Production process of class 200 copper-clad aluminum electromagnetic wire

A production process, copper-clad aluminum technology, applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve problems such as relatively high temperature requirements, failure to meet characteristic requirements, separation of copper and aluminum, etc., to improve quality and improve Product performance, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

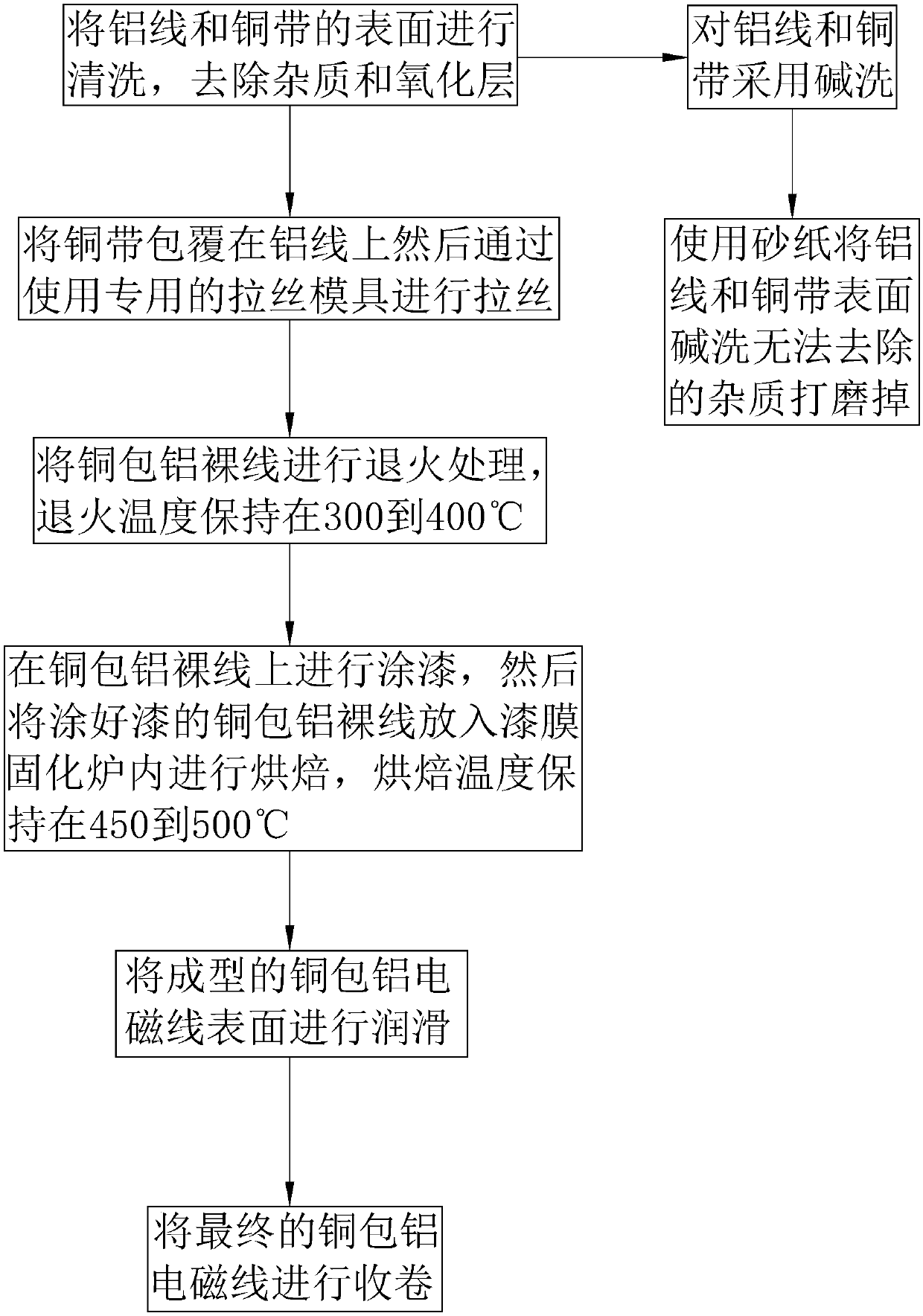

[0053] Embodiment one: a kind of production technology of 200 grade copper-clad aluminum magnet wires, such as figure 1 As shown, the prepared aluminum wire and copper strip are firstly washed with alkali to wash off most of the impurities and oxide film on the surface of the aluminum wire and copper strip. , the remaining impurities that are difficult to remove should be sanded off with sandpaper to ensure that there are no impurities on the surface of the copper strip and aluminum wire.

[0054] Such as figure 1 As shown, the copper strip is wrapped on the aluminum wire, and a special wire drawing die is used for wire drawing to obtain a preliminary formed copper-clad aluminum bare wire. The wire drawing die can use the copper-clad aluminum wire drawing machine produced by Mitutoyo Electromechanical Development Co., Ltd.

[0055] Such as figure 1 As shown, the copper-clad aluminum wire with a diameter of 2.05mm was annealed, and the annealing time was 25min, and the annea...

Embodiment 2

[0067] Embodiment 2: The difference from Embodiment 1 lies in that the annealing temperature is 350° C. and the annealing time is 25 min, 30 min and 35 min respectively during the annealing process.

[0068] Embodiment two prepares the performance test data of copper-clad aluminum bare wire, as shown in table 3:

[0069] table 3

[0070]

[0071] According to Table 3, the best annealing time for copper-clad aluminum bare wire with a diameter of 2.05mm is 30min.

Embodiment 3

[0072] Example 3: The difference from Example 1 is that a copper-clad aluminum bare wire with a diameter of 1.06mm is selected, the annealing time is 60min, and the annealing temperatures are 250°C, 300°C, 310°C, 400°C and 450°C respectively Test separately.

[0073] Embodiment three prepares the performance test data of copper-clad aluminum bare wire, as shown in table 4:

[0074] Table 4

[0075]

[0076] According to Table 3, the optimal temperature for annealing copper-clad aluminum bare wire with a diameter of 1.06mm is 310°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com