Patents

Literature

45results about How to "No stirring dead angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

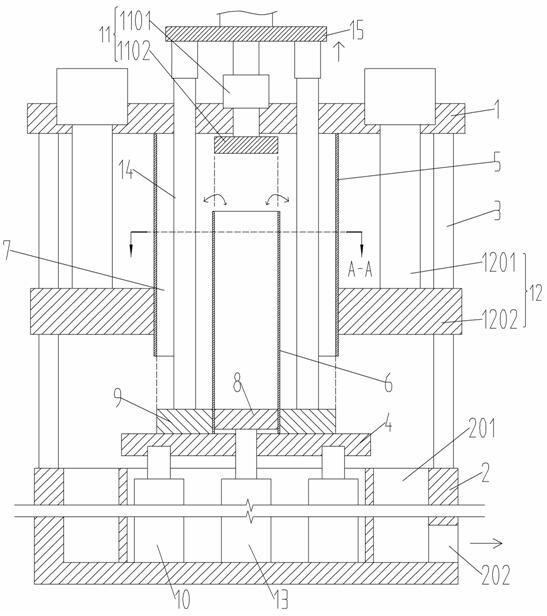

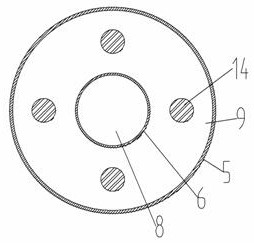

Vertical type efficient mixer for producing ceramics

InactiveCN104923101AStir wellNo stirring dead angleDispersed particle filtrationRotary stirring mixersHydraulic cylinderMixing effect

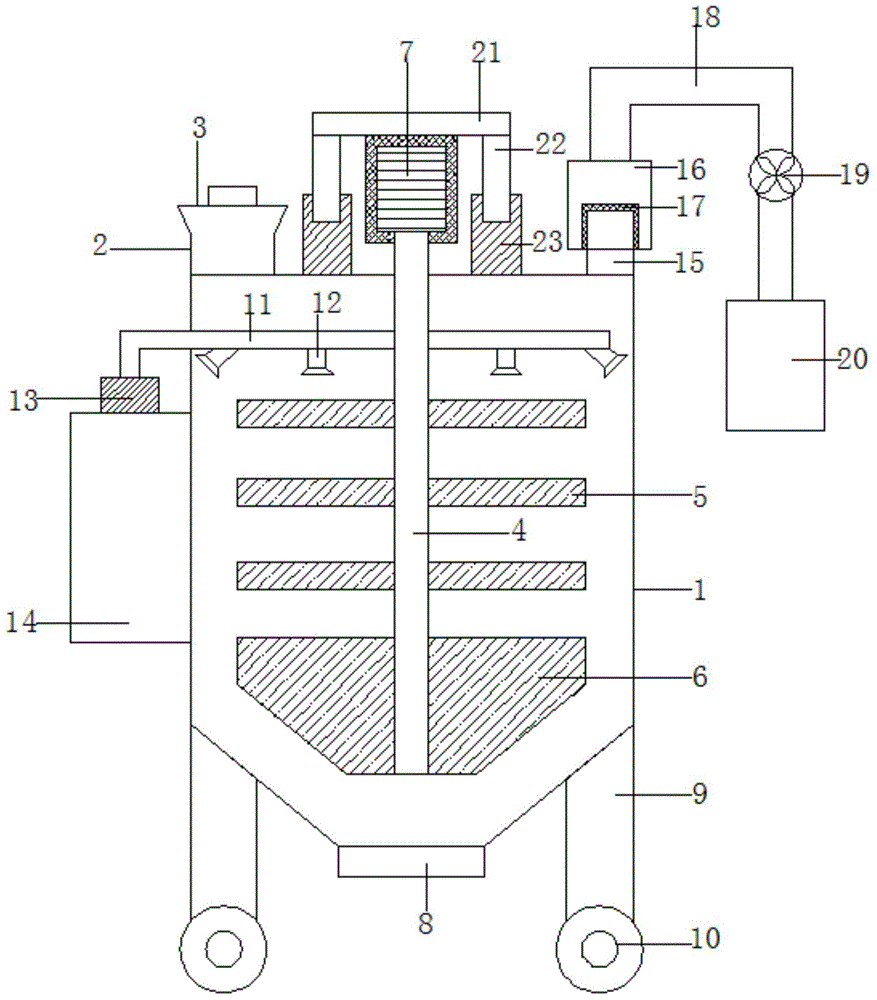

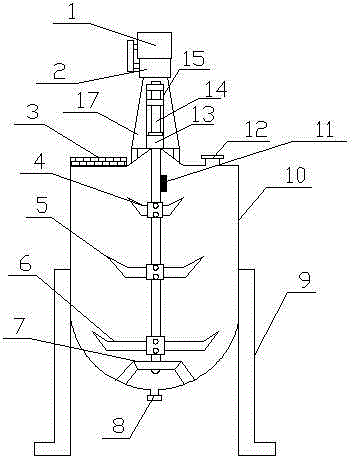

The invention discloses a vertical type efficient mixer for producing ceramics. The vertical type efficient mixer comprises a mixing cylinder, cleaning nozzles and a hydraulic cylinder, wherein a feeding funnel is disposed at the left end of the mixing cylinder, a cover plate is disposed at the top end of the feeding funnel, a rotary shaft is vertically disposed at the axis inside the mixing cylinder, mixing blades are disposed on the upper outer wall of the rotary shaft in a left-right symmetry manner, a mixing plate is fixed on the lower side of the rotary shaft, and the top end of the rotary shaft extends out of the mixing cylinder and is connected with a rotating motor. The vertical type efficient mixer has the advantages that the mixing blades and the mixing plate move up and down to jointly mix materials, mixing dead angle is avoided, mixing effect is guaranteed, mixing efficiency is increased, self-cleaning of the interior of the mixing cylinder can be achieved, manual cleaning is not needed, time and labor are saved, the mixing cylinder can be used conveniently next time, dust leakage during mixing can be avoided by the cover plate on the feeding funnel, dust produced during mixing can be recycled, dust pollution is avoided, and raw materials are saved.

Owner:顾马飞

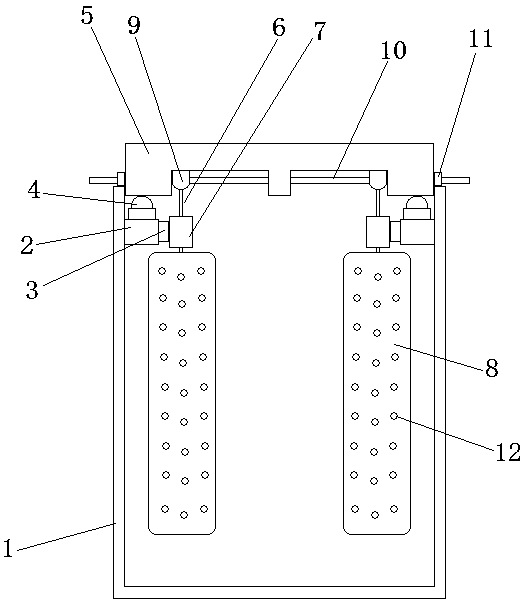

Medical mixing device capable of uniformly mixing and stirring

PendingCN107837733AWell mixedAvoid the problem of uneven mixing up and downRotating receptacle mixersTransportation and packagingCouplingEngineering

Owner:斯圣斌

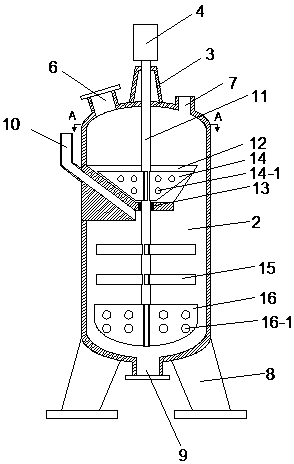

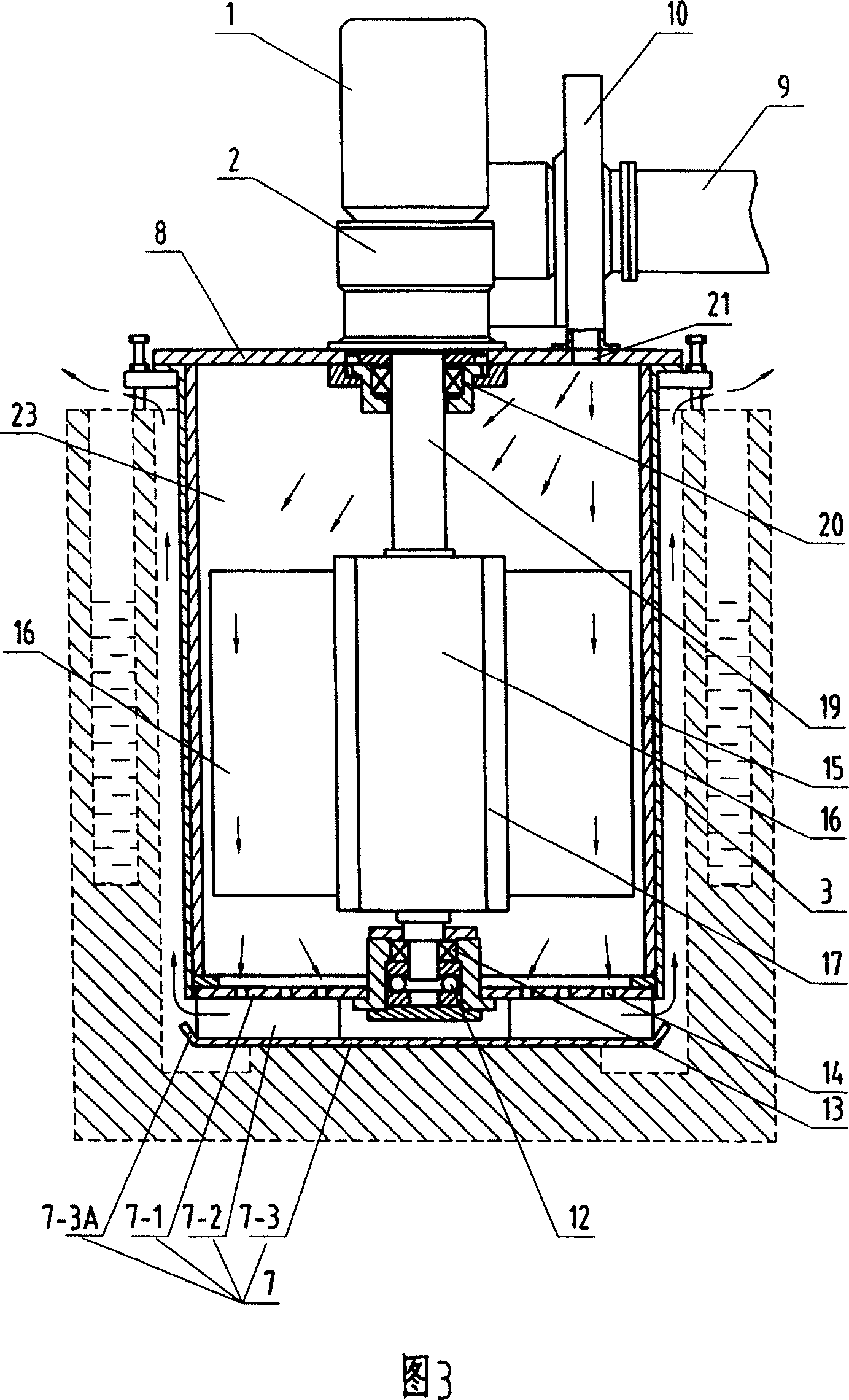

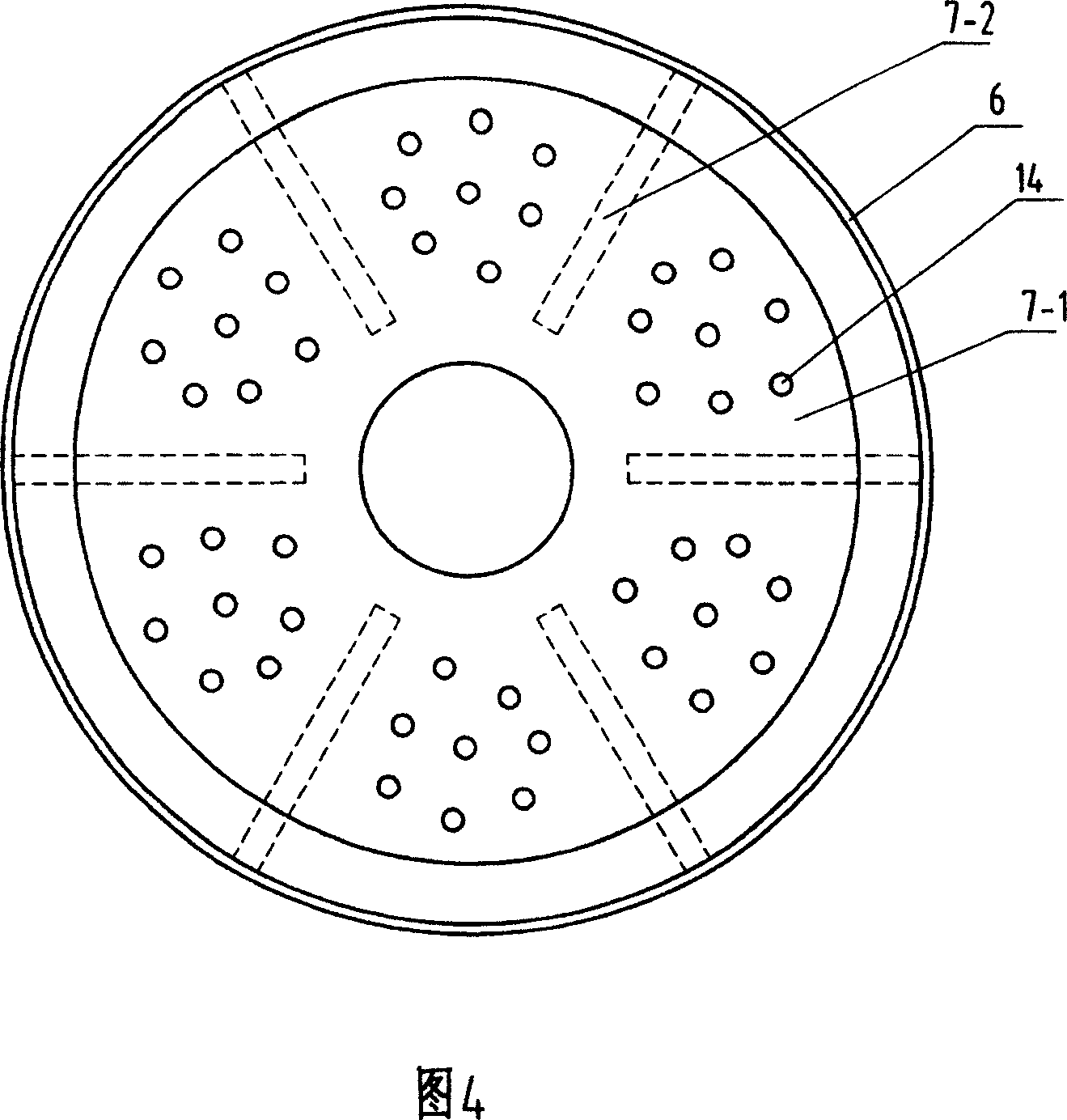

Device and method for homogenizing high-temperature melt

InactiveCN102698634AStirring power is smallIncrease the stirring areaRotary stirring mixersTransportation and packagingSlagHeating system

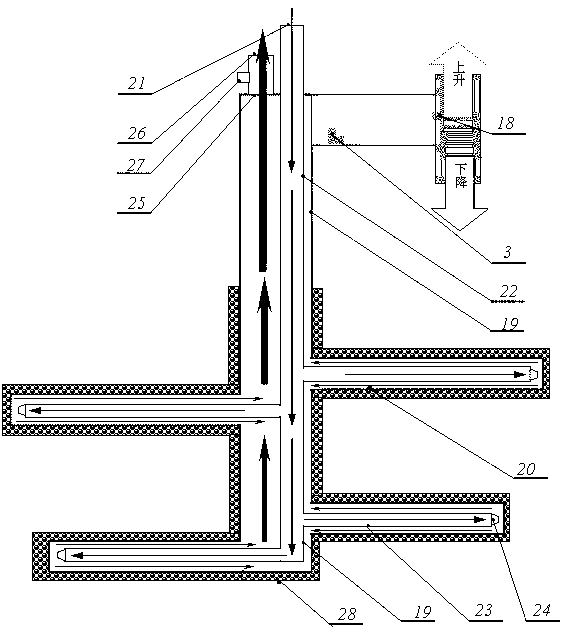

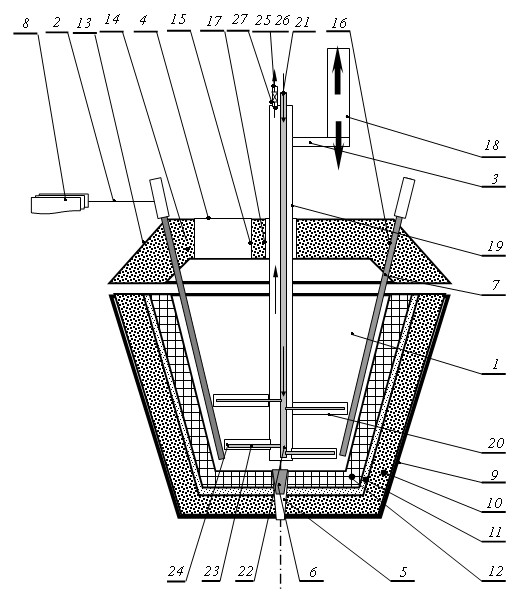

The invention provides a device and a method for homogenizing high-temperature melt and belongs to the technical field of melt homogenization. The device provided by the invention consists of three parts, namely a melting tank, a stirring system and a heating system. The detailed steps for homogenizing high-temperature melt carried out by the device provided by the invention are as follows: adding hot silicate slag and quenching-tempering material into the melting tank; after heating to melt the raw material, turning off the power supply; enabling the stirring part of the cooled stirring system to fall into the high-temperature melt, and finishing fall-rise-fall operating actions for stirring the melt in order, wherein the stirring process and the heating process are carried out alternatively; and under the condition that the test result of the samples shows that the composition uniformity and viscosity of the melt are suitable for the process conditions that the fiber is formed or the glass ceramics is prepared, opening a choke plug of the melting tank and making the melt flow out via the flow hole by the gravity of the melt to finish the homogenization process. The homogenizing device and the homogenizing method, provided by the invention, have the advantages of good homogenizing effect, good high-temperature strength and long service life of the stirring part.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Asphalt mixing equipment with heating device

