Mixer

A technology of mixing machine and mixing barrel, which is applied in the direction of mixers, mixers with rotating stirring devices, mixer accessories, etc., and can solve the problems of continuous operation of process flow affecting the treatment system, health hazards of operators, and mixing machine Shutdown manual cleaning and other problems, to achieve the effect of easy incineration, shortening the time of burning treatment, and fine waste particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can implement it with reference to the description.

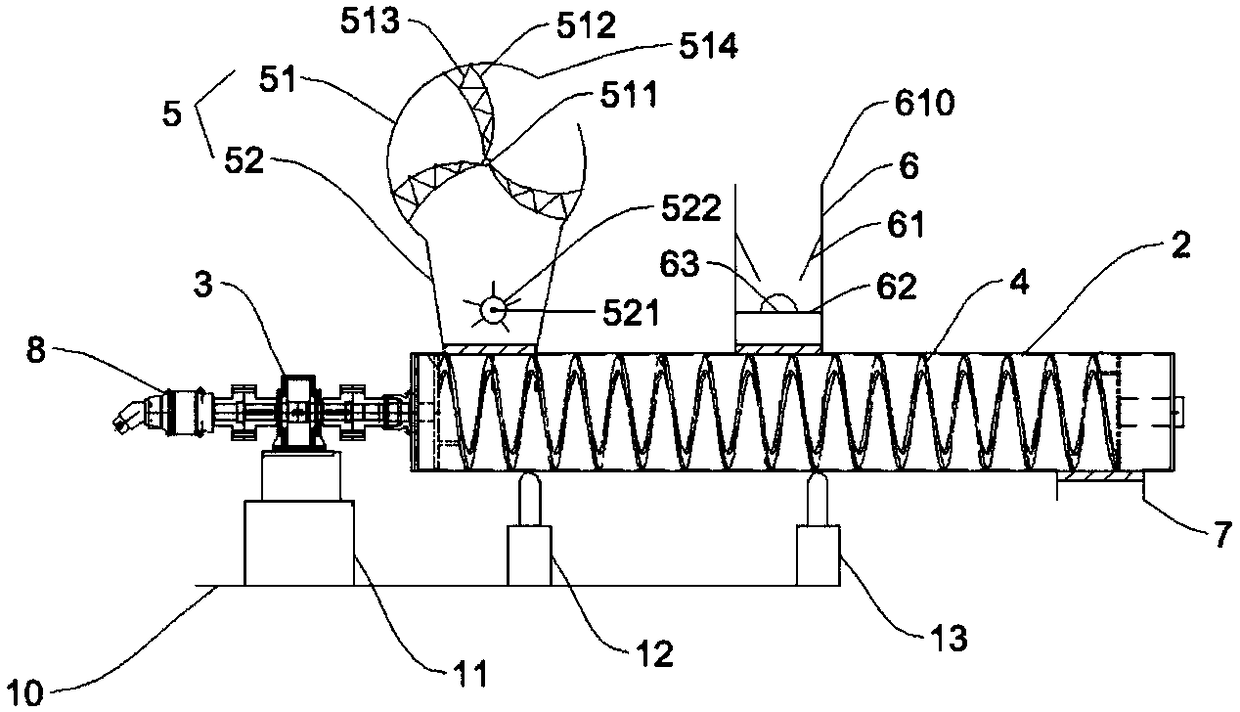

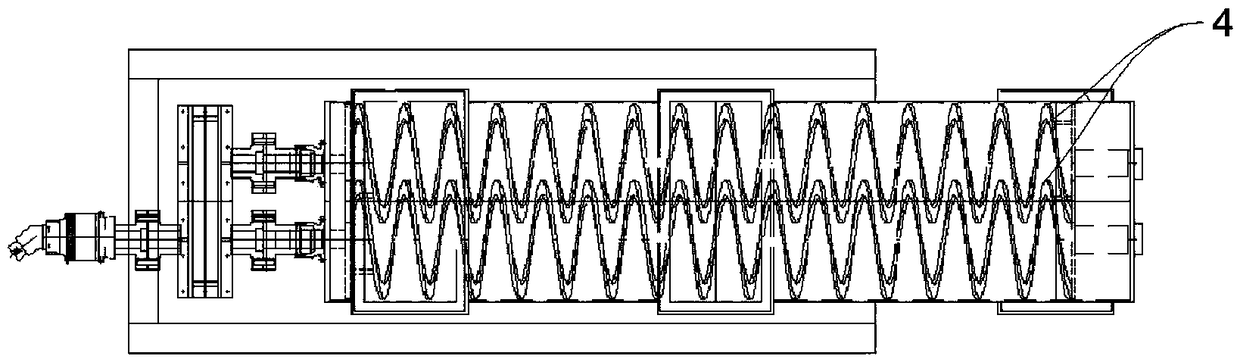

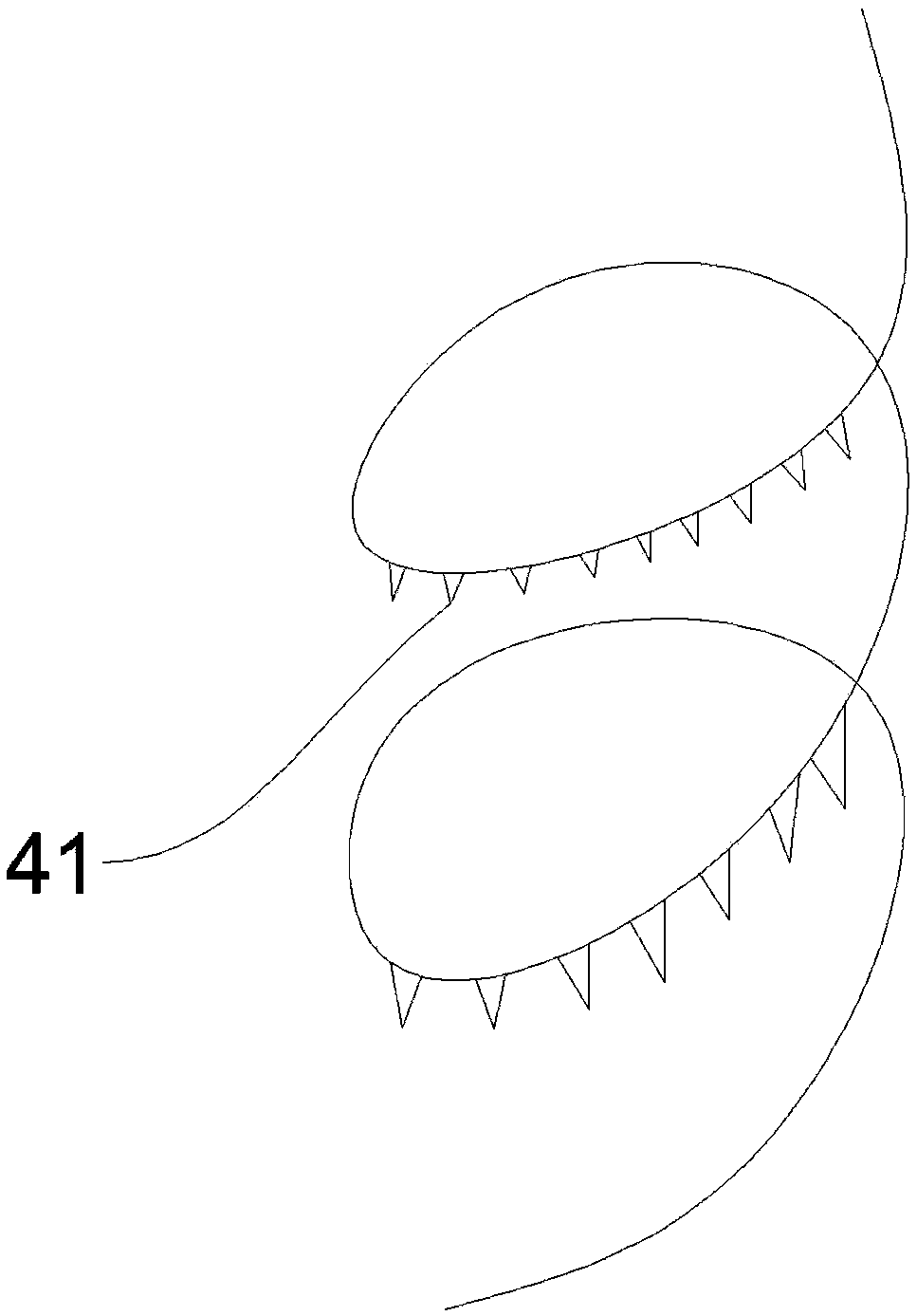

[0033] Such as Figure 1-3 As shown, the invention provides a kind of mixing machine, comprising:

[0034] The base comprises a horizontally arranged base plate 10 and a first hydraulic telescopic rod 11, a second hydraulic telescopic rod 12, and a third hydraulic telescopic rod 13 vertically arranged on the base plate 10 at equal intervals, and the first hydraulic telescopic rod 11, the second hydraulic telescopic rod The second hydraulic telescopic rod 12 and the third hydraulic telescopic rod 13 are located on the same horizontal straight line, and the tops of the first hydraulic telescopic rod, the second hydraulic telescopic rod 12 and the third hydraulic telescopic rod 13 are all contracted to the limit and are on the same horizontal plane , and the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com