Hanger for paint spraying

A hanger and hanger technology, applied in the field of painting hangers, can solve the problems of inconvenient assembly, shaking of painted parts, huge hanger structure, etc., and achieve the effect of convenient and flexible disassembly and assembly, reducing mutual influence, and ensuring the effect of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

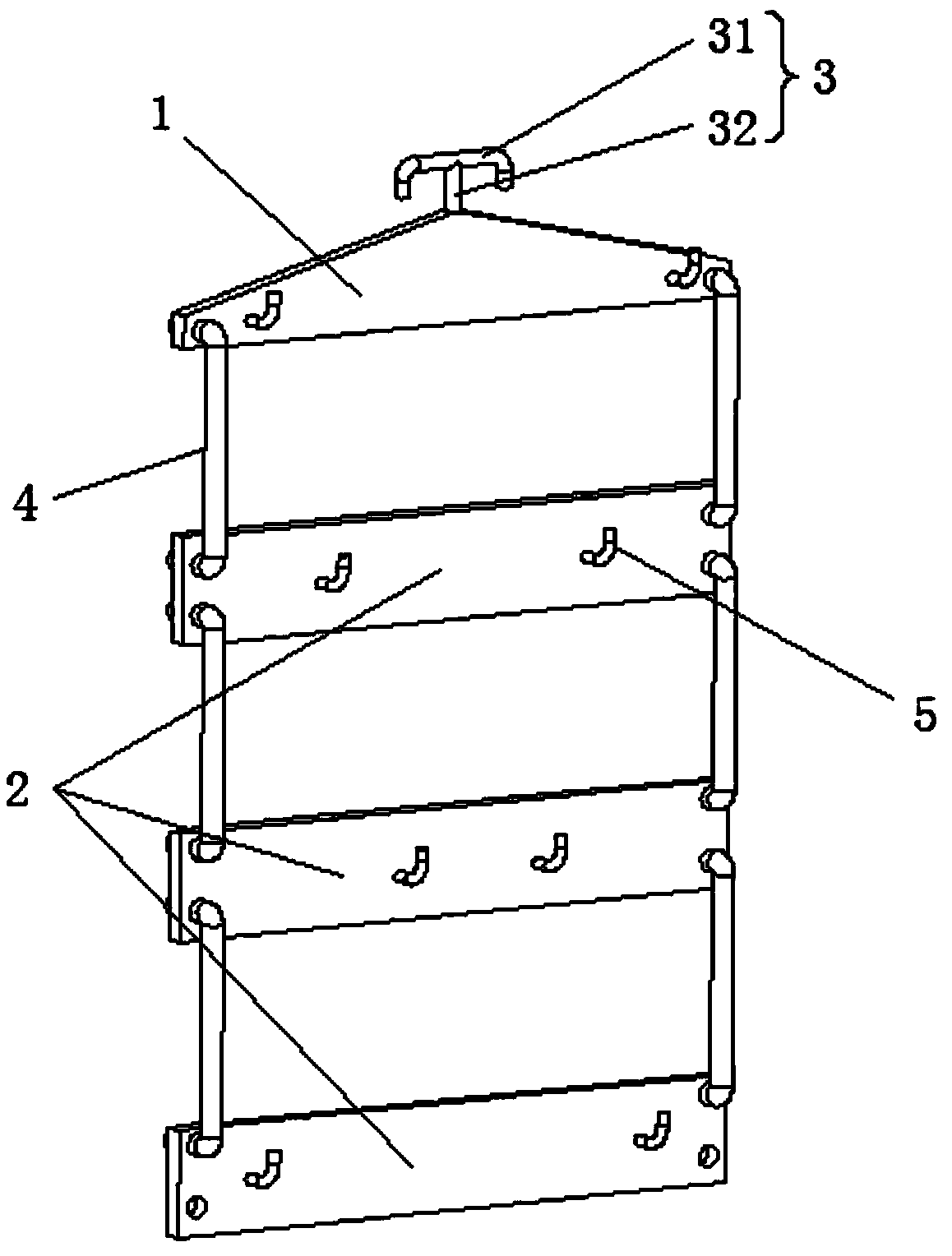

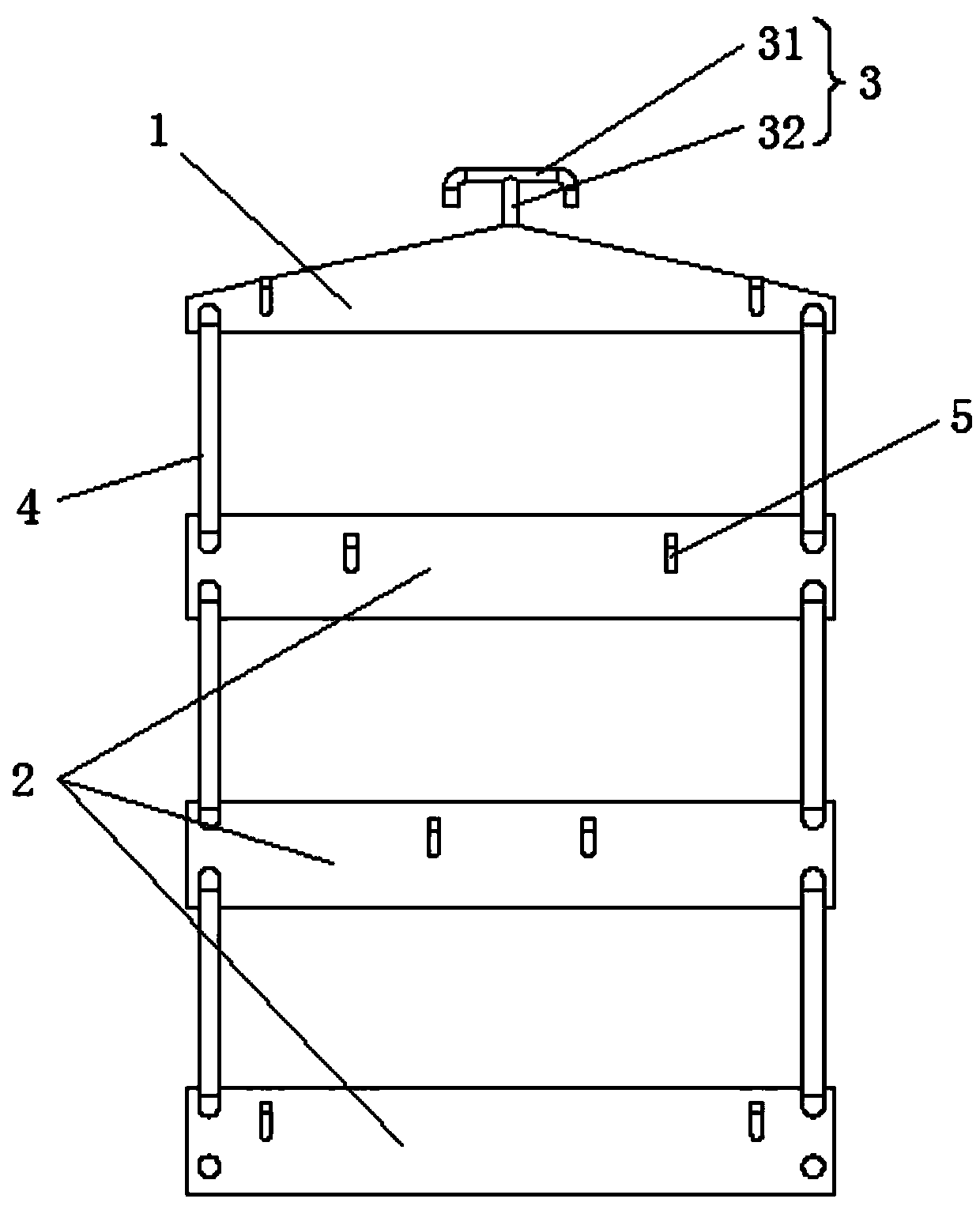

[0011] See figure 1 and figure 2 , the present invention comprises a main hanging body 1 and a plurality of auxiliary hanging bodies 2, the upper end of the main hanging body 1 is provided with a hook 3; An upper connection hole and a lower connection hole are arranged symmetrically; between the main hanging body 1 and a plurality of auxiliary hanging bodies 2, a C-shaped hanging piece 4 passes through the connecting hole of the main hanging body 1 and the upper connecting hole of the auxiliary hanging body 2, The lower connecting holes are connected to form the whole hanger; the main hanging body 1 and the auxiliary hanging body 2 are provided with small hooks 5 for hanging painted parts; the hook 3 at the upper end of the main hanging body 1 is T-shaped, including a horizontal Both ends of the rod 31 and the vertical rod 32 and the transverse rod 31 are bent downward to form a hook shape; the small hooks 5 on the main hanging body 1 and the plurality of auxiliary hanging b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com