Novel painting die for enameled wire

An enameled wire, a new type of technology, applied in the direction of insulating conductors/cables, etc., can solve the problem of low reuse rate, achieve the effect of convenient disassembly and assembly, ensure resistance, and ensure the quality of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

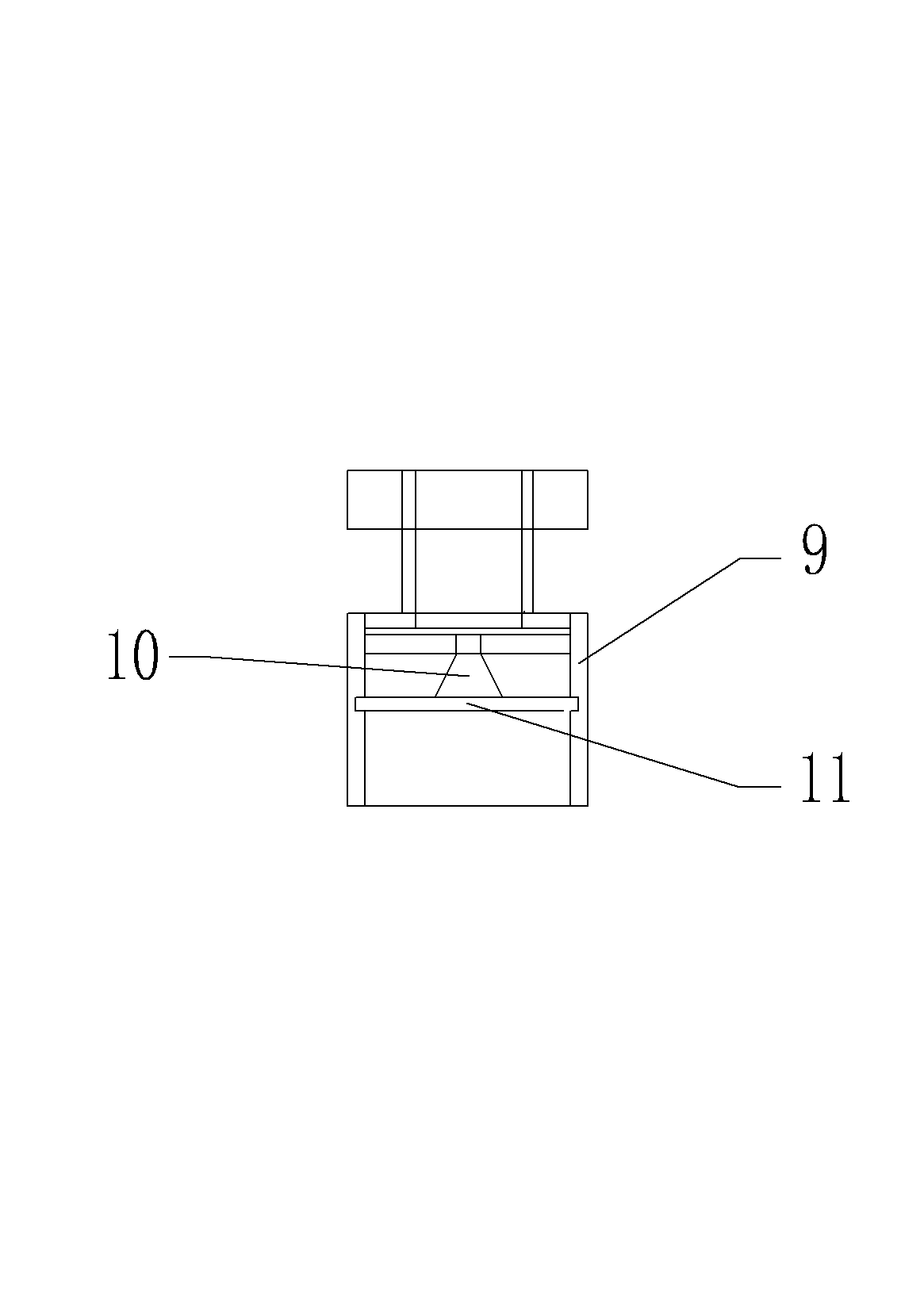

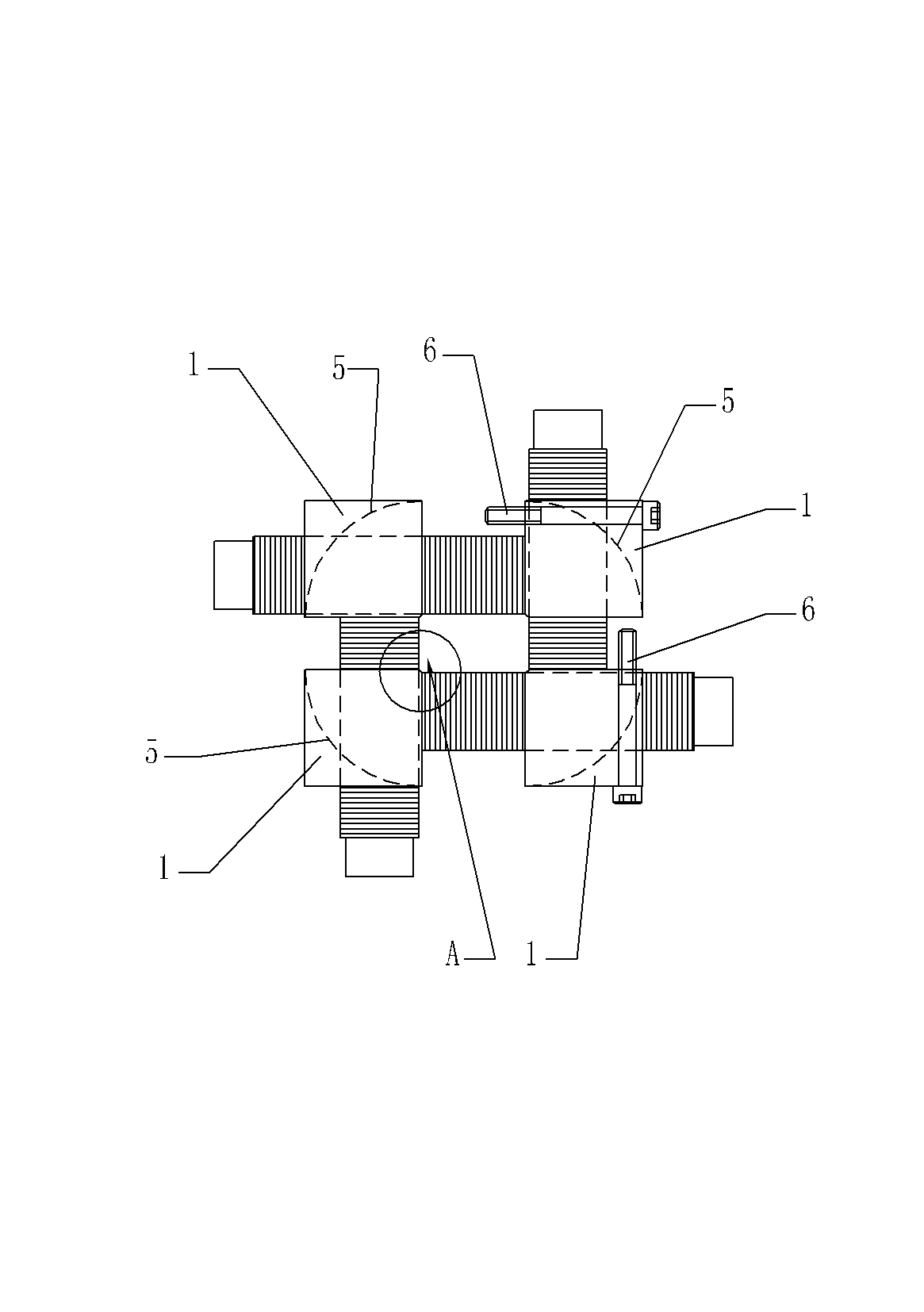

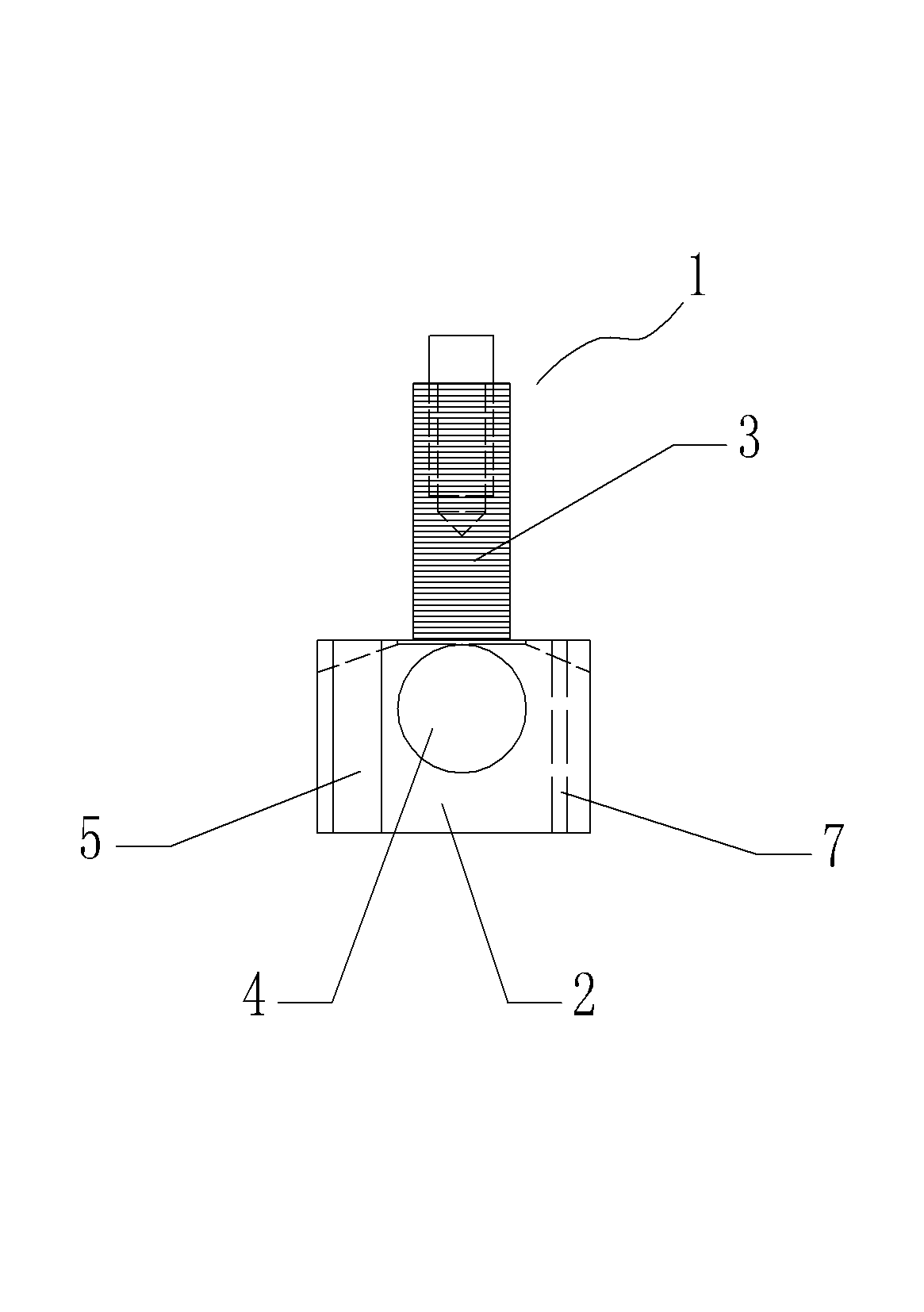

[0019] See figure 2 , image 3 , Figure 4 and Figure 5 , the present invention comprises four mold strips 1 with the same structure, the four mold strips 1 are vertically connected in pairs, and the four mold strips are connected vertically by springs ( figure 2 , spring not shown) fixed. The mold bar 1 includes a connector 2 and a stud 3, the stud 3 is vertically fixed on the bottom surface of the connector 2, the connector 2 is located below the stud 3 and has a threaded through hole 4 perpendicular to the stud 3, and the external thread of the stud 3 It matches the internal thread of the threaded through hole 4; when four mold bars 1 are connected and installed, the stud 3 of one of the mold bars is vertically threaded with the threaded through hole 4 on the connector 2 of the other mold bar. ; The connecting head 2 of the mold bar 1 is provided with a draw-in groove 5 on the two connecting sides of the outer circumference; after the four mold bars 1 are installed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com