Stirrer

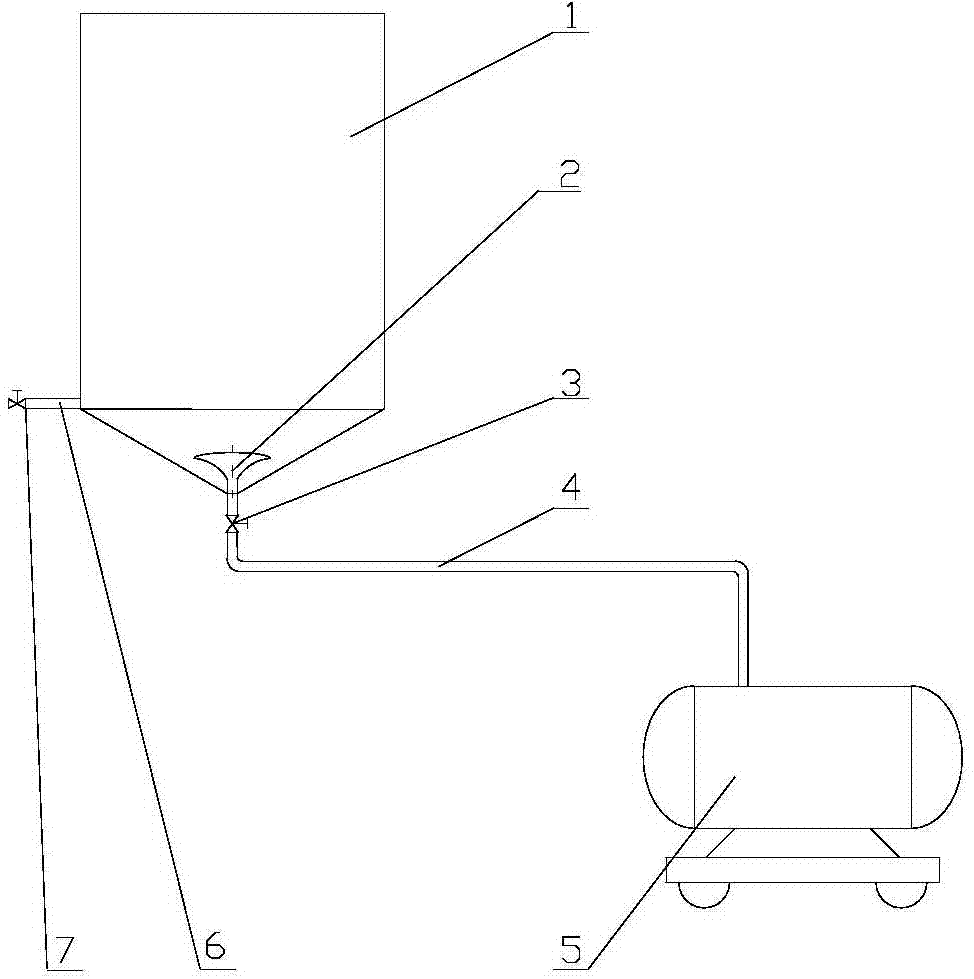

A stirrer and air bubble technology, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, dissolution, etc., can solve problems such as unfavorable cleaning, low stirring efficiency, dead corner of stirring, etc., and achieve easy maintenance and cleaning , Improve stirring efficiency, eliminate the effect of stirring dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

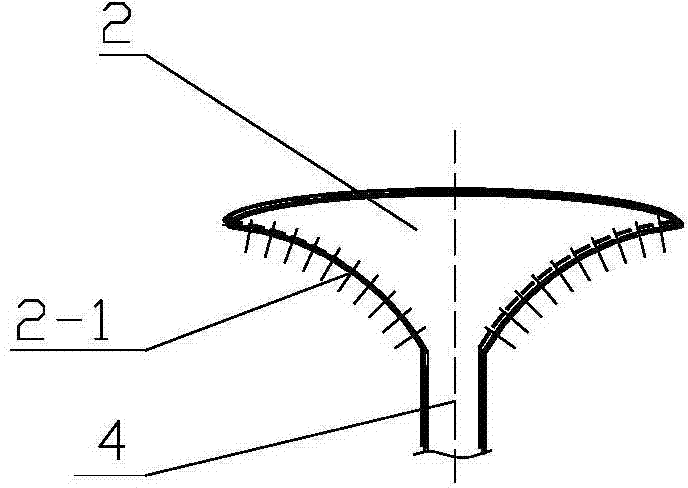

[0018] 1. A stirrer comprising a bubble stirrer 2, an overflow bubble hole 2-1, an air intake valve 3, an air intake pipe 4, and an air compressor 5, characterized in that: the bubble stirrer 2 is an inverted conical shape, and the bubble stirs Overflow foam hole 2-1 is arranged on the side of the cone of device 2, and bubble agitator 2 conical tops connect inlet pipe 4, and inlet valve 3 is housed on the inlet pipe 4, and inlet valve 3 connects air compressor 5.

[0019] 2. A stirrer, characterized in that: the conical side of the bubble stirrer 2 is an arc surface concave inward.

[0020] 3. A stirrer, characterized in that: the conical side of the bubble stirrer 2 is provided with a bubble overflow hole 2-1 with a diameter equal to 2-5mm.

[0021] 4. A stirrer, characterized in that: bubble overflow holes 2-1 are evenly distributed along the concave side of the cone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com