Stirring device

A stirring device and driving device technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of poor stirring effect at the bottom of the tank, affecting the balance of the impeller, and large winding of the transmission shaft, etc., to achieve Eliminate the stirring dead zone, no stirring dead zone, and improve the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

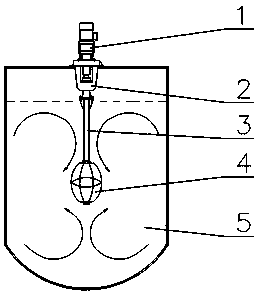

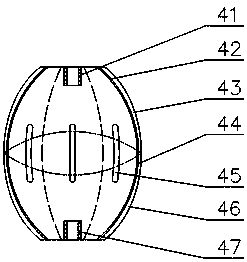

[0020] Such as figure 1 and figure 2 As shown, a stirring device according to an embodiment of the present invention includes a driving device 1, a transmission shaft 3 and a lantern-shaped impeller 4, one end of the transmission shaft 3 is connected to the driving device 1, and the other end of the transmission shaft 3 is connected to the impeller 4 .

[0021] In the stirring device of this embodiment, the impeller 4 is set in a lantern shape, so that when the impeller 4 rotates, flow is formed in the upper part and the lower part respectively, and convection is formed at the junction of the upper part and the lower part (that is, the parting surface of the impeller 4). In this way, it can be fully mixed and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com