Cation gum rosin and preparing method thereof

A technology for cationic rosin gum and rosin, which is applied in the field of cationic rosin gum and its preparation, can solve the problems of affecting the use effect of rosin gum, unsatisfactory stirring effect, and increase the difficulty of operation, so as to shorten the production time, eliminate the dead angle of stirring, and reduce the production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

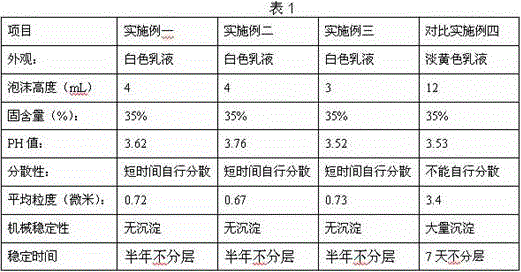

Examples

preparation example Construction

[0027] The invention provides a kind of cationic rosin gum preparation method, comprises the following steps:

[0028] Step 1, add rosin and fortified rosin mixture at the bottom of the reaction kettle, heat to 150°C to melt;

[0029] Step 2: Add an emulsifier to the kettle at one time, turn on the ultrasonic emulsification machine and keep the reactants in the reactor ultrasonically emulsified for 10-60 minutes;

[0030] Step 3: Slowly add deionized water preheated at 80±2°C into the reaction kettle dropwise, and turn off the ultrasonic emulsification machine after dropping;

[0031] Step 4: Cool the material in the reactor to below 30°C, add aluminum salt solution and cold deionized water, adjust the solid content to 35%, and filter the material to obtain cationic rosin gum.

Embodiment 1

[0034] Add 100g of rosin and 200g of strengthened rosin mixture to the bottom of the reaction kettle, heat it to about 150°C to melt, and start the ultrasonic emulsification machine; add 80g of emulsifier OP-10 to the kettle at one time, and keep ultrasonic emulsification for 30min; keep 200g of deionized water at 80 ℃, slowly drop into the reaction kettle, the dropping time is 5min, close the ultrasonic emulsifier after the dropwise addition, cool the material in the reaction kettle to below 30℃, add 50g of aluminum sulfate and cold deionized water, adjust the solid content to After 35%, filter the discharge.

Embodiment 2

[0036] Add 150g of rosin and 100g of enhanced rosin mixture to the bottom of the reaction kettle, heat it to about 150°C to melt, and start the ultrasonic emulsification machine; add 80g of emulsifier NP-10 to the kettle at one time, and keep ultrasonic emulsification for 30min; keep 200g of deionized water at 80 At about ℃, slowly drop it into the reaction kettle, the dropping time is 5min, turn off the ultrasonic emulsifier after dropping, cool the material in the reaction kettle to below 30℃, add 50g of aluminum chloride and cold deionized water to adjust the solid content After being 35%, filter the discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com