Automatic paint spraying production line with movable processing chamber

A technology of activity treatment and treatment room, which is applied in the direction of spraying booths and spraying devices, which can solve the problems of large workload, poor painting effect, waste of paint mist, etc., and achieve the effect of flexible adjustment, reducing the amount of spraying paint, and ensuring the effect of spraying paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

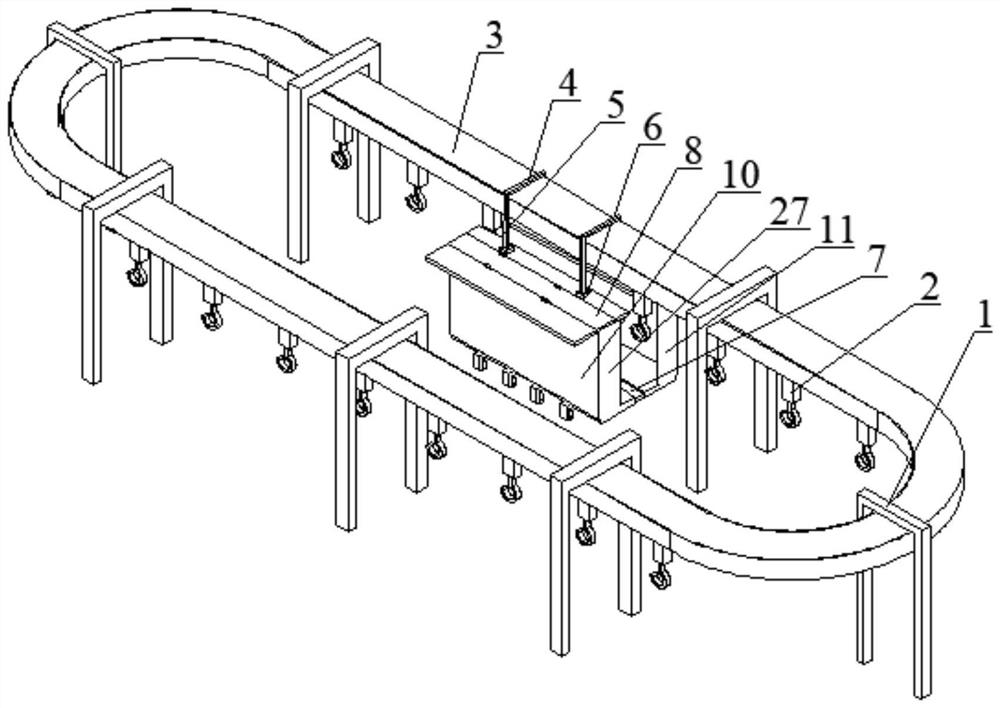

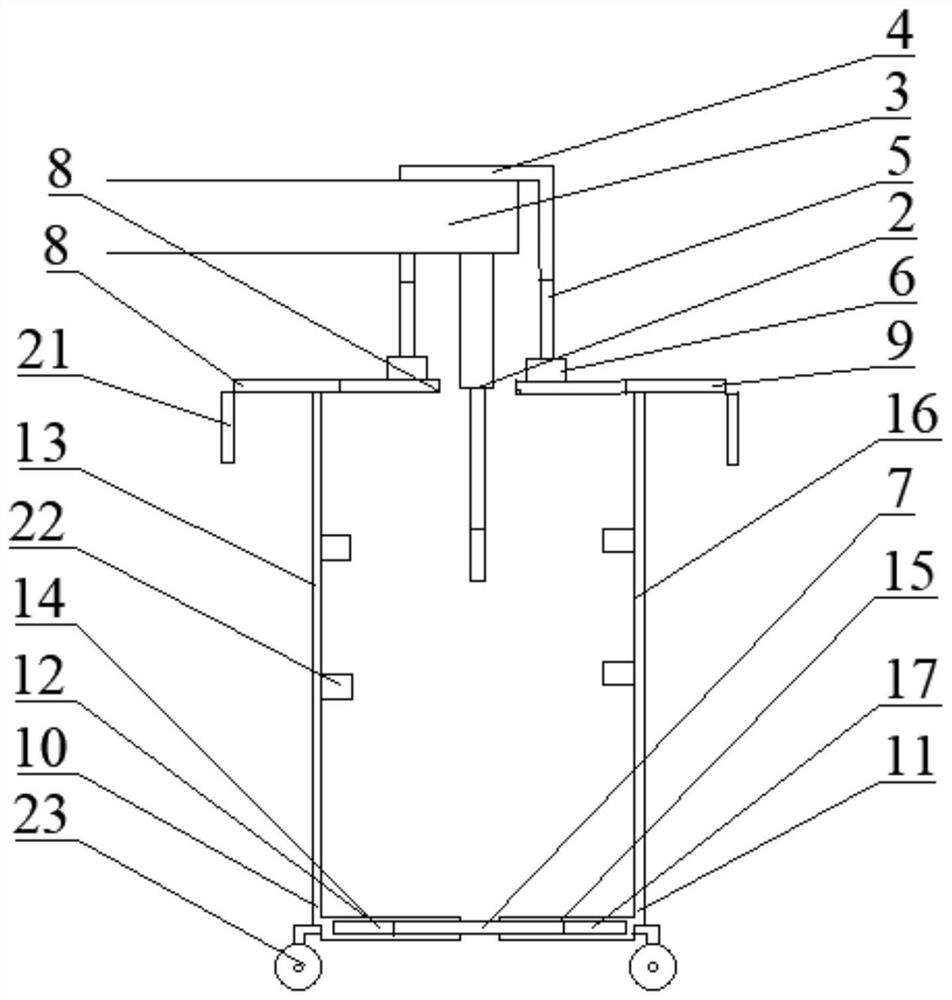

[0055] Please refer to Figure 1 to Figure 3 , Embodiment 1 of the present invention is:

[0056] An automatic painting production line with a movable processing chamber, including a support frame 1, a processing chamber, a fixed structure, a hook 2 connected under the circular track 3, a circular track 3 connected to the support frame 1, and two groups of moving painting parts up and down twenty two.

[0057] Such as figure 1 and figure 2 As shown, the fixed structure includes two fixed frames 4 erected above the circulating track 3, telescopic rods 5 connected below both ends of the fixed frame 4, and a fixed cover 6 arranged at the other end of the telescopic rod 5 connected to the fixed frame 4 The processing chamber is located below the circulation