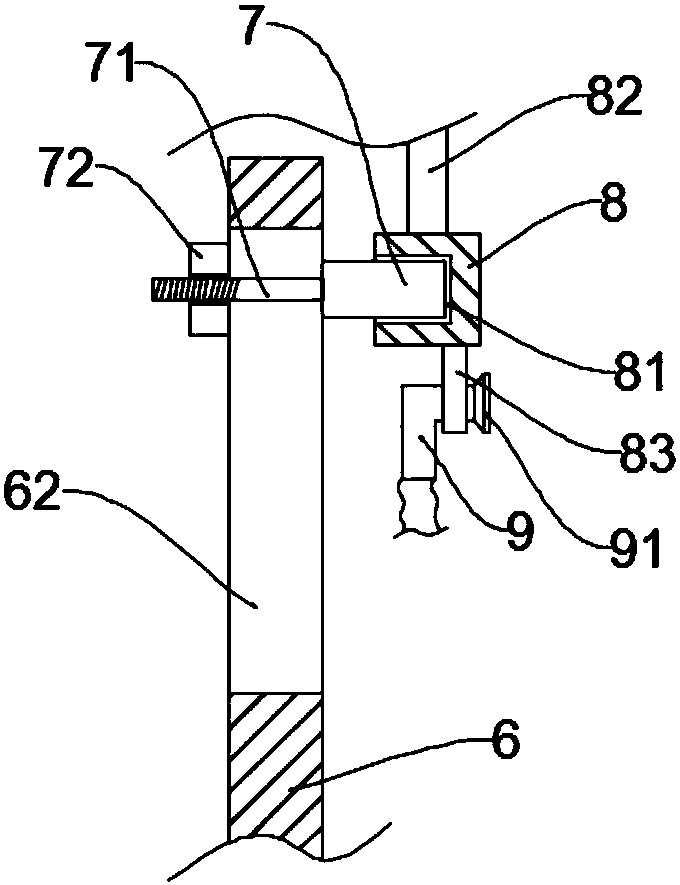

The invention discloses a motor shell paint spraying device with the controllable spraying range. The motor shell paint spraying device comprises a work table, a vertical frame, a rotary shaft, a lifting device, a circular disc, a convex column, a slipping rod and a spraying pipe. The vertical frame is fixed to the left side of the top of the work table, and a top plate is connected to the top ofthe vertical frame. A rotary shaft is arranged on the top plate in a penetrating mode, the upper end of the rotary shaft is provided with a driving mechanism for driving the rotary shaft to rotate, and a base plate is fixed to the bottom of the rotary shaft. The circular disc is arranged on the position below the right side of the vertical frame, the convex column is connected to the right end face of the circular disc in a matched mode, and the slipping rod is longitudinally arranged on the right side of the circular disc. A fixing ring is connected to the center position of the bottom of theslipping rod, and the spraying pipe is arranged in the fixing ring in a penetrating mode. According to the motor shell paint spraying device, efficient paint spaying can be conducted on a motor shell, the paint spraying effect is good, meanwhile the spraying range can further be adjusted correspondingly according to the size of the motor shell, and the applicability of the motor shell paint spraying device is improved.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

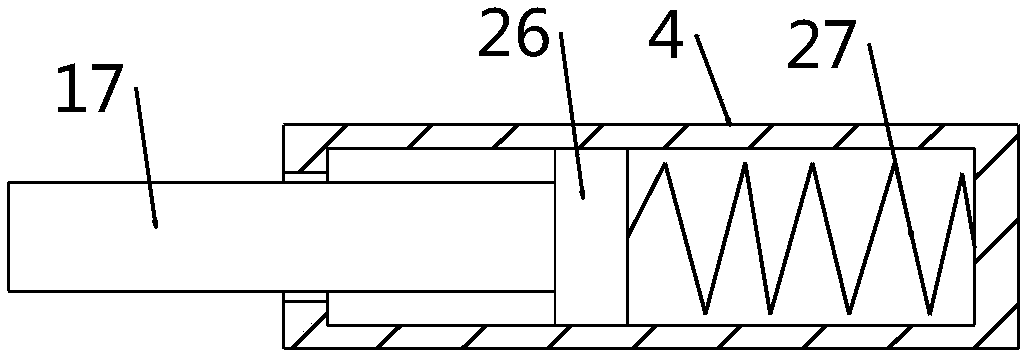

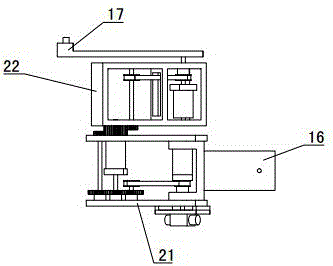

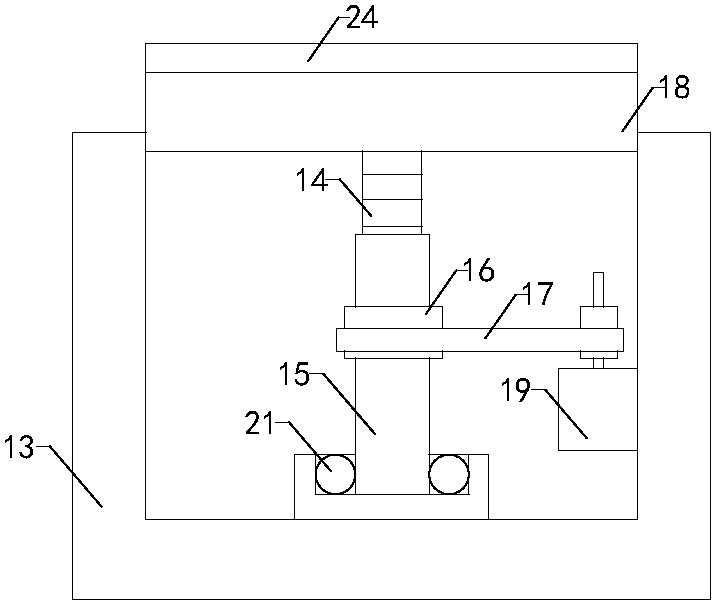

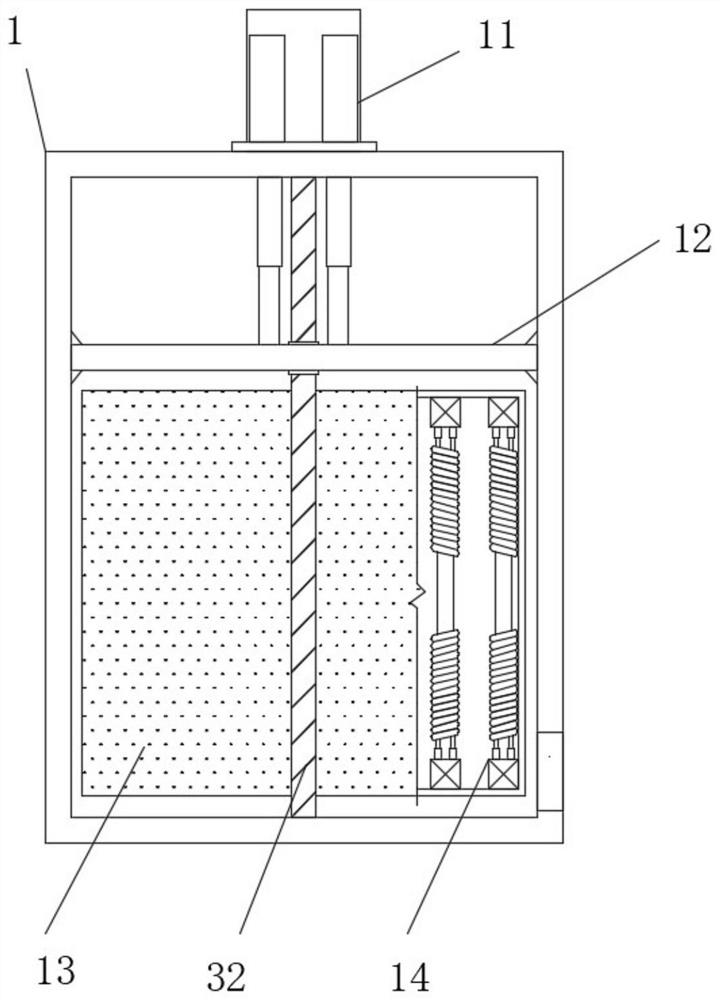

Cam driving based swinging type wooden board painting device for building engineering

ActiveCN108654890ASpray evenlyAvoid the phenomenon of spraying not in placeSpray boothsReciprocating motionElectric machinery

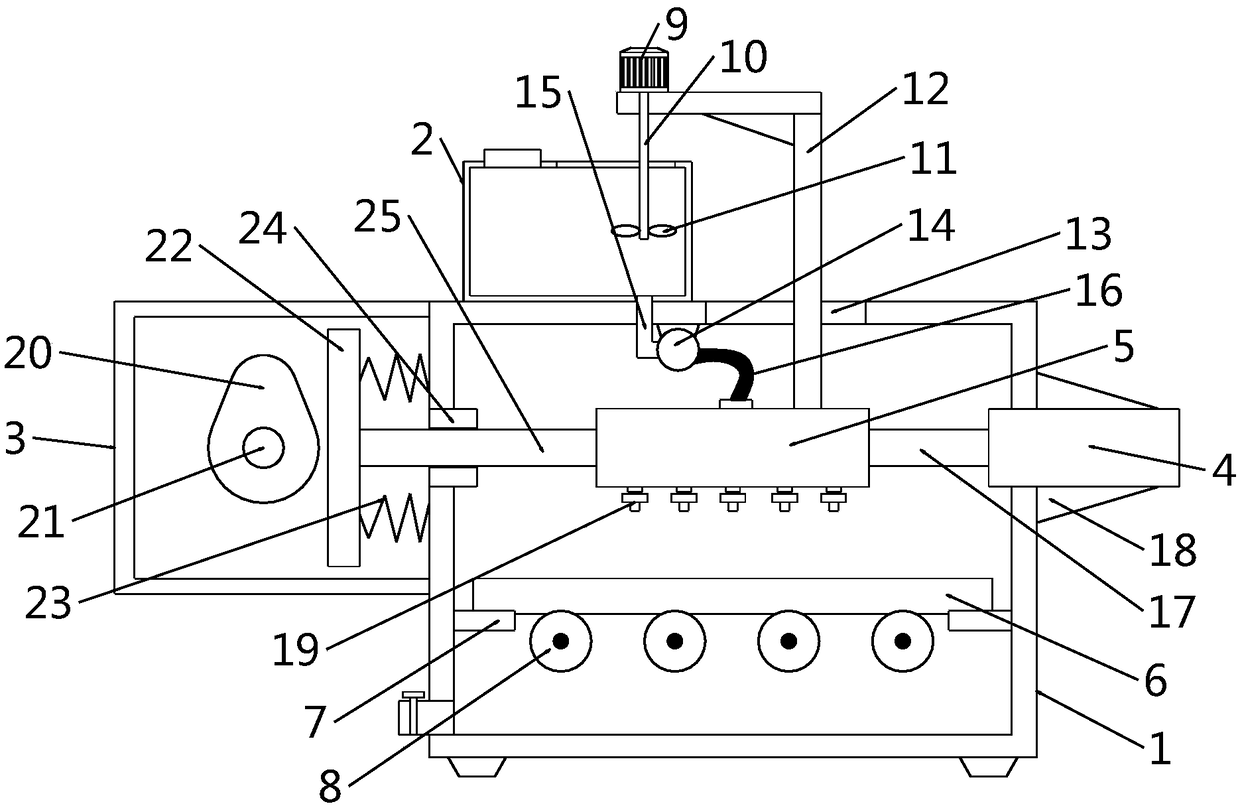

The invention discloses a cam driving based swinging type wooden board painting device for building engineering. The device comprises a painting box, a paint box, a driving box, a moving seat, stirring blades, a spraying head, a cam, a first spring and a left supporting cross rod. According to the device, the cam is driven to rotate through a driving motor, and the rotating cam continuously knockson a pressing plate, and the first spring supports to realize the horizontal reciprocating of the moving seat in the painting box, thus paint sprayed by the spraying head can be uniformly sprayed toa wooden board, and the problem that the paint is not sprayed in place can be avoided; when the moving seat horizontally moves, the rotating stirring blades can be driven to move in the paint box, thus the stirring and mixing effect of paint in the paint box can be effectively improved, and the paint is prevented from deposition, and as a result, the painting effect is ensured, and the device is suitable for popularization and use.

Owner:安徽家骎建设工程有限公司

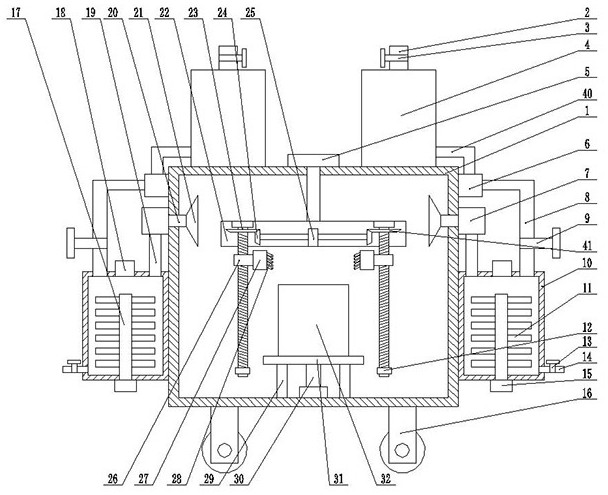

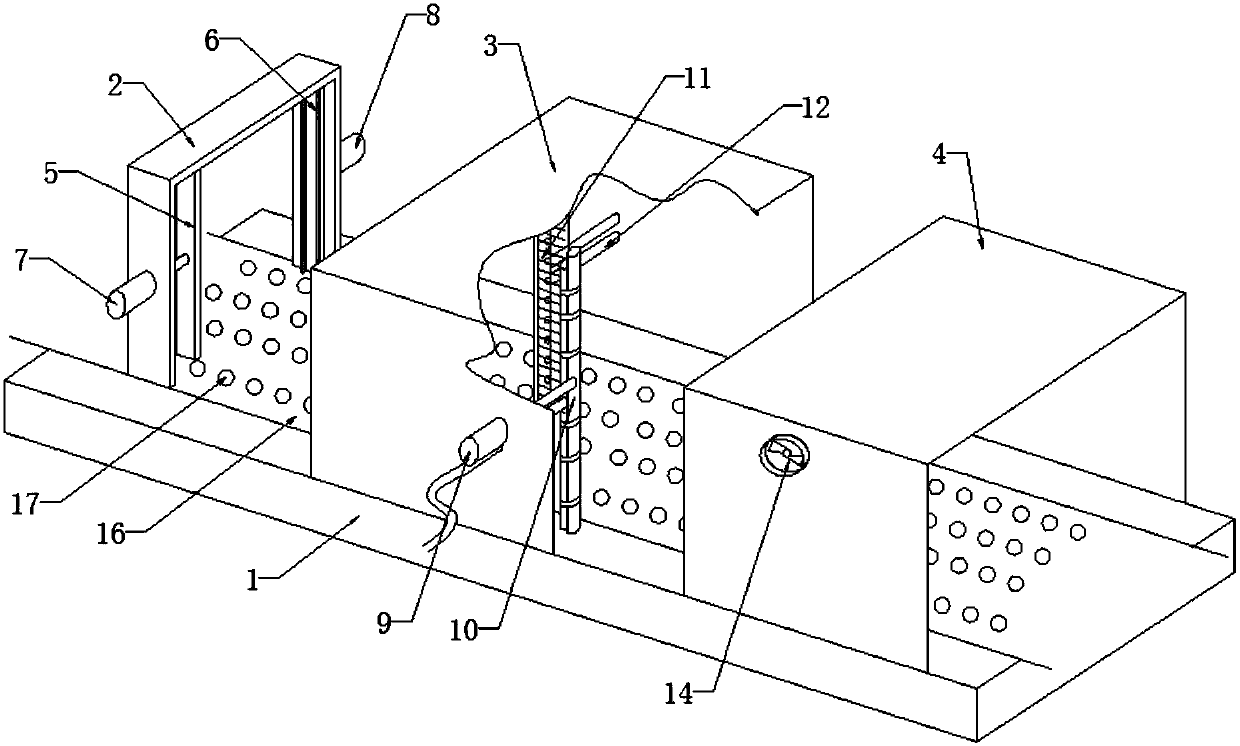

Household appliance gas stove inner and outer burner cap machining device

InactiveCN107584386AImprove high temperature resistanceImprove aestheticsGrinding carriagesPolishing machinesEngineeringGuide tube

The invention relates to a household appliance gas stove inner and outer burner cap machining device. The device comprises a paint storage cylinder, a mounting frame, a polishing table and a base; supporting legs are installed at the four corners of the bottom of the base, and a dust collecting box is arranged at the position, among the supporting legs, at the bottom of the base; one side of the dust collecting box is provided with a dust suction pump, and a dust outlet of the dust suction pump is communicated with the interior of the dust collecting box through a guide pipe; the polishing table is arranged on the top, above the dust collecting box, on the top of the base; two sides of the polishing table are provided with dust suction heads respectively. A limiting block is installed, andthe limiting block can horizontally slide in a limiting groove so that the distance between positioning plates can be adjusted conveniently, then outer burner caps or inner burner caps with differentsizes can be conveniently clamped, and the application range is wider; the device is provided with a first grinding head and a second grinding head so that the inner burner caps and the outer burnercaps can be conveniently polished respectively, and the grinding effect is better.

Owner:王彩英

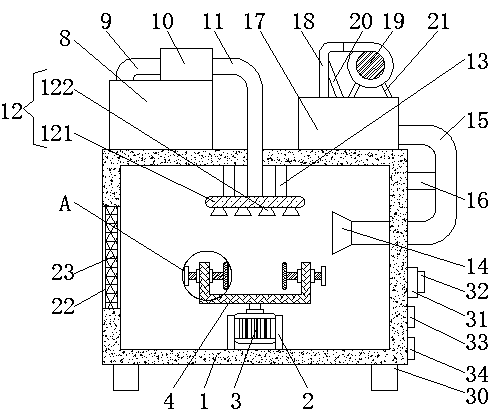

Automatic paint spraying equipment for mobile phone shell

InactiveCN109590146ASpeed up dryingRealize purificationPretreated surfacesLiquid spraying apparatusToxic gasElectric machinery

The invention discloses automatic paint spraying equipment for a mobile phone shell, and relates to the technical field of paint spraying machining of the mobile phone shell. The automatic paint spraying equipment comprises a paint spraying shell, wherein the lower surface of the inner wall of the paint spraying shell is fixedly connected with two first fixed rods; the opposite faces of the two first fixed rods are separately and fixedly connected with the left side face and the right side face of a motor machine body; an output shaft of the motor is fixedly connected with a U-shaped plate; the left side face and the right side face of the U-shaped plate are connected with threaded devices in a clamping manner; and the left end and the right end of each of the threaded devices are separately and fixedly connected with the right side face of each of movable rods and the left side face of each of extrusion plates. According to the automatic paint spraying equipment for the mobile phone shell disclosed by the invention, through cooperation of an air blower, a connection pipe, a first filter screen, a second filter screen, an air suction pipe, an air suction hood and third through holes, purification treatment on toxic gas is realized, the condition that the toxic gas is breathed into a human body by a working personnel is avoided, the health of the working personnel is ensured, and the air-drying speed of the mobile phone shell is quickened.

Owner:湖南融灏实业有限公司

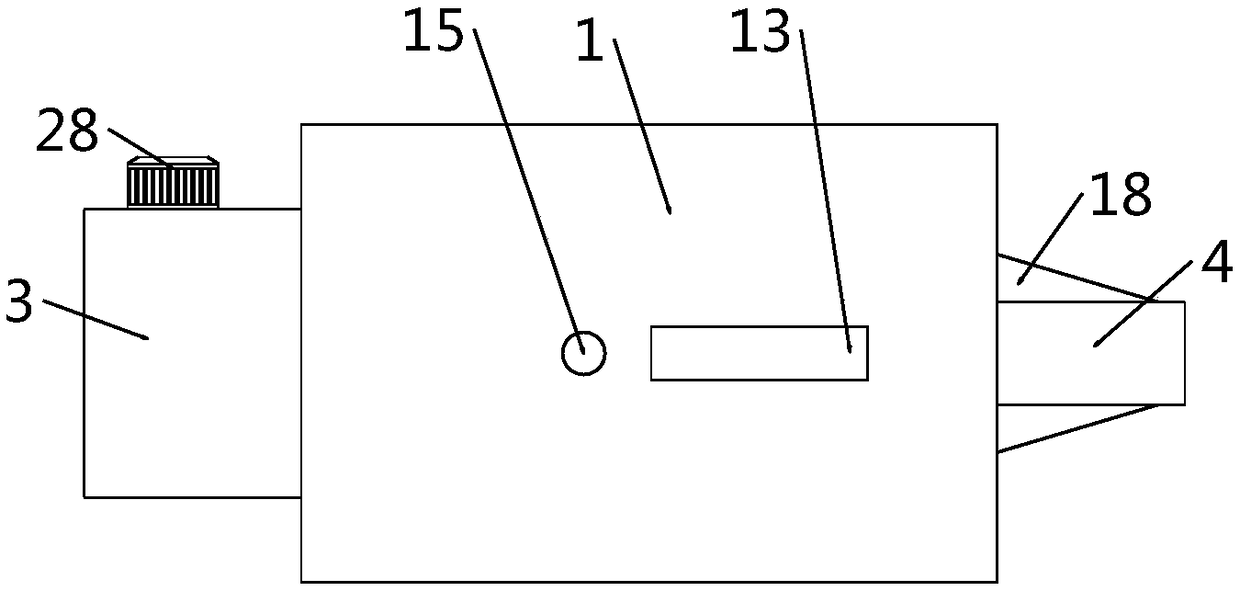

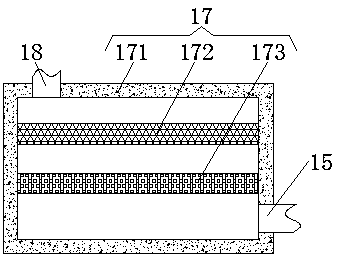

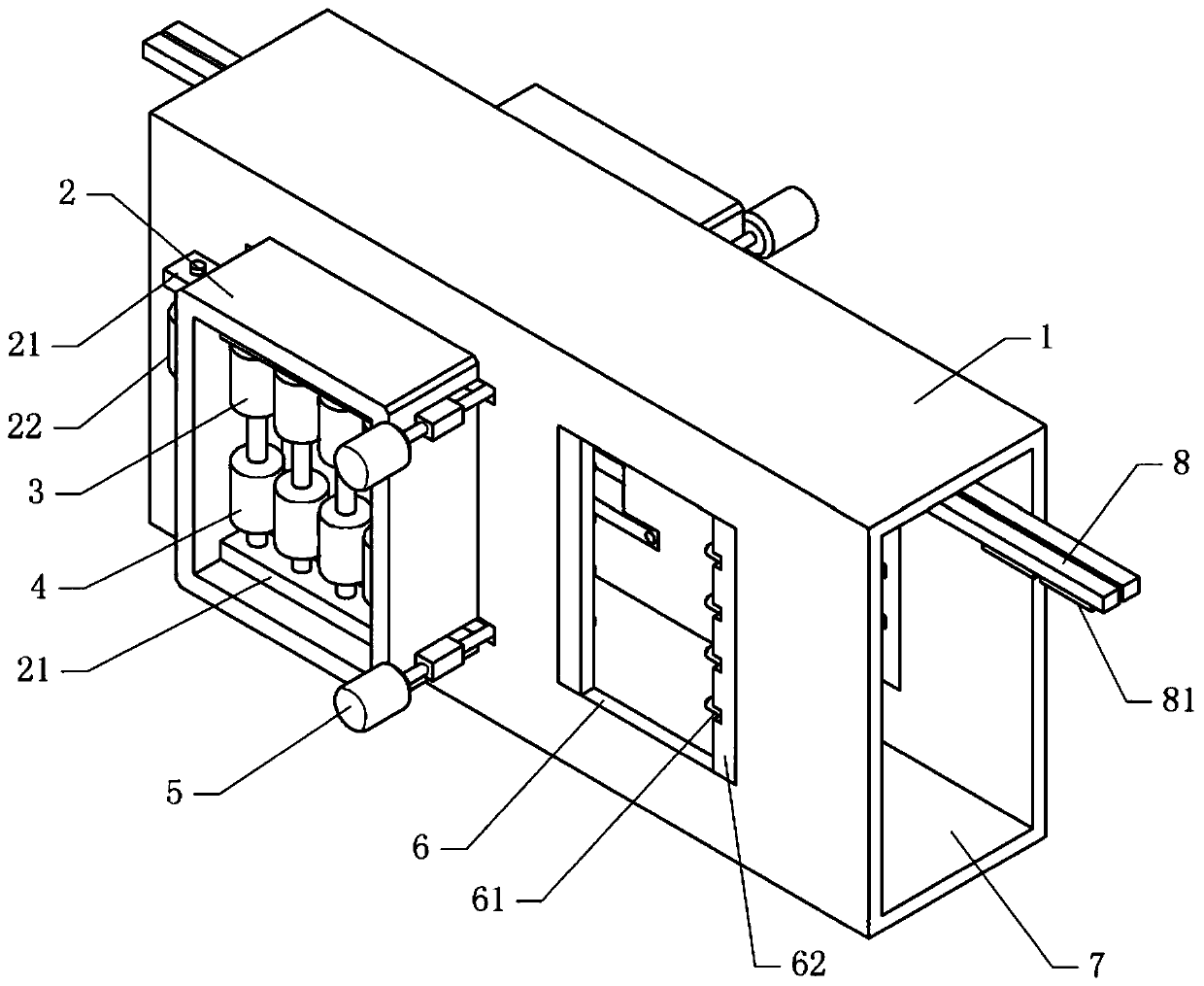

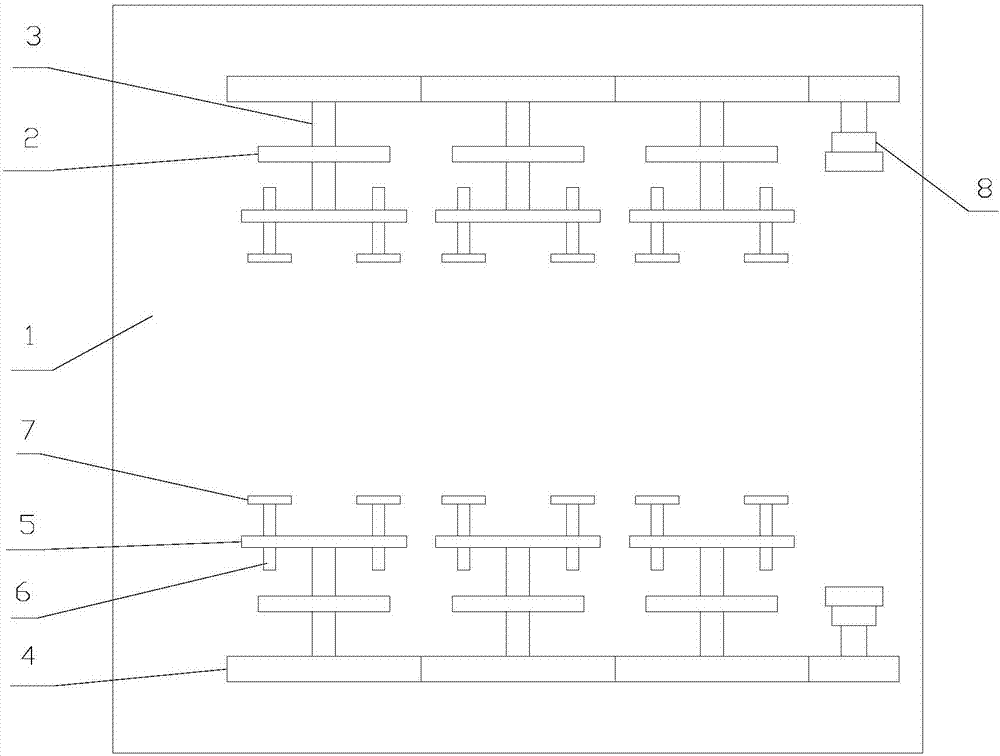

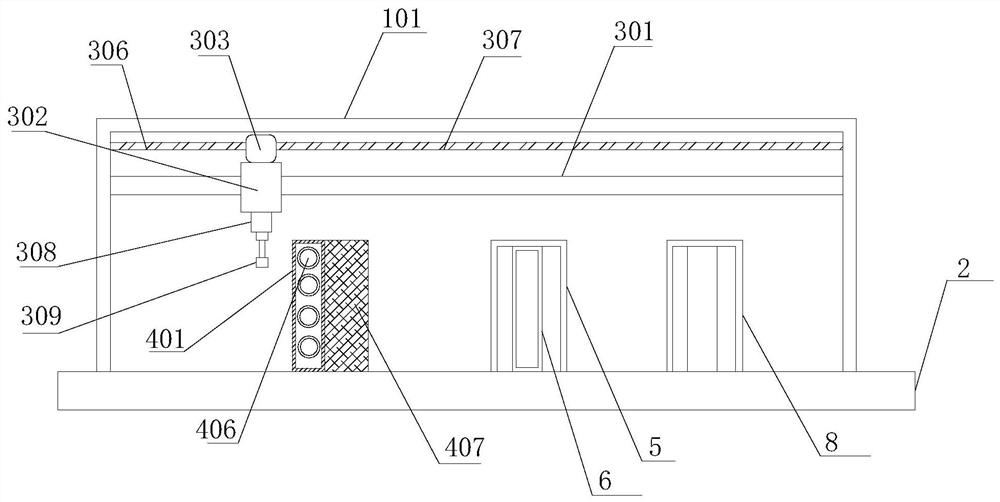

Paint spraying device for furniture plate machining

PendingCN111068968AIncrease productivityGuaranteed paint effectPretreated surfacesDirt cleaningIndustrial engineeringSpray painting

The invention proposes a paint spraying device for furniture plate machining. The paint spraying device comprises a conveying device and a paint spraying device, wherein the conveying device is used for transferring the to-be-machined plates into the paint spraying device, the paint spraying device comprises a pretreatment mechanism and a paint spraying mechanism, and the pretreatment mechanism cleans the plates and then performs surface painting and drying operation through the paint spraying mechanism. According to the paint spraying device, the automatic operation is realized, paint spraying and drying are integrated, and the production efficiency is greatly improved.

