Steel structure painting process

A technology of steel structure and craftsmanship, applied in spray booths, manufacturing tools, grinding workpiece supports, etc., can solve the problems of damage to the health of operators, low work efficiency, long painting time, etc., and achieve fast and uniform work efficiency. High speed and speed up the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A steel structure painting process, using a steel structure painting device, comprising the following steps:

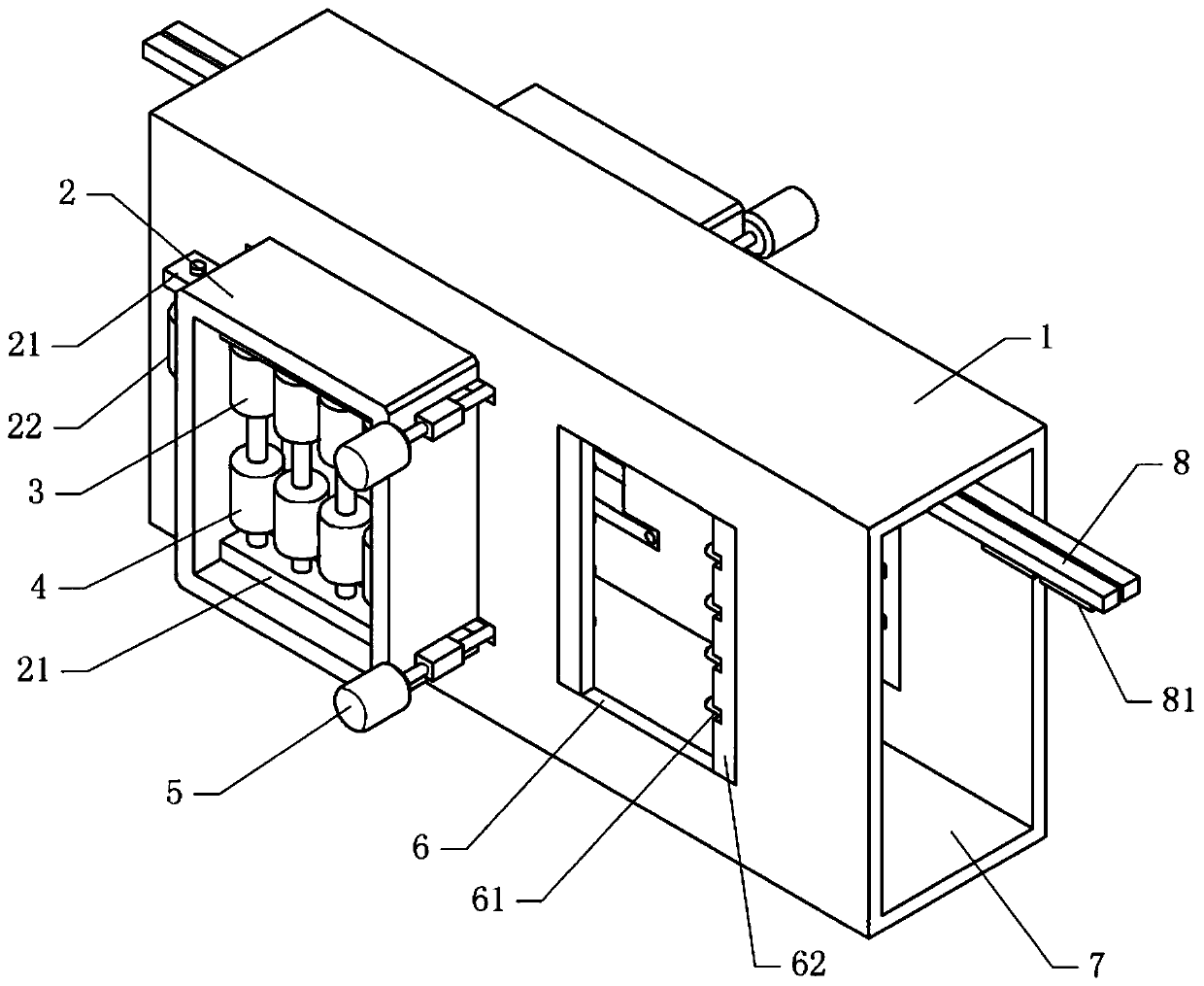

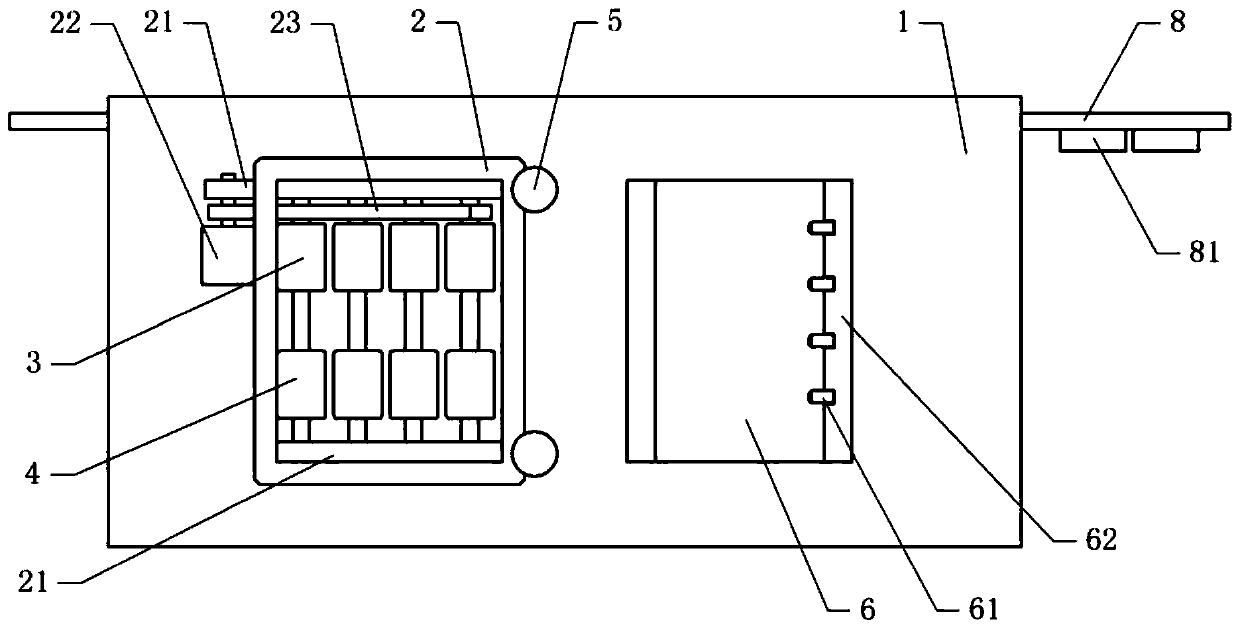

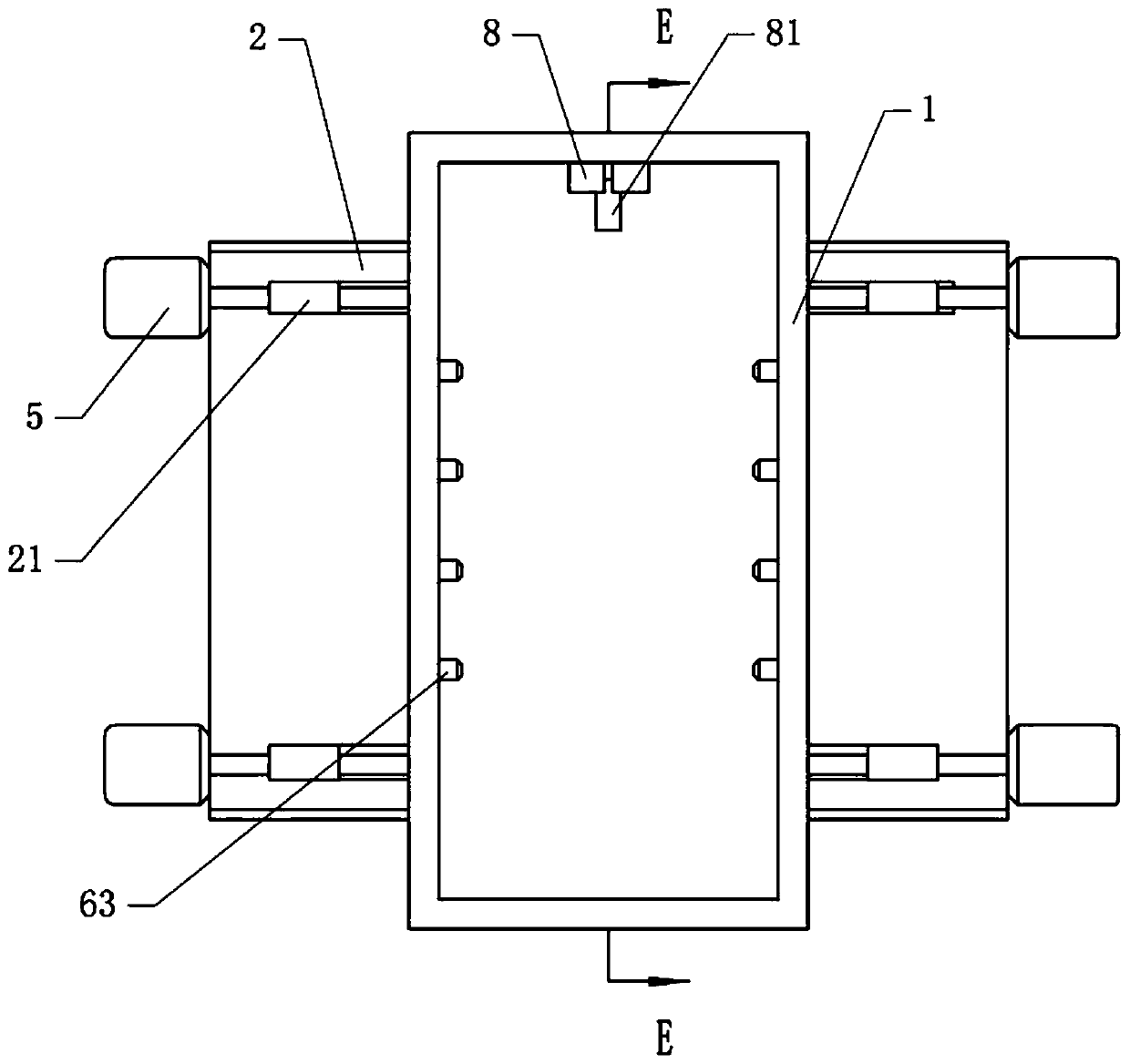

[0040] S1: Basic as attached figure 1 As shown, the steel structure painting device includes a paint box 1 with a rectangular longitudinal section. The two ends of the paint box 1 are respectively provided with a