A powder spray recovery device

A recovery device, powder technology, applied in the direction of the injection device, etc., can solve the problems of blockage, low recovery efficiency, etc., to achieve the effect of preventing blockage, high recovery efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

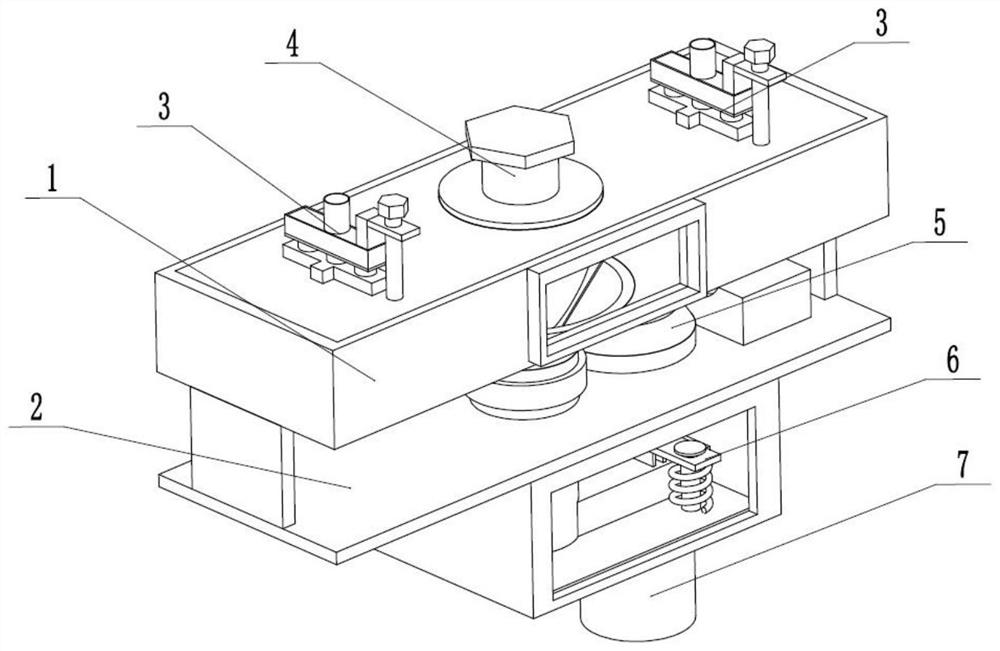

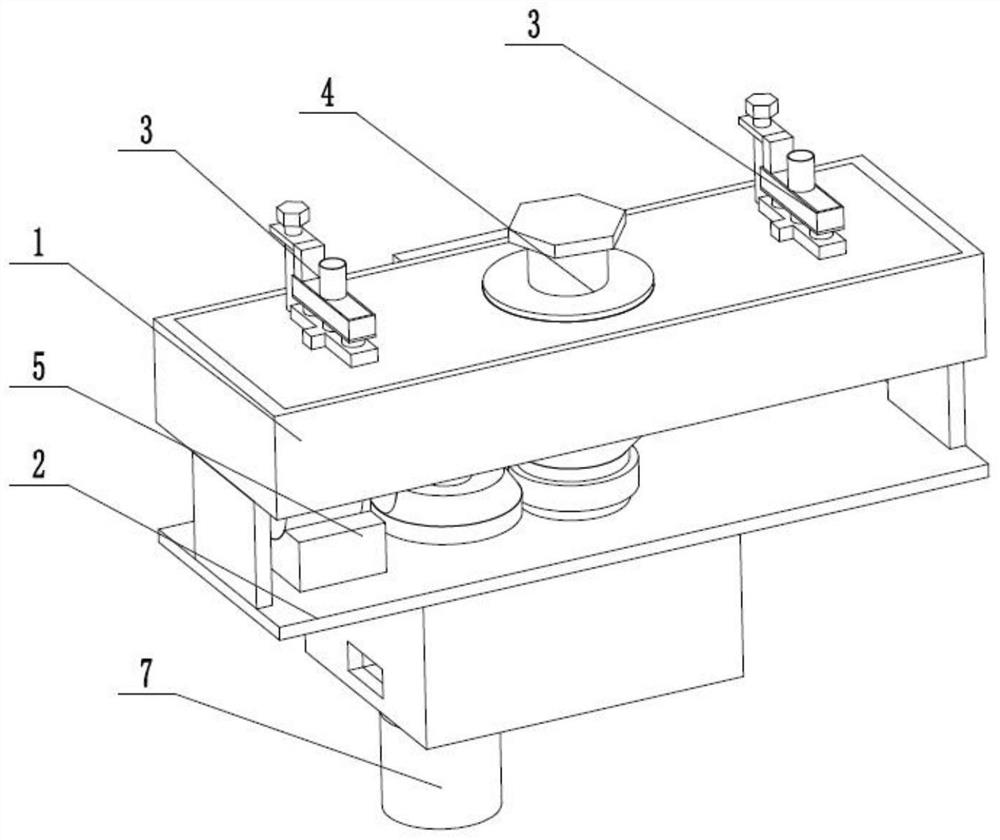

[0031] Such as Figure 1 to Figure 11 As shown, a powder spraying recovery device includes a spraying operation box 1, a powder recovery flow box 2, two spraying operators 3, a spraying fixer 4, a spraying recovery anti-blocking driver 5, a filter brush 6 and a powder recovery cylinder 7. The lower end of the spraying operation box 1 is fixedly connected to the powder recovery flow box 2, and the two spraying operators 3 are respectively slidingly connected to the left and right sides of the upper end of the spraying operation box 1, and the spraying holder 4 is rotatably connected to the spraying operation In the center of the upper end of the box 1, the spraying recycling anti-clogging drive 5 is fixedly connected to the powder recycling flow box 2, the spraying recycling anti-clogging driver 5 is rotatably connected in the spraying operation box 1 and the powder recycling flow box 2, and the lower end of the filter screen brush 6 It is fixedly connected in the powder recove...

specific Embodiment approach 2

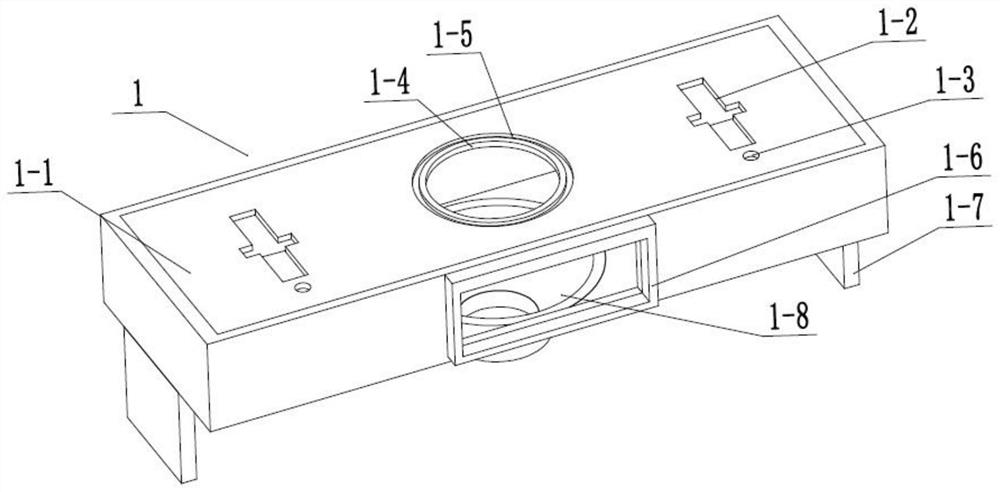

[0033] Such as Figure 1 to Figure 11 As shown, this embodiment will further explain Embodiment 1. The spraying operation box 1 includes an upper operation box 1-1, two limiting cross sliding grooves 1-2, two upper rotating round holes 1-3, a center Add round hole 1-4, plane bearing rotation groove 