track 3, and the treatment chamber includes a central bottom plate 7, a left top plate 8 and a right top plate 9 bounded by the circulation track 3, and a left bottom assembly 10 and a right bottom assembly 11 whose cross s...

Embodiment 2

[0068] Please refer to Figure 4 to Figure 6 , the second embodiment of the present invention is:

[0069] An automatic painting production line with a movable processing chamber, including a support frame 1, a processing chamber, a fixed structure, a hook 2 connected under the circular track 3, a circular track 3 connected to the support frame 1, and two groups of moving painting parts up and down twenty two;

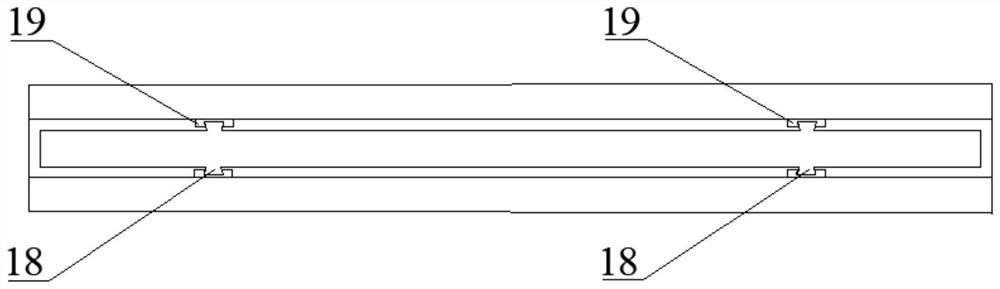

[0070] Such as Figure 5 and Figure 6 As shown, the difference from Embodiment 1 is that the cooperation of the left transverse part 12, the right transverse part 15 and the center bottom plate 7 is:

[0071]The end of the left horizontal part 12 far away from the left vertical part 13 is provided with a left receiving groove 14, and the end of the right horizontal part 15 far away from the right vertical part 16 is provided with a right receiving groove 17, and the central bottom plate 7 is close to both sides of the entrance and exit of the processing chamber. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com