Owner:NANJING FORESTRY UNIV

Steel structure painting process

ActiveCN111097630AImprove work efficiencyEasy to transportGrinding drivesPretreated surfacesRoller millManufacturing engineering

The invention relates to the technical field of steel structure painting, and discloses a steel structure painting process. The process comprises the following steps that S1, a steel structure is clamped through a clamp, and then the steel structure is conveyed into a painting box through a sliding rail; S2, the positions of roller grinding mechanisms on the two sides of the painting box are adjusted till the distance between the roller grinding mechanisms is equal to the thickness of the steel structure; S3, the roller grinding mechanisms are started, then the steel structure is conveyed to the position between the roller grinding mechanisms, and the steel structure is ground through the roller grinding mechanisms; S4, the steel structure is conveyed to a painting assembly through the roller grinding mechanisms, and the two sides of the steel structure are painted through the painting assembly until the surfaces of the two sides of the steel structure are covered with paint; and S5, the steel structure is conveyed to an air injection assembly, the air injection assembly is rotated to face the steel structure, and paint on the steel structure is blown to be dry through the air injection assembly. The process is simple in method, the steel structure can be rapidly painted, and the painting efficiency of the steel structure is improved.

Owner:重庆实创钢结构有限公司

Efficient and uniform paint spraying equipment for wooden crafts

ActiveCN110899019APaint stabilizerGuaranteed paint effectSpraying apparatusStructural engineeringReclaimer

The invention discloses an efficient and uniform paint spraying equipment for wooden crafts. The paint spraying equipment comprises a bottom plate, wherein a first support plate is fixed on the uppersurface of the bottom plate, a top plate is fixed to the top of the first support plate, a movable plate is movably mounted on the top plate, a second mounting groove is installed on one side of the moveable plate, and a material taking mechanism is installed on one side of the second mounting groove; and a jacking cylinder is installed on the upper surface of the bottom plate, a lifting plate isinstalled at the end of an output rod of the jacking cylinder, and a nozzle fixing base is mounted at the top of the lifting plate, and multiple nozzles are installed on the nozzle fixing base. The paint spraying equipment can automatically rotate the wooden crafts, spray the surfaces of the wooden crafts at one time, and effectively improve the production efficiency; the paint spraying equipmentcan drive the wooden crafts to move flexibly and realize carrying of wooden crafts; the paint layers on the surfaces of wooden crafts are scraped by a scraper to ensure that the thickness of the paintlayers on the surfaces of wooden crafts is uniform and the quality of spraying is guaranteed.

