Glue-pouring device for manufacturing power module

A technology of power modules and glue injection devices, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as inaccurate quantitative systems, affecting the working efficiency of the overall device, and blocking the glue outlet, so as to improve the overall Stability, prevent left and right shaking, prevent the effect of being blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

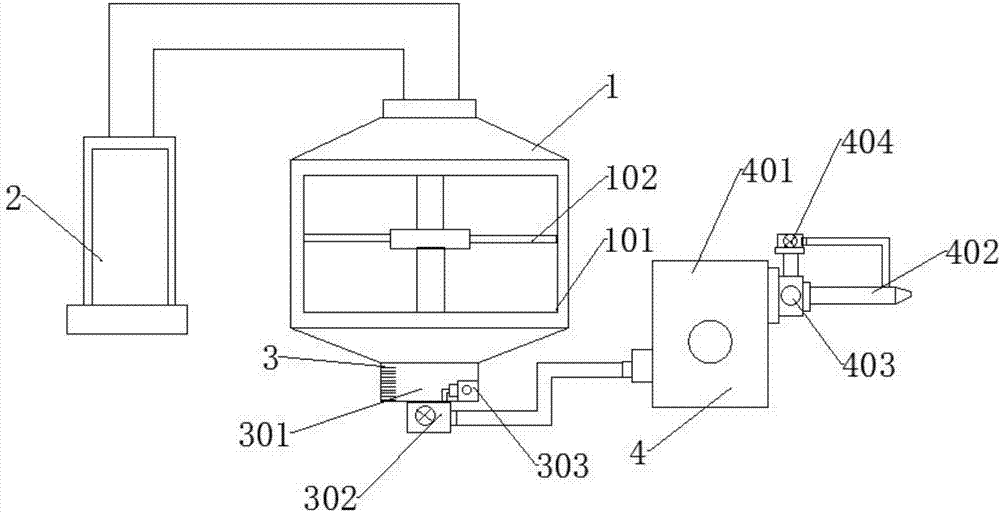

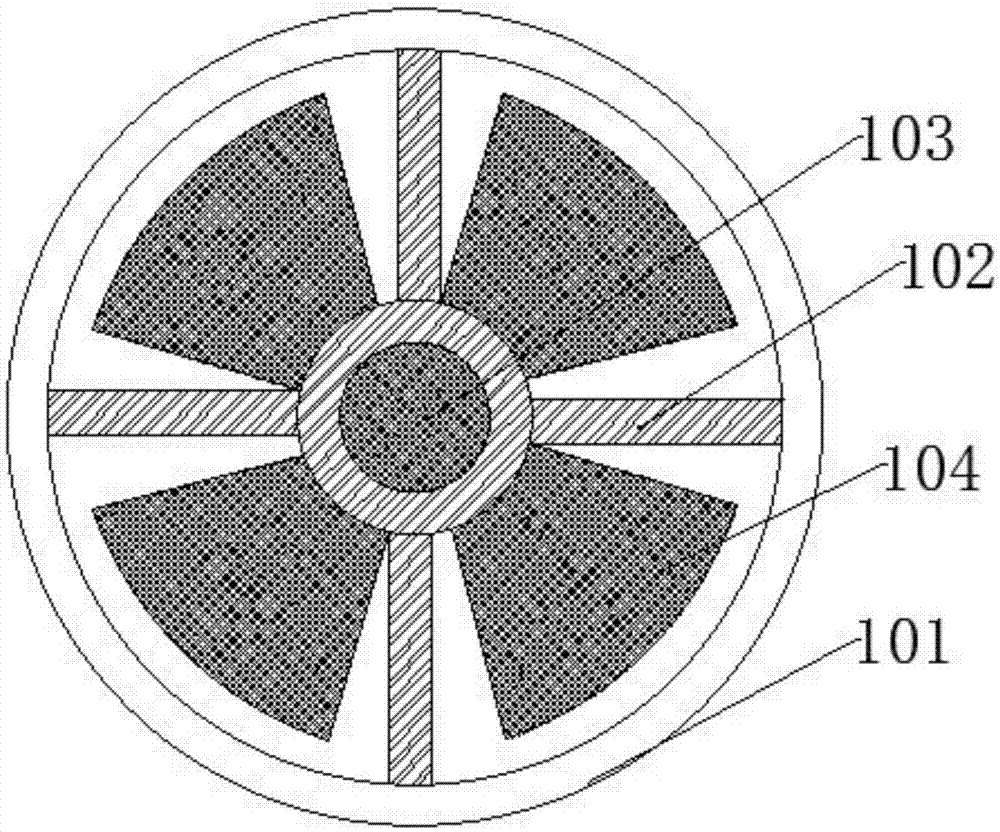

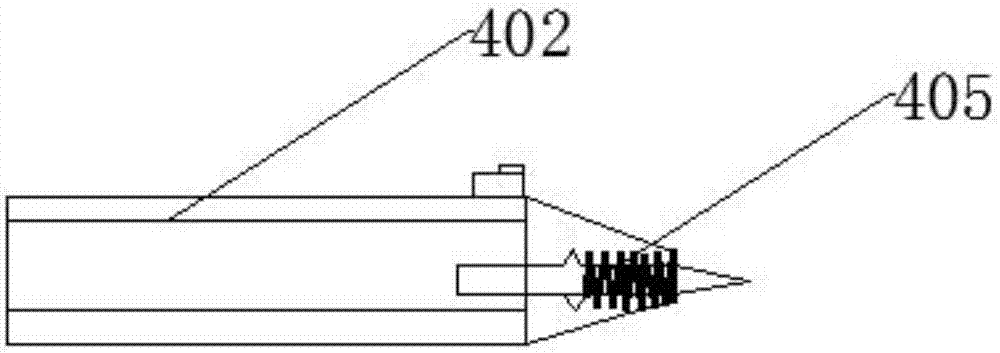

[0027] Such as figure 1 As shown, the present invention provides a glue filling device for power module manufacturing, including a stirring mechanism 1, the feed port of the stirring mechanism 1 is connected to the storage tank 2 through a conduit, and the discharge port conduit of the stirring mechanism 1 Connected with a quantitative system 3, the quantitative system 3 is used to quantitatively control the raw materials, and the outlet of the quantitative system 3 is connected with a glue injection device 4; the storage tank 2 is made of stainless steel. are coated with anti-corrosion paint, and are used to store the colloidal raw materials to be filled; the stirring mechanism 1 mixes the colloidal raw materials to be used, and sends the evenly stirred raw materials into the quantitative system 3, and the quantitative system 3 Quantitatively control the output of the raw material, and control the volume of the output raw material; the injection device 4 injects the quantitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com