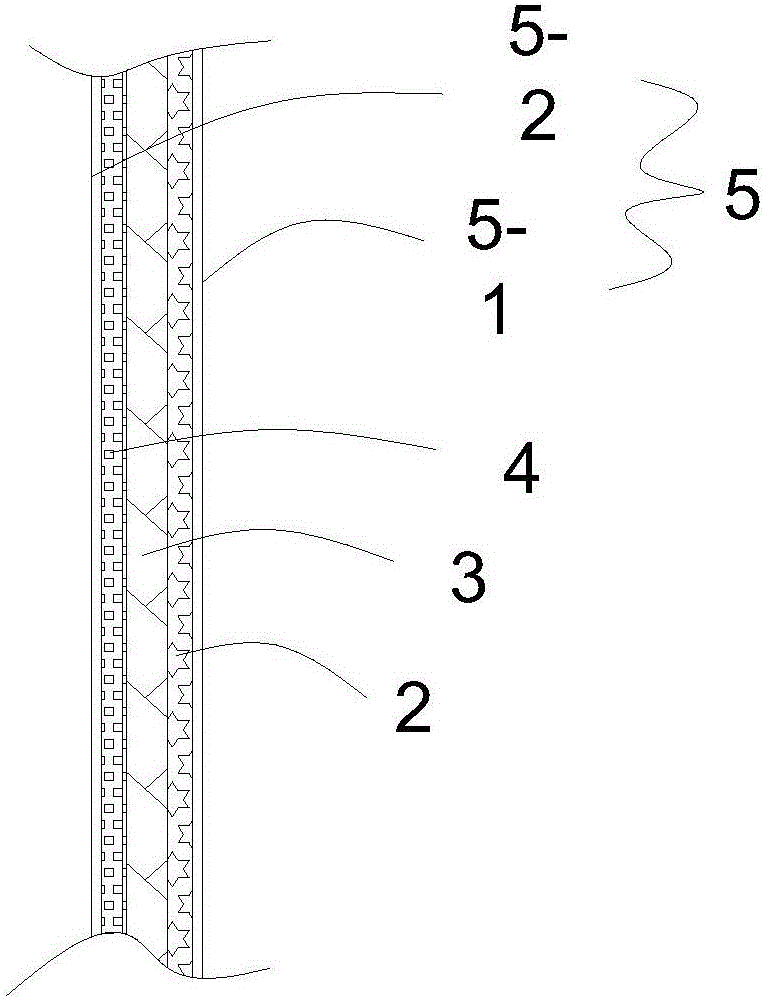

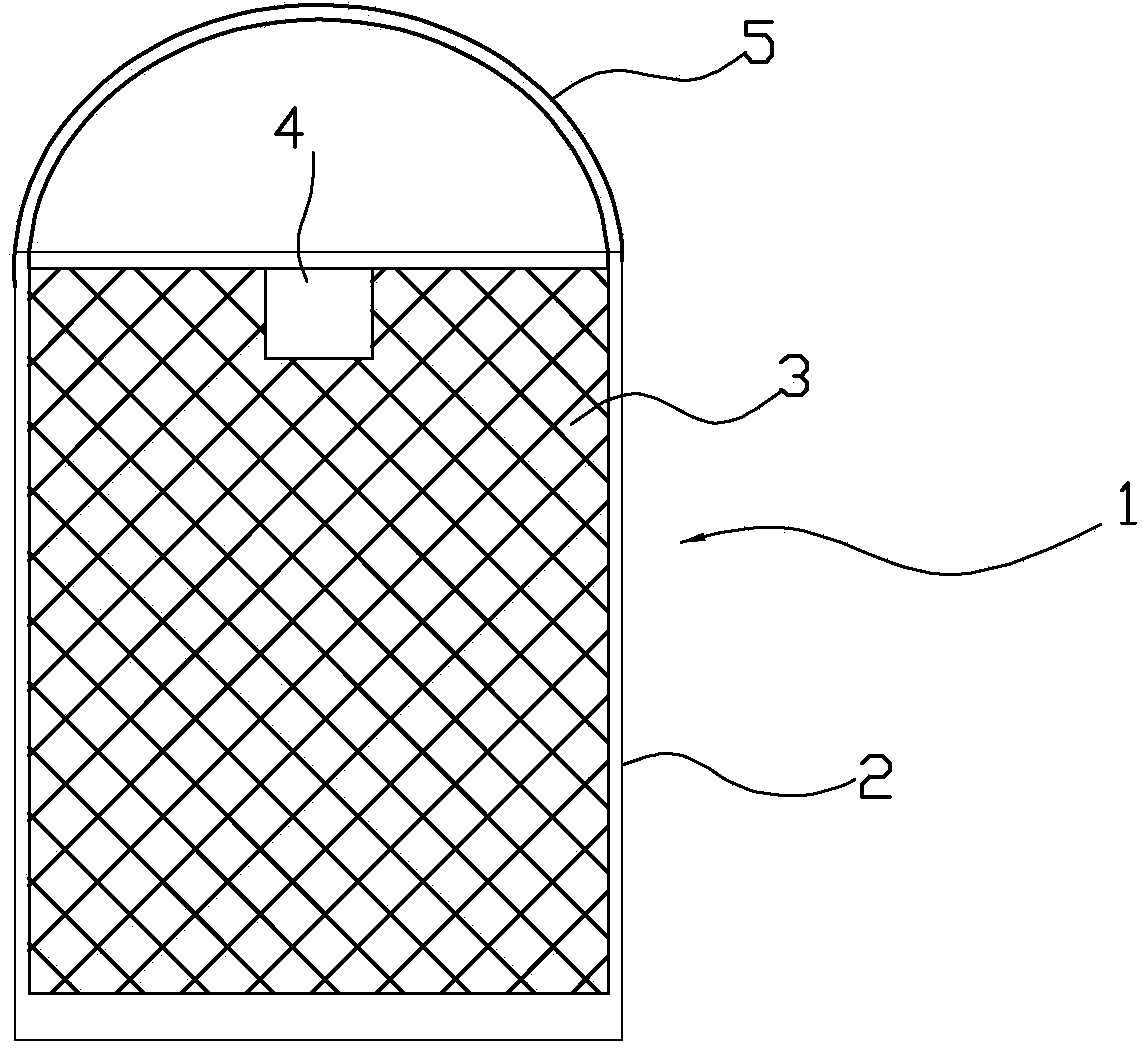

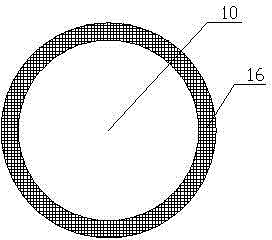

InactiveCN106621905AImprove uniformityImprove modification efficiencyRotary stirring mixersTransportation and packagingBiochemical engineeringIsolation layer

The invention discloses asphalt mixing equipment with a heating device and relates to the technical field of asphalt mixing. The asphalt mixing equipment comprises a tank body and a sealing cover for sealing the tank body, wherein a feeding hole, which is communicated with the inner part of the tank body, is formed in the sealing cover; a discharging hole is formed in one side of the bottom end of the tank body; a stirring shaft located in the tank body is arranged below the sealing cover; a stirring assembly is arranged at the upper end of the stirring shaft; a pair of long stirring blades and a pair of short stirring blades are arranged at the lower end of the stirring shaft; the tank body comprises an inner shell body and an outer shell body; a cavity structure is formed by the inner shell body and the outer shell body; a heat insulating layer, an isolation layer and a heating layer are arranged in the cavity structure in sequence from outside to inside. The asphalt mixing equipment disclosed by the invention has the advantages of simple structure, high working efficiency, no stirring dead angle and high practicability.

Owner:赵黎

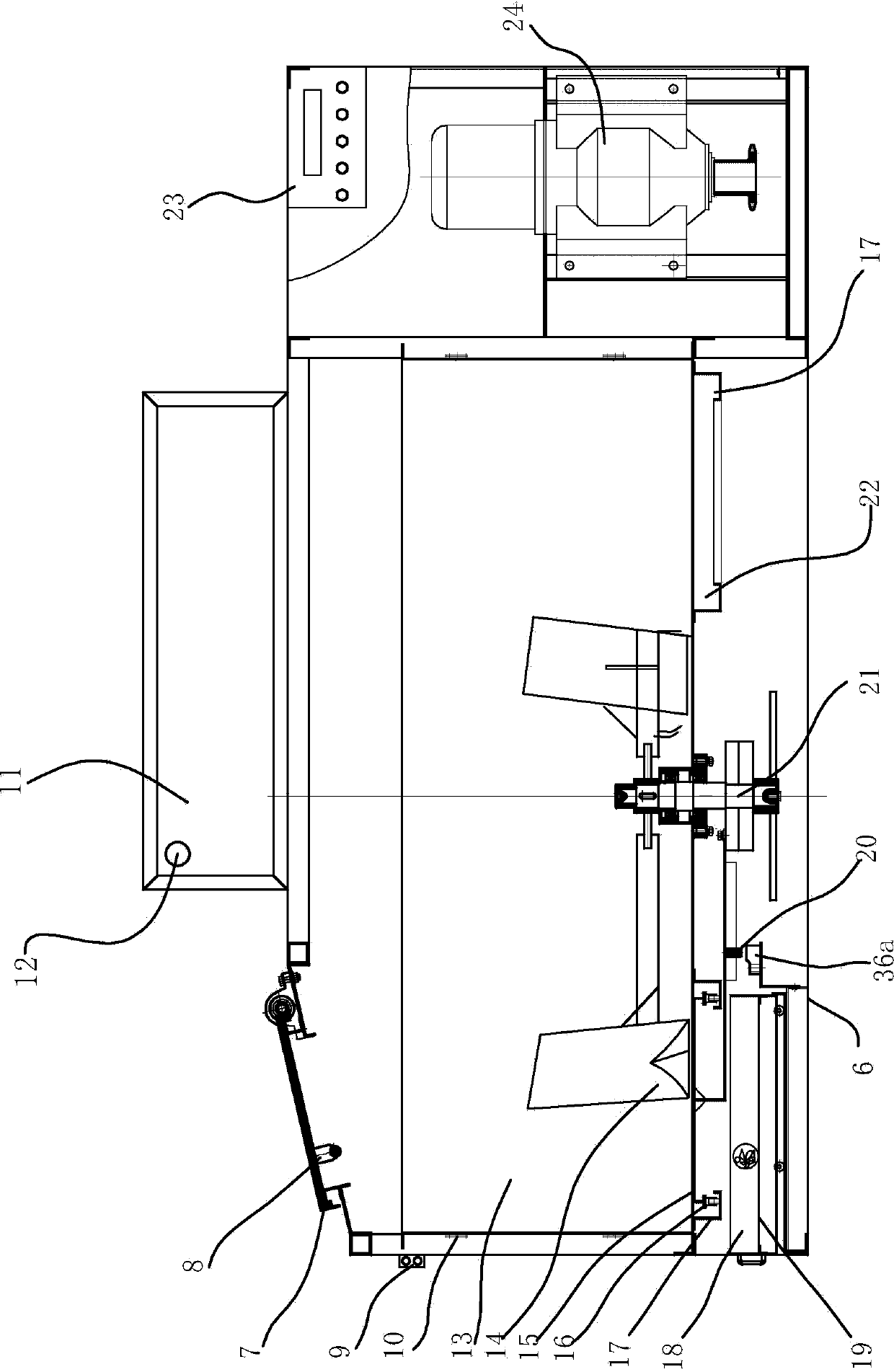

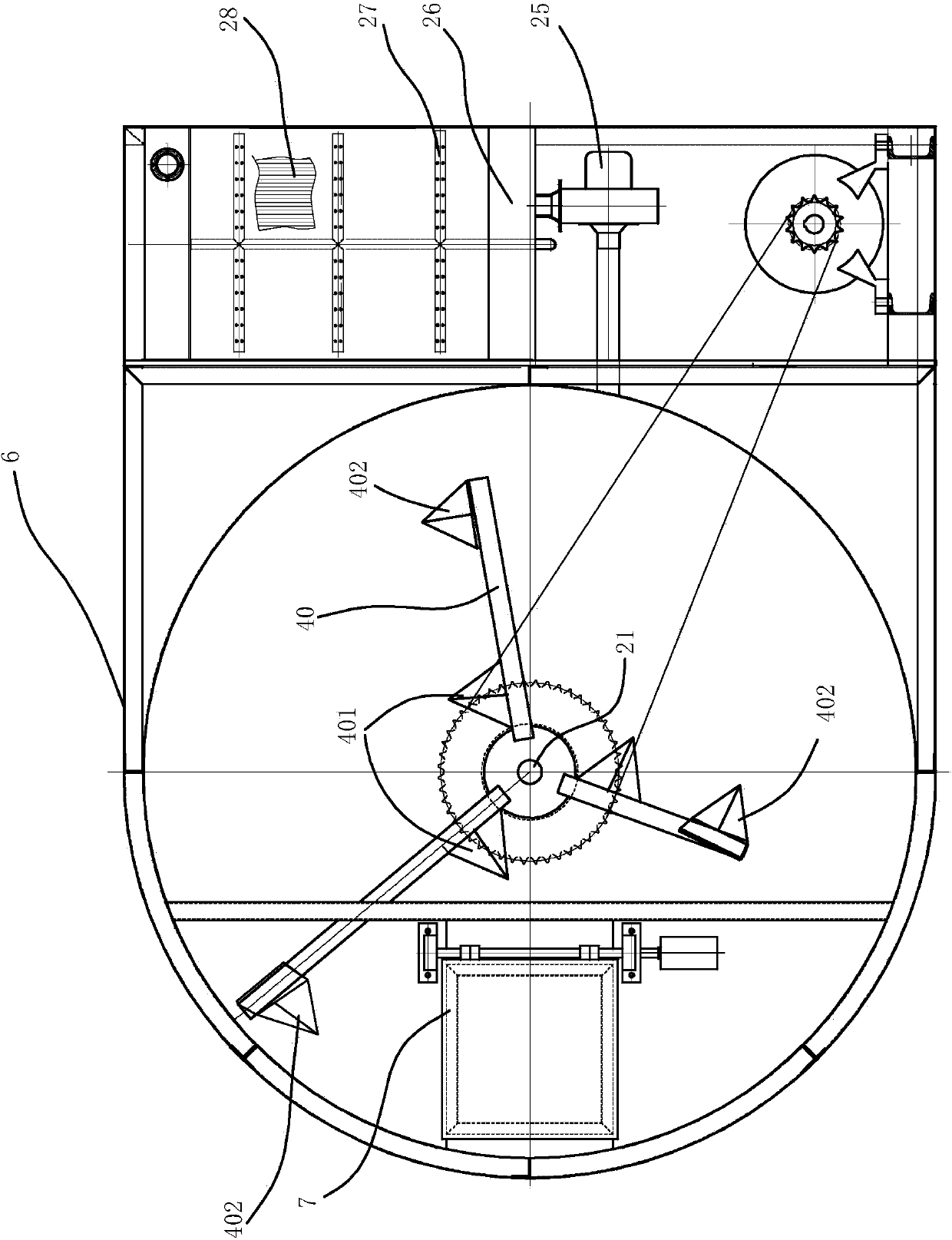

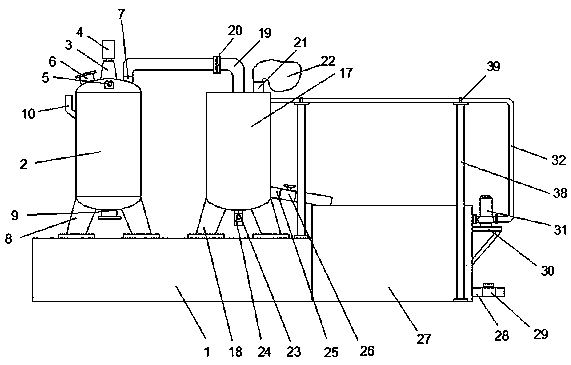

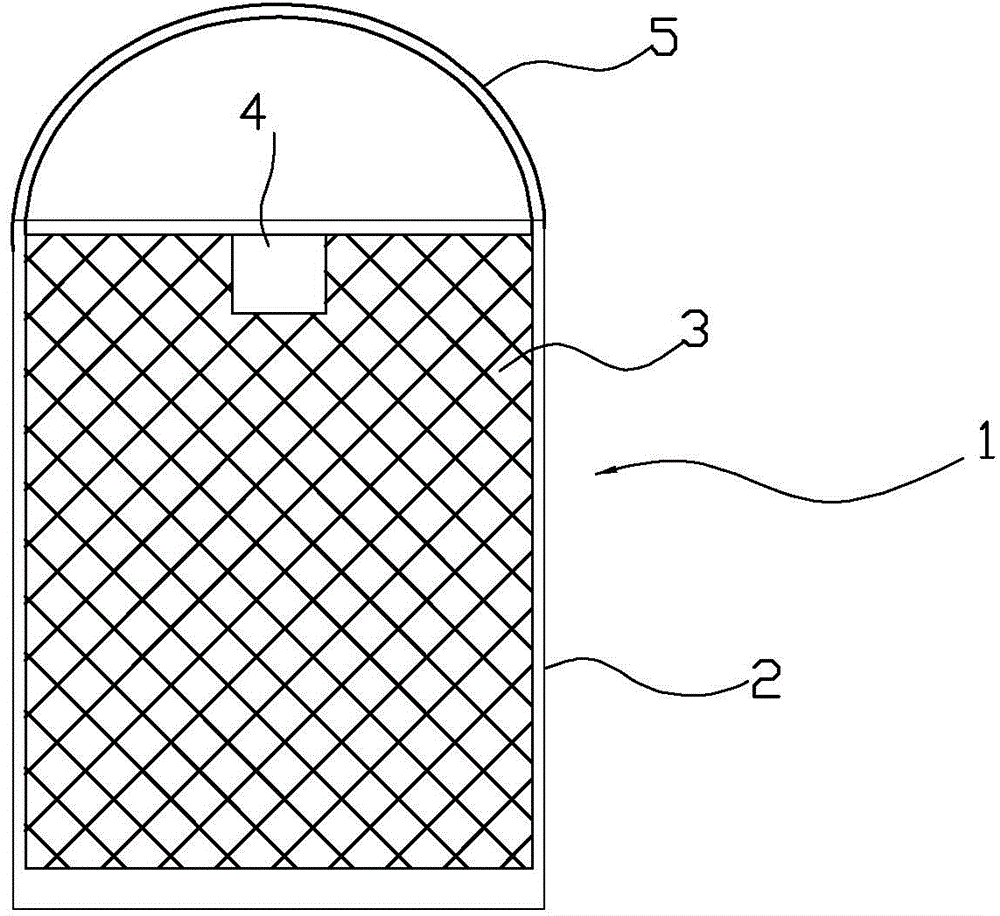

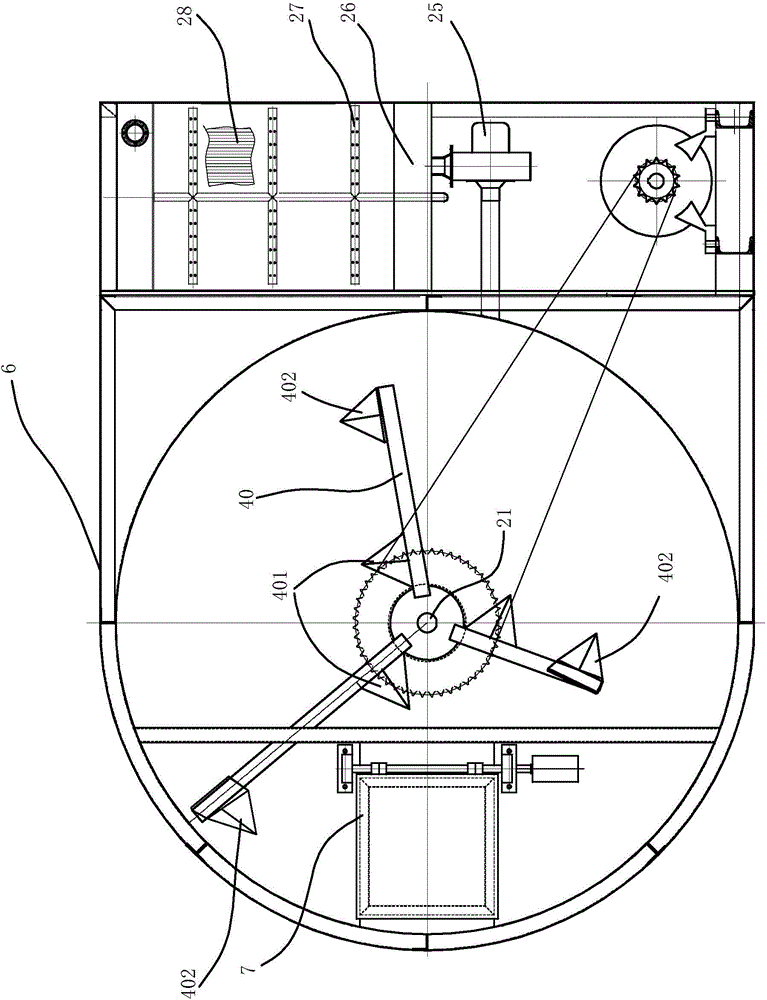

Collecting and treating system of domestic and kitchen garbage

ActiveCN103624061AClassification works wellClassification works adequatelySolid waste disposalRefuse collectionWater discharge

The invention relates to a collecting and treating system of domestic and kitchen garbage. The collecting and treating system is characterized by comprising a garbage collecting barrel and a garbage treating device, wherein the garbage treating device comprises a closed case; the case is internally provided with a container for containing the kitchen garbage and carrying out biological reaction; the container is internally provided with a stirring device for stirring the kitchen waste entering the container; the lower part of the container is provided with a residue discharging port and a water discharging port communicated with a circulating water tank; the upper part of the container is provided with an exhaust fan, and an exhaust port of the exhaust fan is communicated with a biological deodorization device; a bottom plate of the case is provided with a discharging door cover, and a discharging drawer for receiving discharged garbage is arranged under the discharging door cover; and the output end of the control system is respectively connected with an automatic closing device, a stirring device and a clutch. The collecting and treating system provided by the invention has the advantages that the sorted placement of the garbage can be forcibly realized and smooth conduction of sorting working of the garbage is guaranteed.