Owner:阜南县利民工艺品有限公司

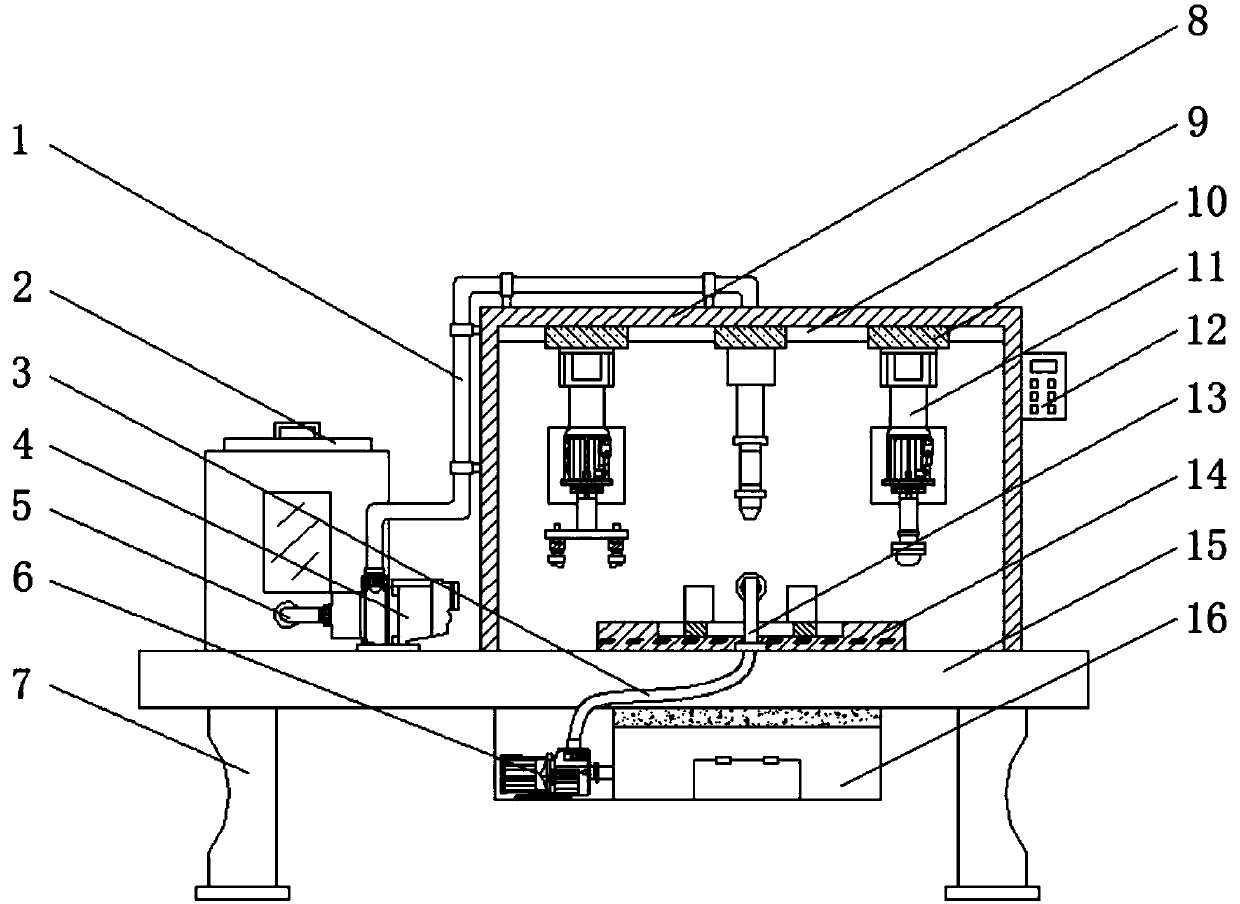

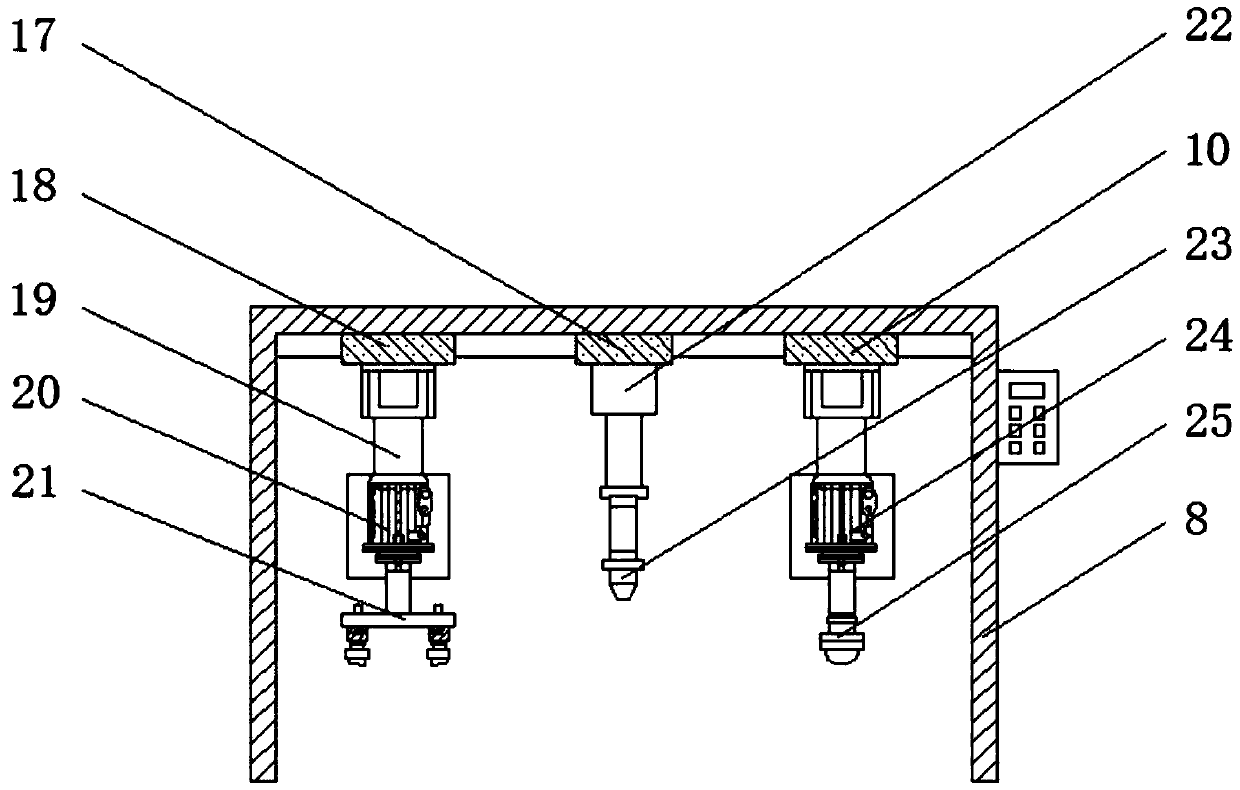

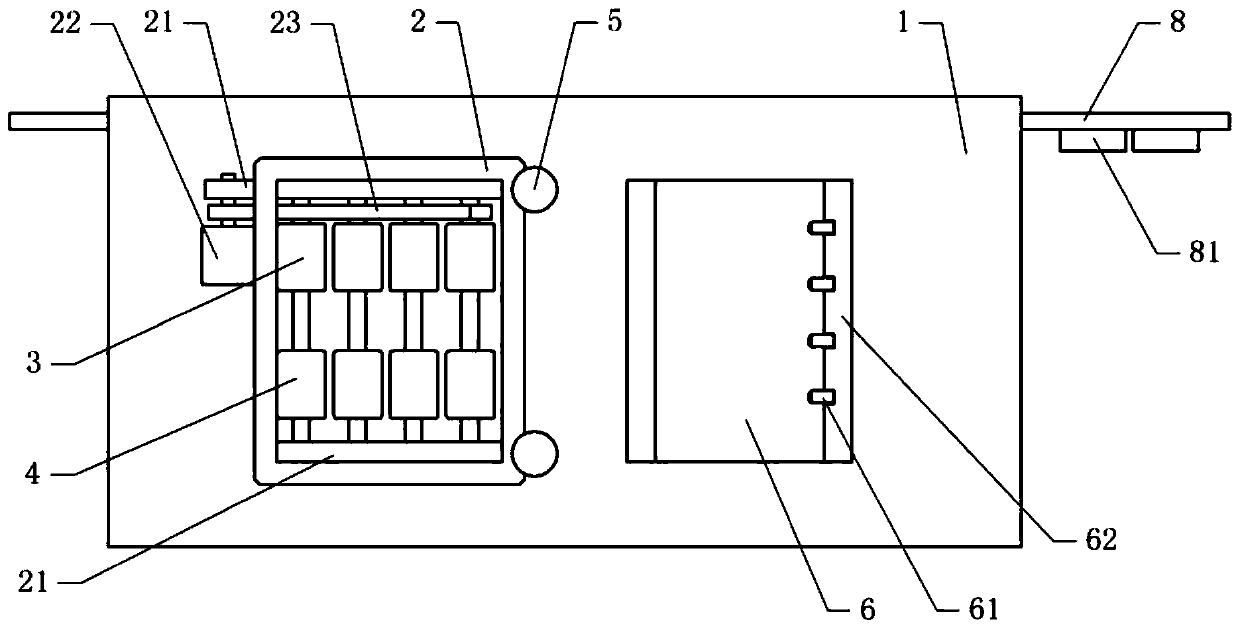

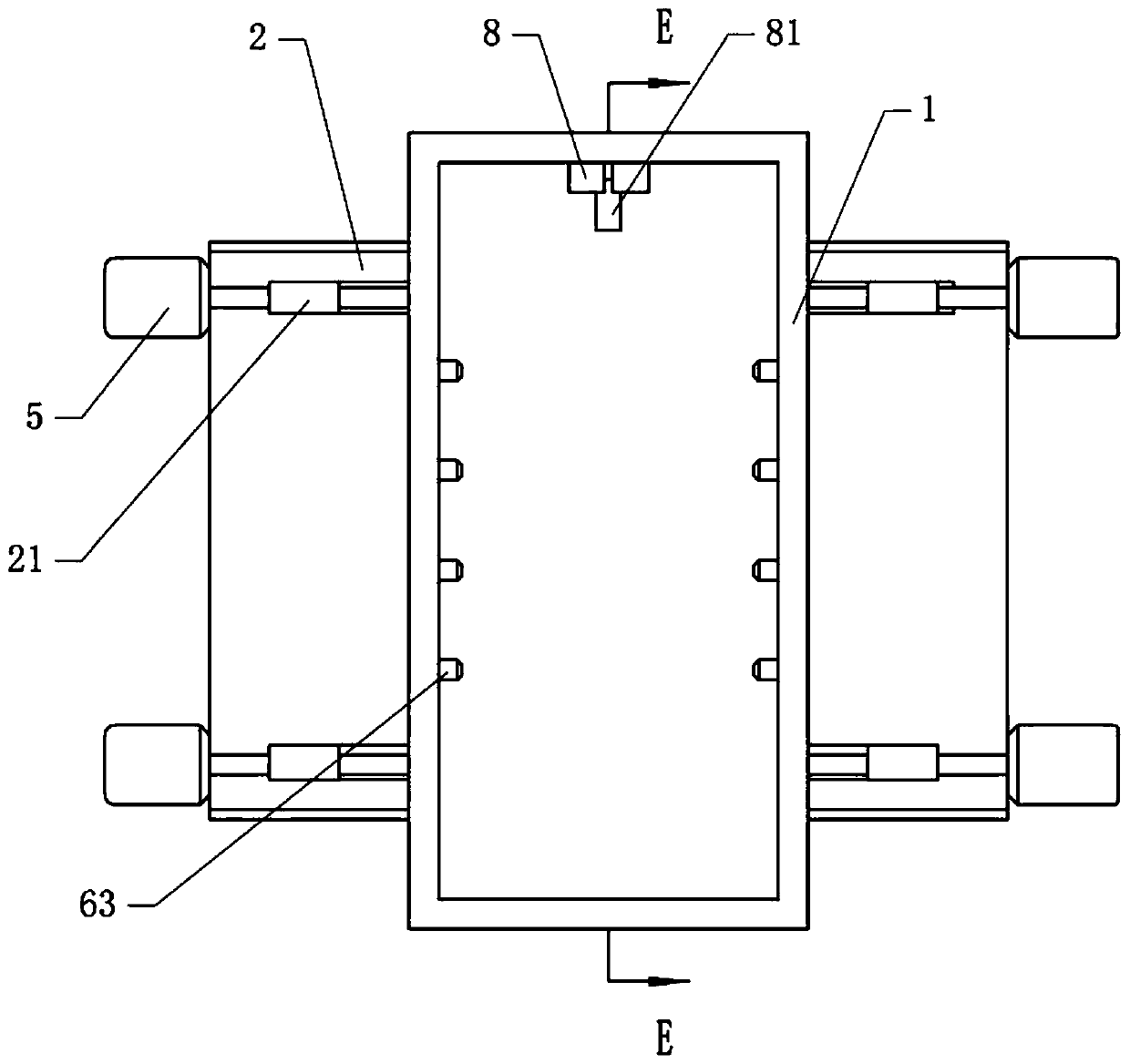

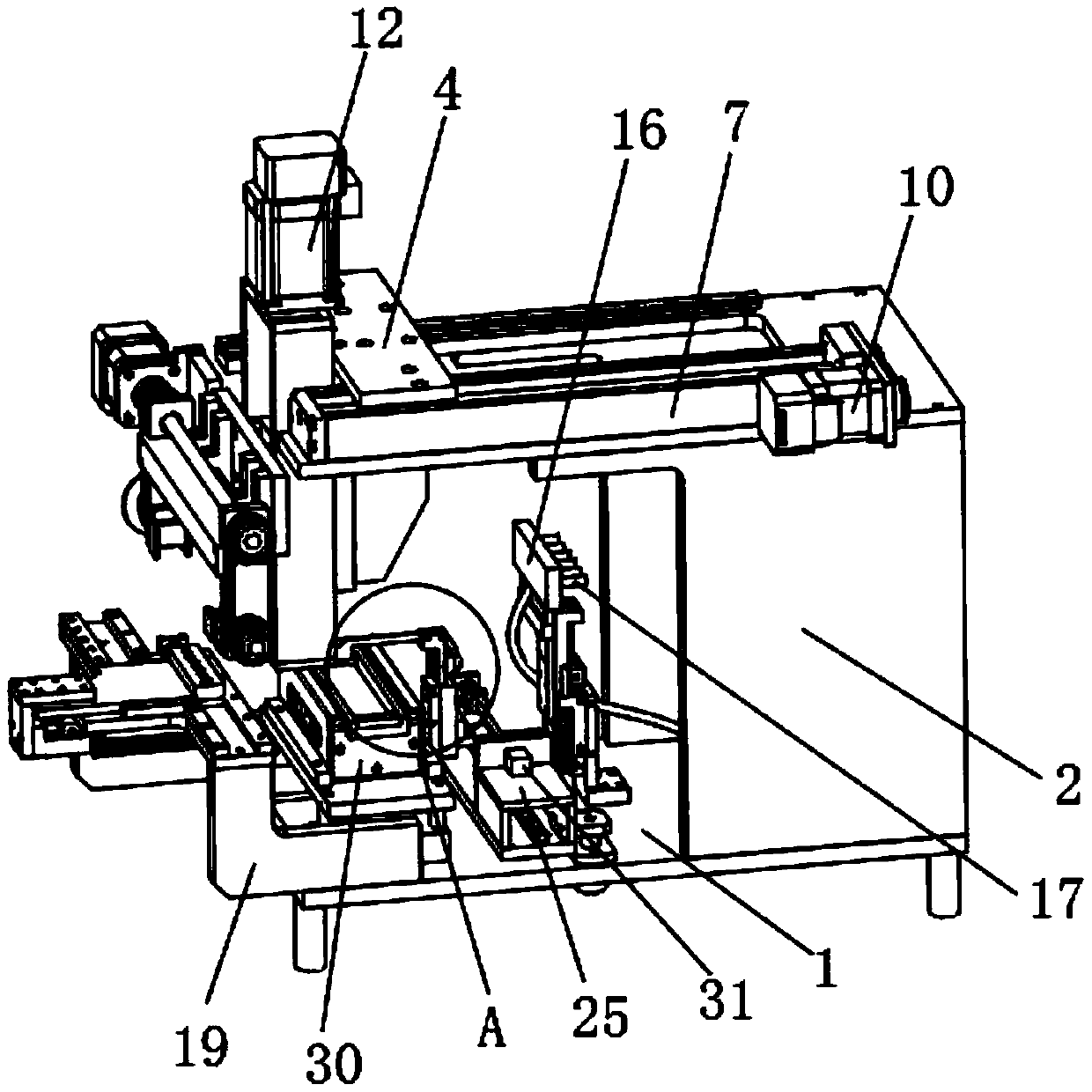

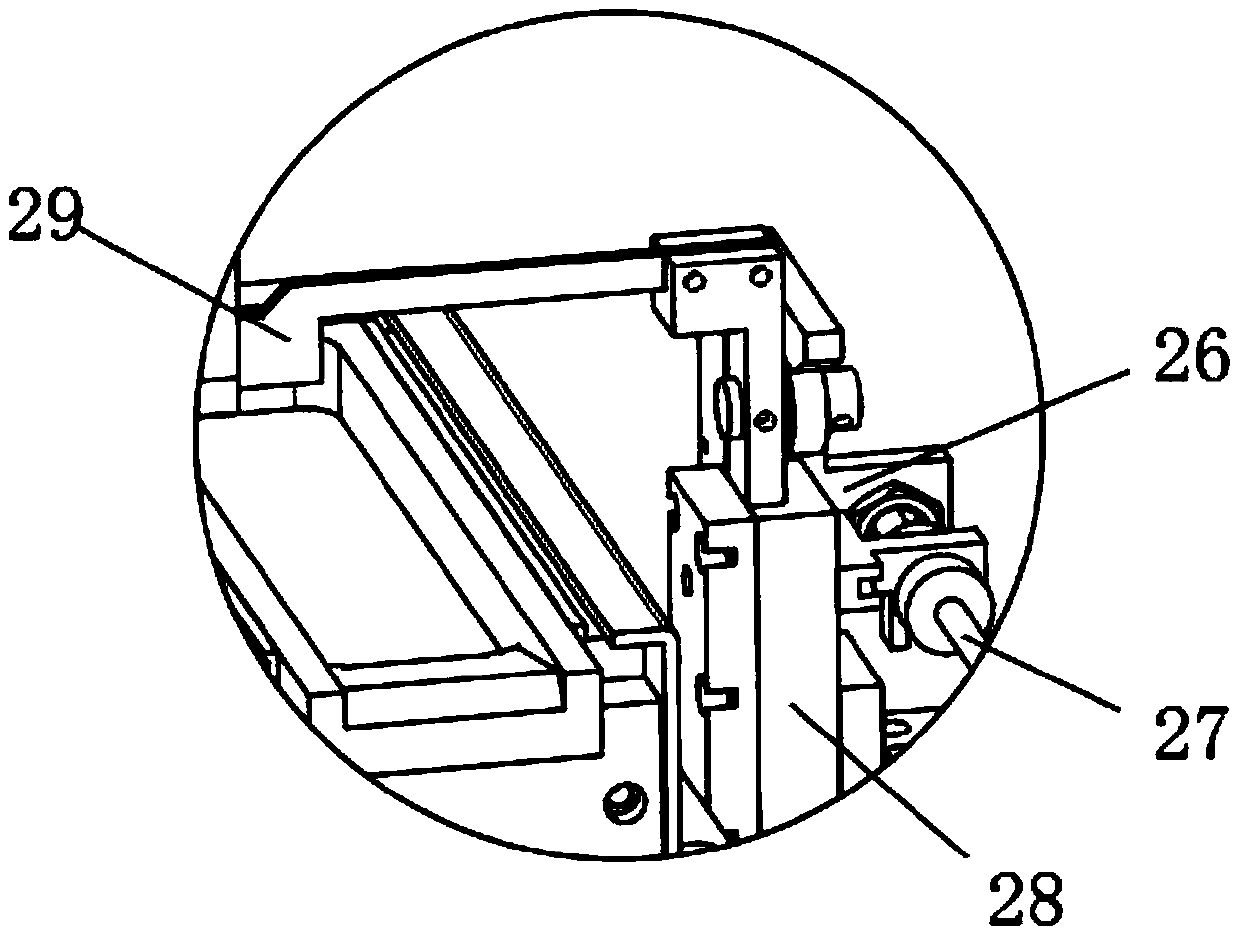

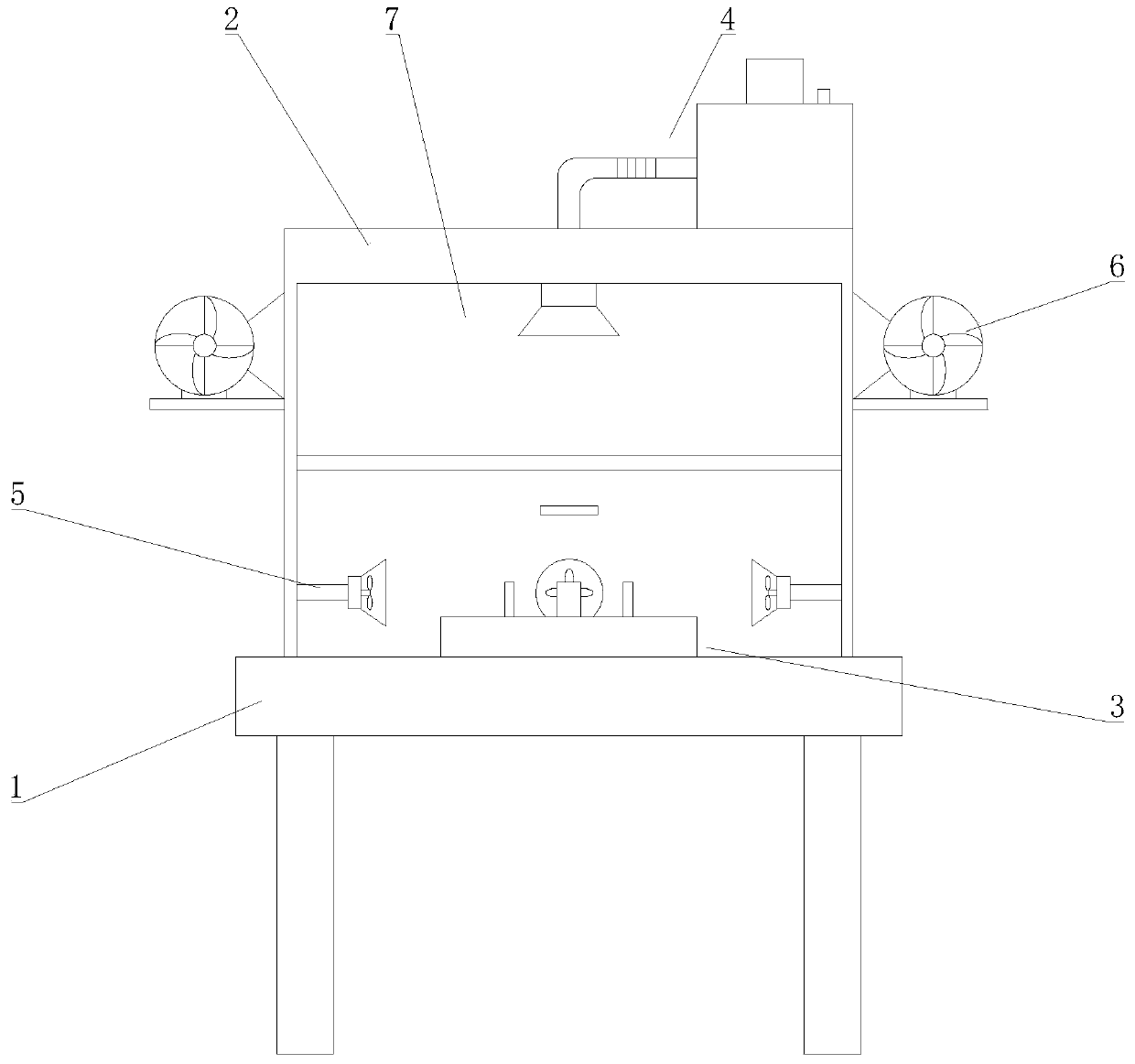

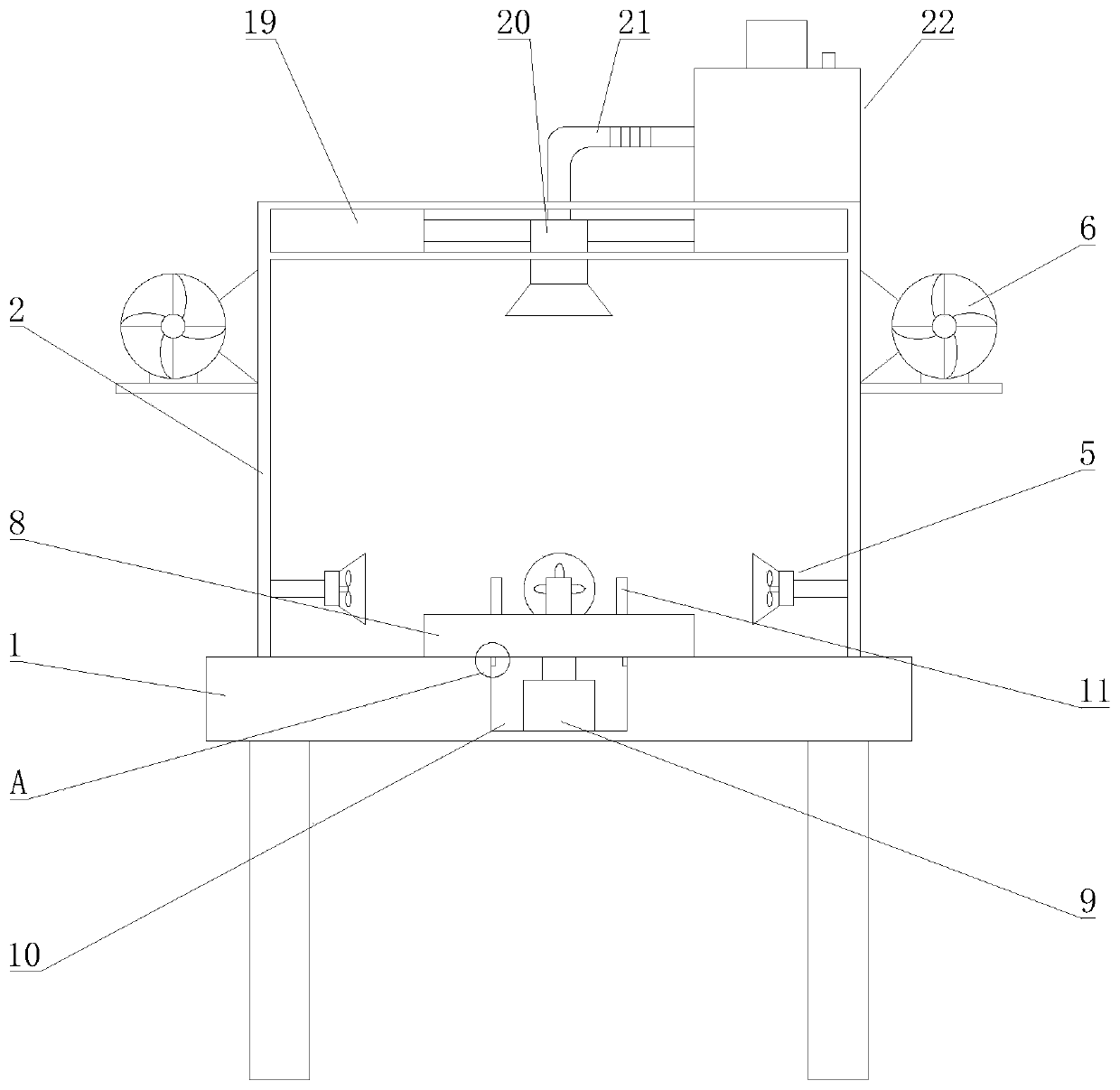

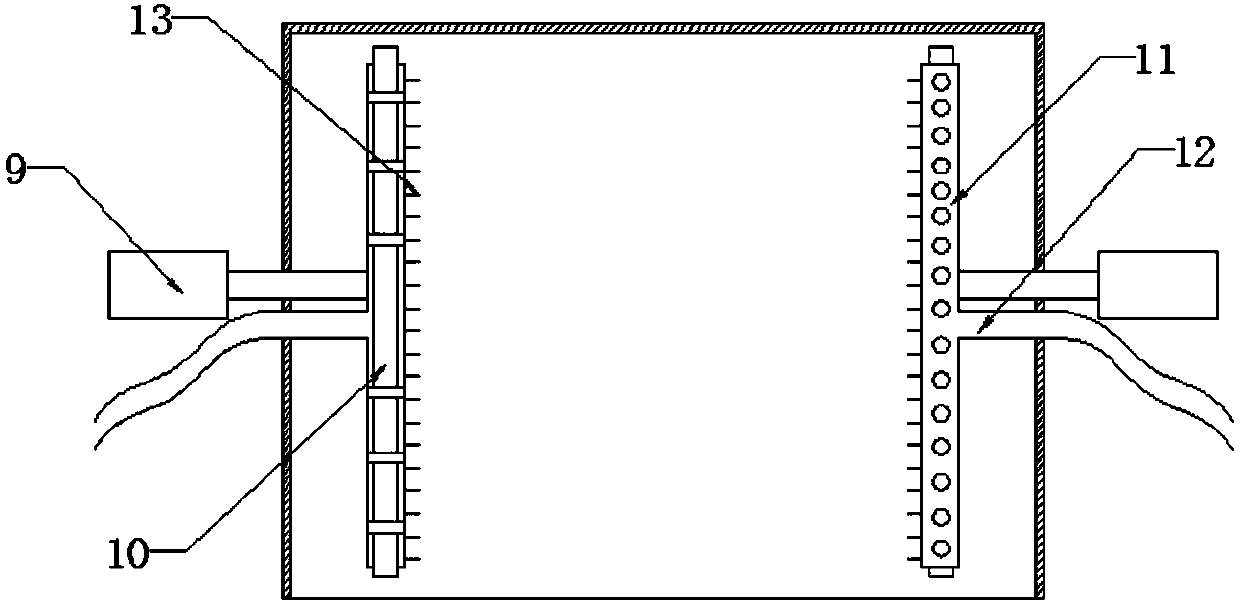

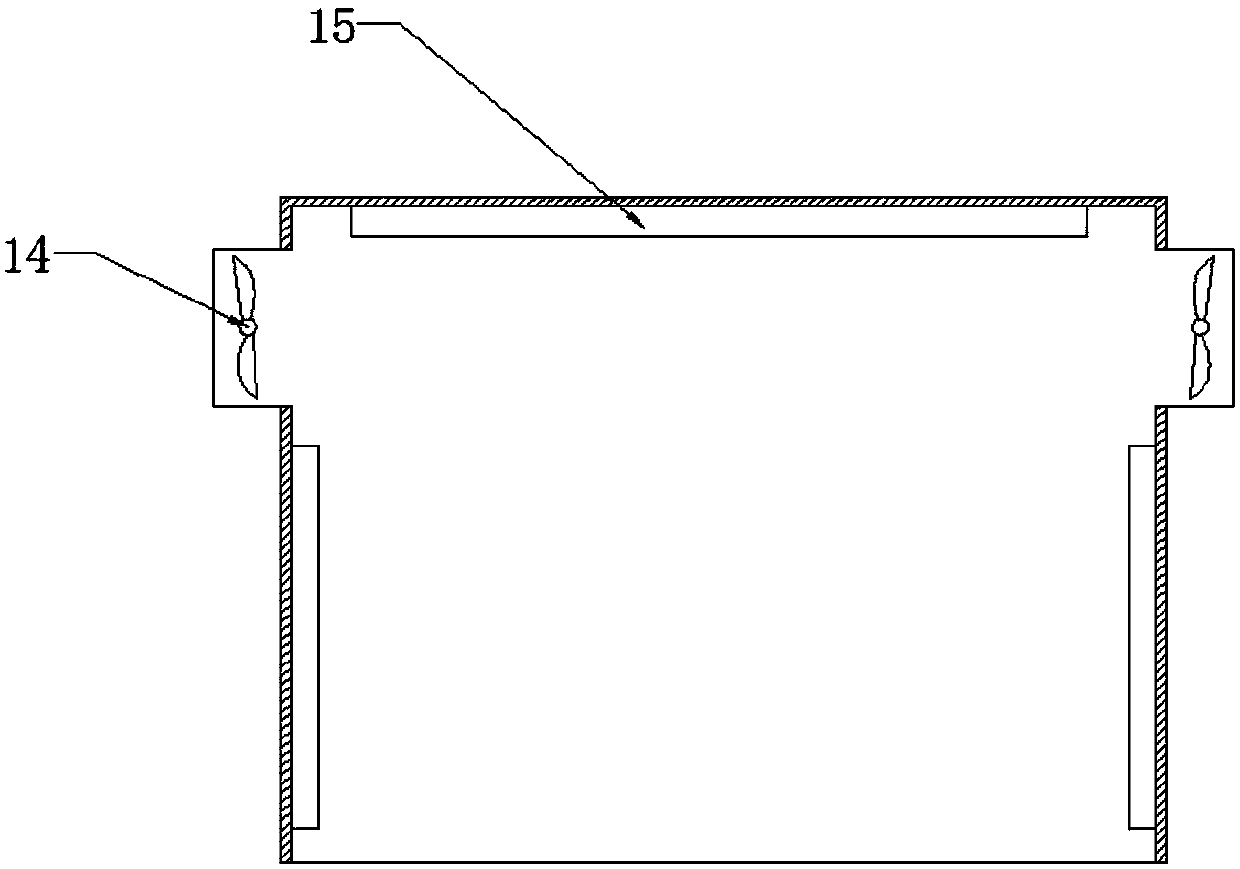

Electric box production machining device

The invention discloses an electric box production machining device. The electric box production machining device comprises an operation table, an isolation cover, a positioning assembly, a paint spraying assembly, a fan and an exhaust fan, wherein the isolation cover is arranged at the upper end of the operation table, the positioning assembly is arranged on the operation table, the paint spraying assembly is arranged on the isolation cover and located above the positioning assembly, the fan is arranged inside the isolation cover, and the exhaust fan is arranged outside the isolation cover. According to the electric box production machining device, paint processing equipment is arranged, so that paint is fully mixed, and the paint spraying effect is guaranteed; the positioning assembly isarranged, and an electric box board to be painted is fixed on a positioning table, so that the situation that the paint spraying efficiency and the paint spraying effect are reduced during paint spraying due to the fact that the electric box board to be painted is displaced is avoided; the positioning table rotates during paint spraying, so that paint spraying is uniform and comprehensive; the fan is arranged to supply air to the electric box board, a heating plate is electrified and heated, generated hot air is used for accelerating drying of the paint, and the drying speed is increased; andmeanwhile, the exhaust fan sucks off the peculiar smell of the paint and sends the peculiar smell to an external purification device for waste gas treatment, so that the pollution of the peculiar smell of the paint to the environment is avoided.