material inlet and a material outlet 7, and a slide rail 8 is installed on the upper part of the paint box 1. , In this embodiment, the paint box 1 is placed in the workshop, and the two ends of the slide rail 8 are fixed on the wall of the workshop by fastening bolts. There are some clamps 81 that are horizontally slidably connected on the slide rail 8, as attached Figure 5 As shown, the clamp 81 includes a support shaft 812, and the two sides of the support shaft 812 are welded with support columns, and the bolts on the support columns are fixed with bearings coaxial with the support shaft 812. In this embodiment, the bearings are ball bearings 811...

Embodiment 2

[0049] The difference between embodiment two and embodiment one is that, as attached Figure 6 , attached Figure 7 And attached Figure 8 As shown, in S3, a pump assembly is fixed on the top wall of the casing 2 by bolts, and the pump assembly in this embodiment is the air pump 24 . The air inlet of the suction pump 24 is communicated with a main pipe 25, and the main pipe 25 is communicated with a plurality of rotating joints 26 fixed on the shell 2 by bolts. as attached Figure 7 And attached Figure 8 As shown, there is an air passage 31 in the upper roller 3, the air passage 31 communicates with the rotary joint 26, a cavity 33 is opened in the connecting shaft 32, the cavity 33 communicates with the air passage 31, and an air hole 34 is opened on the connecting shaft 32. The air holes 34 are directed towards the upper part of the painting box 1 .

[0050] When the steel structure is polished, some particles will remain on the surface of the steel structure, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com