Owner:ZHEJIANG DEAN TECH

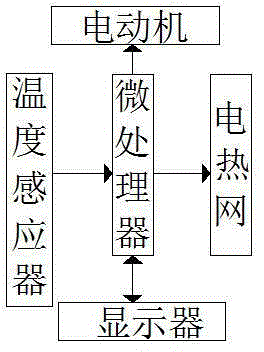

Temperature control stirring chemical reactor

InactiveCN105771847AImprove efficiencyNo stirring dead angleRotary stirring mixersMixer accessoriesTemperature controlReduction drive

The invention discloses a temperature control stirring chemical reactor, comprising a cylindrical kettle body, a microprocessor, a feed inlet mounted on one side of the kettle body top, a feed outlet mounted on the bottom of the kettle body, and a support frame installed above the kettle body and used for fixing a driving device. The driving device is provided with, from top to bottom, a motor, a reducer, a coupling and a rotation shaft; the rotation shaft extend downwards into the kettle body, and the a bearing seat is in cup joint to the end of the rotation shaft; the upper portion of the motor is provided with the microprocessor; the rotation shaft in the kettle body is provided with a temperature sensor, a first stirring blade, a second stirring blade and a third stirring blade from top to bottom to form a tower-shaped stirring blade group; and the kettle body shell is internally provided with an electric network. The reactor has the advantages of high efficiency of stirring blade group, no stirring dead corner in the kettle body, stable transmission, heating of the kettle body by the electric network; the microprocessor can control the temperature; and the reactor is simple and strong in structure, low in cost, and easy to implement.

Owner:TIANJIN HAOSHI CARPET

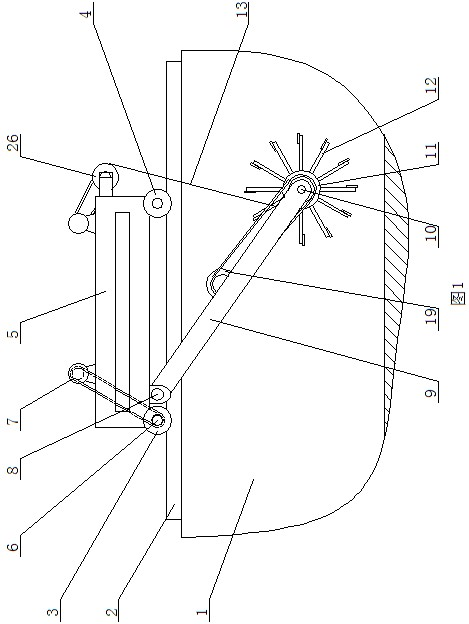

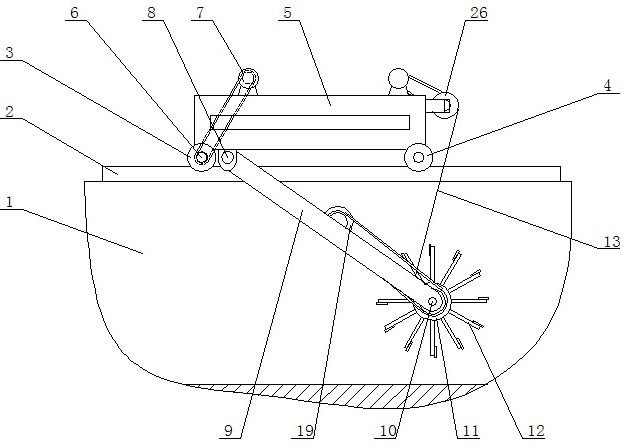

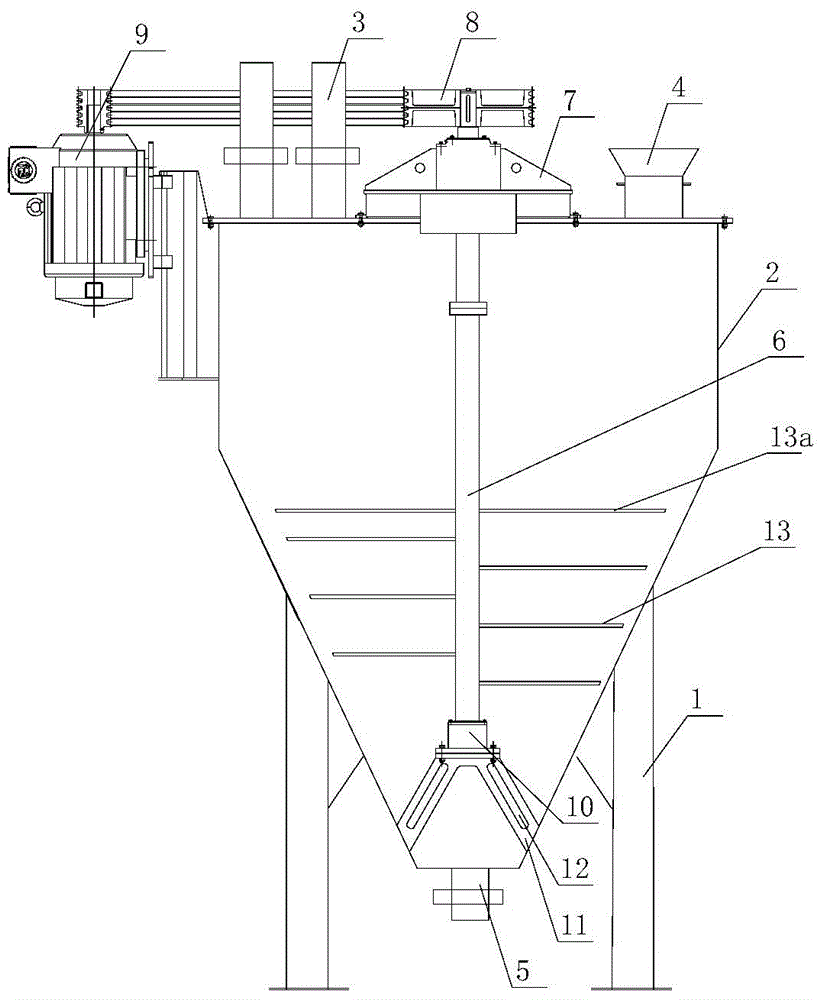

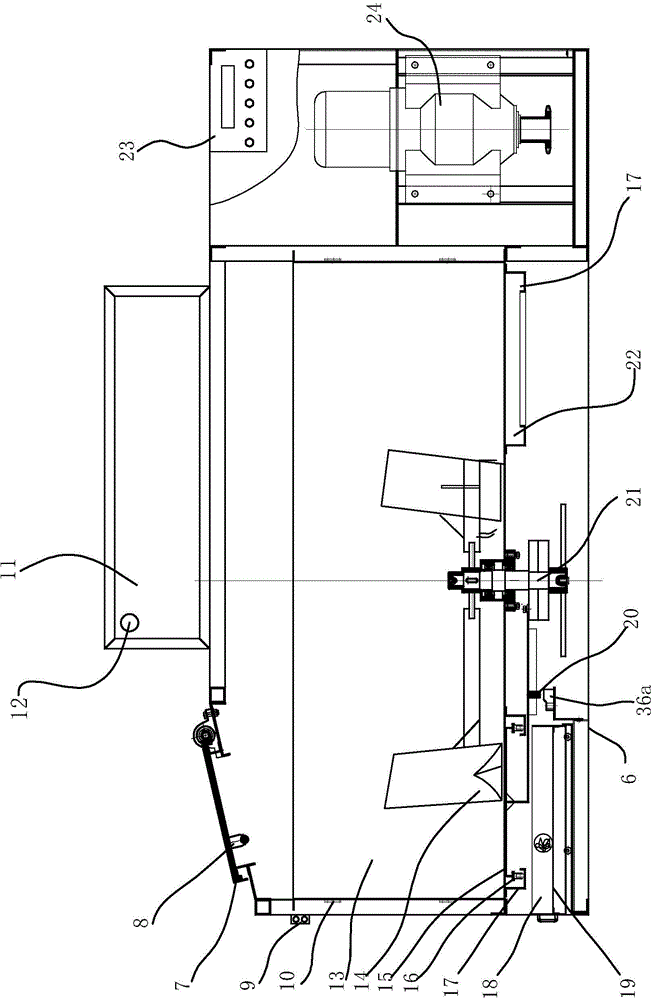

Hanging arm sludge mixing device

InactiveCN102284255AStir wellEasy to cleanRotary stirring mixersMixer accessoriesDrive wheelDrive shaft

The invention discloses a suspension arm type sludge stirring device, which comprises a stirring tank, guide rails are arranged on both sides of the top of the stirring tank, a driving wheel and a driven wheel are installed on the guide rail, the driven wheel is installed on a walking frame, and a driving shaft is passed between the driving wheels Connection, the drive shaft is connected with the travel motor through the travel transmission device, the hinge shaft is installed at the lower part of the travel frame, the two sides of the hinge shaft are hinged with the upper end of the cantilever, the stirring shaft is installed at the lower end of the cantilever, the stirring roller is installed on the stirring shaft, and the stirring teeth are set on the stirring roller , A stirring motor is installed on the cantilever, the stirring motor is connected to the stirring shaft through a stirring transmission device, a hoist is installed on the walking frame, and the hoist is connected to the cantilever through a noose. The present invention can adjust the position of the agitator according to the needs, carry out stratification and regional agitation of the sludge, does not need to be driven by a high-power motor, reduces energy consumption, and is beneficial to reduce the load of the motor, prevents the motor from burning out, and can agitate The sludge everywhere in the pool is evenly stirred, there is no mixing dead angle, and the sludge is easy to clean.

Owner:杨升华

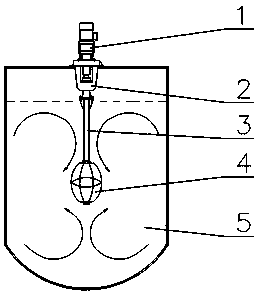

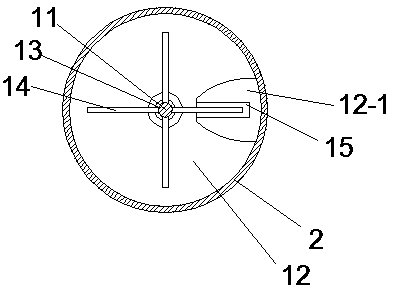

Stirring device

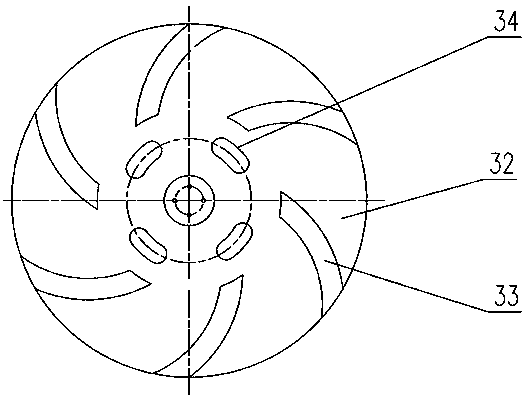

PendingCN107812479ANo stirring dead angleWell mixedRotary stirring mixersTransportation and packagingImpellerDrive shaft

The invention discloses a stirring device. The stirring device comprises a driving device, a transmission shaft and a lantern-shaped impeller, wherein one end of the transmission shaft is connected with the driving device, and the other end of the transmission shaft is connected with the impeller. The stirring device can fully mix and stir, and does not have stirring dead corners, so that the stirring effect is improved.

Owner:NANJING POLYTECHNIC INSITUTE

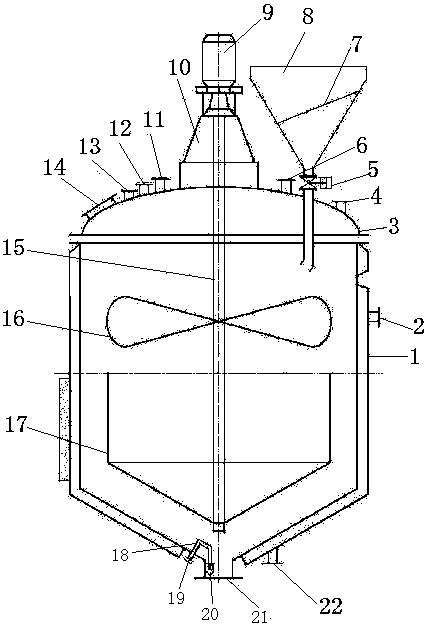

Production method of high-quality PPTA (poly(p-phenylene terephthalamide)) resin and PPD (p-phenylenediamine) stirring vessel

ActiveCN109912795AEfficient mixingAvoid material hanging on the wallRotary stirring mixersMixer accessoriesSolventL&D process

The invention provides a production method of high-quality PPTA (poly(p-phenylene terephthalamide)) resin and a PPD (p-phenylenediamine) stirring vessel, and belongs to the technical field of polymermaterials. The method for obtaining the high-quality PPTA resin comprises the following steps: blending of an NMP / CaCl2 complex solvent; preparation of a PPD solution; measuring of TPC (terephthaloylchloride); condensation polymerization; blank treatment. The PPD stirring vessel is also provided, PPD dissolution parameters such as temperature, stirring speed, dissolution time and the like are optimized, and all PPD can be dissolved and participate in the condensation polymerization. Pre-polymerization and the condensation polymerization are carried out in the same reactor, the technological process is short, the total molar ratio is easy to control, repeated transfer of materials is avoided, and influence of residues in the system on the molar ratio and influence of deterioration of deposited materials at dead corners of a conveying system on the reaction are avoided.

Owner:HENAN SHENMA NYLON CHEM

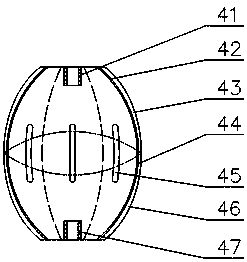

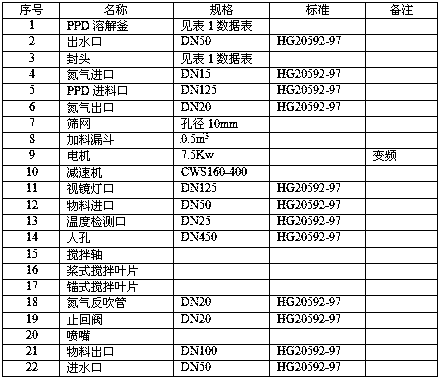

Self-cleaning vertical stirring machine

PendingCN108236860AWith self-cleaning effectNo stirring dead angleRotary stirring mixersTransportation and packagingImpellerDrive shaft

The invention discloses a self-cleaning vertical stirring machine. The self-cleaning vertical stirring machine comprises a driving device, a transmission shaft, a self-cleaning impeller and a tank body, wherein the self-cleaning impeller comprises a cylindrical hub, a curved surface hub, main blades and reflux tanks; and the driving device is assembled to the tank body, the upper end of the transmission shaft is connected with the lower end of the driving device, and the self-cleaning impeller is assembled to the lower end of the transmission shaft. The self-cleaning vertical stirring machinehas the beneficial effects that the self-cleaning of the impeller is realized, materials are adequately mixed and stirred at the bottom of the tank, no stirring dead corner exists, and the good operation of the process is effectively guaranteed.