Owner:中合智腾建设有限公司

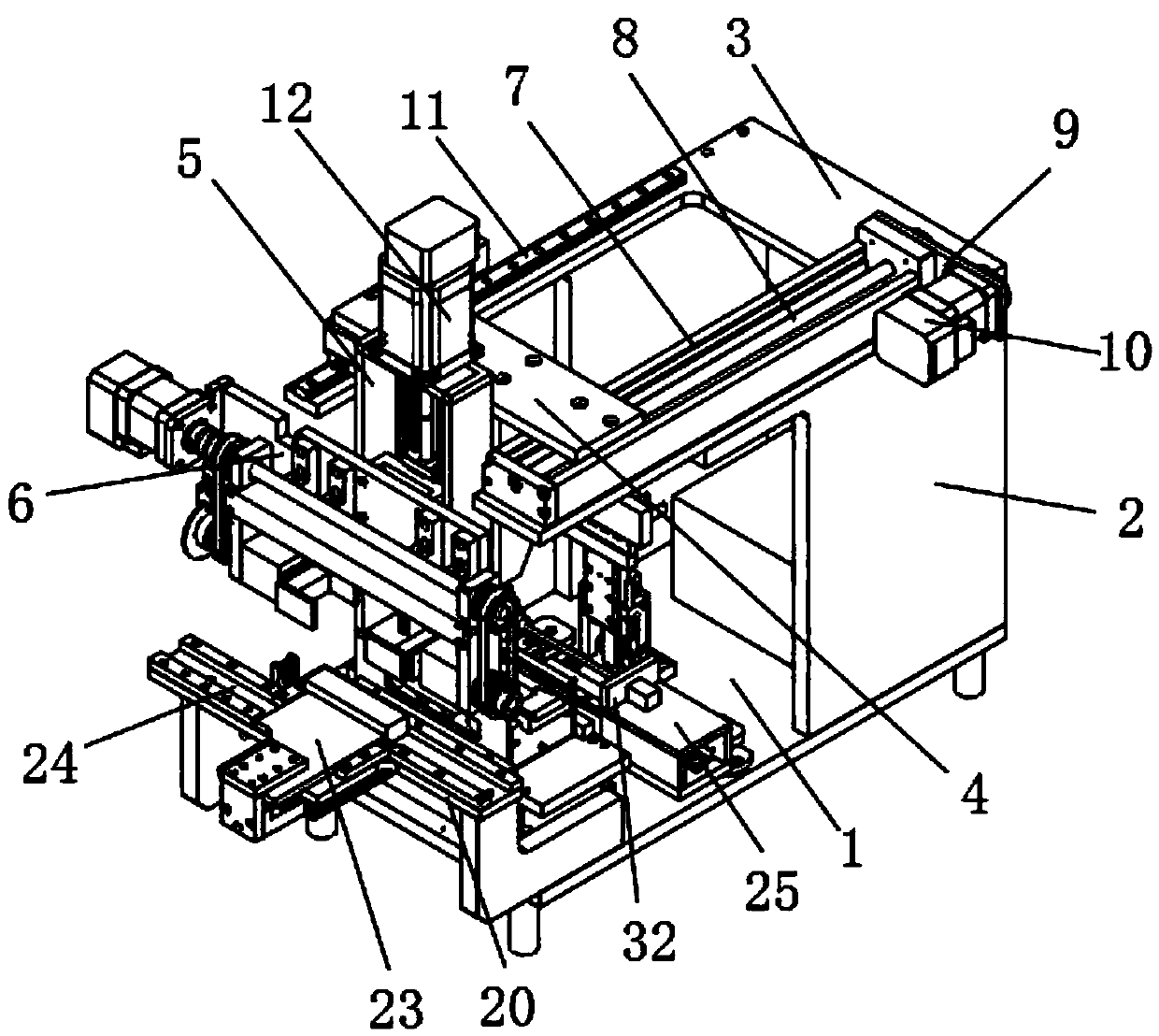

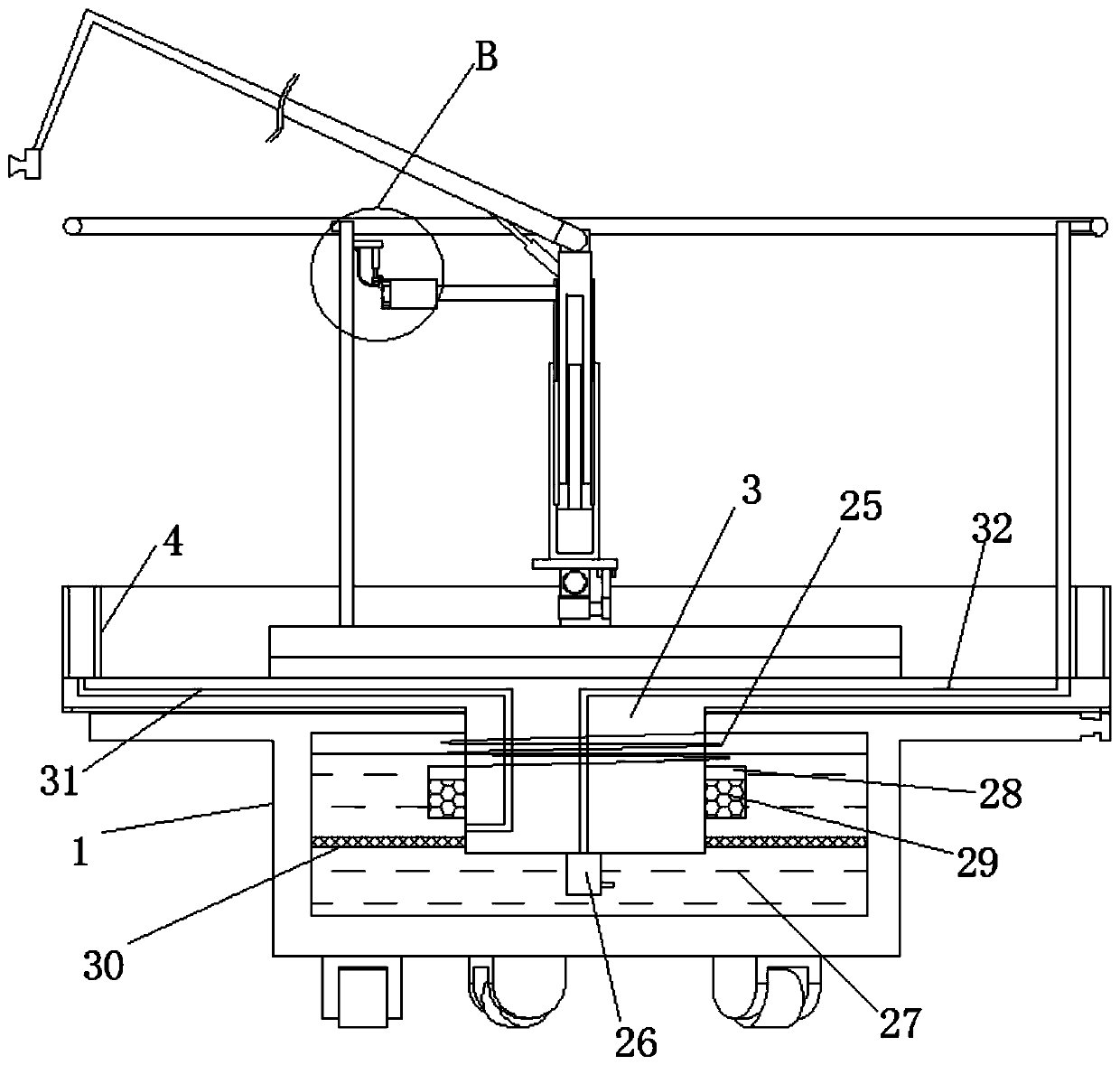

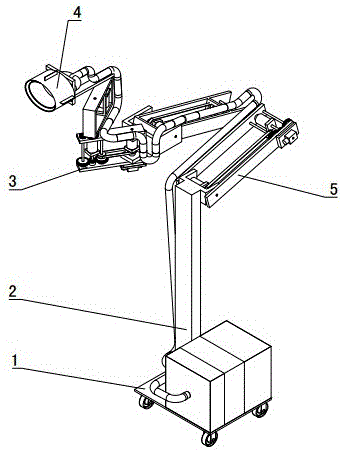

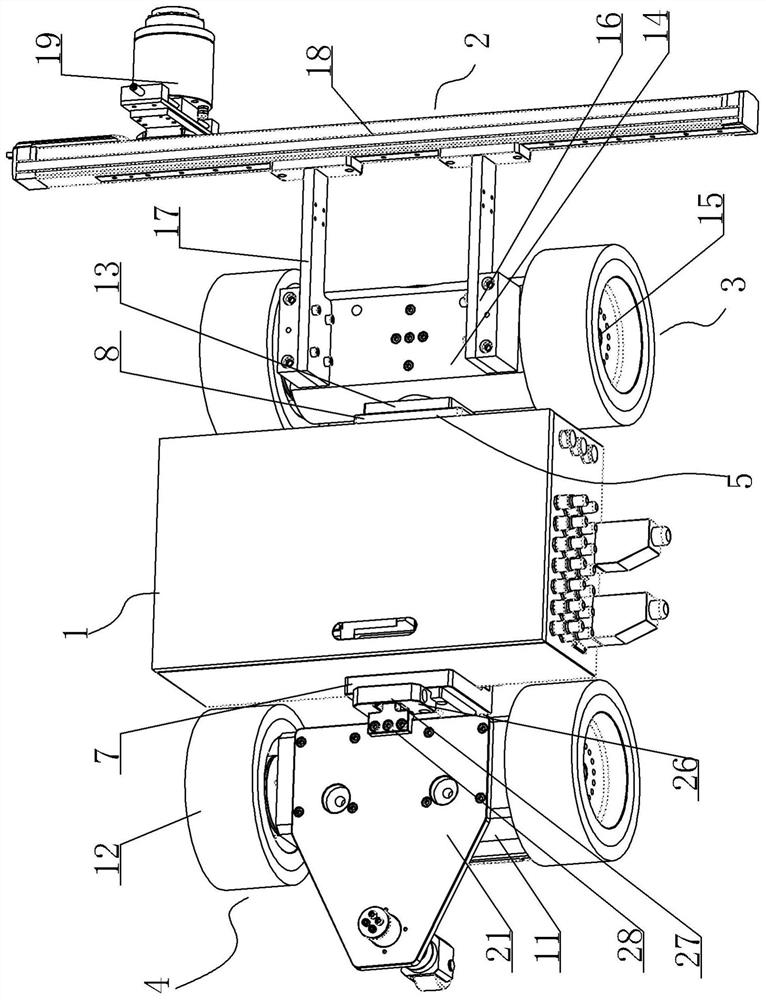

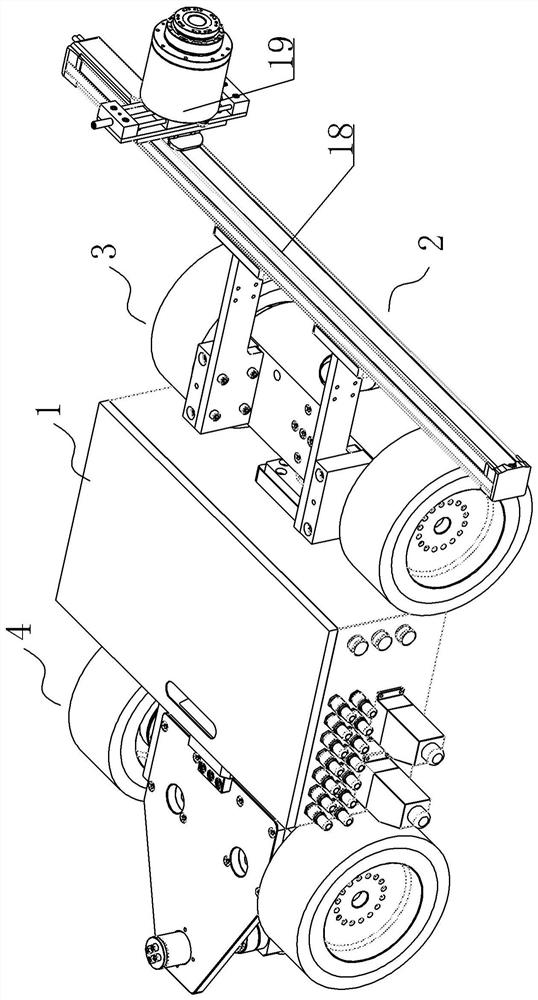

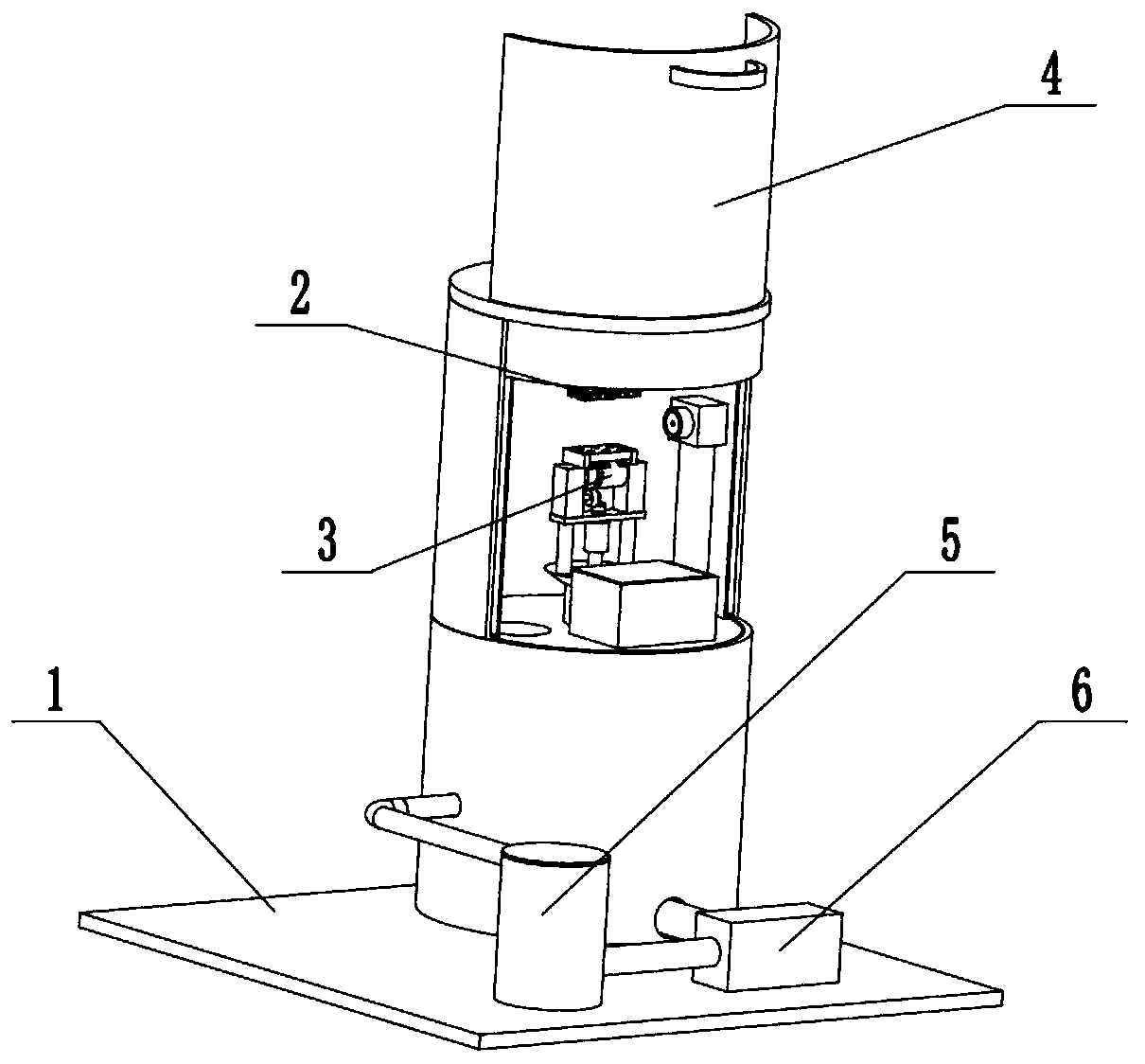

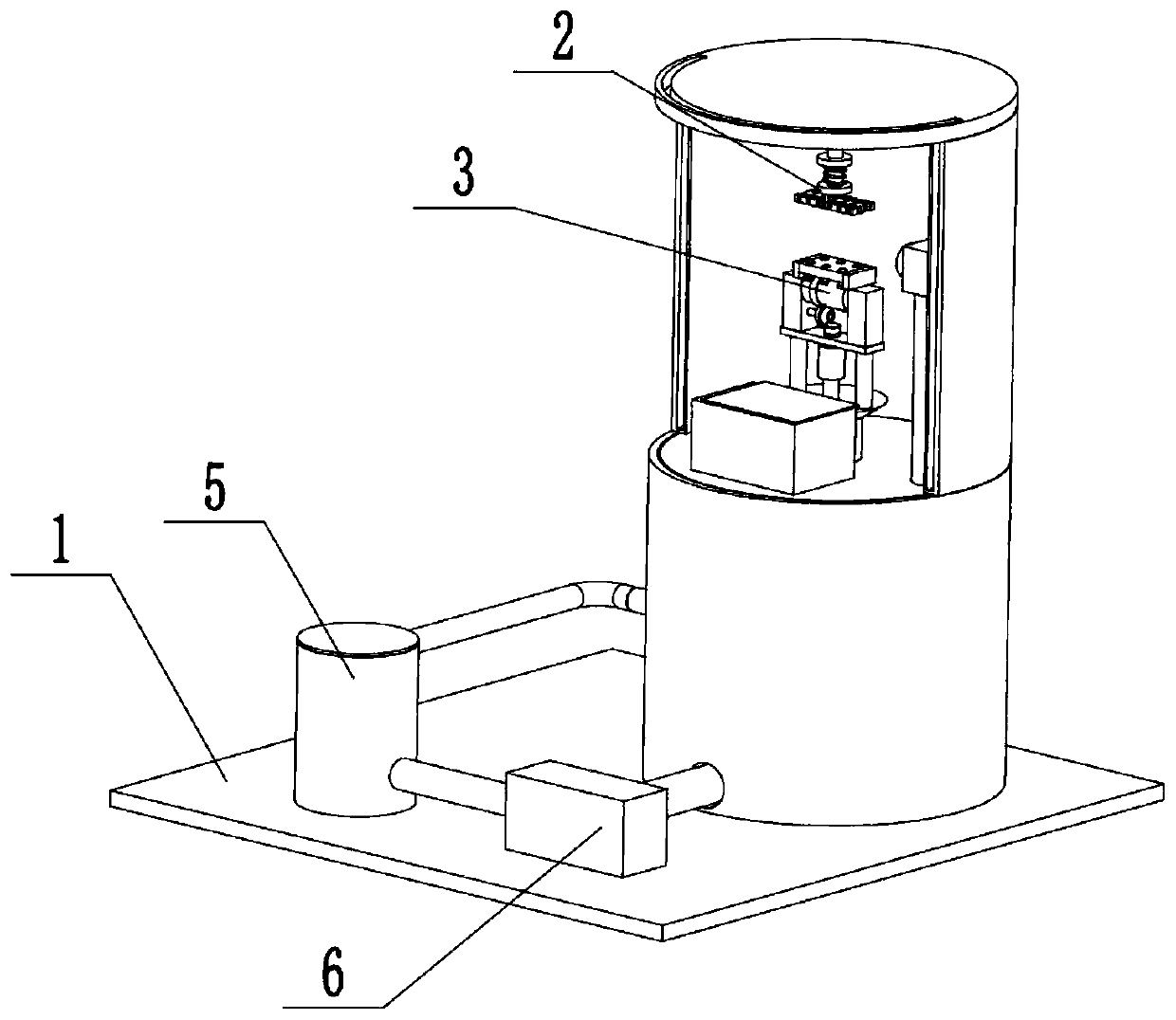

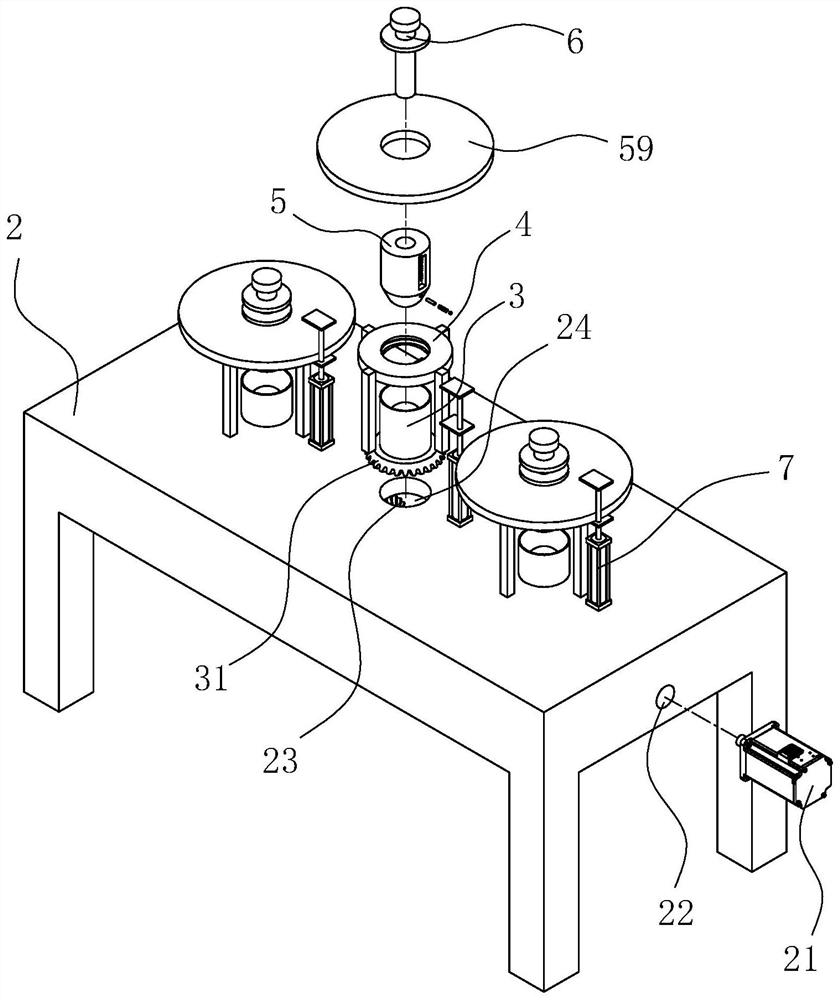

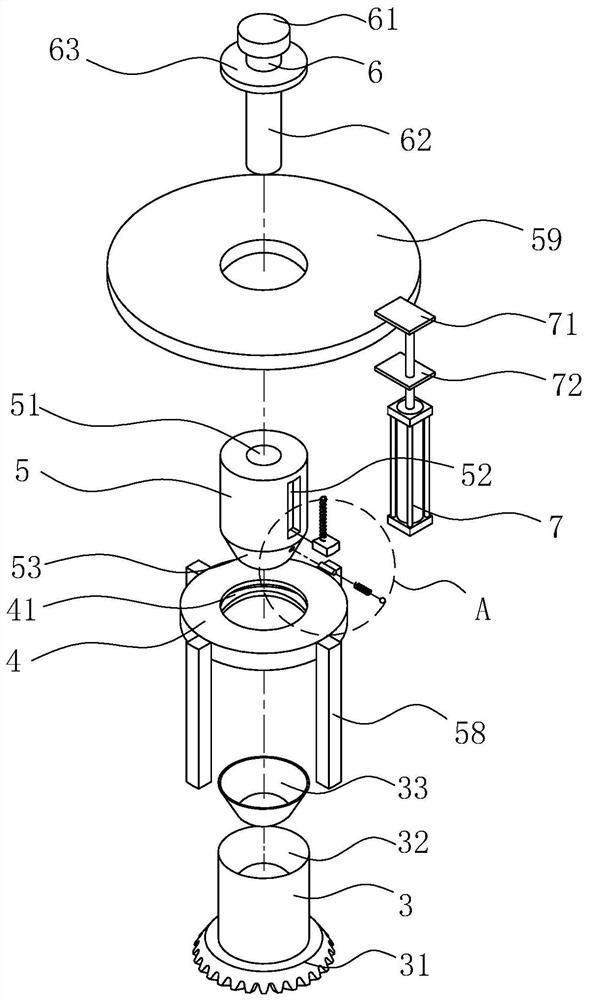

Intelligent spraying robot based on automatic control

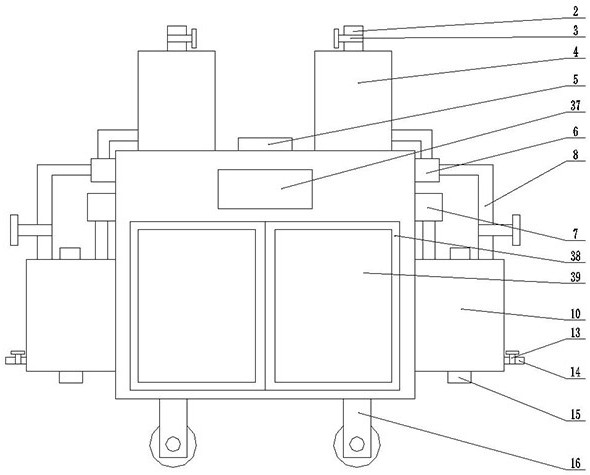

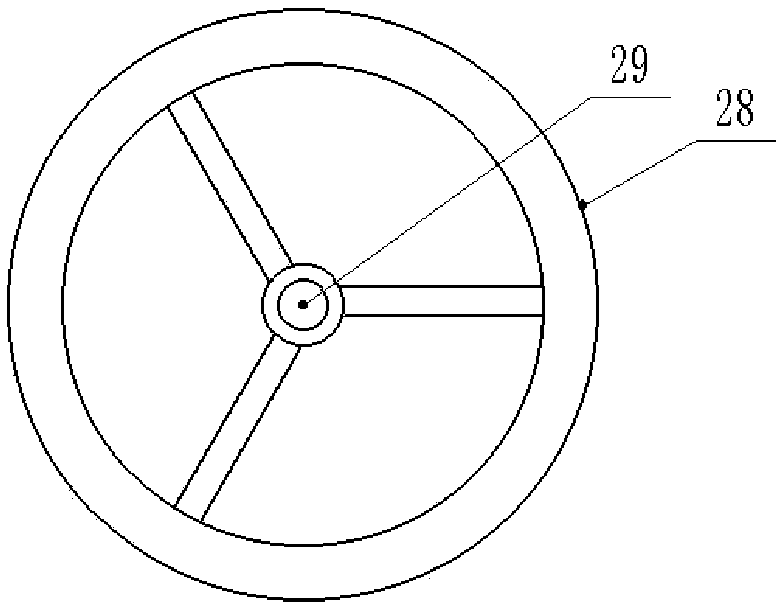

ActiveCN111111973APrevent reboundGuaranteed monitoring effectSpraying apparatusManipulatorAutomatic controlGear wheel

The invention discloses an intelligent spraying robot based on automatic control, and belongs to the field of spraying. The intelligent spraying robot based on the automatic control comprises a movingframe, a first guide rail is fixedly connected to the moving frame, a first moving seat is slidably connected to the first guide rail, a first driving motor is fixedly connected to the first moving seat, a first driving gear is fixedly connected to the driving end of the first driving motor, and a first rack rod meshed with the first driving gear is fixedly connected to the moving frame. According to the intelligent spraying robot based on the automatic control, a submersible pump is used for conveying water in a movable base into a water ring through a water inlet pipe and supporting pipes,then a water ring is used for spraying to form a water curtain downwards, a CCD camera and a workpiece are separated, when paint on the workpiece rebounds, the paint firstly makes contact with the sprayed water curtain, the water curtain absorbs the rebounded paint, the effects of isolation and absorption are achieved, the paint is effectively prevented from being rebounded to the CCD camera, themonitoring effect of the CCD camera is ensured, and the paint spraying effect is ensured.

Owner:中科南京人工智能创新研究院 +1

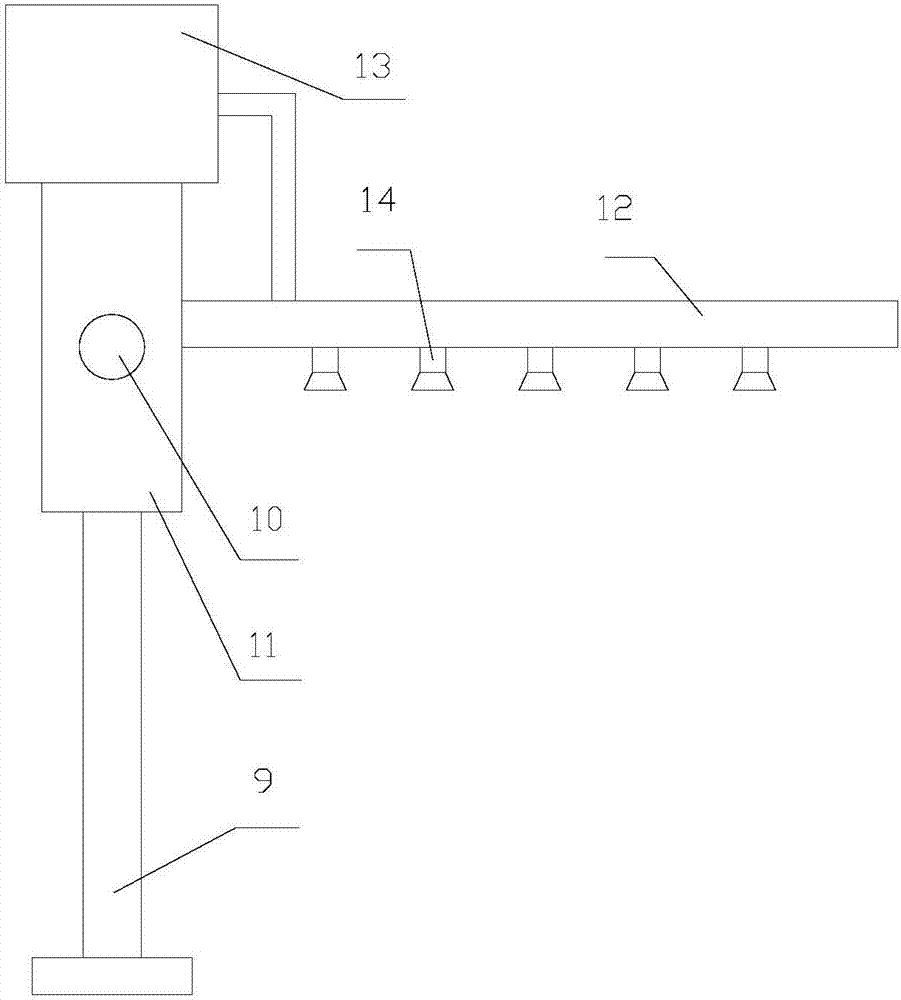

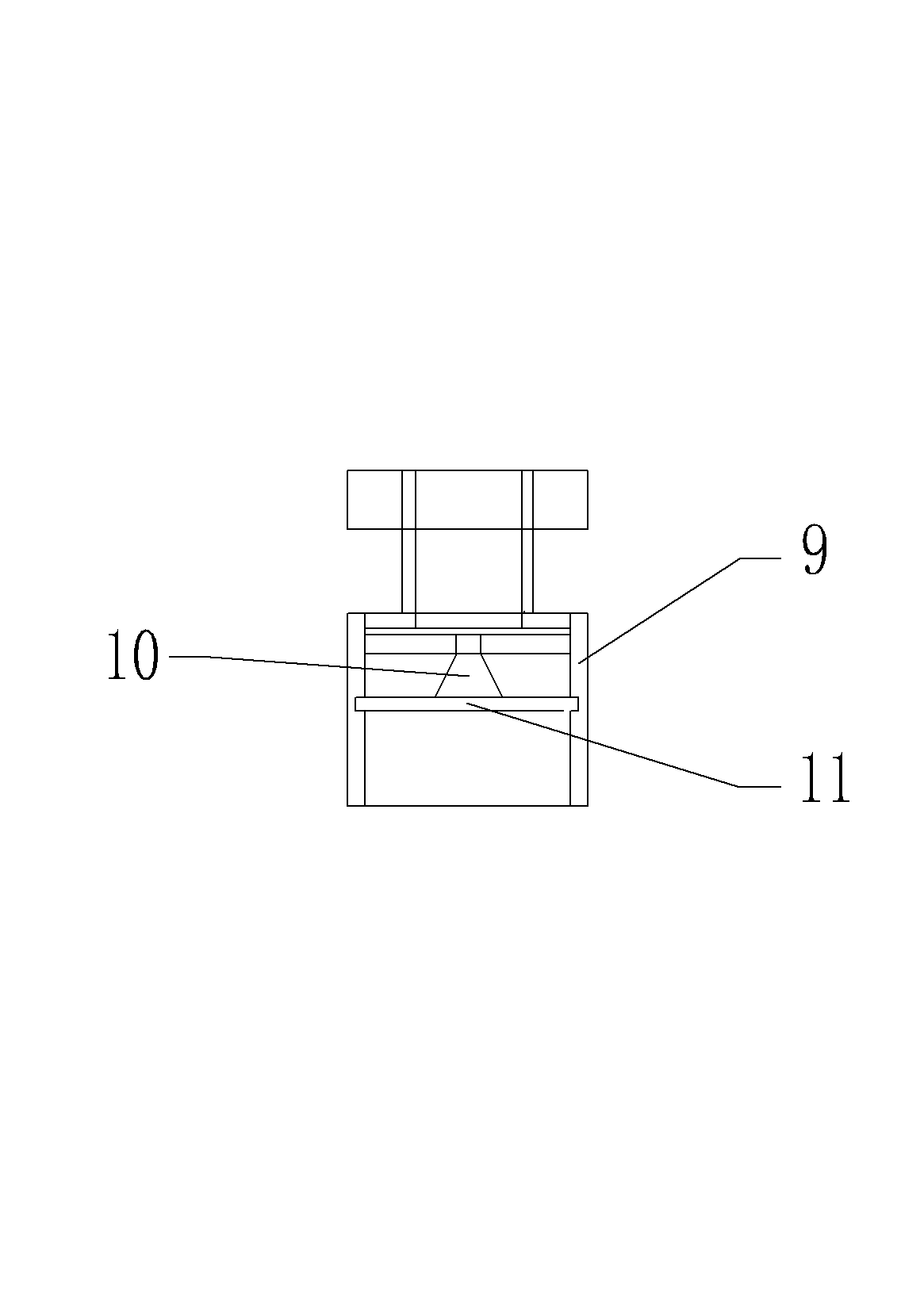

Automatic paint spraying device

ActiveCN105772299AGuaranteed paint effectExtended range of movementSpraying apparatusEngineeringMechanical engineering

Owner:淄博奧冠交通科技有限公司

Environment-friendly spraying device

PendingCN112403790ASpray evenlyThe surface is sprayed evenlyCombination devicesGas treatmentBall bearingMachine parts

The invention relates to the technical field of paint spraying, in particular to an environment-friendly spraying device which comprises a machining box, thrust ball bearings are symmetrically arranged on the inner wall of the bottom end of the machining box, and a workbench is arranged at the top ends of the thrust ball bearings; an execution motor is arranged on the inner wall of the middle of the bottom end of the machining box, and the output end of the execution motor is connected with the outer wall of the bottom end of the workbench; and a machined part is arranged at the top of the workbench. The environment-friendly spraying device is simple in structure, by arranging a rotating motor, a supporting base, execution screws, a double-shaft motor, a first gear, a second gear, sleeves,paint boxes, paint spraying heads and check blocks, the paint spraying heads move in the vertical direction and performs circular motion at the same time, the surface of the machined part is sprayedmore uniformly, the spraying efficiency is high, the paint spraying effect is guaranteed, and the working efficiency is improved.

Owner:德庆县智联机械科技有限公司

Paint spraying process for power distribution cabinet body plates

InactiveCN106903036ANot easy to blister and peel off paintThe painting process is simplePretreated surfacesCoatingsSurface cleaningFree cooling

The invention discloses a paint spraying process for power distribution cabinet body plates and relates to the field of power distribution cabinets. Through the process steps of cabinet body plate surface cleaning, acid pickling, phosphorization, blow-drying, putty brushing, drying, polishing, primer spraying, finish paint spraying, paint drying, forced cooling and natural cooling, the paint spraying effect and the paint spraying quality are guaranteed. The whole paint spraying process steps are controlled reasonably, so that the surfaces of power distribution cabinet bodies are not prone to blistering or depainting, and the service life is prolonged.

Owner:繁昌县易能科技有限责任公司

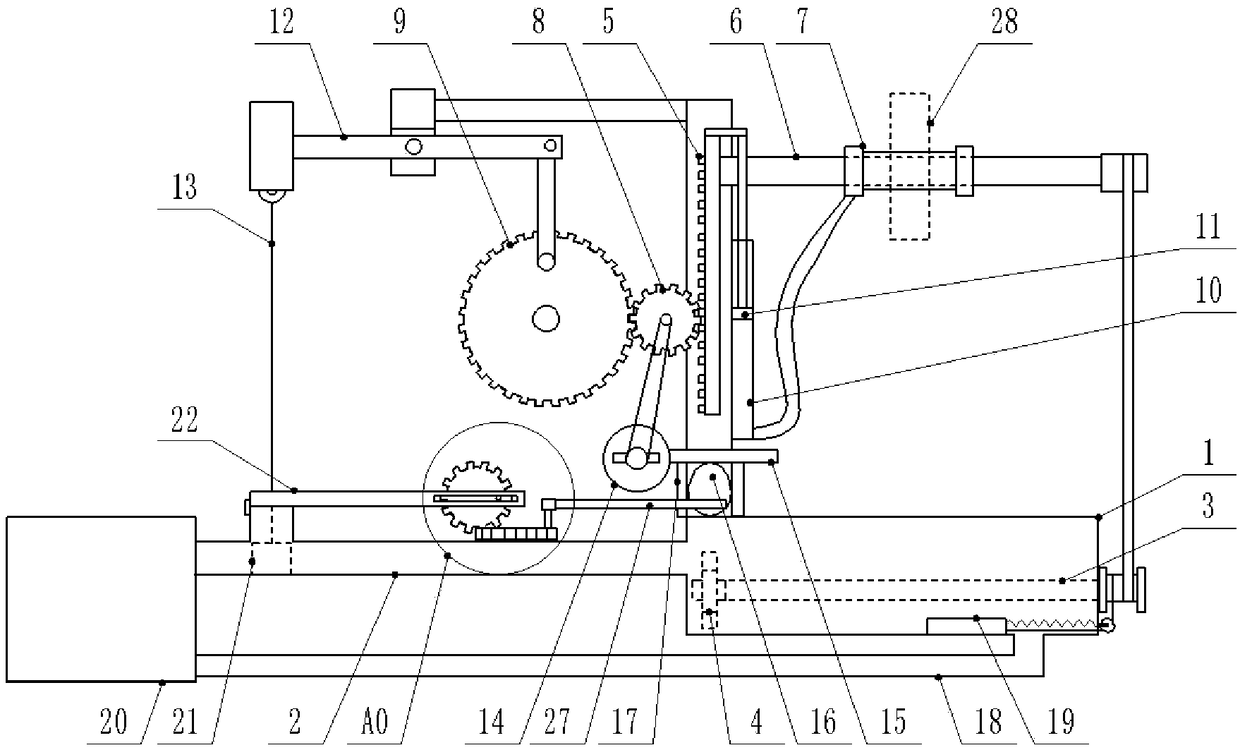

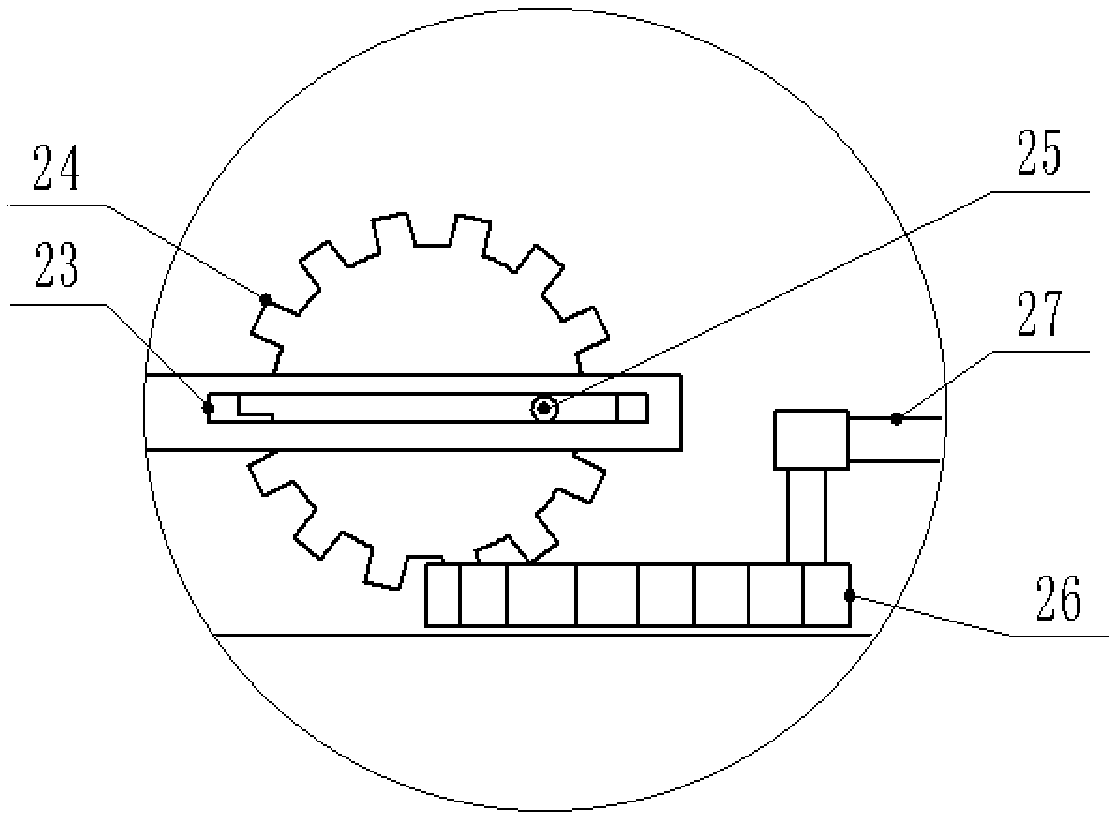

Painting device for valve handwheel

InactiveCN108212670AImprove cleanlinessFirmly connectedLiquid surface applicatorsCoatingsGear wheelEngineering

The invention relates to the field of valve production, and discloses a painting device for a valve handwheel. The painting device comprises a paint groove; a rack is arranged on the paint groove; a rack is slidably connected onto the rack; a small gear is meshed with the rack; a cross rod is rotatably connected to the rack; a fixed position is arranged on the cross rod; the fixed position is sleeved with an elastic inflation barrel; a vertical pipe is arranged on the rack; a piston which is in clearance fit with the vertical pipe is arranged in the vertical pipe; the inside of the vertical pipe is divided into an upper pipeline and a lower pipeline by the piston; a connection rod is arranged in the upper pipeline; two ends of the connection rods are separately hinged to the rack and the piston; an inflation pipe is connected between a lower end of the lower pipeline and the elastic inflation barrel; a paint inlet pipe is connected with the paint groove; a rotary shaft is rotatably connected into the paint groove; a turbine is fixedly connected to one end of the rotary shaft and is located at a connection opening of the paint inlet pipe and the paint groove; and an elastic belt isconnected between the other end of the rotary shaft and the cross rod. By adopting the painting device, while the handwheel is painted, a through hole of the handwheel is prevented from being paintedwith paint; and machining efficiency of the handwheel is improved.