1-5, upper observation frame 1-6, two connecting plates 1-7 and conical recovery and receiving bobbin 1-8, and both sides of the upper end of upper operation box 1-1 Two limiting cross sliding grooves 1-2 that penetrate up and down are respectively provided with, and the rear sides of the two limiting cross sliding grooves 1-2 are provided with upper rotating round holes 1-3 on the upper operation box 1-1, and the center Add round hole 1-4 to be arranged on the center of the upper end of the upper operation box 1-1, and the outer side of the upper operation box 1-1 is provided with a plane bearing rotation groove 1-5 on the upper operation box 1-1, and an upper observation frame 1-6...

specific Embodiment approach 3

[0035] Such as Figure 1 to Figure 11 As shown, this embodiment will further explain Embodiment 2. The powder recovery flow box 2 includes a lower fixing plate 2-1, a lower recovery flow pipe 2-2, a lower rotating hole 2-3, and a lower observation frame 2 -4. Observation slot 2-5, air discharge rectangular tube 2-6, three sealing sliding slots 2-7, three filter screen seats 2-8, recovery slot 2-9 and external thread connection tube 2-10, The two connection plates 1-7 are fixedly connected to the lower fixed plate 2-1, the lower observation frame 2-4 is fixedly connected to the lower end of the lower fixed plate 2-1, and the lower recovery flow pipe 2-2 is fixedly connected to the lower fixed plate 2-1 and In the lower observation frame 2-4, the lower rotating hole 2-3 is arranged on the lower fixed plate 2-1, and the rear end of the lower observation frame 2-4 is provided with an observation slot 2-5, and the air flow is discharged from the rectangular tube 2-6. The left end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com