Owner:JIANGSU OPEN UNIV

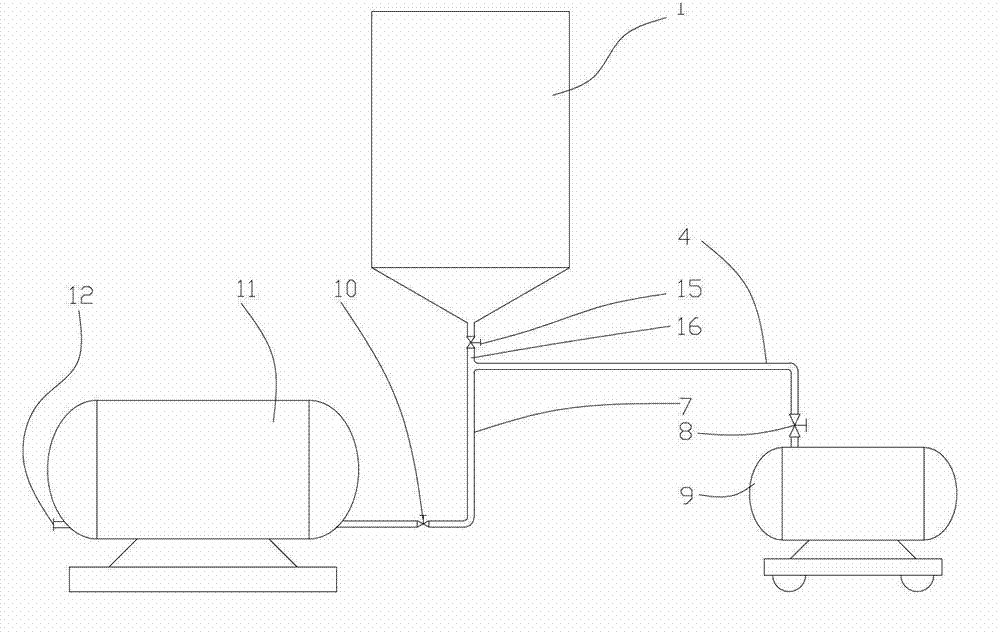

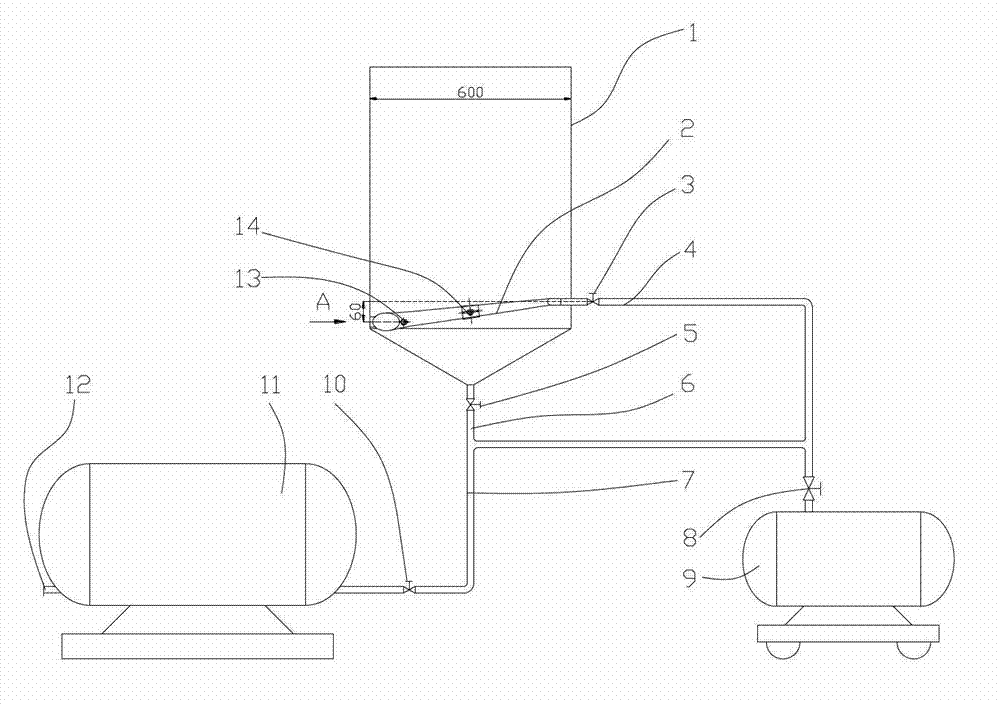

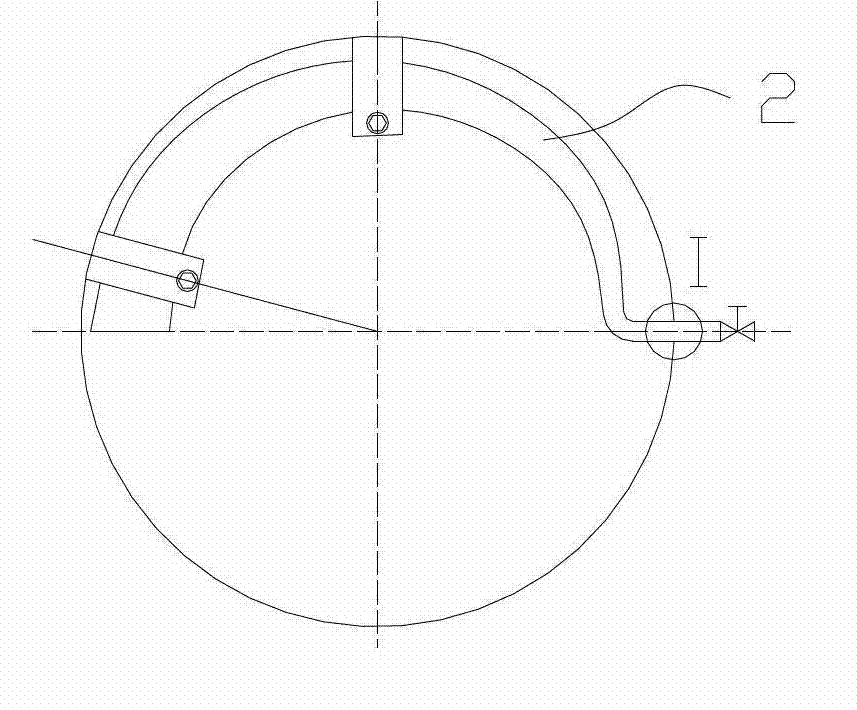

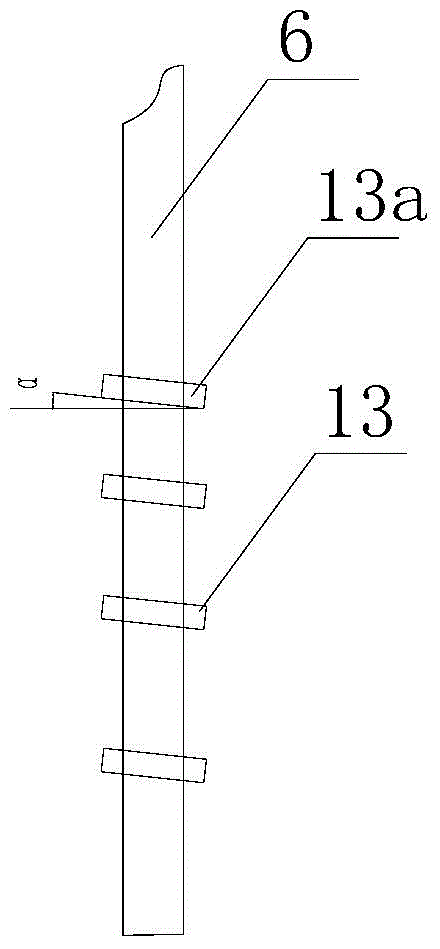

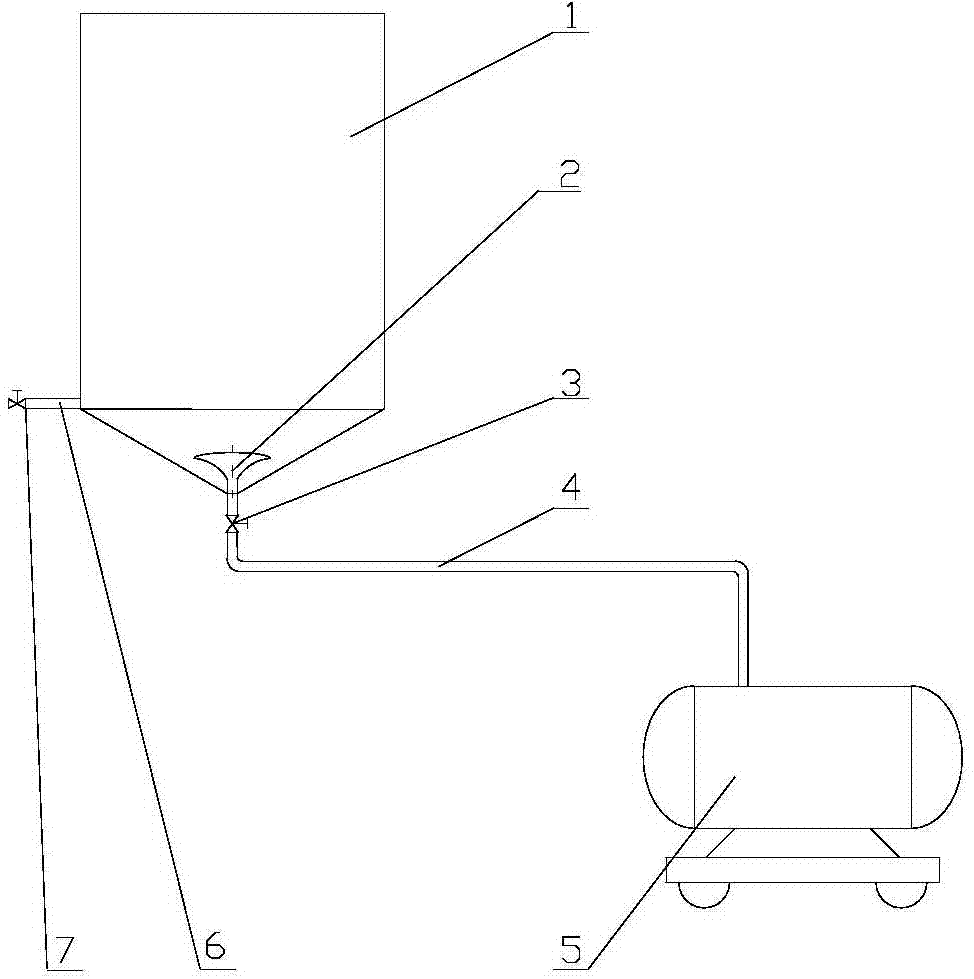

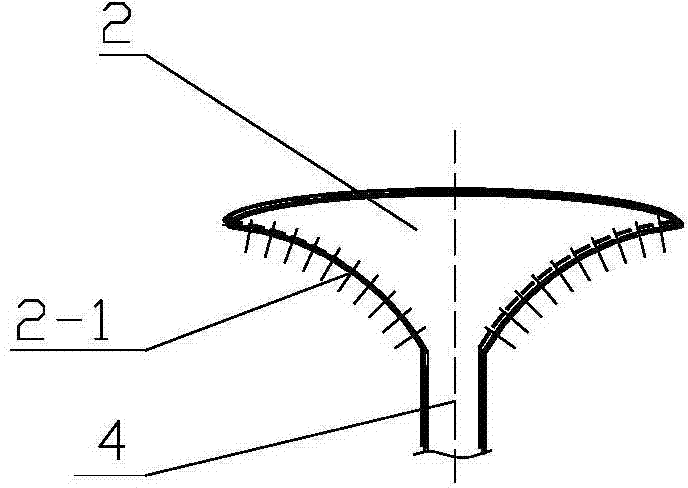

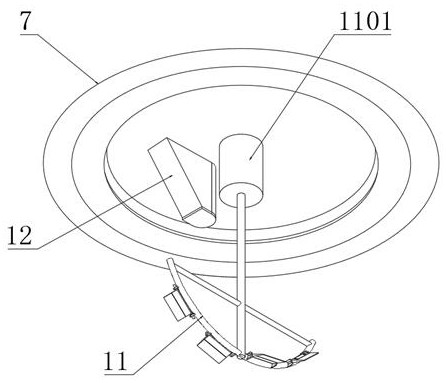

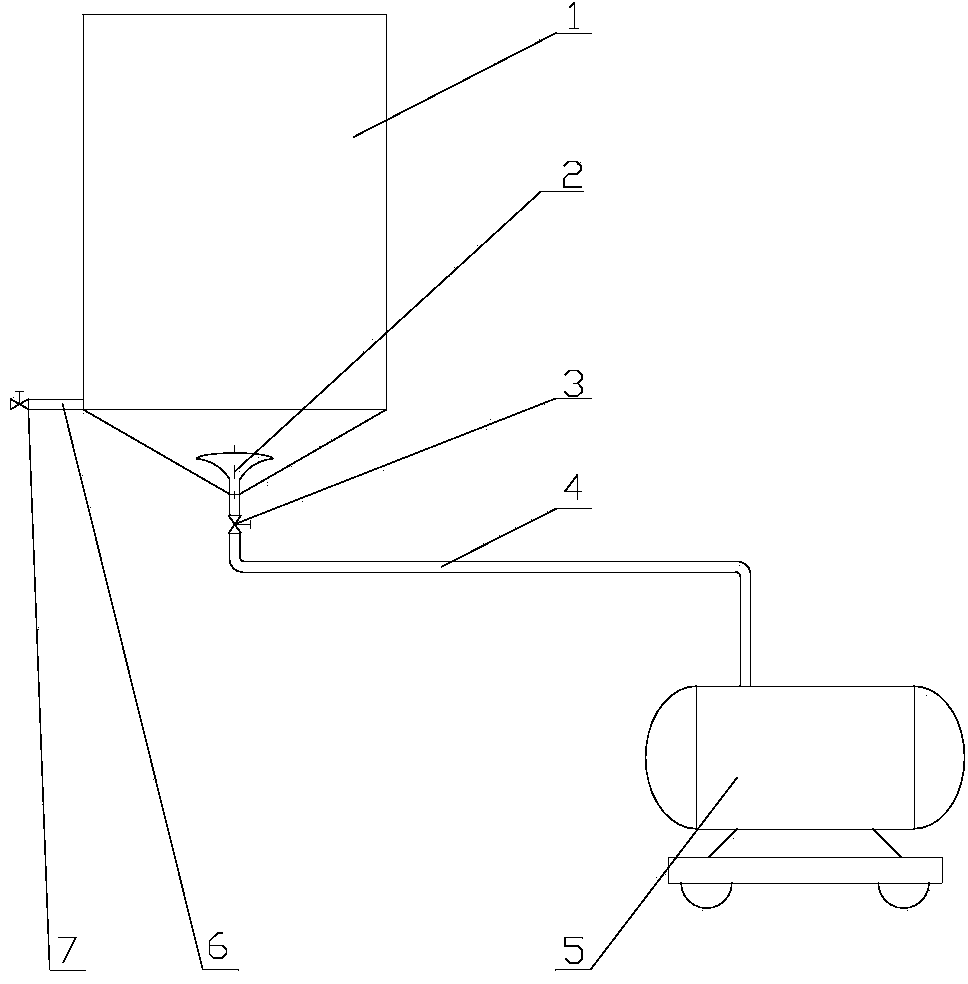

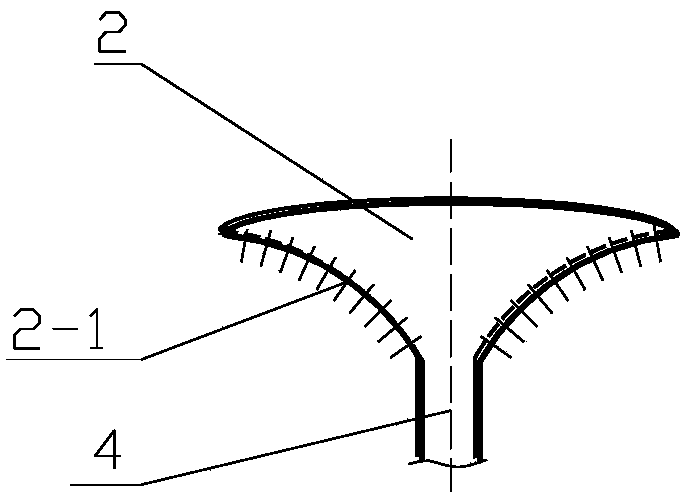

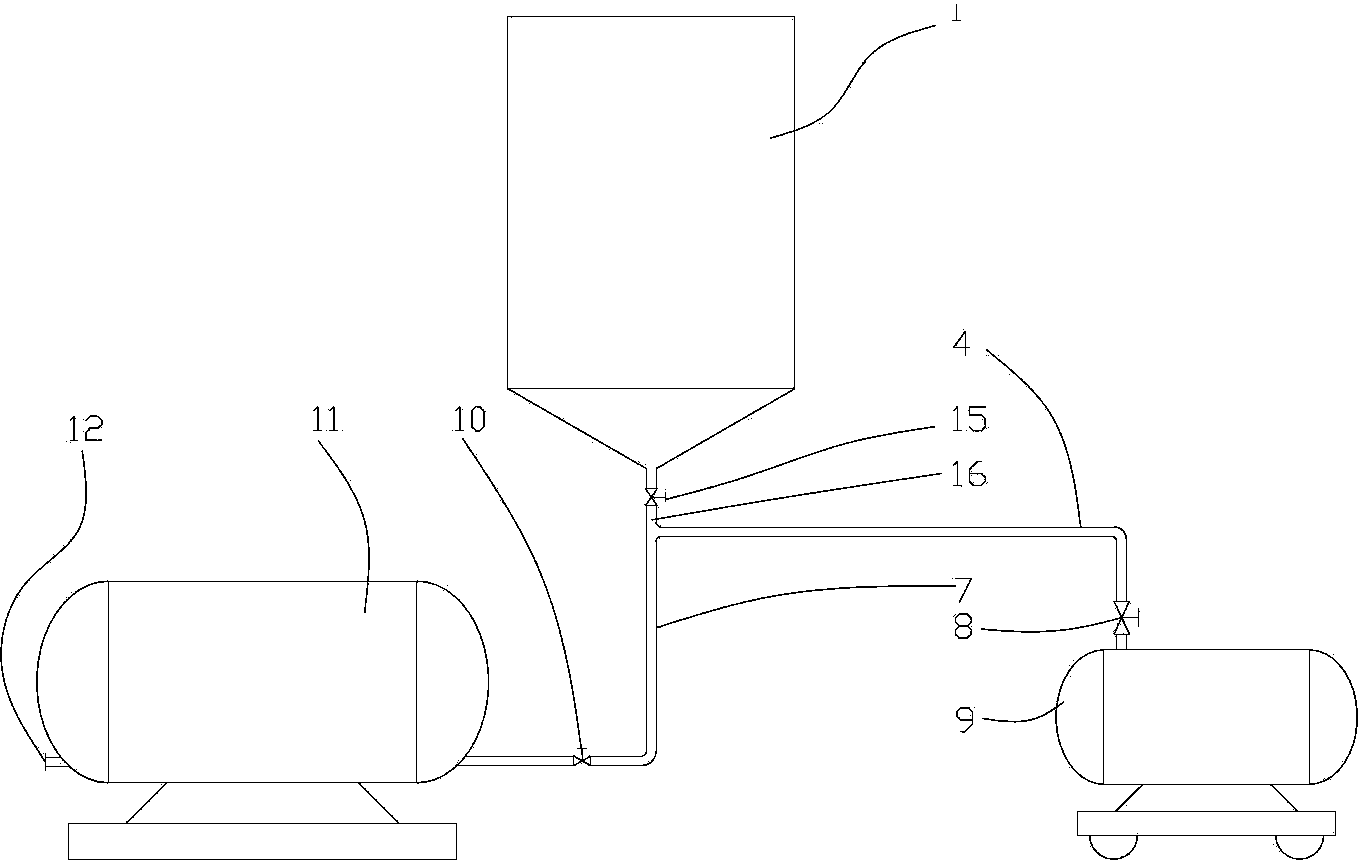

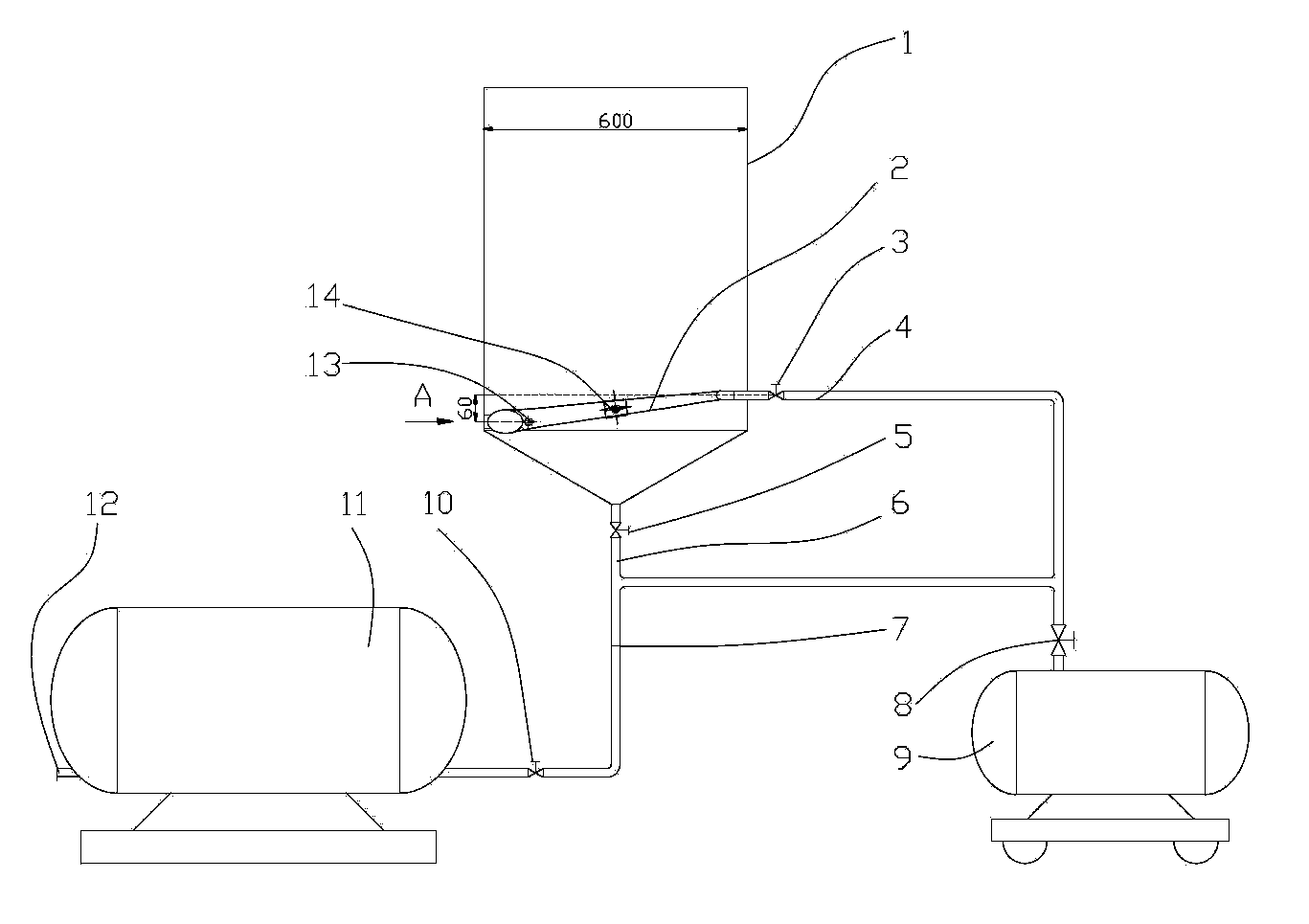

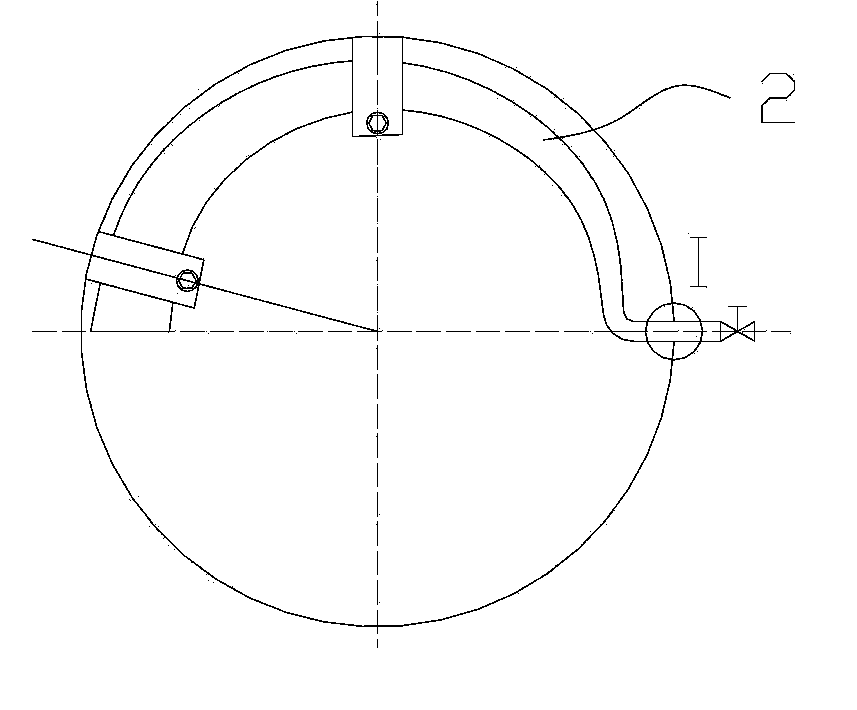

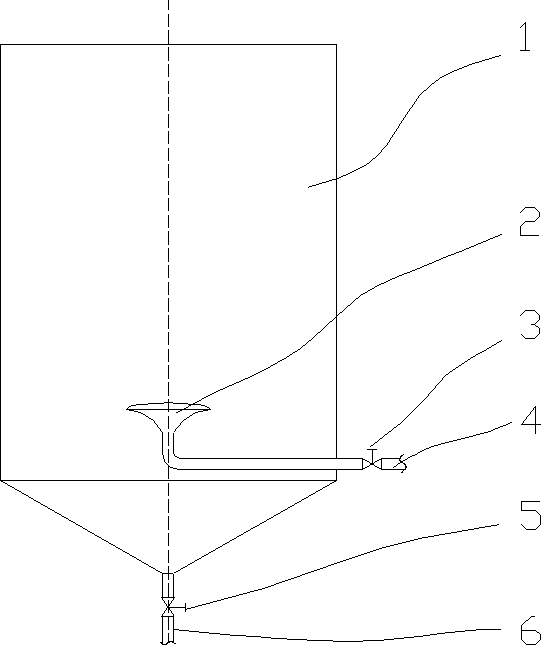

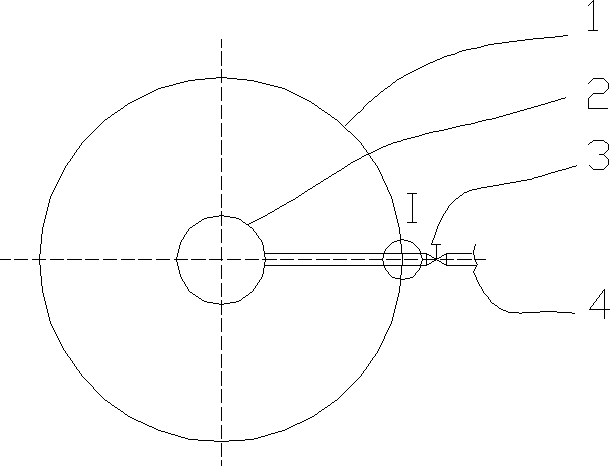

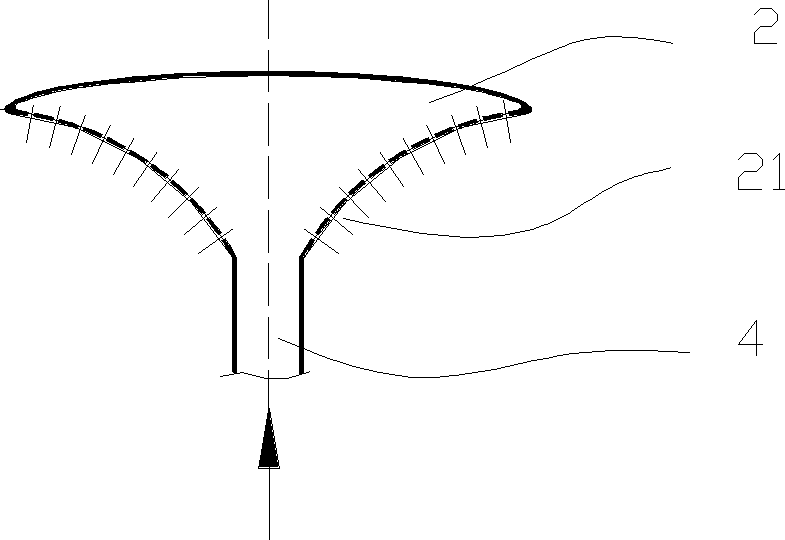

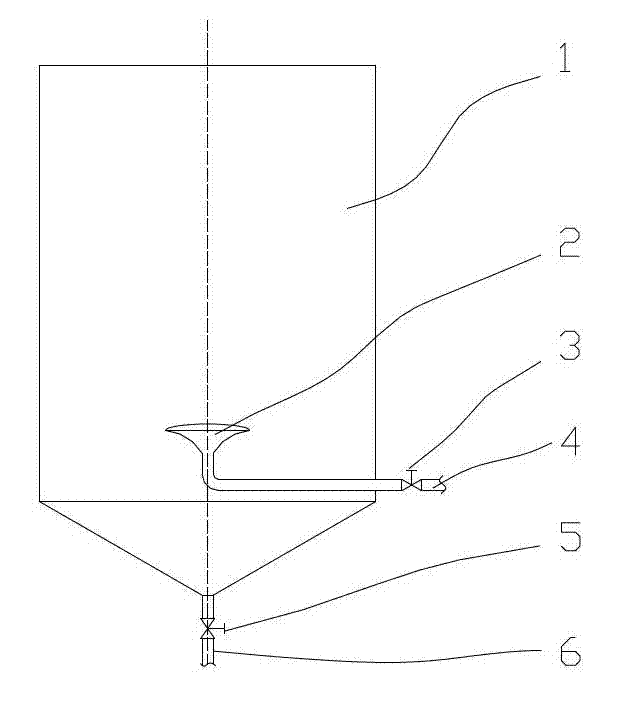

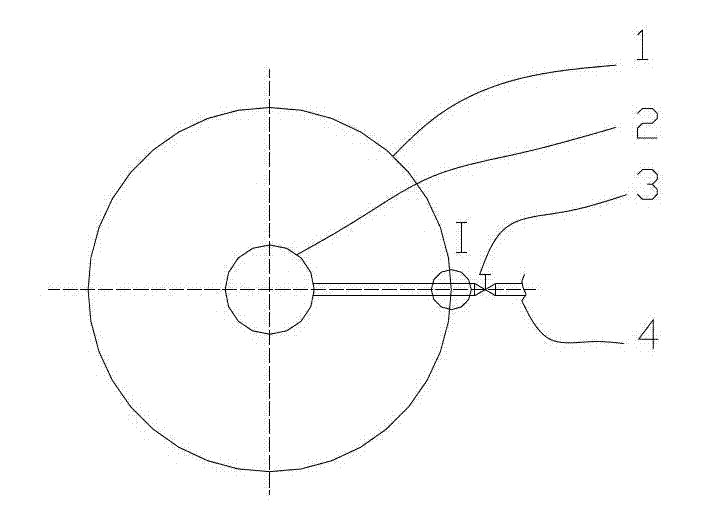

Gas explosion-preventive spiral spray pipe bubbling stirring apparatus

InactiveCN102755852ASimple structureEasy to operateTransportation and packagingMixer accessoriesInlet valveAir compressor

The invention relates to the field of bubbling stirring technology, in particular to a gas explosion-preventive spiral spray pipe bubbling stirring apparatus which comprises a make-up tank, a spiral spray pipe, a gas inlet valve, a gas inlet pipe, a gas outlet valve, a discharge valve, a discharge pipe, a pressure gas inlet feed pipe, a compressed air outlet valve, an air compressor, a pressure tank gas inlet feed valve, a pressure tank, a pressure tank discharge pipe, a spiral spray pipe fixed clamp A, a spiral spray pipe fixed clamp B and a spiral spray pipe fastening device; the spiral spray pipe is arranged at the bottom side part of the make-up tank, the discharge valve is arranged at the taper bottom of the make-up tank, and the spiral spray pipe and the make-up tank are fastened by a fastening nut and a sealing pad; the diameter of the spiral spray pipe is gradually increased after entering the make-up tank, and the spiral spray pipe is spirally downward slanted along with inner arc of the make-up tank; and the make-up tank is internally provided with the spiral spray pipe fixed clamp A13 and the spiral spray pipe fixed clamp B14 which are used for fixing the spiral spray pipes. The gas explosion-preventive spiral spray pipe bubbling stirring apparatus can reduce the gas flow rate through reducing the spiral spray pipe, and can effectively prevent gas explosion phenomenon due to overhigh gas speed, and has the advantages of being long in continuously stirring time, high in efficiency, low in energy consumption, simple in structure, easy to maintain and clean, and low in cost.

Owner:UNIV OF JINAN

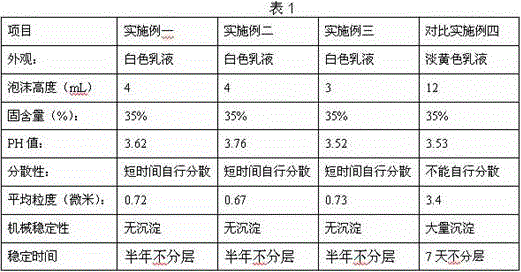

Cation gum rosin and preparing method thereof

InactiveCN106283849AImprove homogeneityImprove stabilityWater-repelling agents additionRosin additionGranularityFiltration