Owner:CHONGQING QIANYAN MACHINERY CO LTD

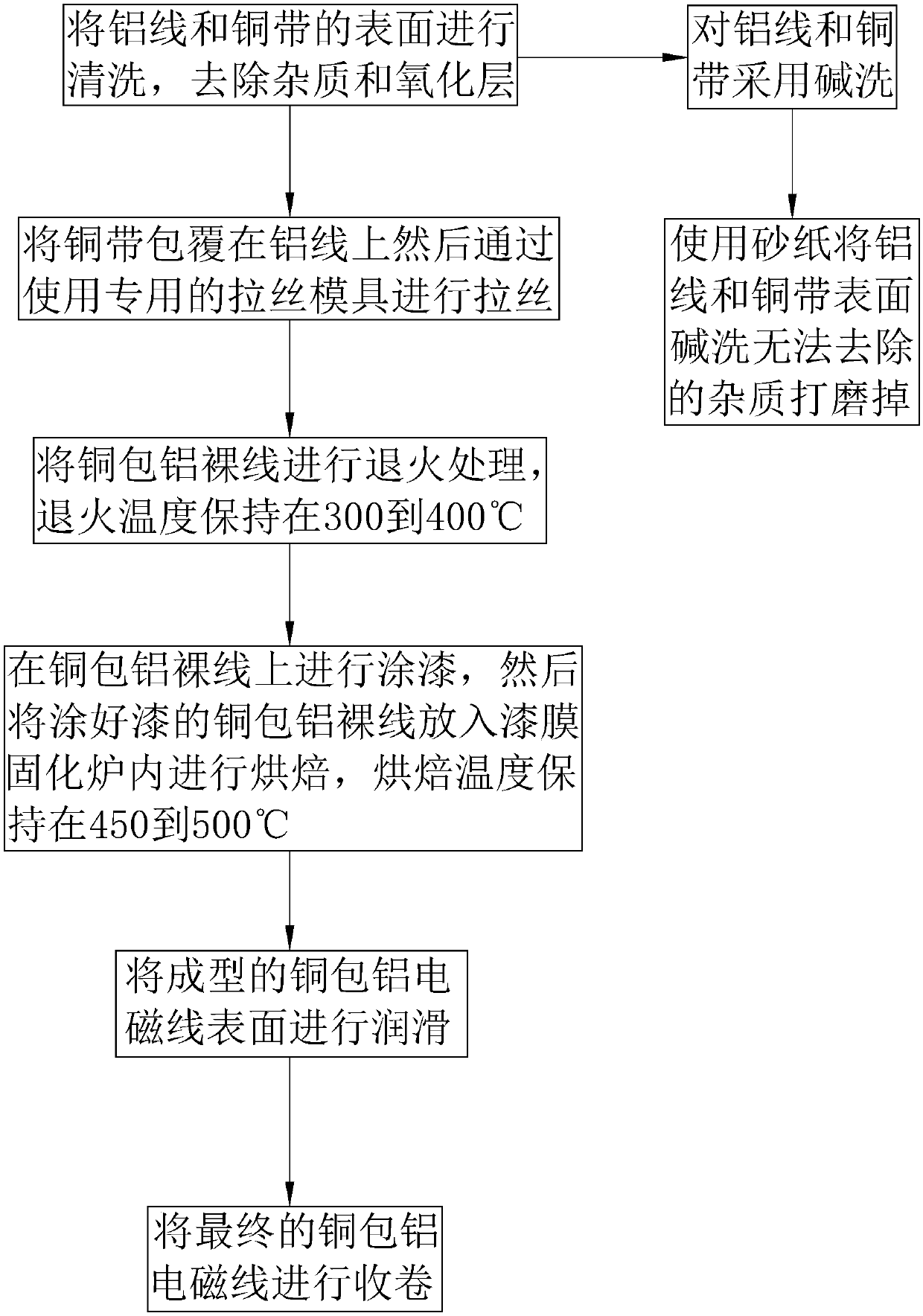

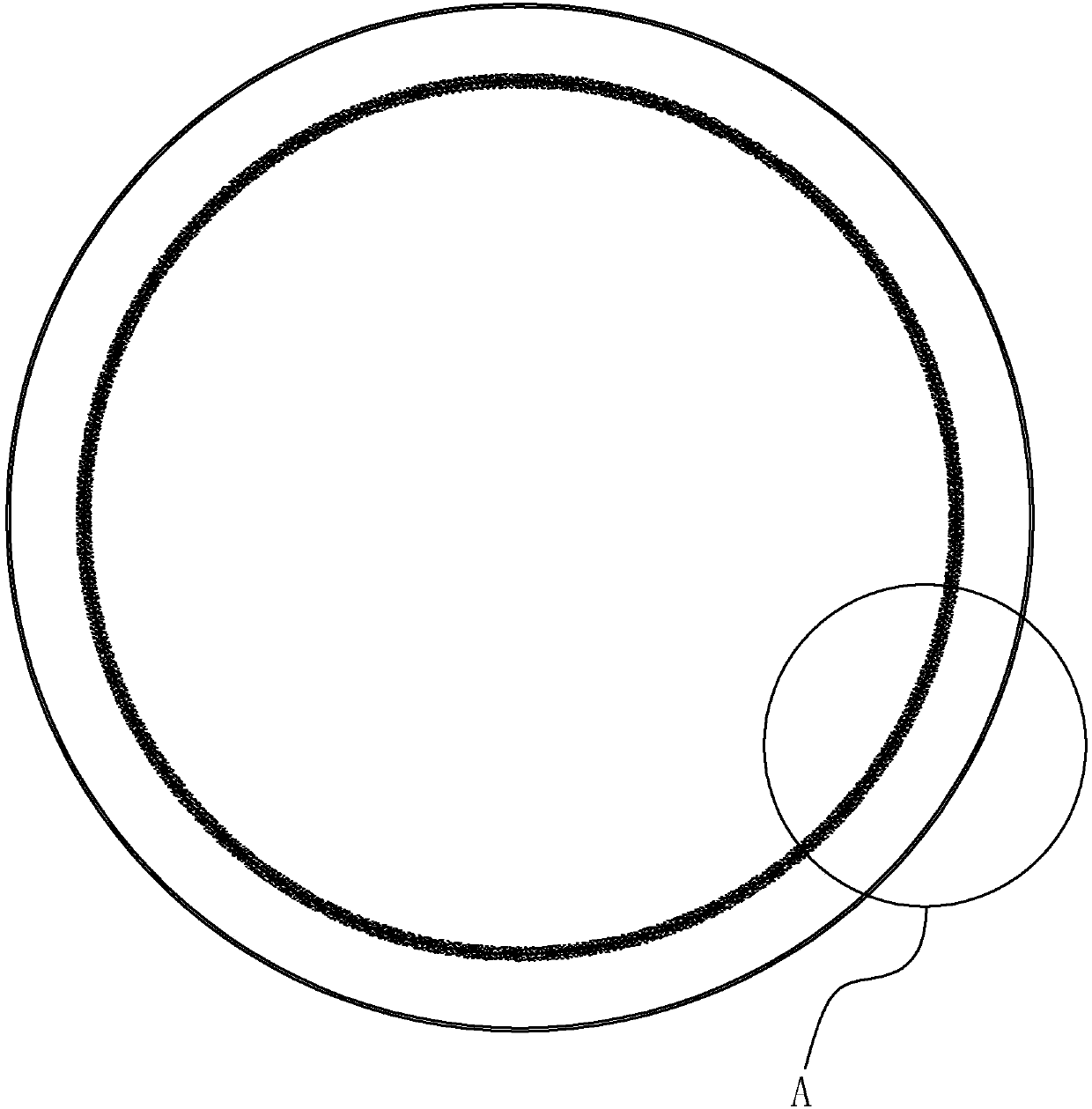

Production process of class 200 copper-clad aluminum electromagnetic wire

InactiveCN108597687AImprove bindingImprove toughnessManufacturing extensible conductors/cablesInsulating conductors/cablesCopperToughness

The invention discloses a production process of a class 200 copper-clad aluminum electromagnetic wire, belonging to the field of copper-clad aluminum electromagnetic wires, and the technical proposalthereof comprises the following steps of: cleaning the surfaces of the aluminum wire and the copper strip to remove impurities and an oxide layer; coating the copper strip on the aluminum wire and then drawing by using a special wire drawing die; annealing the copper-clad aluminum bare wire, maintaining the annealing temperature at 300 to 400 degrees centigrade; painting the copper-clad aluminum bare wire to ensure uniform painting, placing the painted copper-clad aluminum bare wire in the film curing oven for baking, and maintaining the baking temperature at 450 to 500 degrees centigrade; lubricating the surface of the formed copper-clad aluminum electromagnetic wire to make the surface of the copper-clad aluminum electromagnetic wire smooth and uniform in thickness; and winding up the final copper-clad aluminum magnet wire, thereby solving the problem that it is difficult to select a suitable temperature in the production process of the copper-clad aluminum magnet wire, and improvingthe quality of the copper-clad aluminum magnet wire, so that the connection between copper and aluminum is tight and the toughness is good.

Owner:天津精达漆包线有限公司

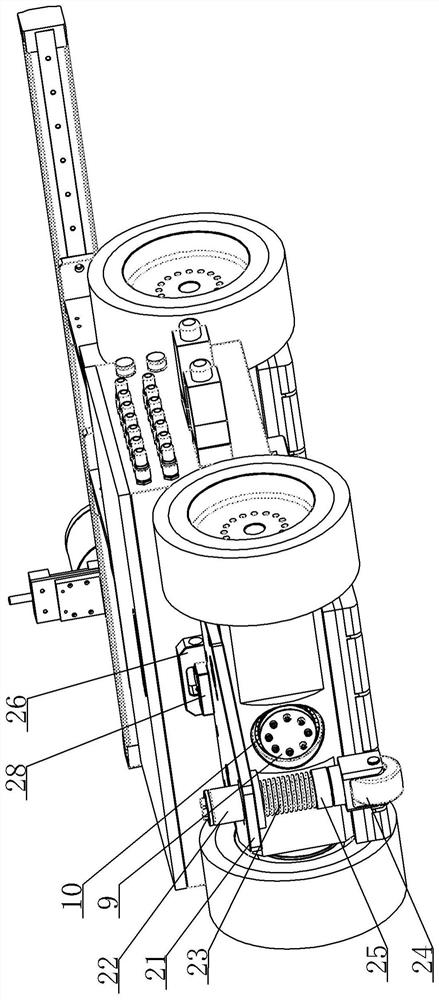

Wall-climbing paint spraying robot

PendingCN111790551AGuaranteed freedom of movementImprove passabilityLiquid surface applicatorsSpraying apparatusWall climbingStructural engineering

The invention provides a wall-climbing paint spraying robot. The robot can move stably along a metal wall, smooth and uniform spraying is ensured, labor costs are reduced, and spraying effect is ensured. A control module is installed in a concave supporting frame of a connecting module. The connecting module further comprises a first vertical plate and a second vertical plate. The exposed end surface of the first vertical plate is fixedly connected with a convex rotating shaft. The rotating shaft is arranged perpendicular to the first vertical plate. Bearings respectively sleeves both ends ofthe rotating shaft in the length direction. A floating shaft module particularly comprises a floating shaft frame. The floating shaft frame is provided with a through avoidance hole at a position corresponding to the rotating shaft. The floating shaft frame sleeves the outer rings of the bearings on the corresponding sides. Traveling wheels respectively sleeves two sides of the floating shaft frame through rotating bearings. The exposed end surface of the second vertical plate is fixedly connected to a connecting vertical plate of a fixed shaft module. The fixed shaft module particularly comprises a fixed shaft frame. The fixed shaft frame is provided with a connecting vertical plate at a position corresponding to the second vertical plate.

Owner:苏州镌山企业管理合伙企业(有限合伙)

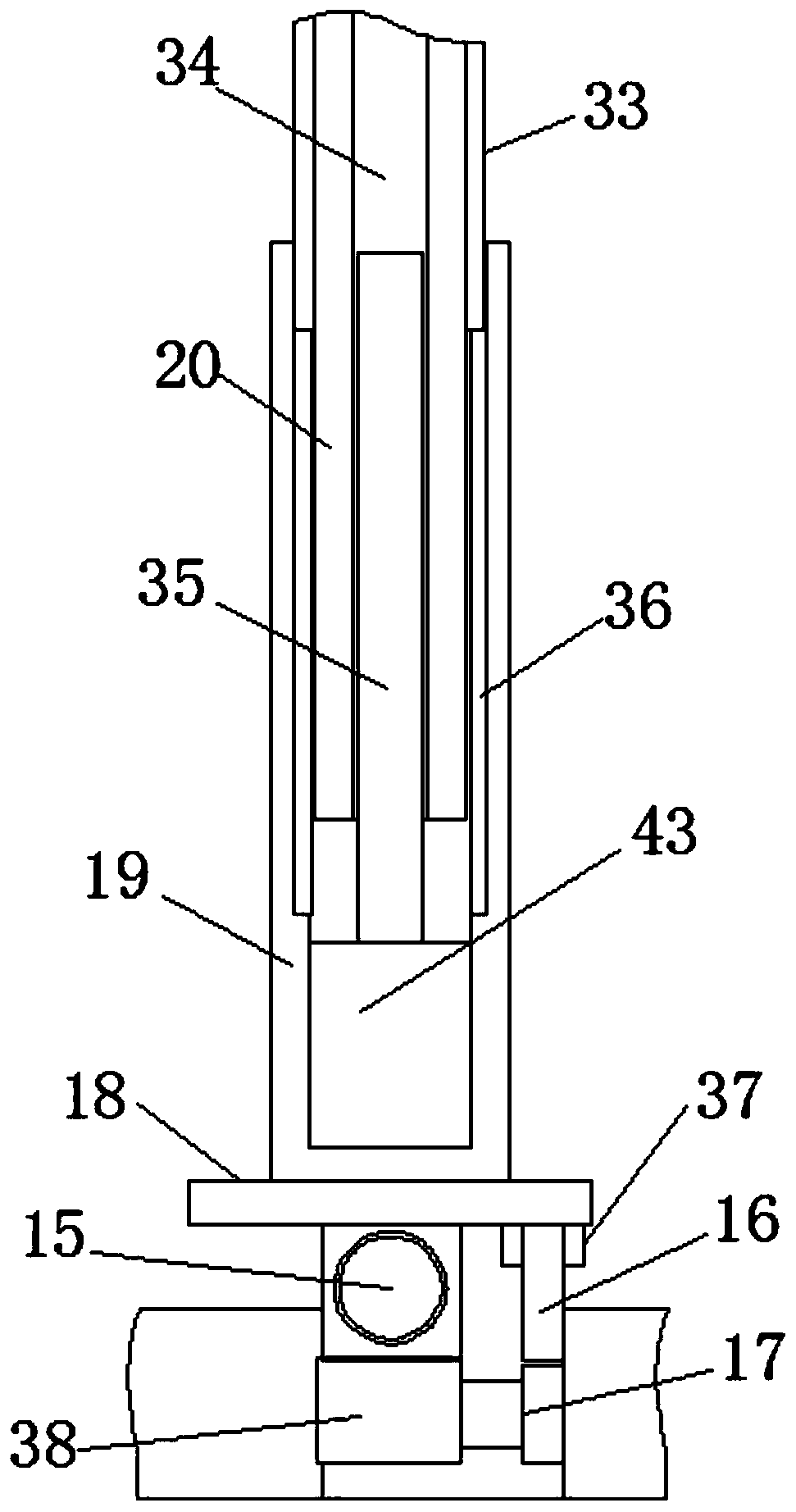

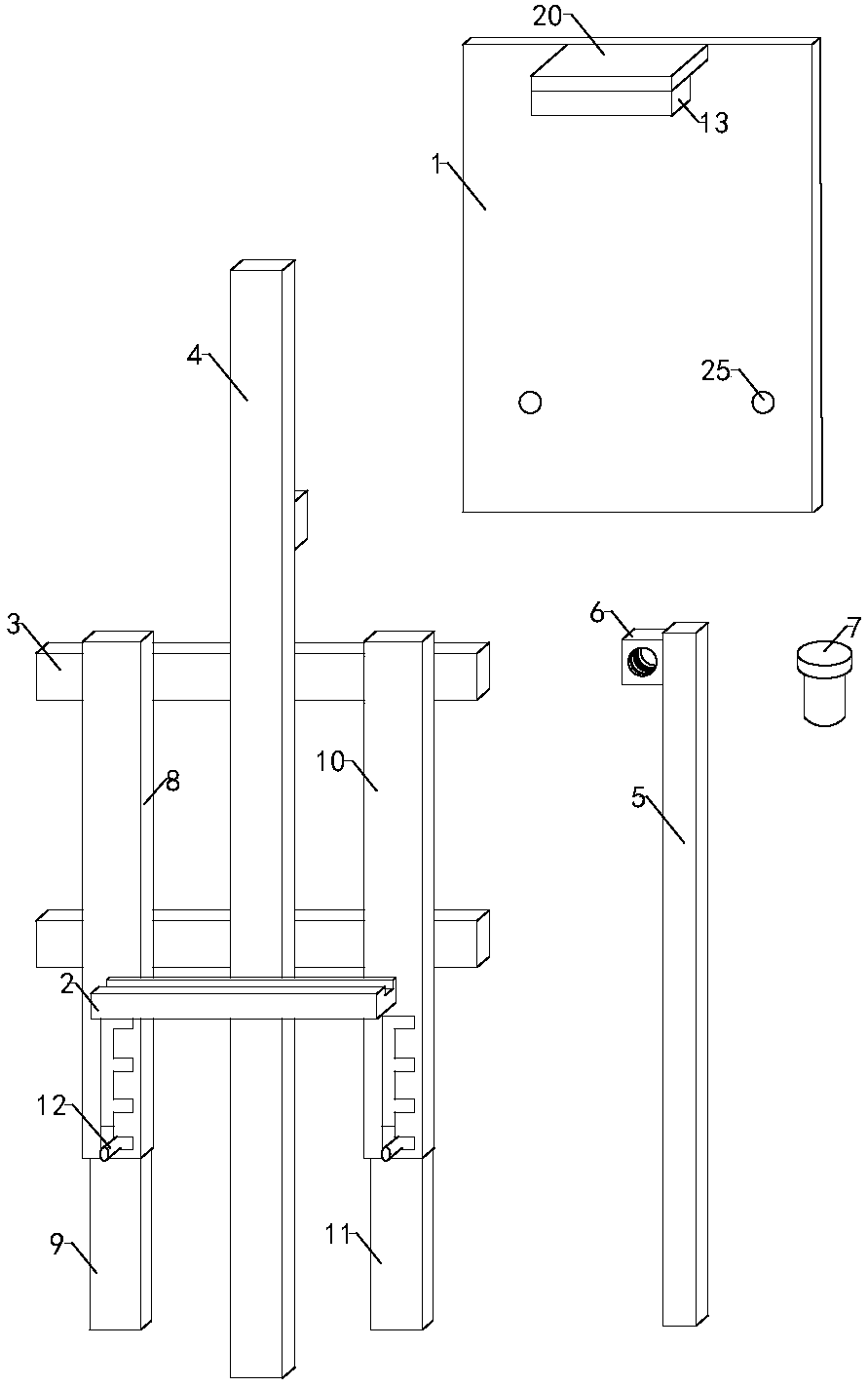

Magnetic one-piece easel

InactiveCN108407536AAdjust working heightEasy to fixFurniture partsOther artistic work equipmentsEngineeringScrew thread

The invention relates to the technical field of accessory devices of culture articles and particularly relates to a magnetic one-piece easel. The magnetic one-piece easel provides convenience for regulating the working height of a fixed plate, is relatively low in use limitation, provides convenience for a user and is relatively high in practicability; moreover, paper for drawing can be conveniently fixed, the drawing effect is effectively guaranteed, the using effect is relatively good, and thus the use reliability of the magnetic one-piece easel is improved; the magnetic one-piece easel comprises left fixing rods, right fixing rods, a fixed plate, a supporting plate, two groups of connecting rods, upright rods, supporting rods, two groups of connecting frames and bolts; the top end of the supporting plate is provided with grooves; the inner sidewalls of two groups of mounting holes and the outer sidewalls of the bolts are each of a threaded structure; the left fixing rods include a first left fixing rod and a second left fixing rod; the right fixing rods include a first right fixing rod and a second right fixing rod; the magnetic one-piece easel further comprises a shrinkable frame, a threaded rod, a threaded tube, a driving gear, a driven gear, a chain, a clamping plate and a servo motor; the chain is arranged on the driving gear and the driven gear in a sleeving manner; anda magnetic plate is arranged inside the fixed plate.

Owner:张雨欣

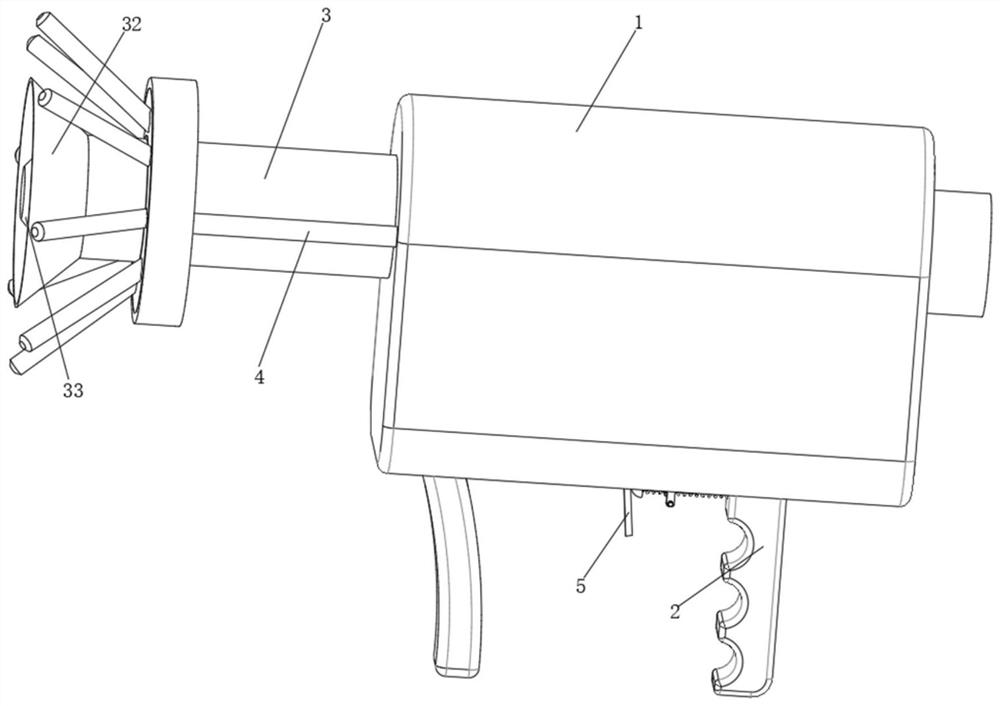

Paint spraying device and method for construction site

The invention discloses a paint spraying device for a construction site. The paint spraying device comprises a shell, a spraying mechanism, an air injection mechanism and a transmission mechanism, wherein two handles used for holding are arranged at the bottom of the shell, the spraying mechanism is mounted in the shell, so that paint and compressed air are mixed and sprayed out, the air injection mechanism is mounted on the outer side of the spraying mechanism, so that floating ash on the wall surface is blown away by the spraying mechanism before paint spraying, the transmission mechanism is installed in the shell, and when the transmission mechanism moves, the spraying mechanism and the air injection mechanism work synchronously, floating ash on the wall surface is blown away, and paint spraying is conducted. According to the paint spraying device, the spraying mechanism is combined with the air injection mechanism to spray paint on the wall surface, dust needs to be removed on the part, needing to be sprayed, of the wall surface while spraying is conducted, therefore dust on the spraying portion is reduced, even if the wall surface is not completely cleaned, the air injection mechanism can also clean the wall surface in advance, so that the spraying effect of the wall surface is ensured, the time for repairing paint on the wall surface is shortened, and the labor cost is reduced.

