Surface spraying device and method for automobile brake discs

A surface spraying and automobile braking technology, which is applied in the field of brake disc processing, can solve the problems of reducing the service life and achieve the effect of guaranteeing the effect, uniform painting and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-4 The application is described in further detail.

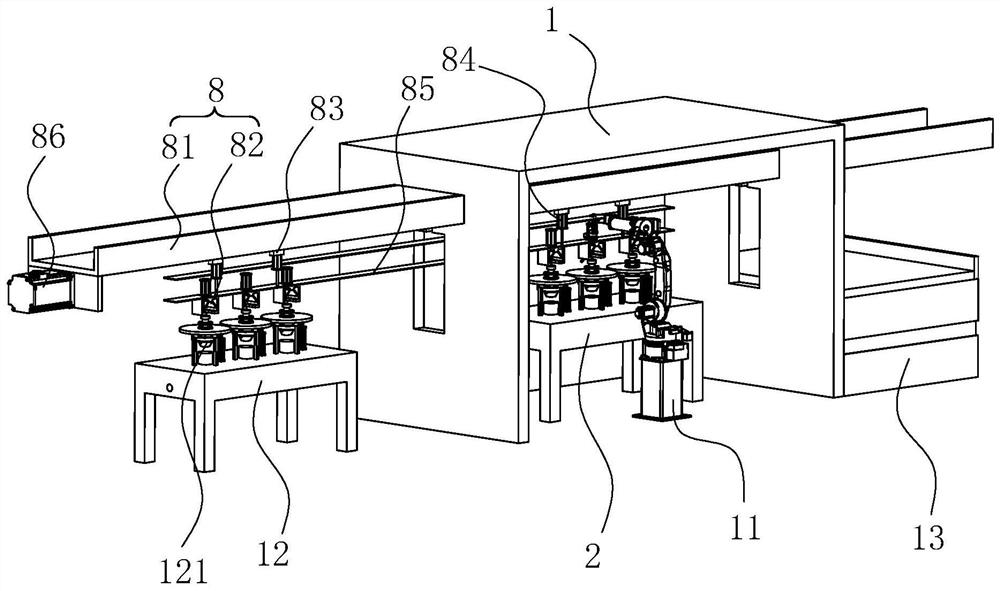

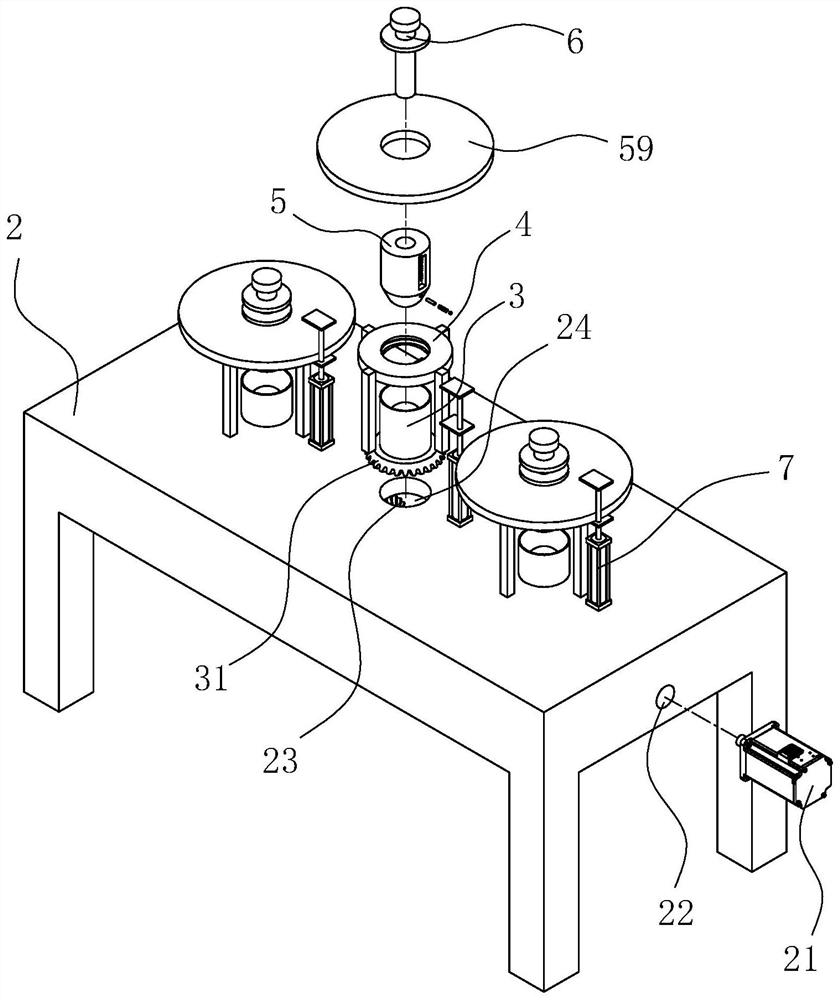

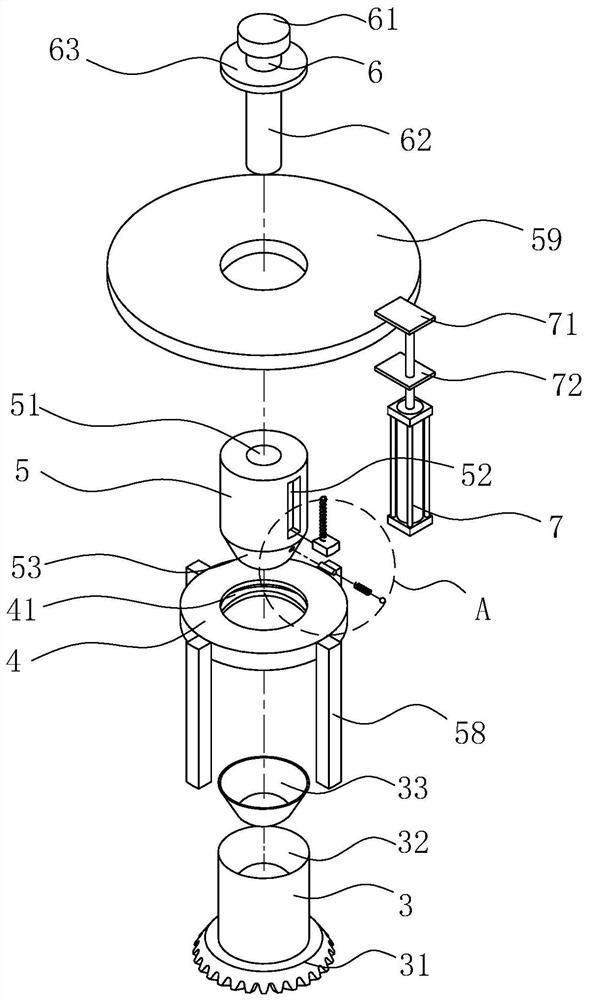

[0036] The embodiment of the present application discloses a surface spraying device for an automobile brake disc. refer to figure 1 , the surface spraying device of the automobile brake disc comprises a spray booth 1, a front placing platform 12 and a rear placing platform 13. A spray booth 2 , a spray robot 11 and a transport mechanism 8 are fixedly connected in the spray booth 1 . The user places the brake disc on the front placement platform 12, and then the transport mechanism 8 transports the brake disc to the spray booth 1, and then places it on the spray booth 2. At this time, the spray robot 11 works to spray paint the brake disc. , the transport mechanism 8 transports the brake disc to the rear placement platform 13 .

[0037] refer to figure 1, the transportation mechanism 8 includes a transportation frame 81 and a gripper 82, the transportation frame 81 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com