The invention discloses the cation gum rosin and preparing method thereof. The method comprises the steps of 1, putting the mixture of rosin and fortified resin to the reactor and heating it to 150oC for fusion; 2, adding the emulgator one time and turning on the ultrasonic homogenization machine to keep ultrasonic homogenization on the reactant in the reactor for 10-60min; 3, dropping slowly the 80+-2oCpreheating deionized water to the reactor and turning off the ultrasonic homogenization machine after finishing the instillment; 4, reducing the temperature of the material in the reactor to less than 30oC, adding the aluminum salt solution and cold deionized water and adjusting the solid content to 35%. The material gained after filtration is the Cation gum rosin. This invention adds the ultrasonic homogenization technology at the emulsification stage of preparing gum rosin, which maximizes the micronization, emulsification, mixture, even stir and dispersion of the solid particle, such as the rosin in a short time, improves the emulsification efficiency and reduces the production cost, preparing the products with fine granularity, small foam, high whiteness and better stability.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

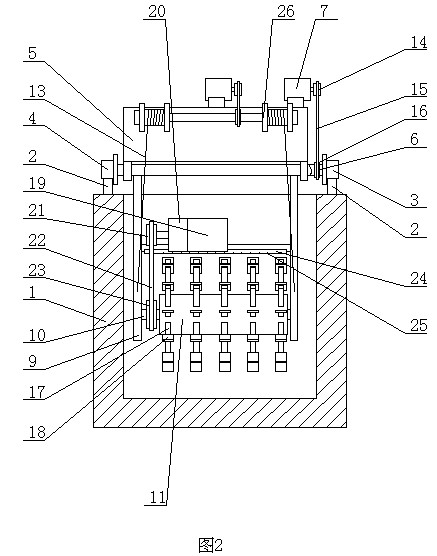

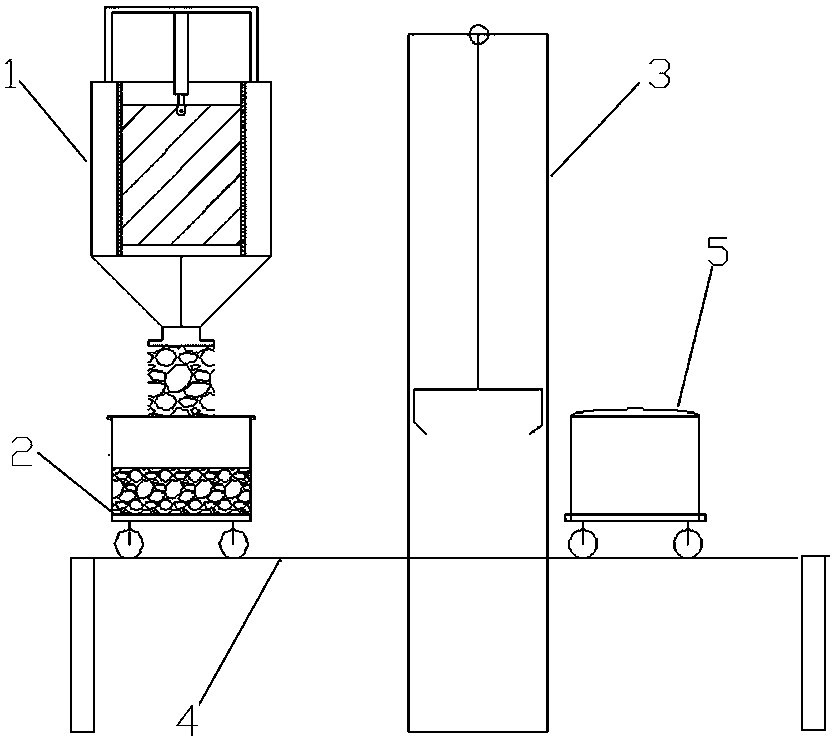

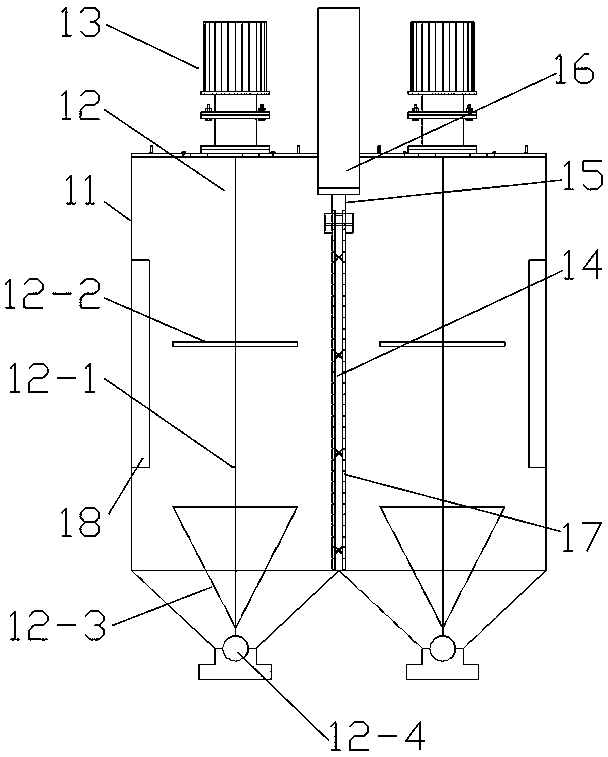

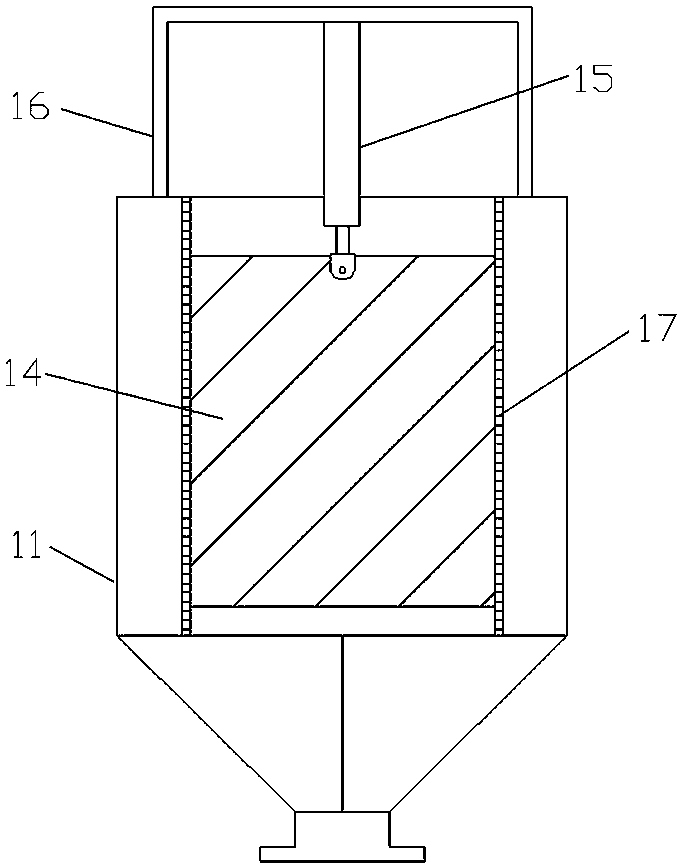

Stirring and forming device assembly and method for producing building block blank body by stirring and forming device assembly

PendingCN109435057AFlexible and free movementReduce manufacturing costDischarging arrangementFeeding arrangmentsFoaming agentEngineering

The invention discloses a stirring and forming device assembly. The stirring and forming device assembly comprises a stirring device for stirring slurry, a forming device for enabling the slurry to befoamed and formed and a grabbing device for separating the forming device from foamed formed building blocks. A mold track is arranged at a discharging outlet of the stirring device, the forming device is slidably mounted on the mold track, and the grabbing device is erected above the mold track. According to the stirring and forming device assembly, the structures of the stirring device, the forming device and a pulling device are separately improved, so that the stock of the foamed building blocks on the same track is greatly increased, and the production efficiency can be nearly doubled. The invention relates to a method for producing a building block blank body. The method for producing the building block blank body comprises the following steps of (1) stirring and preparing the slurry, (2) adding a foaming agent for secondary stirring, (3) foaming and forming, and (4) separating a mold. Two stirring mechanisms can separately stir two independent chambers, so that the stirring effect of the slurry is remarkably improved.