Owner:广州天翔建设工程有限公司

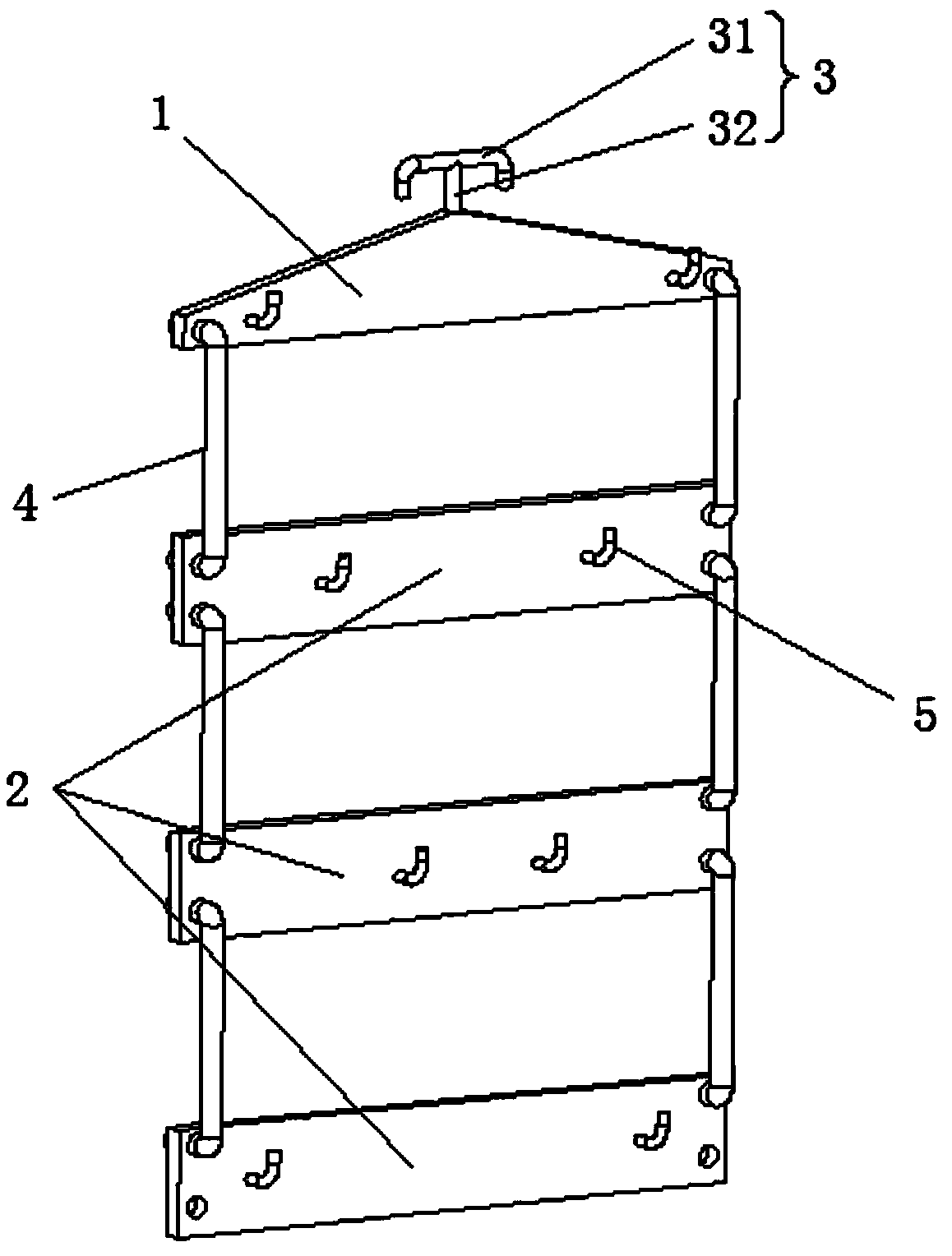

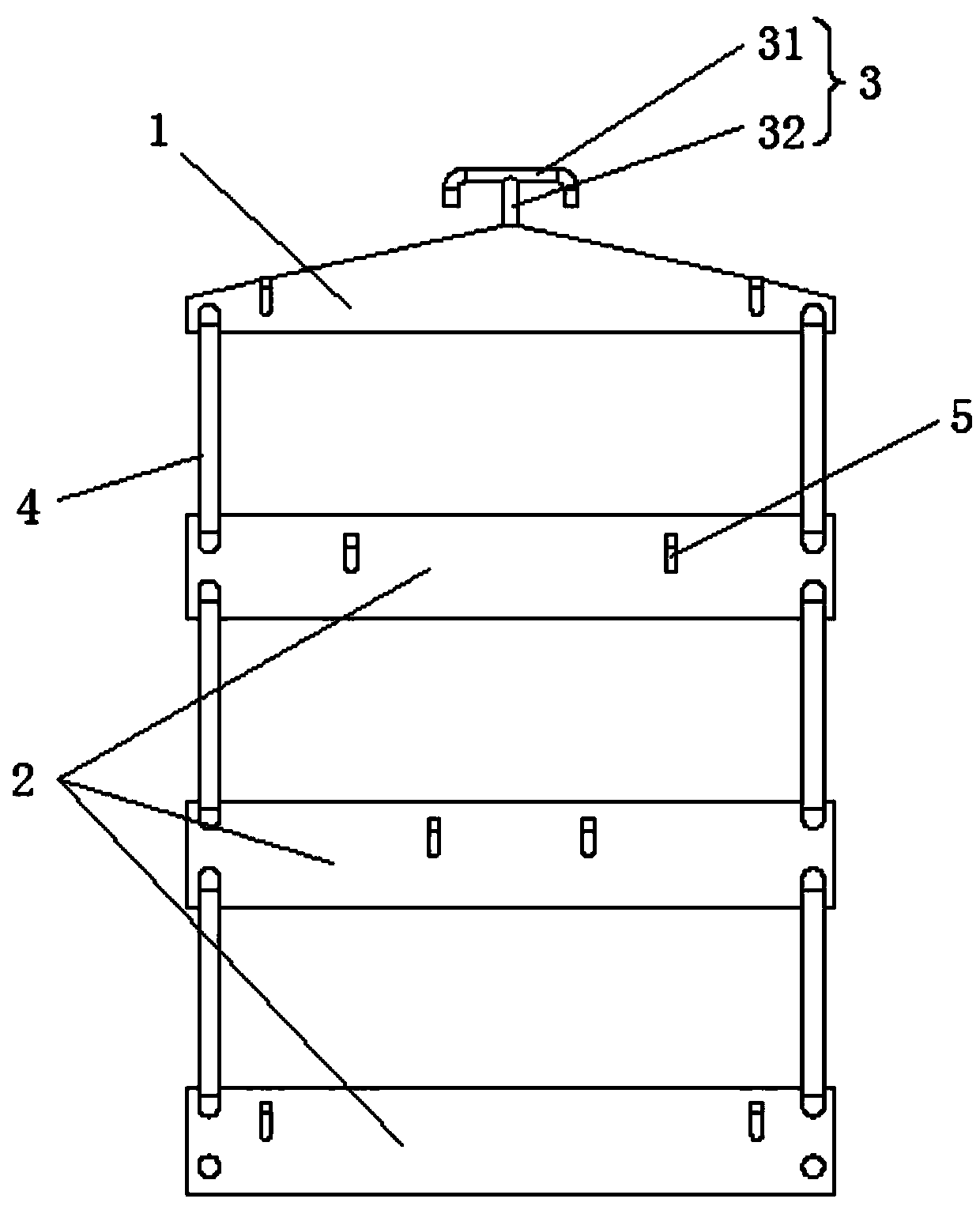

Hanger for paint spraying

InactiveCN104028406AImprove stabilityReduce interactionSpraying apparatusMechanical engineeringEngineering

Owner:TAIZHOU ANJI ELECTRONICS

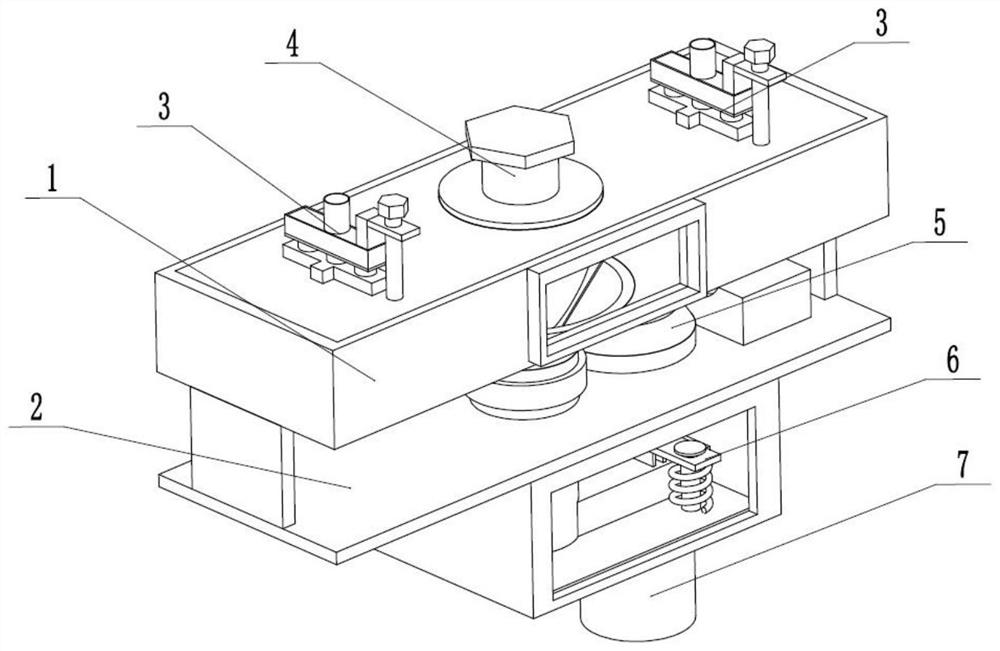

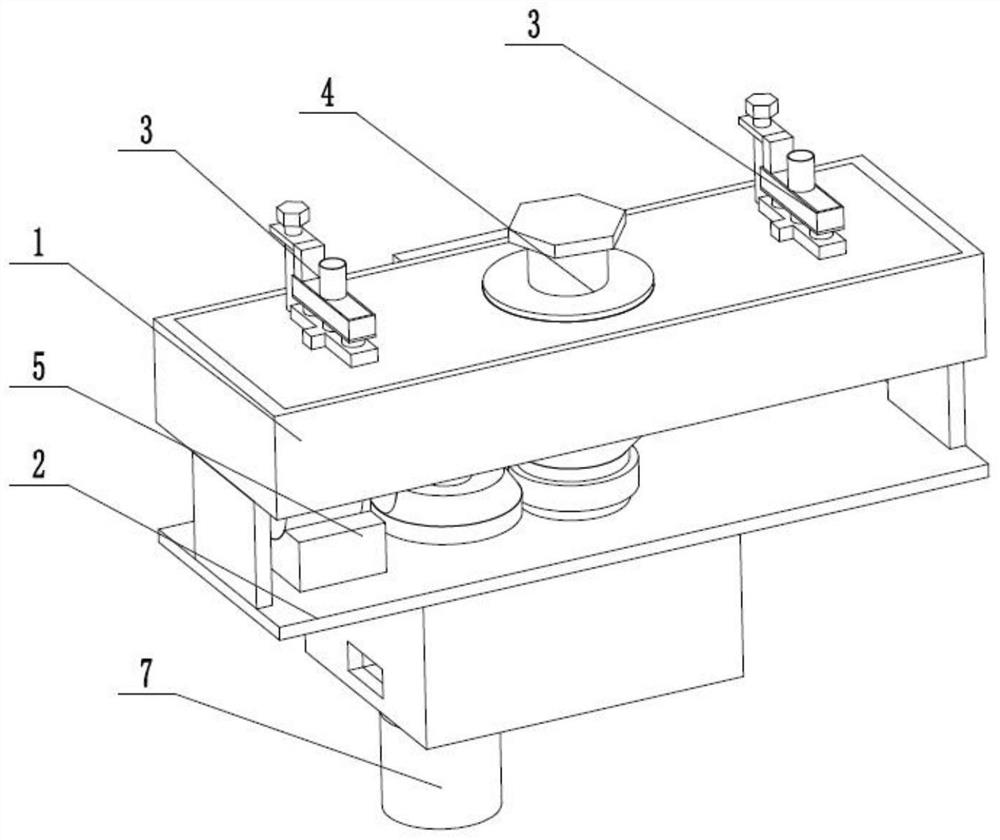

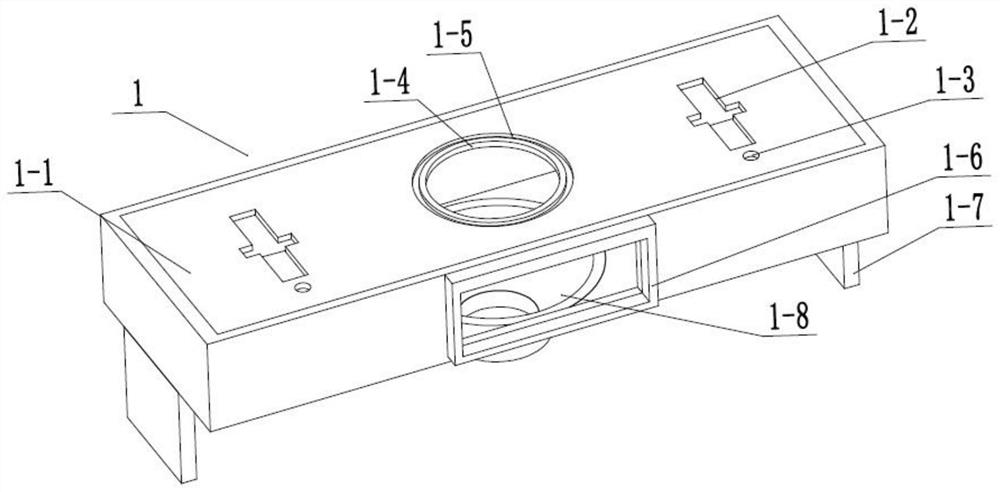

Uniform dead angle-free paint spraying protection device

ActiveCN109731706AAvoid painting blind spotsGuarantee the quality of paintingLiquid spraying apparatusEngineeringMechanical engineering

The invention relates to the field of paint spraying, in particular to a uniform dead angle-free paint spraying protection device. The uniform dead angle-free paint spraying protection device comprises an operation base, an upper clamping block, a lower clamping block, a baffle, an oil paint recovery box and a feeding pump. The operation base comprises a bottom plate, a bottom frame, a baffle insertion groove, an upper frame, two sliding grooves, a center plate, a motor baffle, a feeding pipe, a spray gun, a sliding bottom frame, a recovery notch and a round feeding pipe fixing hole. The bottom frame is fixedly connected to the bottom plate. The upper frame is fixedly connected to the upper end of the bottom frame. The baffle insertion groove penetrates through the rear end of the upper frame up and down. The two sliding grooves are formed in the left side and the right side of the rear end of the upper frame correspondingly. The center plate is fixedly connected to the upper end of the inner wall of the bottom frame. The uniform dead angle-free paint spraying protection device has the beneficial effects that 360-degree dead-angle-free paint spraying can be carried out on an objectneeding paint spraying, a paint spraying blind area caused by clamping of a fixture is avoided, the paint spraying quality and the paint spraying effect are guaranteed, and meanwhile sprayed atomizedoil paint can be resisted and recovered.

Owner:ZHEJIANG DAFENGFAN FURNITURE CO LTD

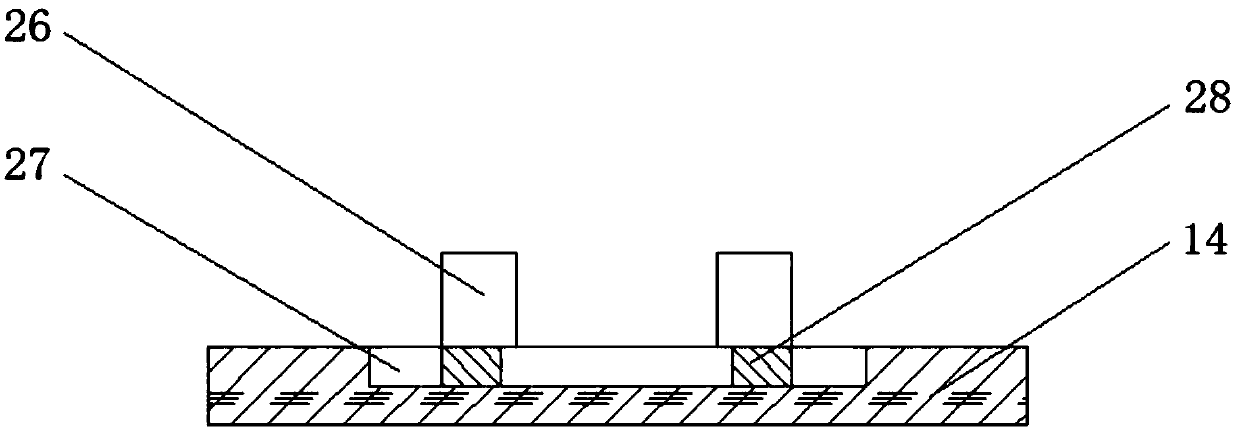

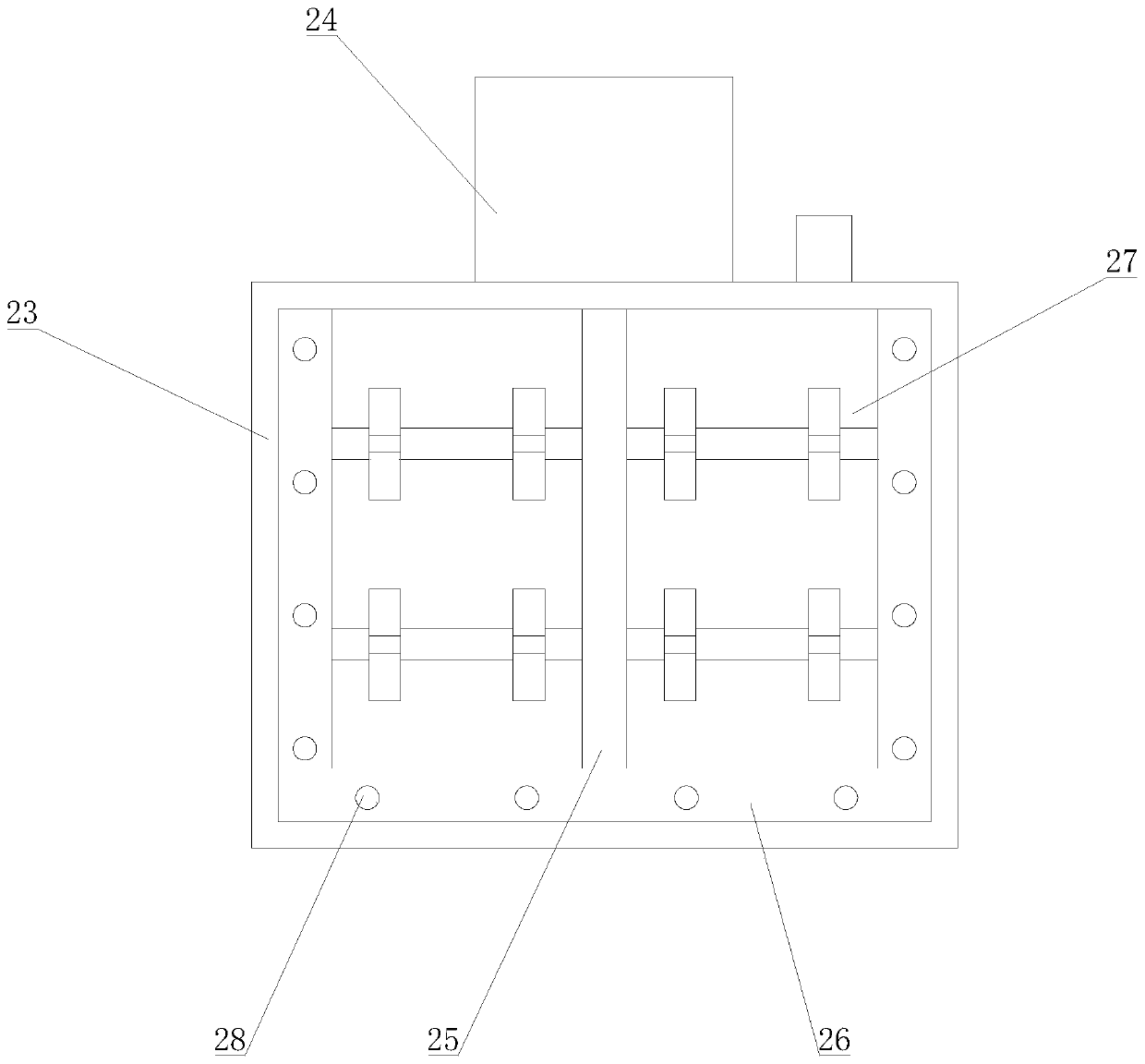

High-efficiency board paint spraying machine

InactiveCN107008594AAvoid damageReduce duplication of effortSpraying apparatusEngineeringMechanical engineering

The invention discloses a high-efficiency board paint spraying machine. The paint spraying machine comprises a plurality of clamping parts, power mechanisms and a paint spraying part; the multiple clamping parts are distributed in sequence, each clamping part comprises a base plate and two clamping units, wherein the two clamping units are distributed oppositely, each clamping unit comprises a fixed plate, a rotating shaft, a gear, a supporting plate, threaded rods and pressing plates, wherein the fixed plate is mounted on the base plate; each rotating shaft is horizontally connected with the corresponding fixed plate in a rotating mode; each gear is mounted on the corresponding rotating shaft, and the gears in any two adjacent clamping parts are engaged with each other; each supporting plate connected with the corresponding rotating shaft is provided with threaded holes; each threaded rod is placed in the corresponding threaded hole and matched with the corresponding threaded hole; each pressing plate is placed at one side, away from the corresponding fixed plate, of the corresponding supporting plate, each the pressing plate is connected with the corresponding threaded rod; the power mechanisms are used for driving the gears to rotate; and the paint spraying part is used for conducting paint spraying on a board.

Owner:蚌埠抒阳自动化设备制造有限公司

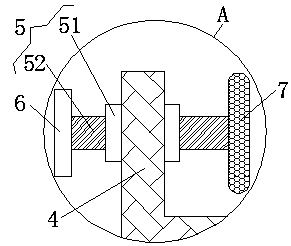

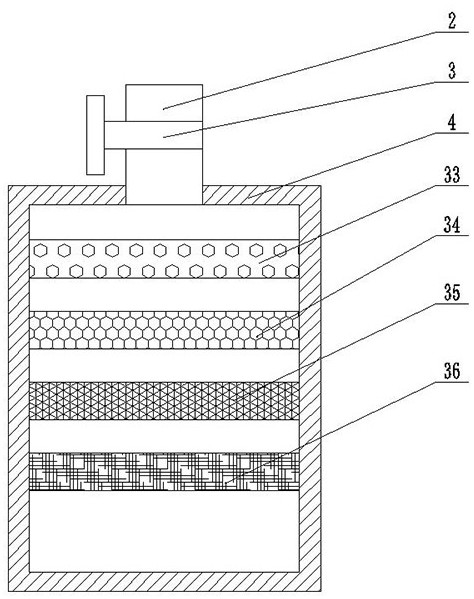

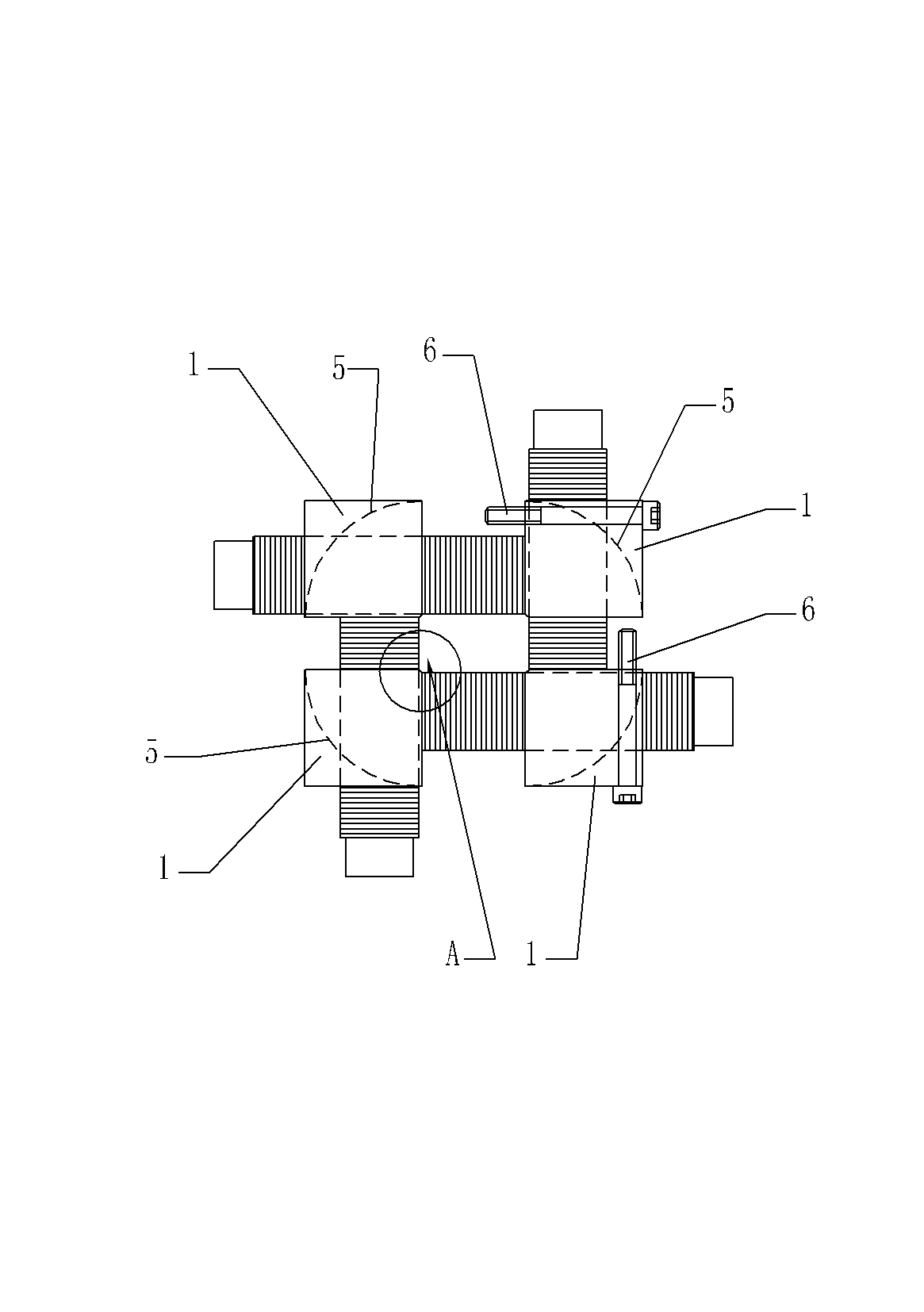

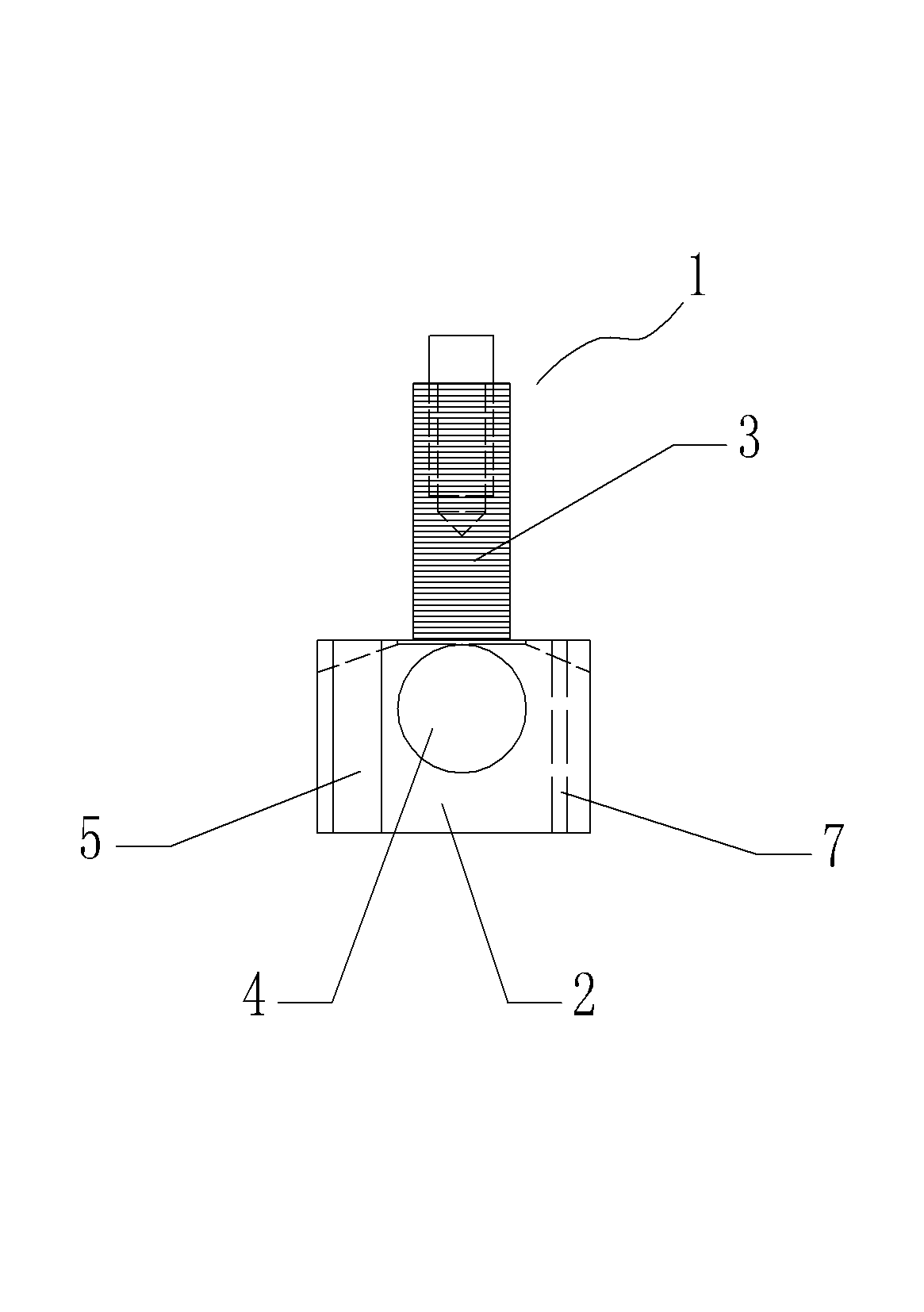

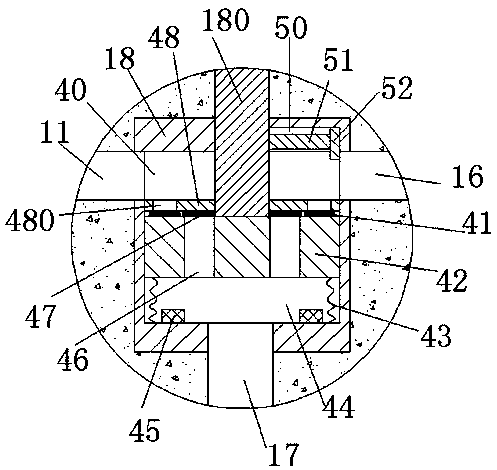

Novel painting die for enameled wire

ActiveCN102709001AReduce scrap rateSave materialInsulating conductors/cablesCopper wireMechanical engineering

The invention provides a novel painting die for an enameled wire, which can solve a problem that a conventional painting die structure has low reutilization ratio, greatly simplify the die replacement process, improve the efficiency and effectively lower the scrappage of bare copper wires and has lower manufacturing cost. The novel painting die is characterized by comprising four identically structured die bars, and every two of the four are vertically connected end to end in sequence.

Owner:WUXI XIZHOU MAGNET WIRES

Multifunctional environment-friendly coating device

The invention discloses a multifunctional environment-friendly coating device which comprises an environment-friendly box fixedly mounted on a base body, a discharge pipe connected to a coating filling box and a connecting pipe connected to a pollution discharging system. A mounting and connecting cavity is formed in the ground; an adapting plate is rotatably mounted at the left bottom end of themounting and connecting cavity through an adapting shaft; a first through slot is formed in the left end of the adapting plate; a flow guide device is fixedly mounted at the lower end of the mountingand connecting cavity; the flow guide device comprises a first sleeve, a first accommodating groove is formed in the first sleeve, a first partition plate is fixedly mounted in the first accommodatinggroove to cut the first accommodating groove into a first upper accommodating groove and a first lower accommodating groove; a first sliding connecting block is mounted in the first lower accommodating groove in a sliding manner up and down; a first ejecting shaft is fixedly mounted in the middle of the upper end surface of the first sliding connecting block; the upper end of the first ejecting shaft penetrates through the first partition plate and the first sleeve and penetrates into the mounting and connecting cavity; and second through slots communicating to the first upper and lower accommodating grooves are symmetrically arranged on the left and right sides of the first partition plate.

Owner:乐绪春

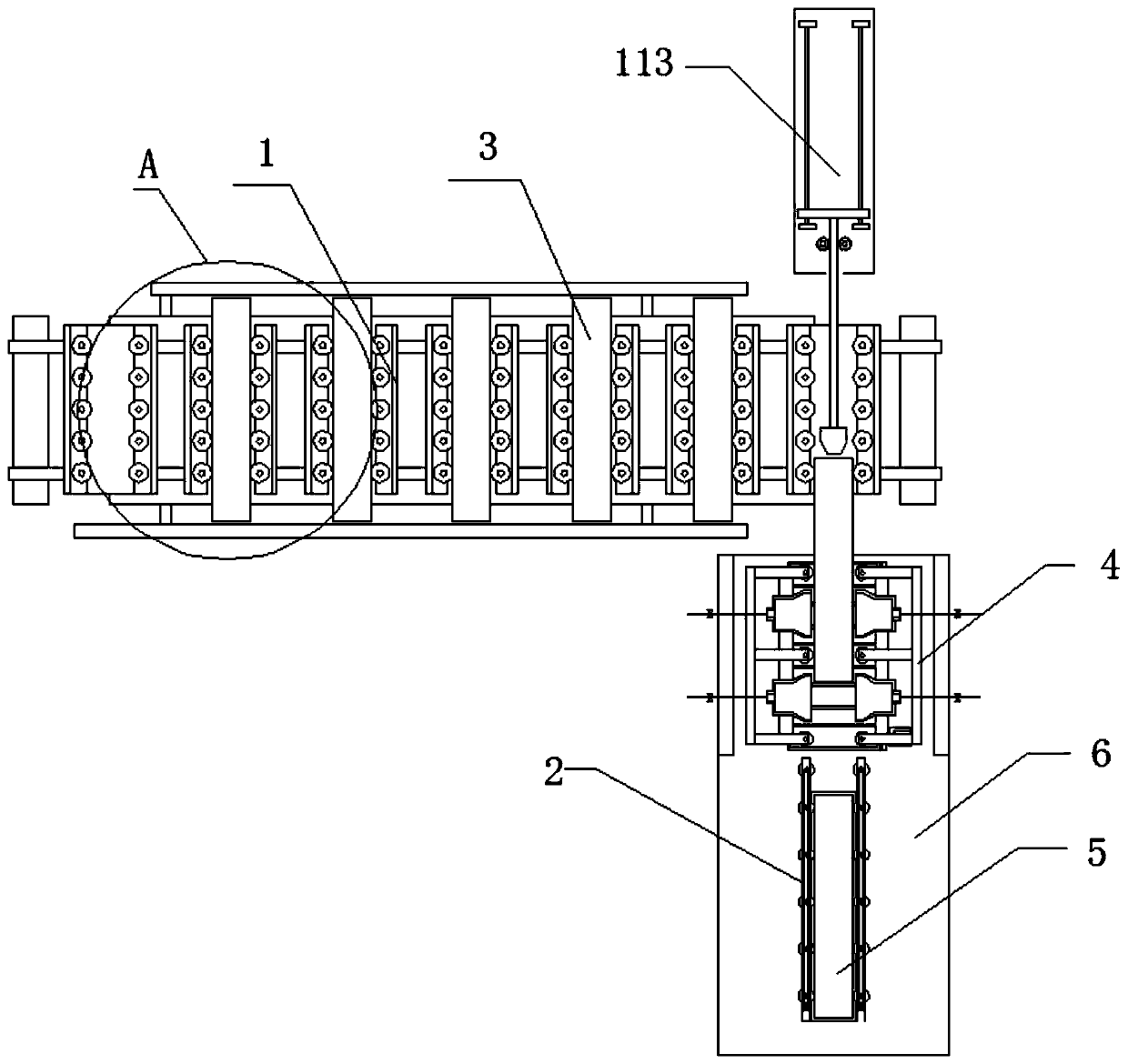

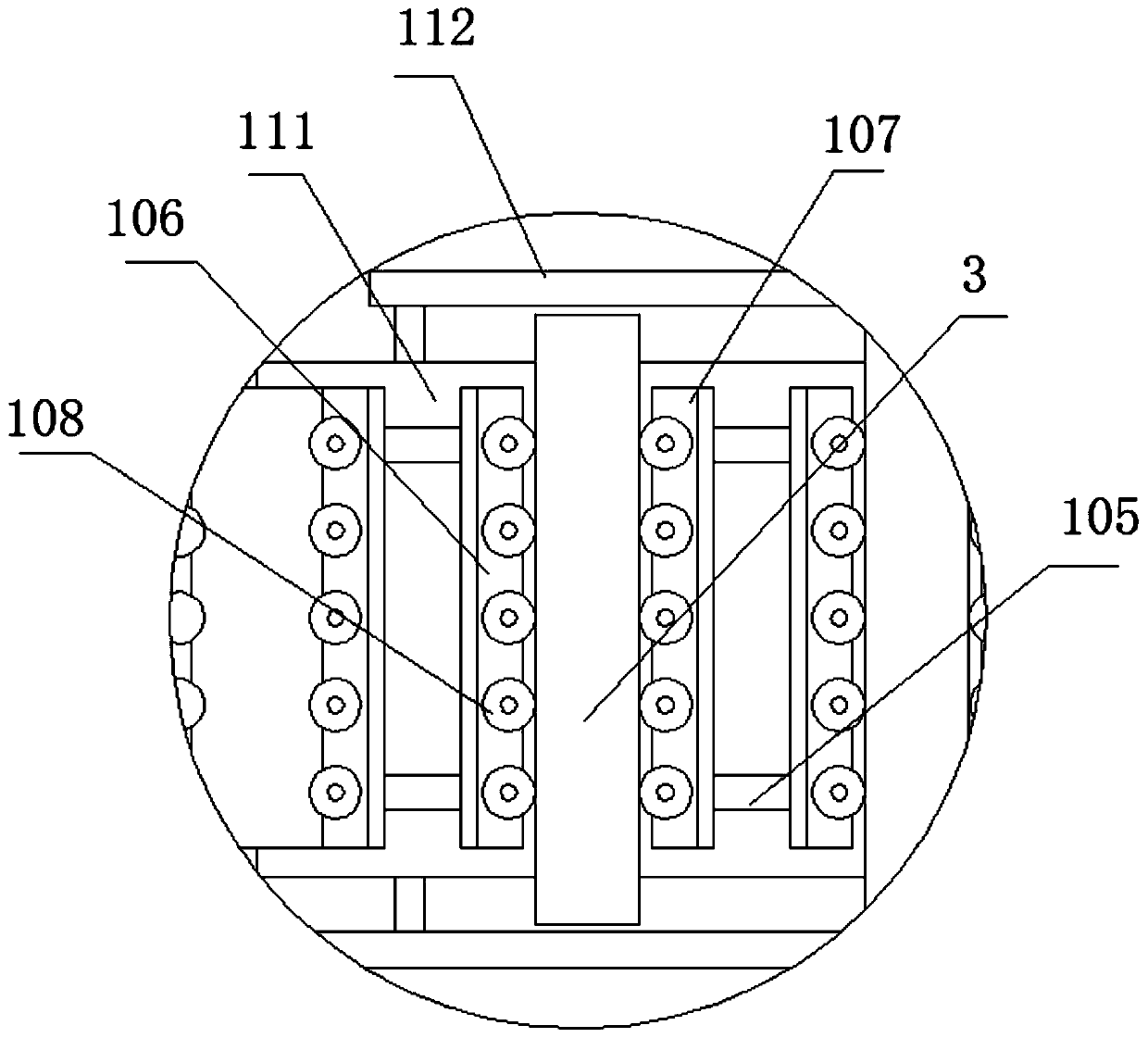

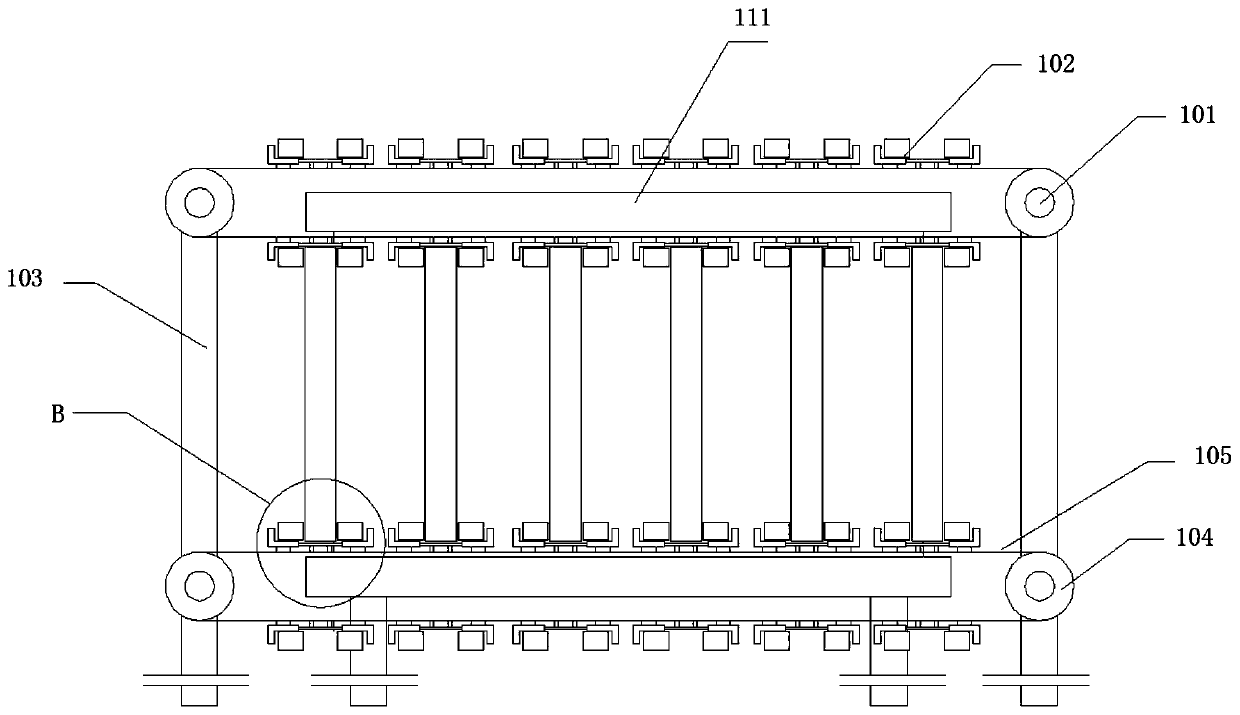

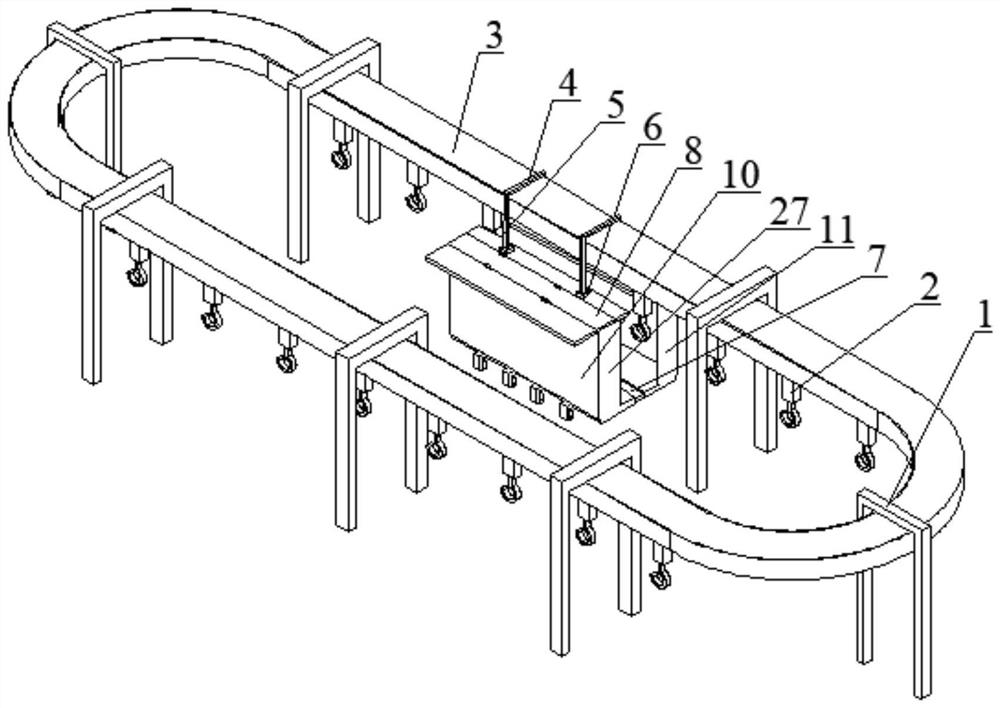

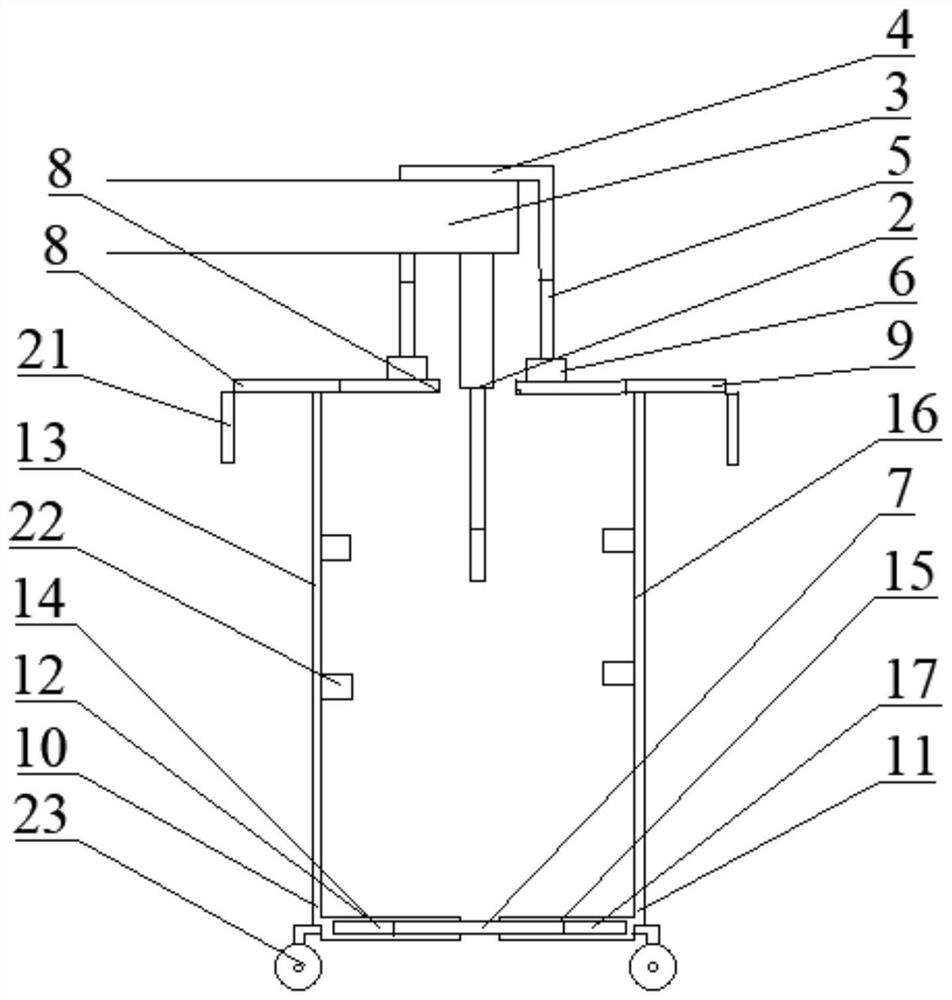

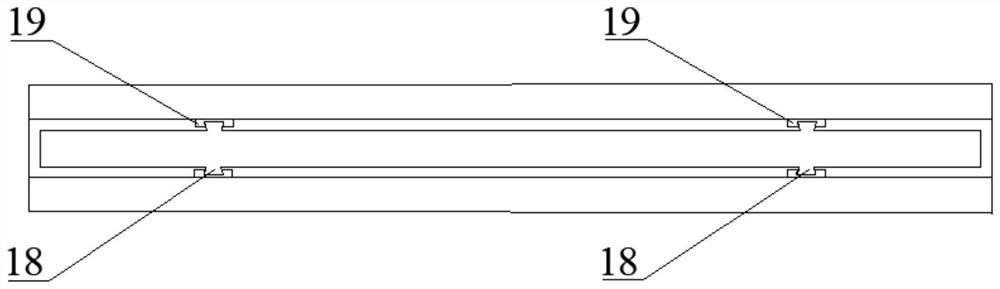

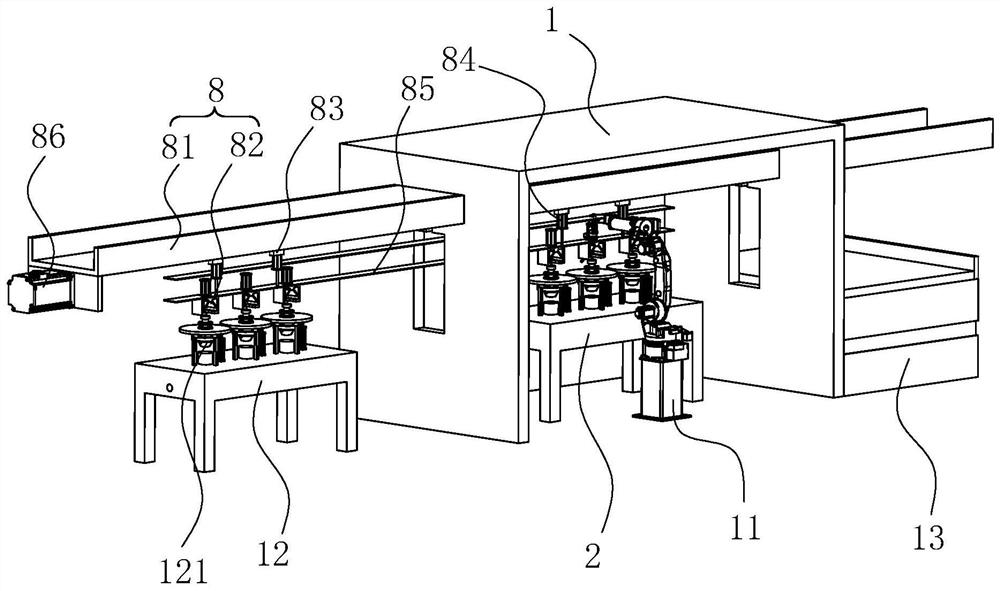

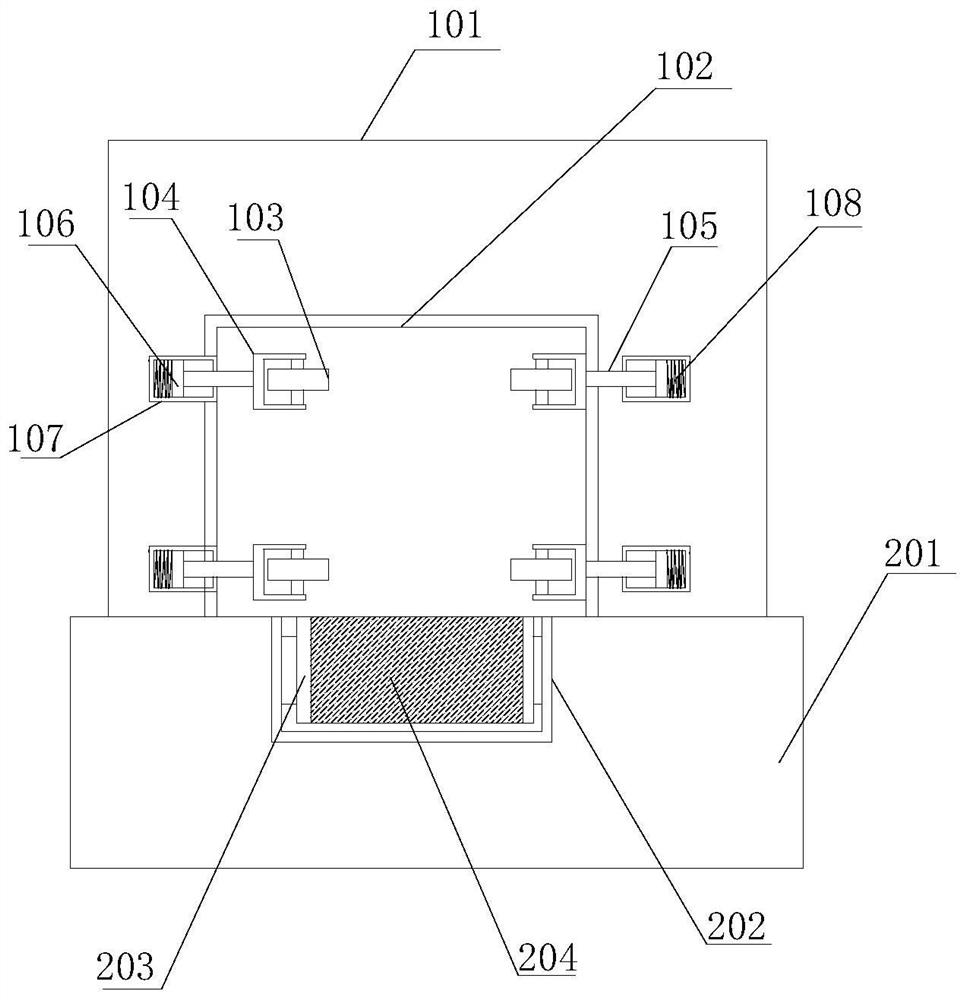

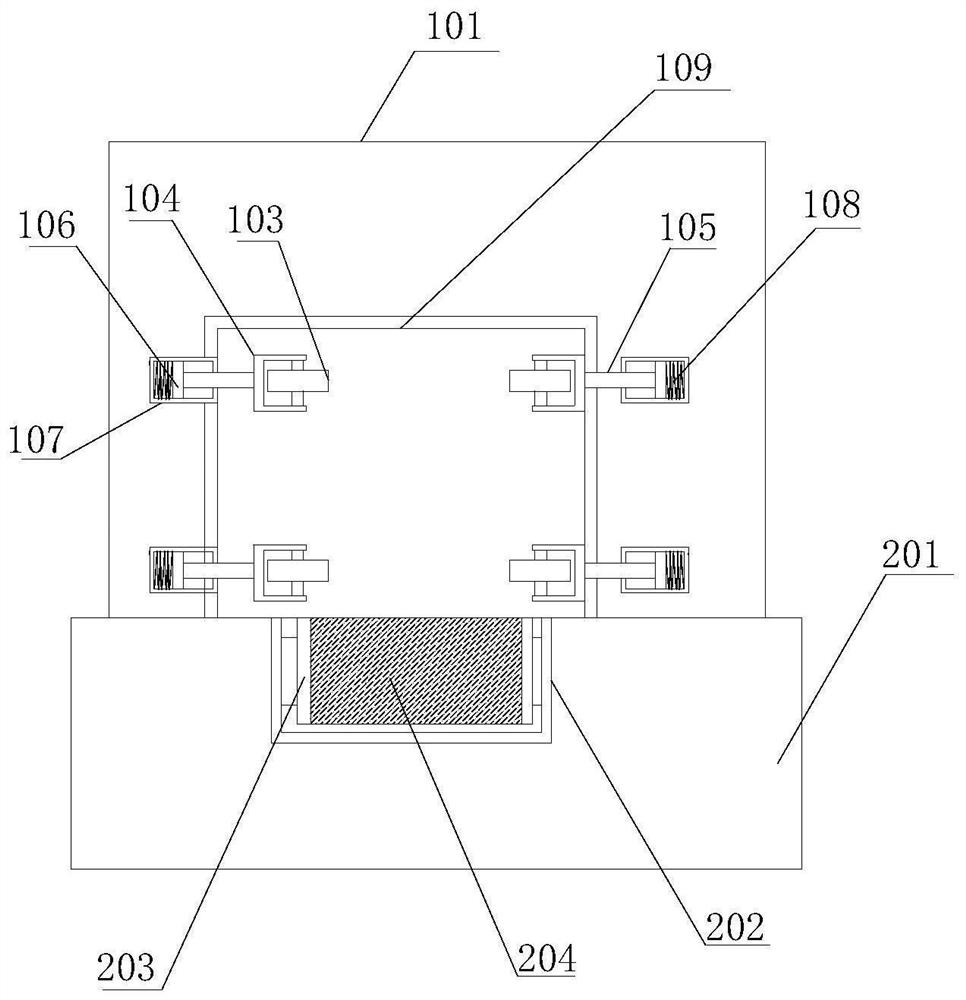

Automatic paint spraying production line with movable processing chamber

The invention discloses an automatic paint spraying production line with a movable processing chamber. The automatic paint spraying production line comprises a supporting frame, the processing chamber, a fixing structure, lifting hooks connected to the lower portion of a circulating track, the circulating track connected with the supporting frame and two sets of paint spraying pieces moving up and down, wherein the processing chamber is located below the circulating track and comprises a center bottom plate, a left top plate, a right top plate, a left bottom assembly and a right bottom assembly, the left top plate and the right top plate are bounded by the circulating track, the sections of the left bottom assembly and the right bottom assembly are L-shaped, and a left transverse part of the left bottom assembly and a right transverse part of the right bottom assembly are slidably connected with the two ends of the center bottom plate; and the end, away from the left transverse part, of a left vertical part of the left bottom assembly is slidably connected to the bottom of the left top plate, and the end, away from the right transverse part, of a right vertical part of the right bottom assembly is slidably connected to the bottom of the right top plate. According to the automatic paint spraying production line, the size of the processing chamber can be controlled, so that flexible adjustment of the size of the processing chamber is achieved, the paint spraying effect is guaranteed, and the paint spraying amount is reduced.