Owner:中创环能建材科技有限公司

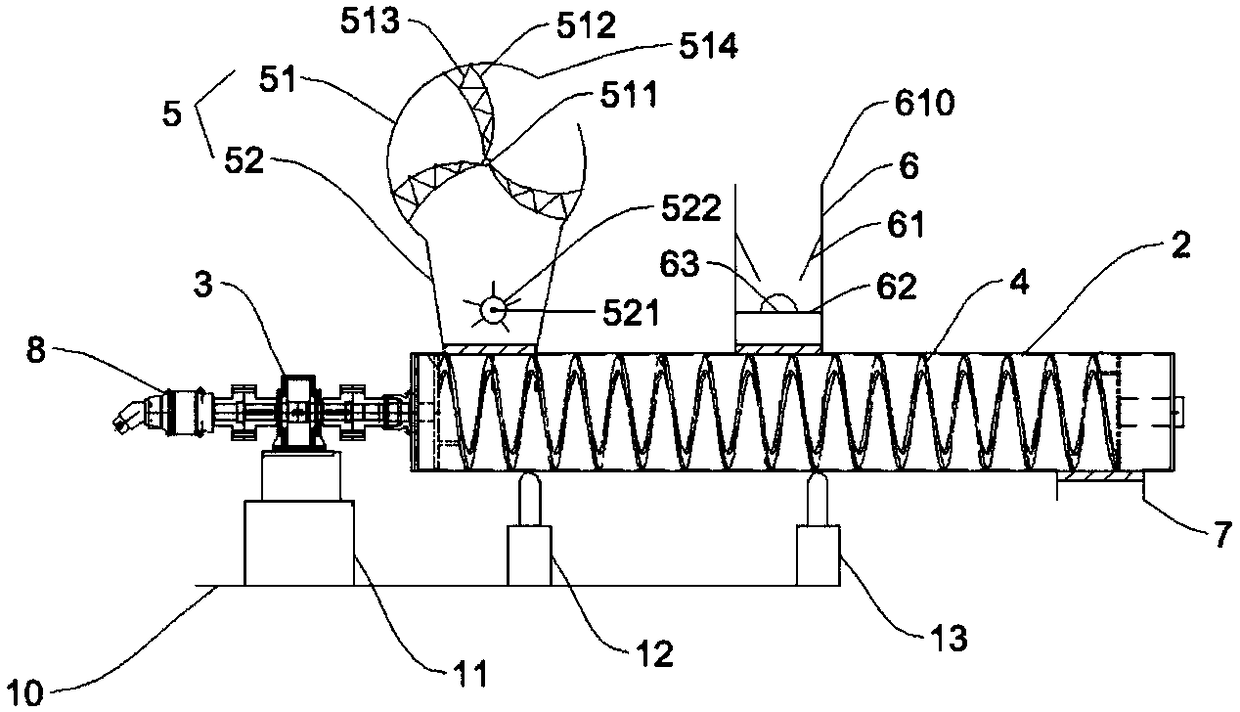

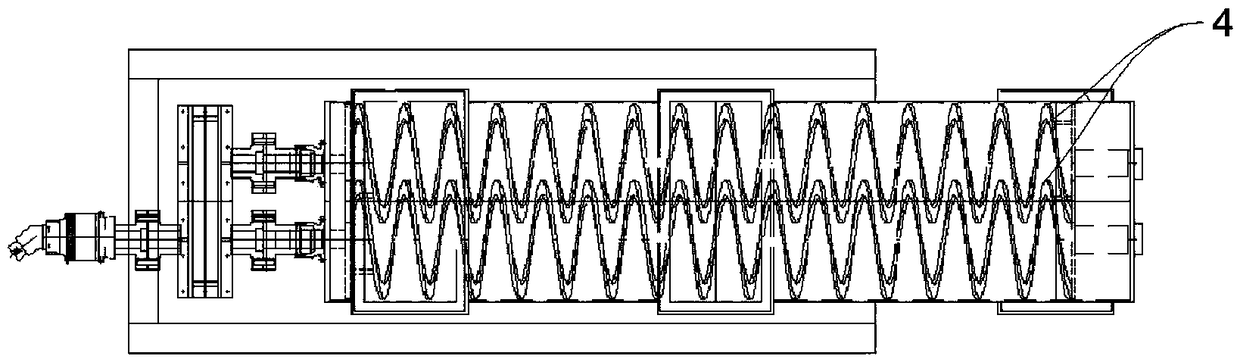

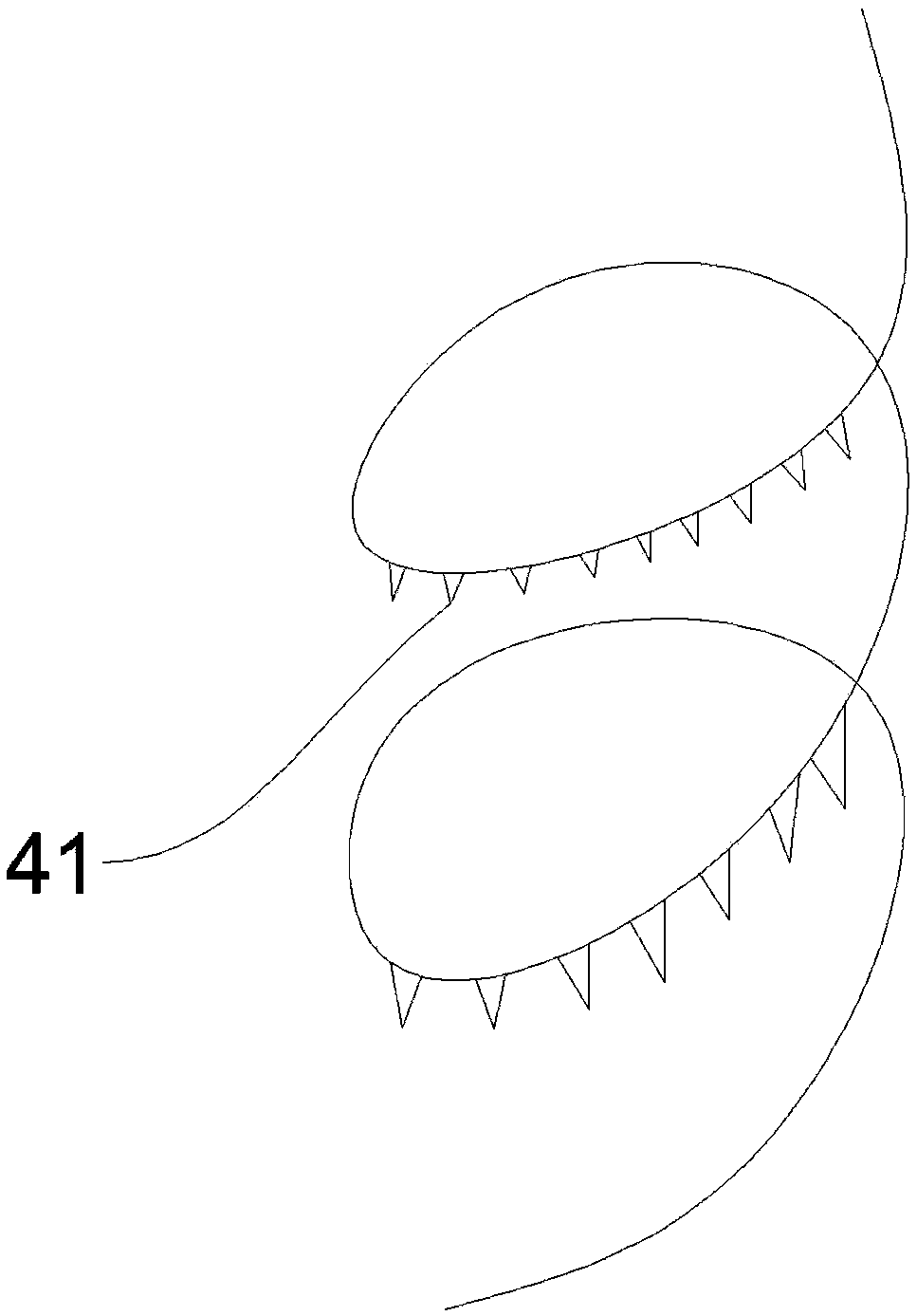

Mixer

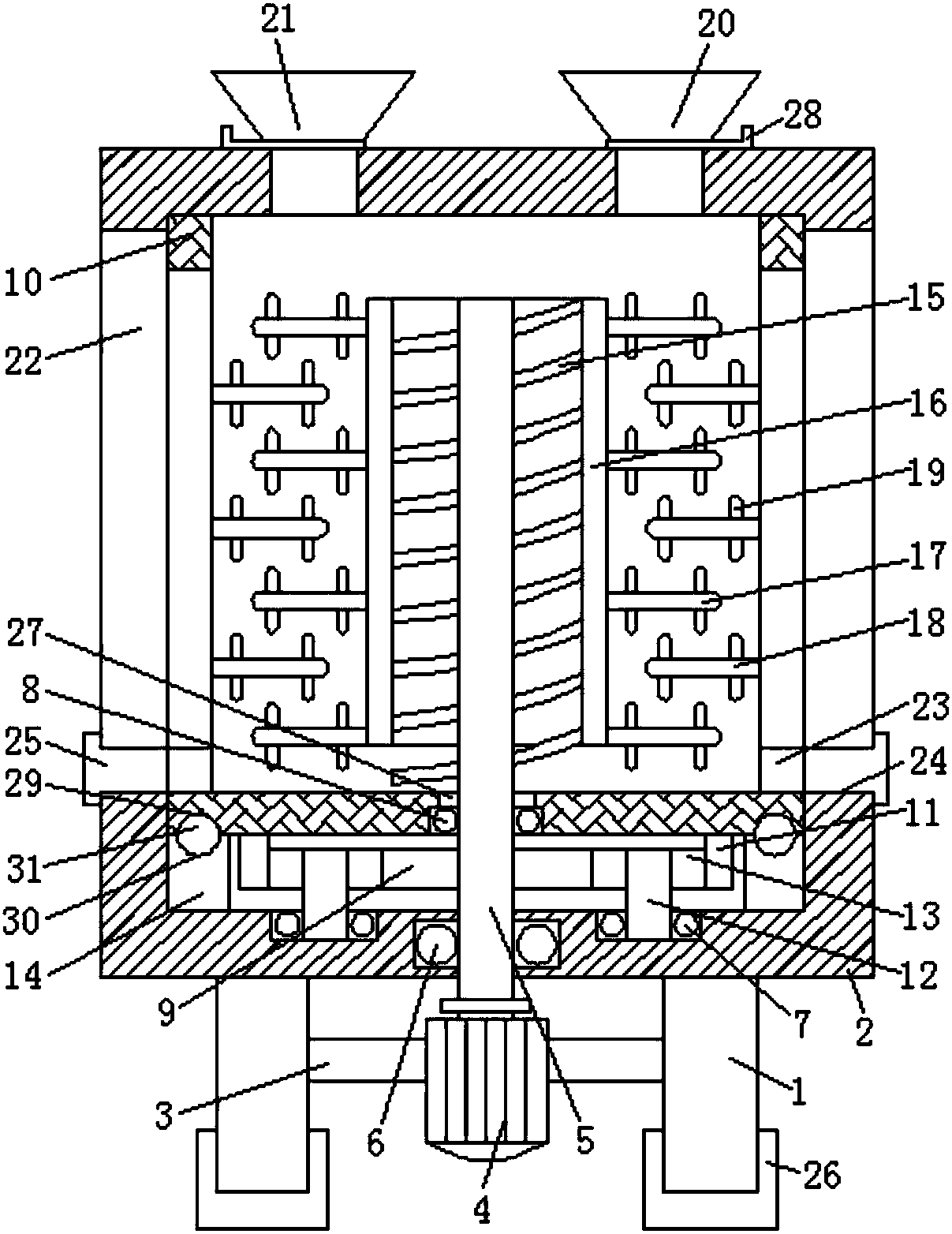

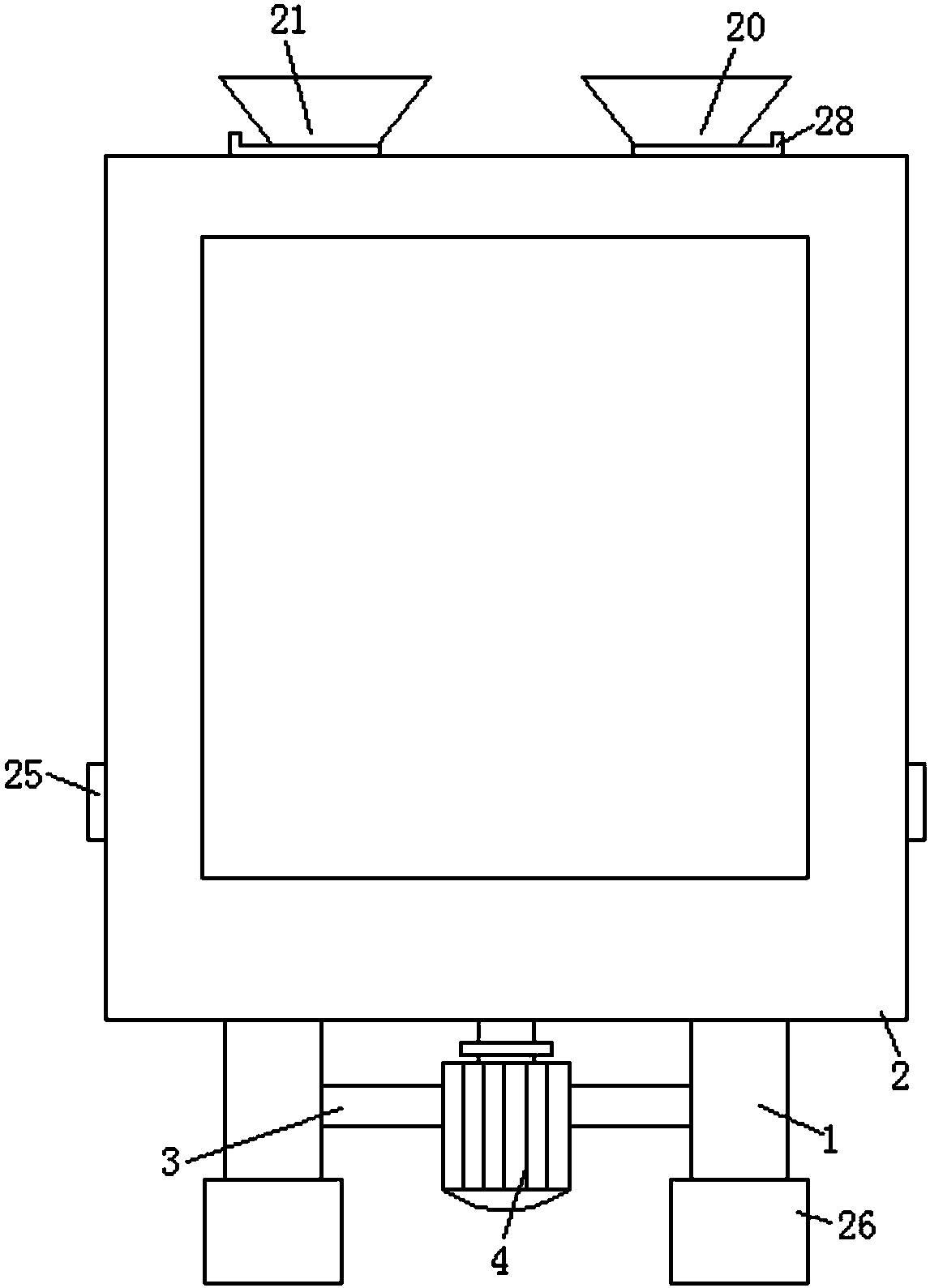

ActiveCN108568234AEasy dischargeWell mixedRotary stirring mixersTransportation and packagingSludgeCoupling

The invention discloses a mixer. The mixer comprises a base, a mixing barrel, a synchronous coupling, a pair of stirring bars, a first feed hopper, a second feed hopper and a discharge hole, wherein the base comprises a bottom plate which is horizontally arranged as well as a first hydraulic telescopic rod, a second hydraulic telescopic rod and a third hydraulic telescopic rod which are verticallyarranged on the bottom plate at equal intervals; the mixing barrel is horizontally arranged above the base along an axial direction; the synchronous coupling is horizontally arranged on the first hydraulic telescopic rod; the pair of stirring bars are horizontally arranged side by side parallel to the axial direction of the mixing barrel; the first feed hopper is arranged above the mixing barreland close to the synchronous coupling; the second feed hopper is arranged above the mixing barrel and close to the first feed hopper; the discharge hole is formed in the side wall of the mixing barrel; and the synchronous coupling is driven by a driving device. The mixer disclosed by the invention can be applied to multiple complicated working conditions of mixing multiple materials such as stripmaterials, fibrous materials, viscous semi-solid materials and sludge, the discharged waste materials can be fully mixed and can be easily incinerated, and few ash residues are produced after incineration.

Owner:北京东方波特蓝环保科技有限责任公司 +1

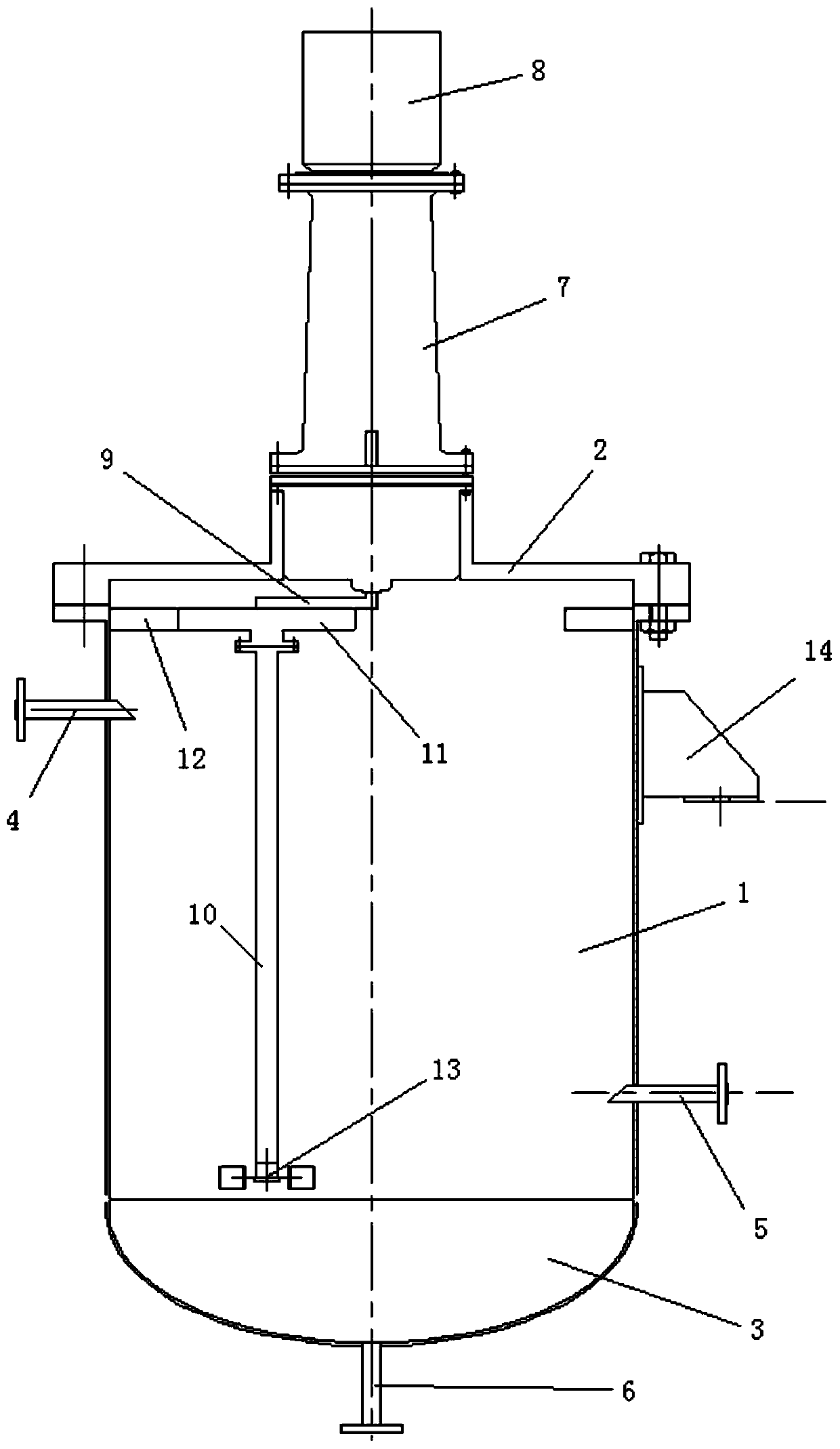

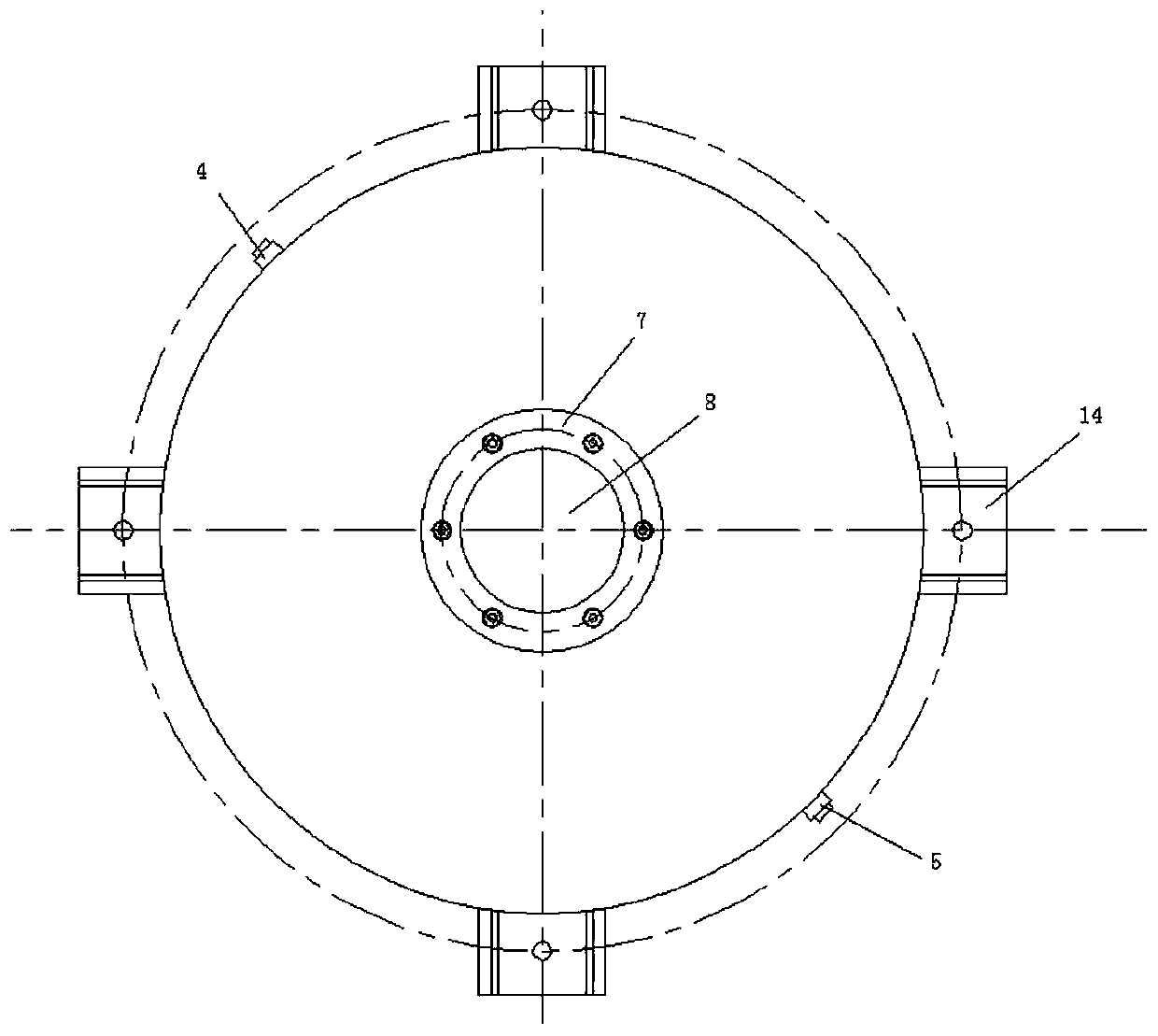

Device for producing liquid cement grinding aid

InactiveCN105709638AEfficient mixingNo stirring dead angleRotary stirring mixersMixing methodsCircular coneCement grinding

The invention relates to a device for producing a liquid cement grinding aid. The device comprises a frame and a tank fixed to the frame. The top of the tank is provided with a feeding inlet. The upper part of the tank is cylindrical, the lower part of the tank is in a shape of a tapered drum, the lower end of the tapered drum is provided with a discharge outlet, a rotation shaft is vertically arranged in the tank, the upper end of the rotation shaft is rotatingly supported in a support beat and is connected to a motor through a belt driving mechanism, the lower end of the rotation shaft is rotatingly supported by a support in the tank, the support comprises support legs and a bearing pedestal fixed to the support legs, each one of the support legs is provided with a bar-type hole allowing a liquid cement grinding aid to go through, the lower end of the rotation shaft is rotatingly supported in the bearing pedestal, the side wall of the rotation shaft is provided with several stirring blades, long edges of the stirring blades extend along a horizontal direction, wide edges of the stirring blades extend inclinedly and form an inclined angle alpha with the horizontal plane. The device can effectively mix various materials and the tank has no stirring blind angle so that product quality is improved.