Owner:泉州芸台科技有限公司

Quick paint spraying device with anti-splashing mechanism for fabricated building

InactiveCN112756157ARealize all-round mixing treatmentGuaranteed liquidityMovable spraying apparatusConstruction engineeringStructural engineering

The invention discloses a quick paint spraying device with an anti-splashing mechanism for a fabricated building, and belongs to the technical field of fabricated buildings. The quick paint spraying device comprises a paint bucket, the anti-splashing mechanism, a paint pump, a lifting frame, a stirring assembly, a positioning assembly and a driving motor; A middle screw rod is installed inside, an electric push rod is started, the electric push rod can push the lifting frame downwards, paint is pressed into the paint pump, and when the lifting frame descends, a mounting threaded sleeve of the stirring assembly in the lifting frame can drive stirring blades to rotate; and the paint in the paint bucket can be effectively stirred in all directions while paint pressing and spraying are carried out, the overall flowability and the using effect of the paint are guaranteed, meanwhile, outer scraping plates with second outer jacking springs are installed at the top and the bottom of the lifting frame, when the lifting frame moves up and down, paint or particles attached to the paint inner wall of the paint bucket can be rapidly scraped off, accumulation of the particles is avoided, and it is guaranteed that solid particles in the paint can be effectively stirred and dissolved.

Owner:温州艾米华农业科技有限公司

Surface spraying device and method for automobile brake discs

ActiveCN113019758AExtended service lifeGuaranteed stabilityLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention relates to a surface spraying device and method for automobile brake discs. The surface spraying device comprises a spraying chamber, wherein a spraying robot is arranged in the spraying chamber, supporting tables used for placing the brake discs are arranged above the spraying chamber, a conveying mechanism used for conveying the supporting tables is arranged at the top end of the spraying chamber, and a spraying table is arranged in the spraying chamber; a plurality of rotating rods distributed along a straight line are rotationally connected to the spraying table, a circular-truncated-cone-shaped containing groove is formed in the upper surface of each rotating rod, rotating rings located above the rotating rods are fixedly connected to the spraying table, a sliding block is slidably connected to the inner wall of each rotating ring and slides in the circumferential direction of the corresponding rotating ring, and a buffering table slidably connected with the corresponding sliding block is arranged in each rotating ring; and the bottom end of each buffering table is fixedly connected with a containing block matched with the corresponding containing groove, and the side, away from the spraying table, of each sliding block is fixedly connected with a spring. The surface spraying device and method have the advantages that abrasion between the rotating rods and the supporting tables is reduced, and meanwhile, shutdown is not needed, and the service life of a motor is guaranteed.

Owner:烟台乐泰汽车配件有限公司

Piano cover painting device

InactiveCN112317186AAvoid bruisesExtended service lifeCleaning using toolsSpray boothsRubber materialPiano

The invention relates to the technical field of piano component processing equipment, and discloses a piano cover painting device. The piano cover painting device comprises a box body assembly, a bottom plate assembly, a traction device and a dust removal device, and the bottom of the box body assembly is fixedly connected with the bottom plate assembly. In the box body assembly, a plate inlet anda plate outlet are formed in the left end and the right end of a box body correspondingly, meanwhile, mounting grooves are formed in the front sides and the rear sides of the plate inlet and the plate outlet, first springs and limiting plates are placed in the mounting grooves, the sides, away from second springs, of the limiting plates are connected with connecting rods, the ends, away from thelimiting plates, of the connecting rods are connected with mounting supports, and meanwhile, guide wheels made of the rubber material are arranged in the middles of the mounting supports, so that whena piano cover plate is put into the box body and discharged out of the box body, the piano cover plate can be buffered while being guided, and the piano cover plate is prevented from being collided and damaged.

Owner:德清浦赛尔钢琴有限公司

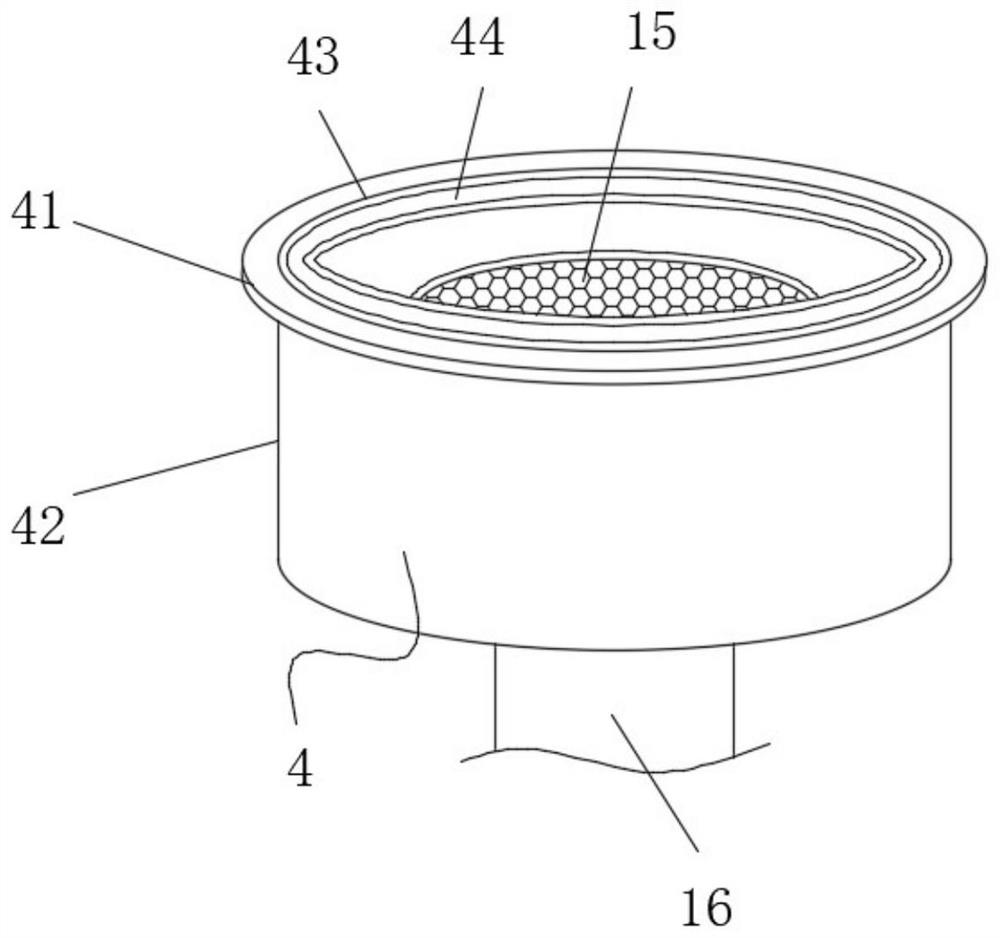

A powder spray recovery device

ActiveCN111085363BImprove recycling efficiencyAvoid cloggingSpraying apparatusProcess engineeringMechanical engineering

The present invention relates to the field of powder spraying, more specifically a powder spraying recovery device, comprising a spraying operation box, a powder recovery flow box, two spraying operators, a spraying fixer, a spraying recovery anti-blocking driver, a filter screen brusher and The powder recovery cylinder, the lower end of the spraying operation box is fixedly connected to the powder recovery flow box, the two spraying operators are respectively slidingly connected to the left and right sides of the upper end of the spraying operation box, and the spraying fixer is rotatably connected to the upper end of the spraying operation box In the center, the spray recovery anti-blocking driver is fixedly connected to the powder recovery flow box; the beneficial effect of the present invention is that the process of spraying paint can be adjusted during the process of powder spraying, and the spraying effect can be guaranteed while preventing powder leakage, and the operation is convenient ;After the multi-layer filter screen isolates the fraction, the airflow flows out and the powder is recovered; in the process of powder recovery, the powder recovery efficiency is high, and at the same time, it prevents powder blockage during the flow recovery process.

Owner:深圳市华信一机械有限公司

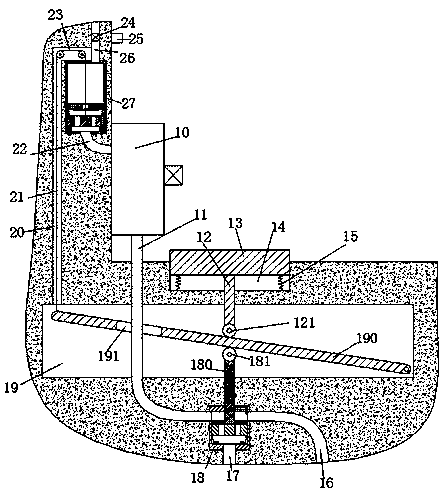

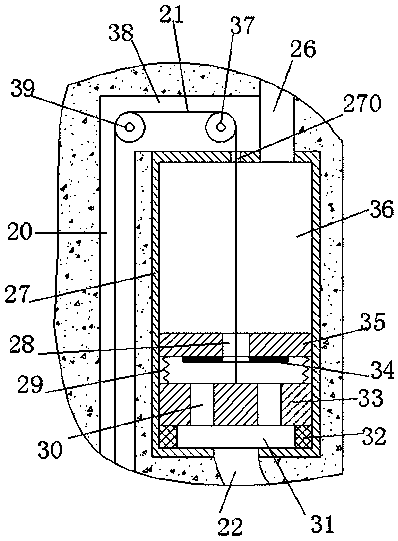

Intelligent whitewashing device

The invention relates to an intelligent whitewashing device. The intelligent whitewashing device comprises two linkage large suction cups, two retractable guiding rails, four medium suction cups, a whitewashing chamber, a medium lead storage battery pack, a single chip microcomputer and a guided system, wherein the single chip microcomputer and the guided system are arranged in a driverscope. The front end of each retractable guiding rail is provided with the corresponding linkage large suction cup, and the two sides of the rear portion of each retractable guiding rail is provided with retractable guiding rail gears; the retractable guiding rail gears are engaged with fixed gears which are engaged with motors; a base plate is arranged in the center of each retractable guiding rail and is provided with an advancing suction cup air guide tube, and the advancing suction cup air guide tubes are connected with the linkage large suction cups and a first air pump; the four medium suction cups are fixed to a framework, and four air guide tubes are arranged on the framework and are connected with the medium suction cups and a second air pump; supplying tubes are arranged on the upper portion of the whitewashing chamber, and the whitewashing chamber is internally provided with the forward motor, a roller brush, the backward motor and the medium lead storage battery pack; and the multiple supplying tubes are connected with a slurry inlet pipeline which is connected with a slurry conveying pump, and the slurry conveying pump is connected with a water head adjuster connected with the guided system. The intelligent whitewashing device is good in safety and high in efficiency.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Multifunctional paint spraying device

InactiveCN109718981AGuaranteed paint effectDry fastPretreated surfacesCoatingsSupport planeMultiple function

The invention provides a multifunctional paint spraying device. The multifunctional paint spraying device comprises a support table, a support frame, a paint spraying box, a drying box and a conveyorbelt; the support table is provided with the paint spraying box and the drying box from left to right in sequence, and movable doors are arranged on the left and right sides of the paint spraying boxand the drying box; a paint spraying tube is arranged in the paint spraying box; an exhaust fan is arranged on the side wall of the drying box, and 2-4 heating lamps are arranged on the inner wall ofthe drying box; and the conveyor belt is arranged on the support table, the conveyor belt penetrates through the paint spraying box and the drying box from left to right in turn, the conveyor belt isprovided with the support frame, the support frame is provided with a first cylinder and a second cylinder which expand and contract in the horizontal direction, the first cylinder and the second cylinder are separately connected with a first clamping plate and a second clamping plate through telescopic rods, and the first clamping plate and the second clamping plate are used in a matched mode. According to the multifunctional paint spraying device, the two surfaces of a plate can be simultaneously painted, the painting effect is good, and a drying function is achieved.

Owner:新昌县永益包装有限公司

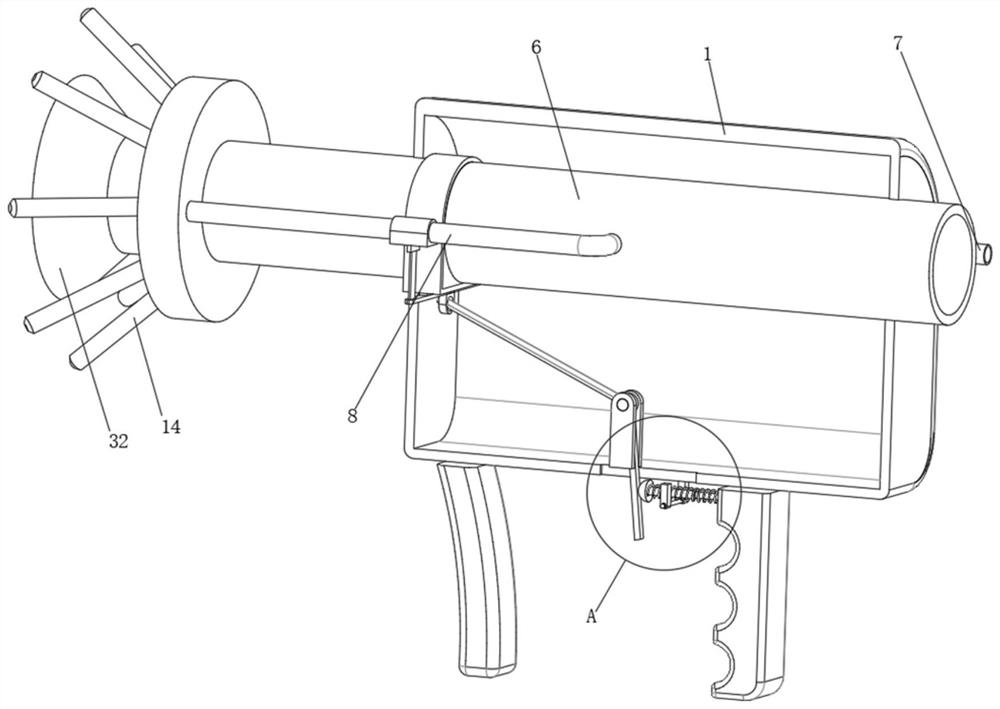

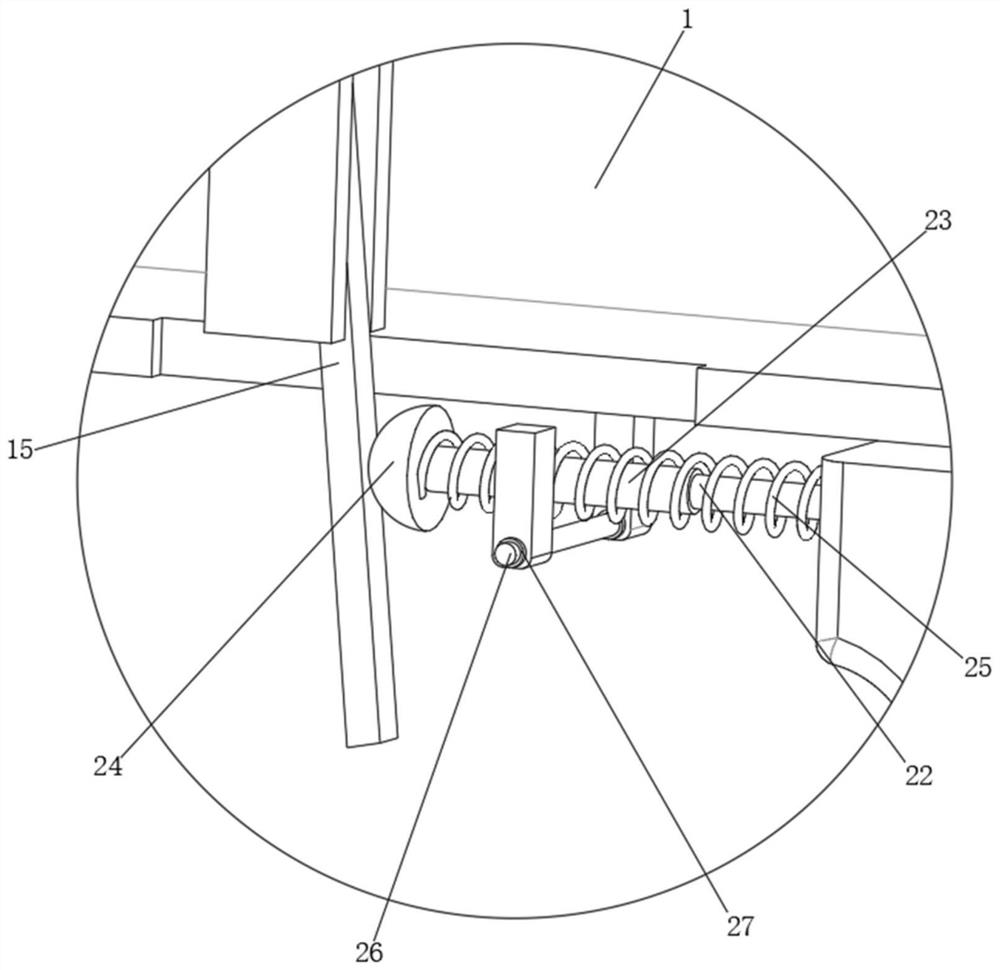

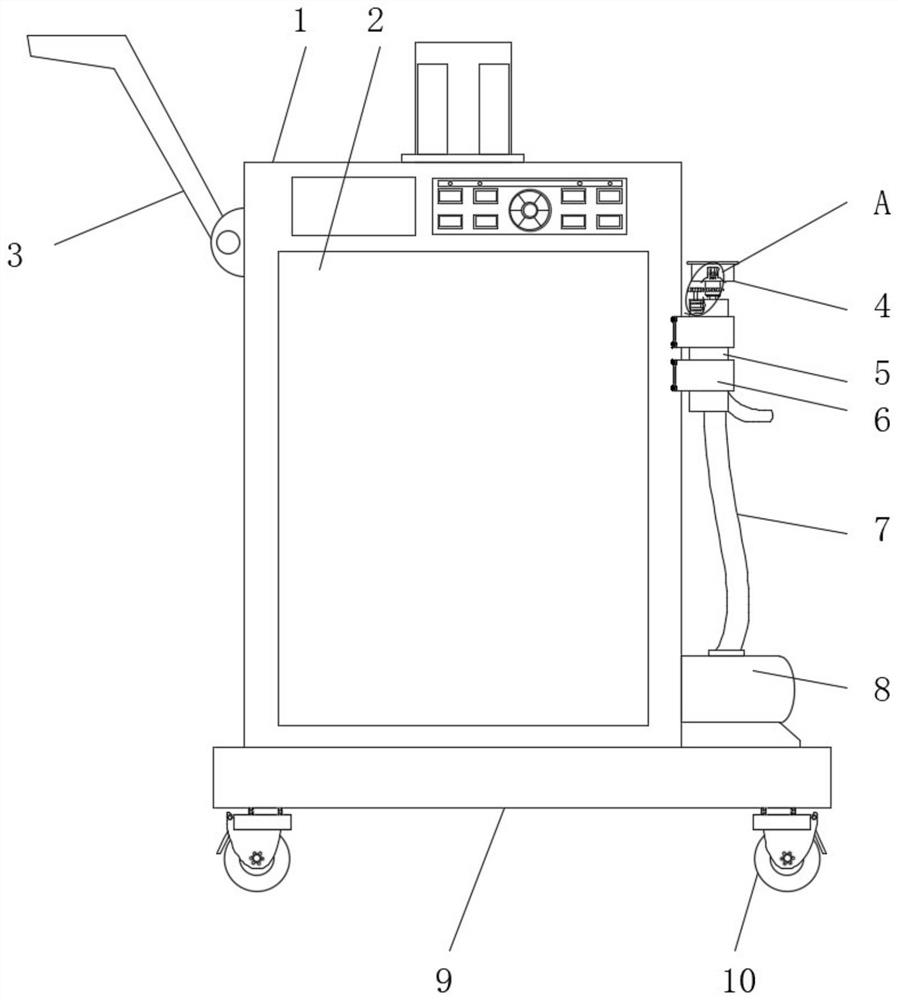

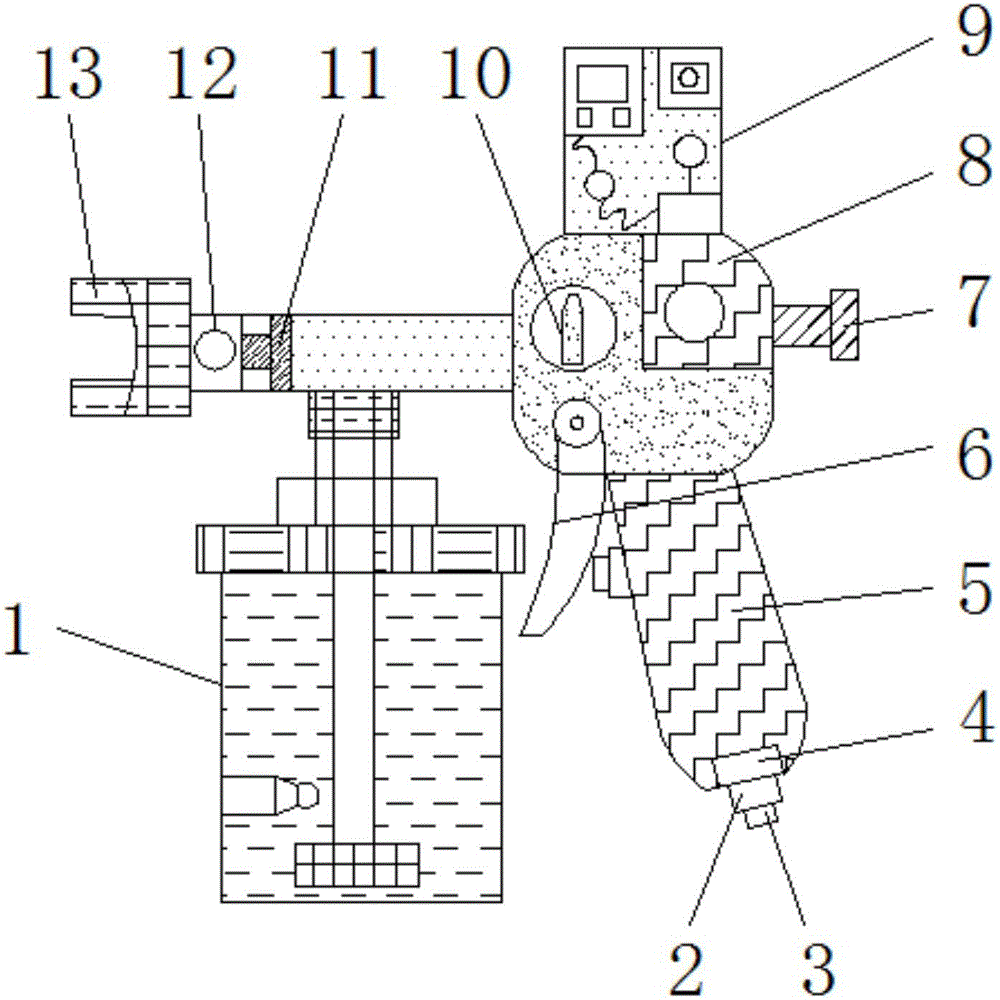

Intelligent paint spraying gun

InactiveCN106140516AIntelligent workGuaranteed paint effectLiquid spraying apparatusLacquerAir filter

The invention discloses an intelligent paint spraying gun. The intelligent paint spraying gun comprises a paint loading barrel, a gun body and a control panel; a paint straw is mounted in the paint loading barrel; a remainder inductor is mounted on one side of the paint straw; an intelligent paint flow adjuster is mounted above the paint loading barrel; an air filter is mounted at the lower end of the gun body; an intelligent air pressure adjuster is mounted at the lower end of the air filter; a spraying amplitude adjusting knob is mounted above a trigger; an intelligent control system is mounted on one side of the spraying amplitude adjusting knob; a paint flow adjusting knob is mounted at one end of the intelligent control system; the control panel is mounted at the upper end of the intelligent control system; a control display screen is mounted in the control panel; a wind cap is mounted on the left upper side of the paint loading barrel; an intelligent fog-shaped adjuster is mounted on one side of the wind cap; and a nozzle is mounted on one side of the intelligent fog-shaped adjuster. The intelligent paint spraying gun has the characteristics of stable work and intelligent control, and greatly improves the working efficiency.

Owner:成都元始信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com