Owner:CHONGQING JINBO IND GRP

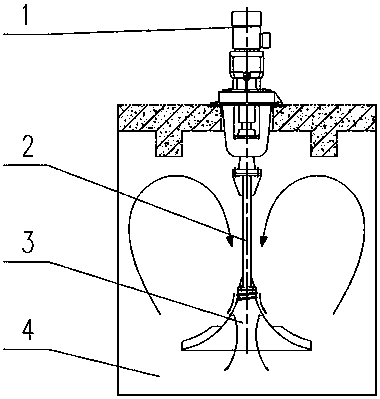

Composite rotary stirring device and working method thereof

ActiveCN110449074ANo stirring dead angleImplement chaotic mixingTransportation and packagingRotary stirring mixersMechanical engineering

Owner:SHANDONG UNIV

Stirrer

InactiveCN104722233ASimple structureEasy to installTransportation and packagingMixersGas compressorInlet valve

The invention provides a dead-angle-free stirring reactor and relates to the technical field of a reaction kettle. The stirrer comprises an air bubble stirrer, foam overflowing holes, an air inlet valve, an air inlet pipe and an air compressor, and is characterized in that the air bubble stirrer is in the shape of a reversed cone; the foam overflowing holes are formed in the side face of the cone of the air bubble stirrer; the top of the cone of the air bubble stirrer is connected with the air inlet pipe; the air inlet pipe is provided with the air inlet valve; and the air inlet valve is connected with the air compressor. The side face of the cone of the air bubble stirrer is an arc surface which is concave inwards. The foam overflowing holes with the equal pore diameter of 2mm-5mm are formed in the side face of the cone of the air bubble stirrer. The dead-angle-free stirring reactor has the characteristics of simple structure, convenience for installation, convenience for maintenance and low power consumption.

Owner:薛应东

Milk cow forage stirring device

ActiveCN106000167AReduce nutrient lossImprove efficiencyRotary stirring mixersTransportation and packagingAnimal ForagingNutrition

The invention relates to a milk cow forage stirring device. The milk cow forage stirring device comprises a stirring tank. A stirring shaft is arranged in the stirring tank. A spiral paddle is arranged on the stirring shaft. A turning paddle located below the spiral paddle is arranged on the stirring shaft. The turning paddle stretches to the edge of the bottom of the stirring tank from the stirring shaft. Screening teeth are evenly distributed on the inner wall of the stirring tank, and screen holes are formed in the tooth surfaces of the screening teeth. A low-temperature interlayer is arranged on the outer ring of the stirring tank, and a heat insulating layer is arranged on the outer ring of the low-temperature interlayer. According to the milk cow forage stirring device, impurities left in forage can be screened out while the forage is stirred in the stirring tank, efficiency is improved, and cost is reduced; the forage on the edge of the bottom of the stirring tank can be turned up by the turning paddle, and no stirring dead corner is left; through the arrangement of the low-temperature interlayer, nutrition loss caused by high-temperature damage to the forage can be relieved.

Owner:湖北俏牛儿牧业有限公司

Continuous stirring device for cloth dyeing liquid

PendingCN109056252ALarge mixing rangeIncrease stirring speedTextile treatment machine arrangementsDyeingEngineering

The invention discloses a continuous stirring device for cloth dyeing liquid. The device comprises a stirring barrel with an opening in the upper portion, the portion, close to the opening, of the stirring barrel is provided with a circle of bosses, a circle of an inner ring of each boss is provided with an inner gear ring, a rolling ball is limed at the upper portion of each boss, a rotating plugis installed above the bosses, rotating shafts are arranged on the lower surface of the rotating plug and provided with gears meshed with the inner gear rings, and the lower end of each rotating shaft is provided with a stirring piece. Compared with the prior art, the continuous stirring device for the cloth dyeing liquid has the advantages that through the overall rotation of the rotating plug and the self-rotation of the stirring pieces, the double-stirring function is achieved to irregularly stir the dyeing liquid in the stirring barrel, the stirring range is wide, the stirring speed is high, the mechanization degree is high, the better effect of mixing the cloth dyeing liquid with various auxiliary material proportions is achieved, and the color and luster quality of the dyeing liquidis better.

Owner:YI HE STOCK

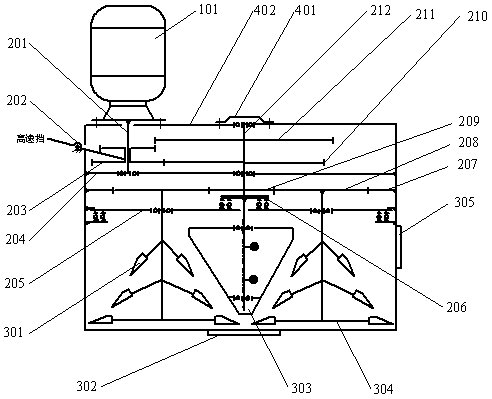

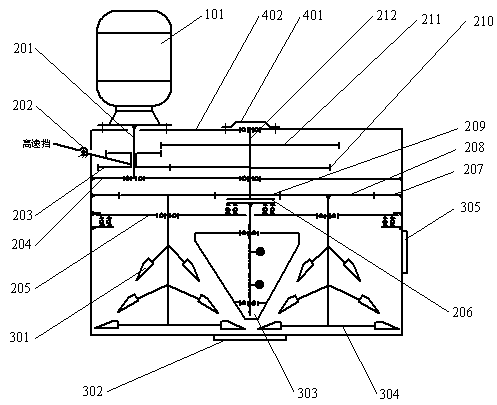

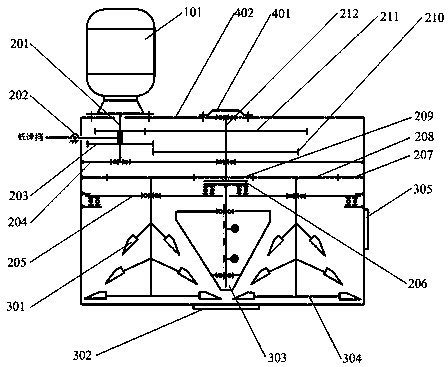

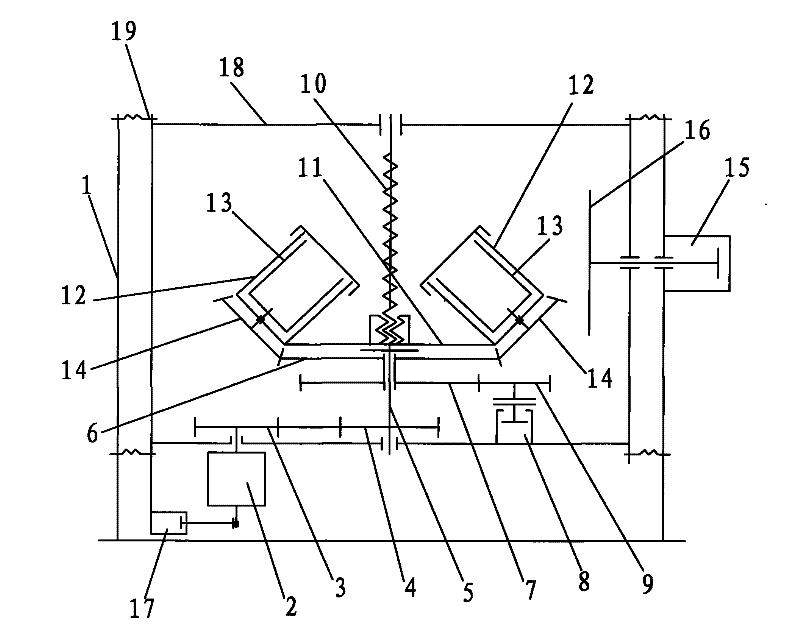

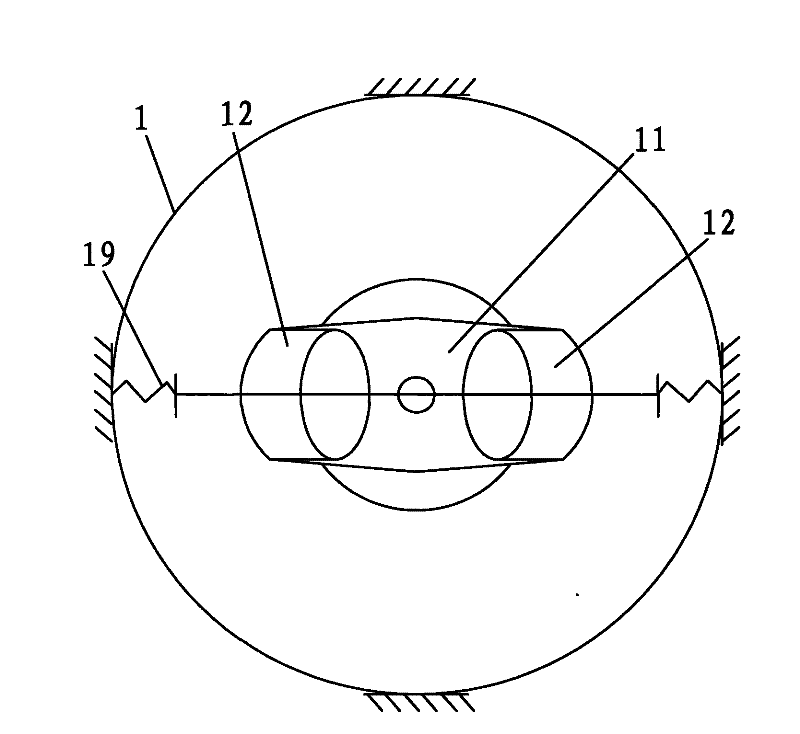

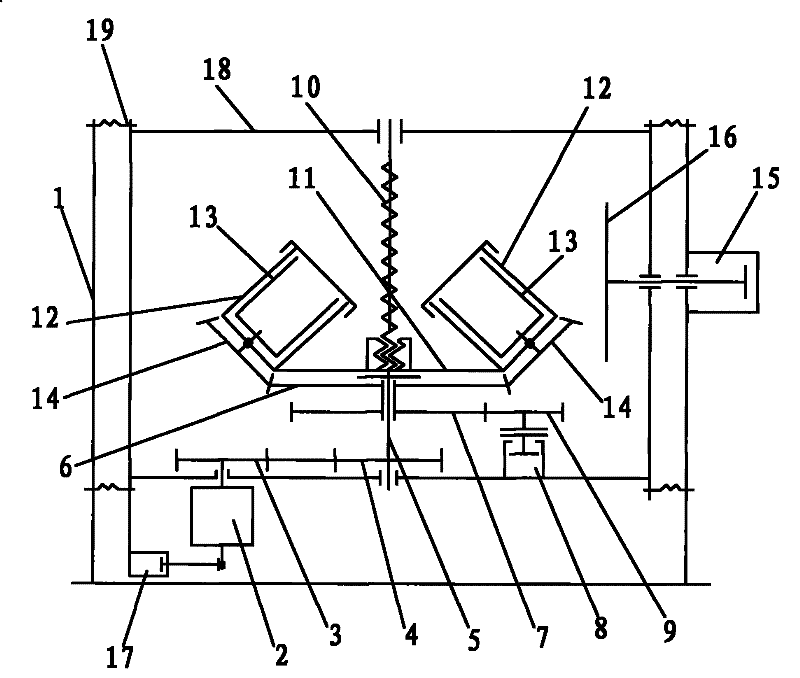

Novel vertical shaft type planetary mixer with balance vibration exciter

InactiveCN107813424AMix well and evenlyEfficient and high-quality outputCement mixing apparatusHydration reactionCoupling

The invention discloses a mixer product which has two stirring operation speeds of high and low speeds, two operation modes with or without vibration controllable and a plurality of stirrers operating simultaneously. It is characterized in that it has a shifting mechanism, two high and low speed ratio gears, a clutch and a balance exciter, a planetary transmission mechanism composed of planetary gear pairs, and a fixed connection between the agitator and the planetary gear of the planetary transmission mechanism. The purpose of the invention is to solve the existing production quality problems of mortar concrete and cement slurry (especially foamed cement slurry). The advantages of the present invention are mainly manifested in the following aspects: high and low working speeds can be controlled to meet the different application requirements of the mixing operation and the cement hydration reaction operation in the slurry pouring process, and the operation with or without excitation can be controlled to meet The application needs of different working conditions such as before and after mixing with or without foaming agent, normal slurry mixing operation and slurry pouring process to ease the cement hydration reaction operation.

Owner:吉林省田舍建筑材料研发制造有限公司

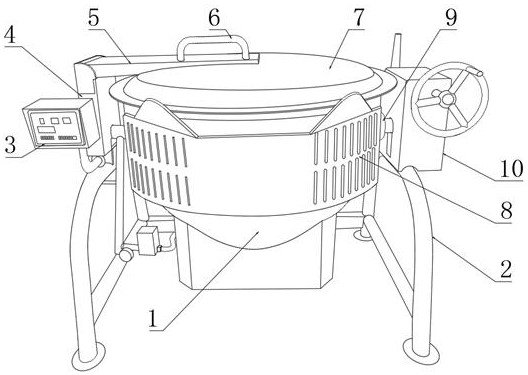

Intelligent control automatic cooker

ActiveCN112716266ANo stirring dead angleStir wellCooking insertsTime-controlled ignitorsTemperature controlElectric machinery

The invention discloses an intelligent control automatic cooker.The automatic cooker comprises a pot body, a pot frame is installed outside the pot body, a temperature control box is installed on one side of the top end of the pot frame, a supporting plate is installed at the position, corresponding to the temperature control box, of one side of the top end of the pot frame, a connecting plate is rotatably connected to the top end of the supporting plate, a pull rod is installed at the top end of one end of the connecting plate, a pot cover is installed at the bottom end of one end of the connecting plate, the pot body is sleeved with an external heat preservation cylinder, and rotating shafts are symmetrically installed on the outer end face of the pot body. By arranging a stirring motor, a stirring rod, a connecting cross rod, an arc-shaped rod, a connecting block, a rotating hole, a limit shaft, a clamping plate and a scraping plate, the stirring motor drives the arc-shaped rod and the scraping plate in the pot to rotate in the pot to stir and mix internal food materials, so that the internal food materials are stirred more uniformly, the scraping plate makes full contact with the pot body, the attachment degree is high, no stirring dead angle exists in the pot, bottom scraping is more thorough, and the pot pasting phenomenon is not likely to happen.

Owner:江门市永成厨具设备有限公司

Agitated reactor without dead angle

InactiveCN103418322ASimple structureEasy to installTransportation and packagingMixersInlet valveCircular cone

The invention discloses an agitated reactor without a dead angle, and belongs to the technical field of reaction kettles. The agitated reactor without the dead angle comprises a reactor body, a bubble agitator, an air inlet valve, an air inlet pipe, an air compressor, a discharging pipe, a discharging valve and bubble overflowing holes. The agitated reactor without the dead angle is characterized in that the reactor body is a cone-base reactor, the bubble agitator is of an inverted-cone shape, the bubble overflowing holes are formed in the side face of a conical body of the bubble agitator, the bubble agitator is arranged at the bottom of the reactor body, the conical top of the bubble agitator is connected with the air inlet pipe, the air inlet valve is installed on the air inlet pipe, the air inlet valve is connected with the air compressor, the conical side face of the bubble agitator is an inwards-concave cambered surface, the equal-hole-diameter bubble overflowing holes are formed in the conical side face of the bubble agitator, the diameter of each bubble overflowing hole is 2-5mm, and the bubble overflowing holes are evenly distributed along the inwards-concave side face of the conical body. The agitated reactor without the dead angle has the advantages of being simple in structure, convenient to install and maintain and low in power consumption.

Owner:薛应东

Stirrer

InactiveCN101579607BAvoid pollutionEasy to take outRotating receptacle mixersTransportation and packagingLine shaftPulp and paper industry

The invention discloses a stirrer, which comprises a machine frame, wherein the machine frame is provided with a motor which is connected with a driving synchronous belt wheel through a driven synchronous belt wheel and a synchronous belt and has a main shaft which is connected with the shaft sleeve of the driven synchronous belt wheel, and the main shaft is also sleeved with integrally connectedupper and lower gears; the machine frame is also provided with a pneumatic clutch and a transmission gear meshed with the lower gear, the surface of the main shaft is provided with threads, a socket platform is sleeved on the threads, a revolution tank and a rotation tank are fixed on the left and right sides of the socket platform respectively, the lower part of the rotation tank is connected with a pinion through a connecting shaft, and the pinion is meshed with the upper gear; and the machine frame is provided with an air cylinder and the front end of the air cylinder is connected with a baffle plate. The stirrer is reasonable in structure and convenient in use and can uniformly stir materials, avoid generating air bubbles, eliminate air bubbles and be used in fields of electronics, chemical, light manufacturing, food, medicine, building materials, farm chemical and the like for mixing, dispersing and other processing of materials.

Owner:佛山市恒之芯复合材料有限公司

Gas explosion-preventive spiral spray pipe bubbling stirring apparatus

InactiveCN102755852BAvoid gas explosionImprove efficiencyTransportation and packagingMixer accessoriesInlet valveGas explosion

The invention relates to the field of bubbling stirring technology, in particular to a gas explosion-preventive spiral spray pipe bubbling stirring apparatus which comprises a make-up tank, a spiral spray pipe, a gas inlet valve, a gas inlet pipe, a gas outlet valve, a discharge valve, a discharge pipe, a pressure gas inlet feed pipe, a compressed air outlet valve, an air compressor, a pressure tank gas inlet feed valve, a pressure tank, a pressure tank discharge pipe, a spiral spray pipe fixed clamp A, a spiral spray pipe fixed clamp B and a spiral spray pipe fastening device; the spiral spray pipe is arranged at the bottom side part of the make-up tank, the discharge valve is arranged at the taper bottom of the make-up tank, and the spiral spray pipe and the make-up tank are fastened by a fastening nut and a sealing pad; the diameter of the spiral spray pipe is gradually increased after entering the make-up tank, and the spiral spray pipe is spirally downward slanted along with inner arc of the make-up tank; and the make-up tank is internally provided with the spiral spray pipe fixed clamp A13 and the spiral spray pipe fixed clamp B14 which are used for fixing the spiral spray pipes. The gas explosion-preventive spiral spray pipe bubbling stirring apparatus can reduce the gas flow rate through reducing the spiral spray pipe, and can effectively prevent gas explosion phenomenon due to overhigh gas speed, and has the advantages of being long in continuously stirring time, high in efficiency, low in energy consumption, simple in structure, easy to maintain and clean, and low in cost.

Owner:UNIV OF JINAN

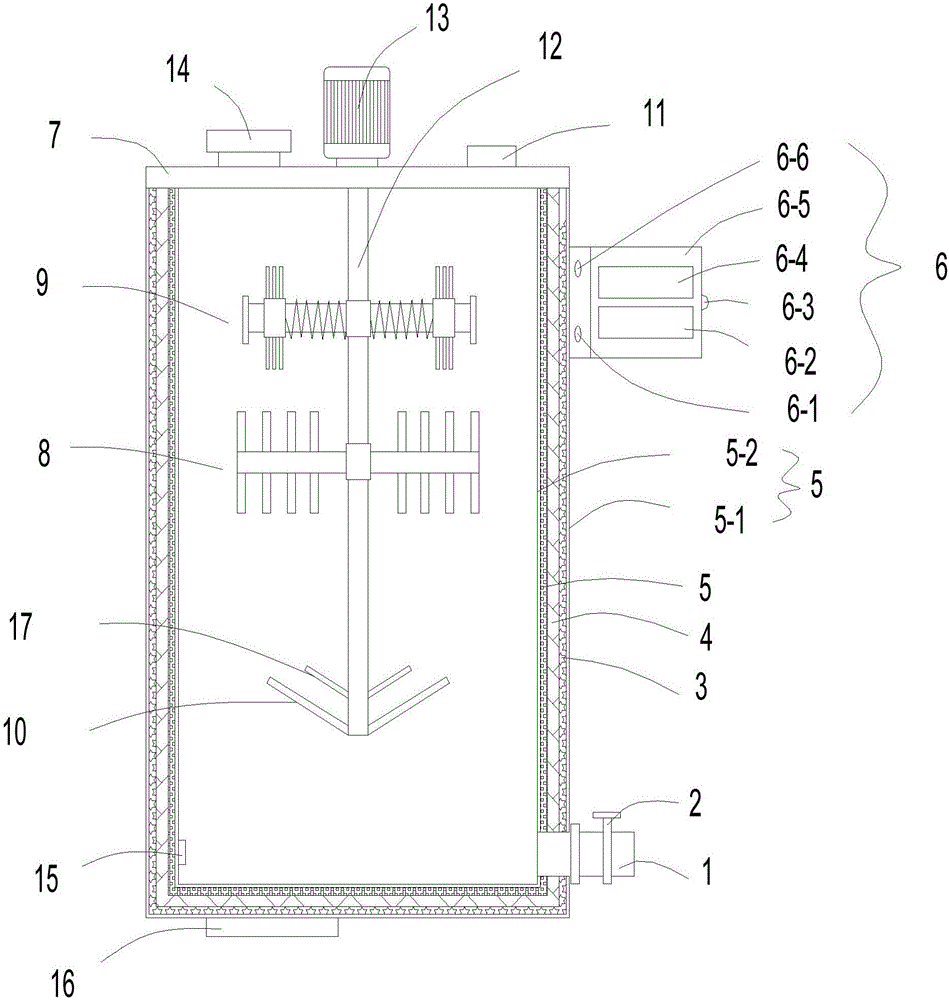

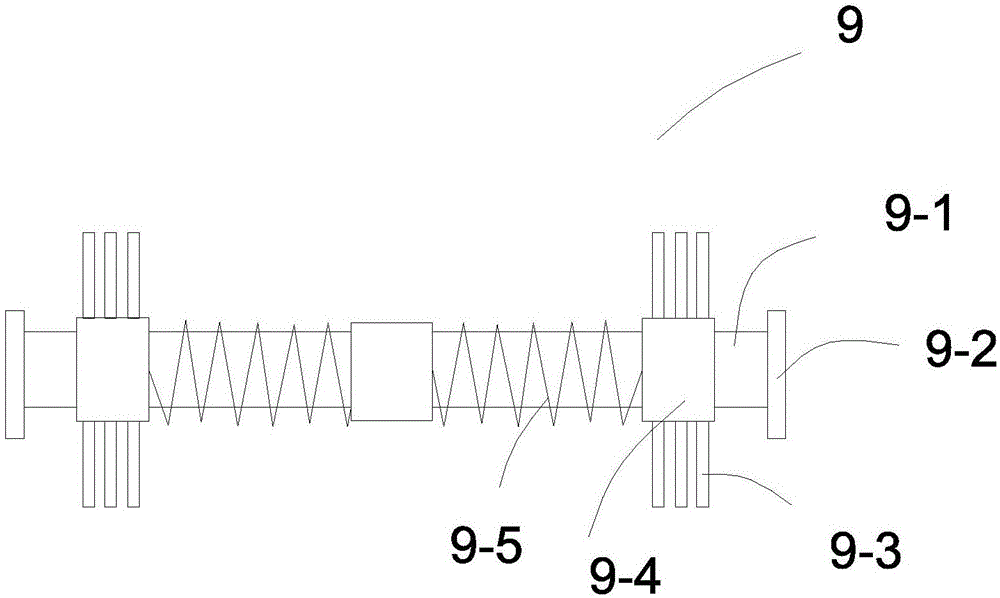

An efficient and environmentally friendly concrete preparation equipment

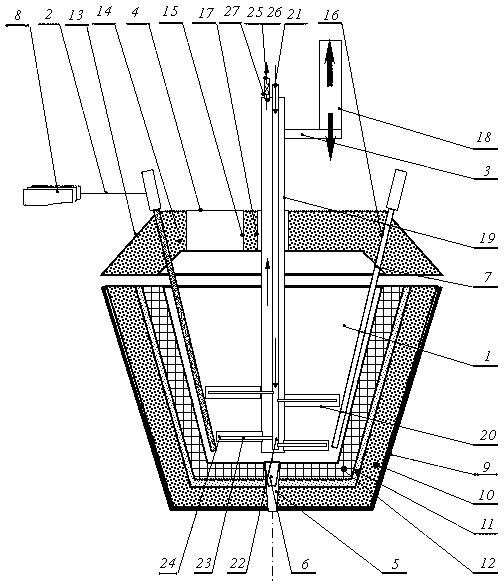

ActiveCN109366730BReduce consumptionStir wellUsing liquid separation agentMixing operation control apparatusDust controlElectric machinery

The invention discloses efficient environment-friendly concrete production equipment. The efficient environment-friendly concrete production equipment comprises a concrete foundation, a stirring tank,a stirring motor support, a stirring motor, a stirring tank hanging ring, a feeding opening, a stirring tank exhaust opening, stirring tank pillar feet, a discharging opening, a water inlet pipe, a stirring rod, an isolation plate block, a stirring rod rotating shaft, mixing paddles, fist stirring paddles, second stirring paddles, a dedusting tank, dedusting tank pillar feet, an air inlet pipe, aconnection draught fan, a dedusting tank exhaust pipe, a cloth bag, a dedusting tank discharge pipe, a dedusting tank discharge pipe valve, a dedusting tank drainage pipe, a dedusting tank drainage pipe valve, a water collection tank, a water collection tank discharge pipe, a water collection tank discharge pipe valve, circulating water pump supports, a circulating water pump, a circulating waterpipe, first spray pipes, first spray pipe nozzles, second spray pipes, second spray pipe nozzles and spray pipe connecting pipes. By means of the efficient environment-friendly concrete production equipment, pre-stirring can be conducted on raw materials; stirring is conducted uniformly, the stirring time is short, and the stirring efficiency is high; no stirring dead corner exists; dedusting treatment can be conducted on the equipment; dedusting efficiency is high; and the equipment is high in environment protection performance.

Owner:中耕耘成建筑科技(镇江)有限公司

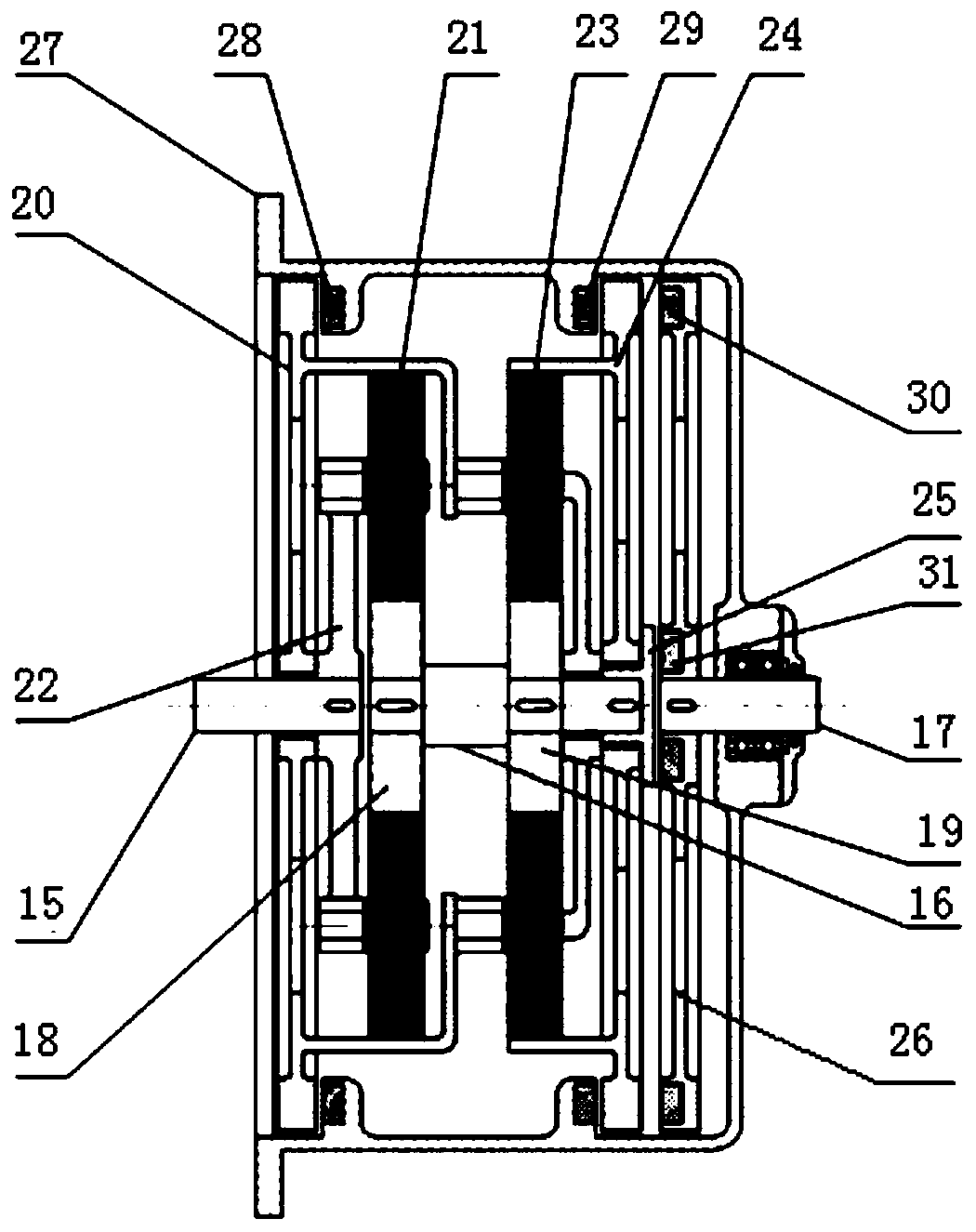

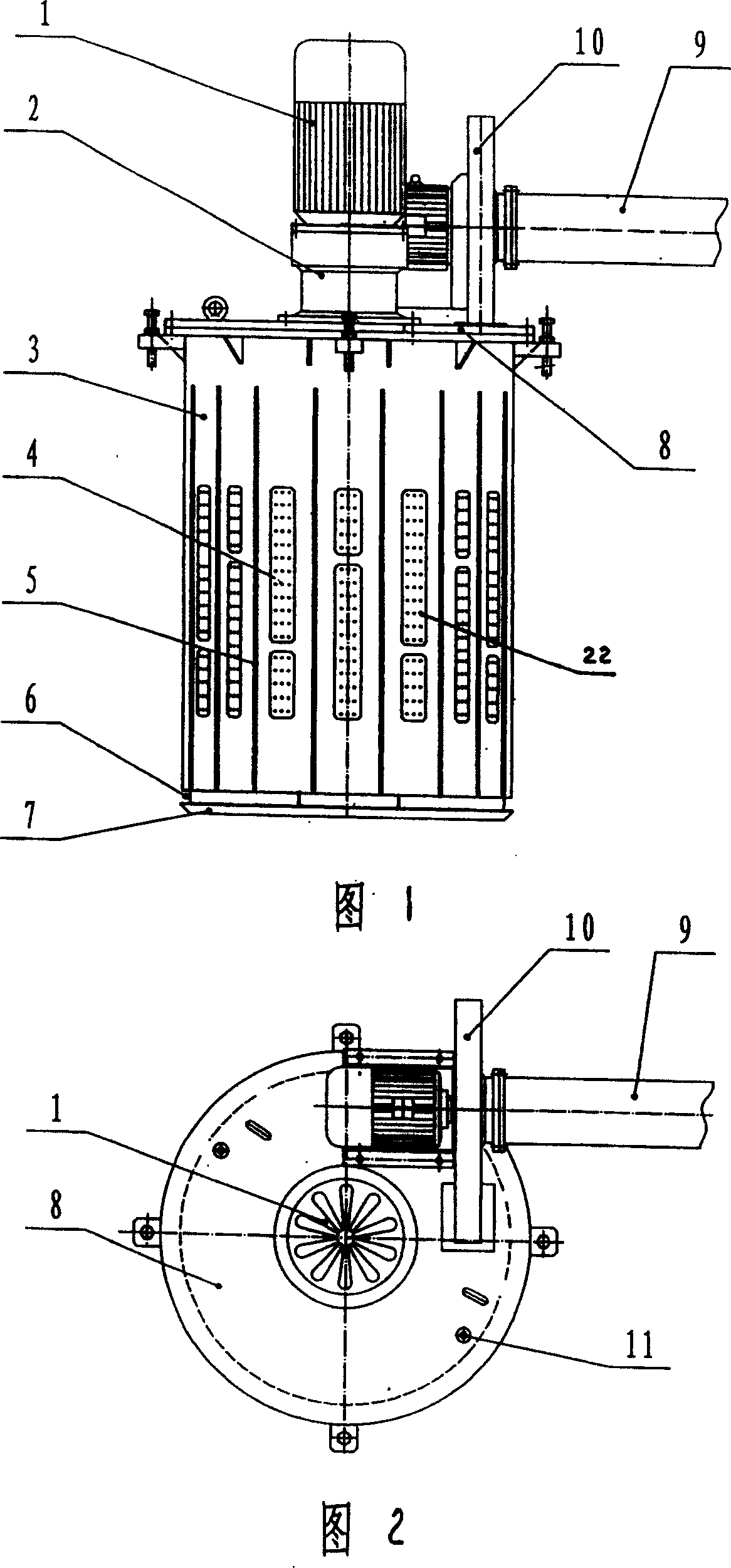

Circulation type permanent magnetic stirrer

The invention relates the circulating magnetic stirrer. The inductor comprises chassis, enclosing cover and upper cover, the revolution axis on the chassis is through inductor, the motor and speed reducer direct axis are connected with out end of revolution axis, the draught fan is connected with the upper cover, the permanent magnet inducer is fixed in the inducer cavity, thermal resistance windows are installed on the enclosing cover, the board insulations are on the thermal resistance windows, on the board insulation there are holes, between thermal resistance windows there are wind-guiding bar, the chassis comprises outer bottom and inner bottom, between outer bottom and inner bottom there are bars which divides the chassis to form air-out grooves, and on every air-out grooves there are inner bottom air outlet. The device has the advantages of saving energy, good heat dissipation effect and long life.

Owner:SHANDONG HUATE MAGNET TECH

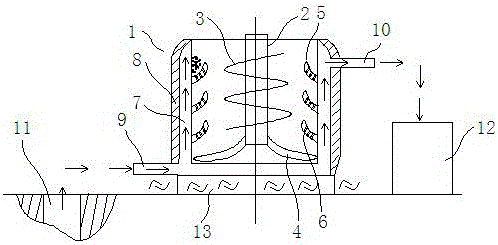

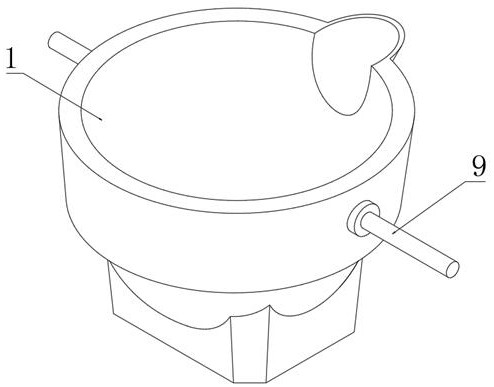

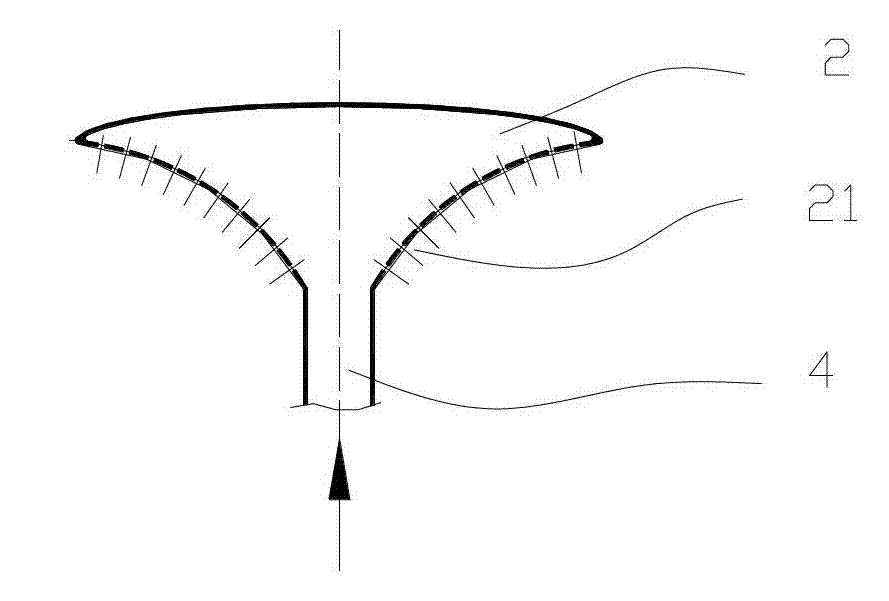

Circular inverted cone type bubbling stirred tank reactor

InactiveCN102824882BAchieving stirringNo stirring dead angleChemical/physical processesInlet valveEngineering

Owner:UNIV OF JINAN

Circular inverted cone type bubbling stirred tank reactor

InactiveCN102824882AAchieving stirringNo stirring dead angleChemical/physical processesInlet valveMechanical engineering

The invention relates to the technical field of bubbling stirred tank reactors. A circular inverted cone bubbling stirred tank reactor provided by the invention comprises a reaction kettle, a circular inverted cone bubbler, an inlet valve, an air inlet pipe, a discharge valve, a discharging pipe, bubbling holes, a connecting device, etc. The circular inverted cone bubbler is installed at a central part at the lower part of the reaction kettle and is connected with the air inlet pipe; the air inlet pipe is provided with the inlet valve; the bottom of the reaction kettle is connected with the discharging pipe, and the discharging pipe is provided with the discharge valve; the circular inverted cone bubbler is provided with N bubbling holes with varying directions; the external surface of the circular inverted cone bubbler is in a streamline shape, flowing resistance of a fluid is small, the moving trajectory of agitated bubbles is long, continuous stirring effects last for a long time, and high stirring efficiency is obtained; the bubbling holes are located at the lower part of a circular inverted cone, and bubbles move along an inclined downward direction at first and act on the bottom of the reaction kettle, leaving no stirring dead angle.

Owner:UNIV OF JINAN

Domestic kitchen waste collection and treatment system

ActiveCN103624061BClassification works wellClassification works adequatelySolid waste disposalWater dischargeRefuse collection

The invention relates to a collecting and treating system of domestic and kitchen garbage. The collecting and treating system is characterized by comprising a garbage collecting barrel and a garbage treating device, wherein the garbage treating device comprises a closed case; the case is internally provided with a container for containing the kitchen garbage and carrying out biological reaction; the container is internally provided with a stirring device for stirring the kitchen waste entering the container; the lower part of the container is provided with a residue discharging port and a water discharging port communicated with a circulating water tank; the upper part of the container is provided with an exhaust fan, and an exhaust port of the exhaust fan is communicated with a biological deodorization device; a bottom plate of the case is provided with a discharging door cover, and a discharging drawer for receiving discharged garbage is arranged under the discharging door cover; and the output end of the control system is respectively connected with an automatic closing device, a stirring device and a clutch. The collecting and treating system provided by the invention has the advantages that the sorted placement of the garbage can be forcibly realized and smooth conduction of sorting working of the garbage is guaranteed.

Owner:ZHEJIANG DEAN TECH

Precious metal stirring and mixing device

ActiveCN112169664BReduce weightWell mixedRotating receptacle mixersTransportation and packagingEngineeringTop cap

The invention belongs to the technical field of stirring equipment, and specifically discloses a precious metal stirring and mixing device, which includes a top cover, a bottom support plate, an outer cylinder, an inner cylinder, a first lifting power cylinder and a rotating part, and the bottom support plate is located under the top cover , the outer cylinder is fixedly connected to the lower surface of the top cover, the inner cylinder is placed on the upper surface of the bottom support plate, the outer cylinder is sleeved outside the inner cylinder, and a second gap is left between the inner cylinder and the outer cylinder. Mixing chamber; the vertical distance from the lower surface of the outer cylinder to the upper surface of the bottom support plate ≥ the vertical distance from the upper surface of the inner cylinder to the lower surface of the top cover; the inner cylinder is provided with a discharge material that can slide along the center line of the inner cylinder plate. The noble metal stirring and mixing device provided by the invention has a long service life and no dead angle of stirring.

Owner:泸西县扩铂贵金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com