Milk cow forage stirring device

A stirring device and cow feed technology, applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve problems such as high temperature, cost increase, and damage to feed nutrients, so as to reduce costs and improve efficiency , reduce the effect of nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

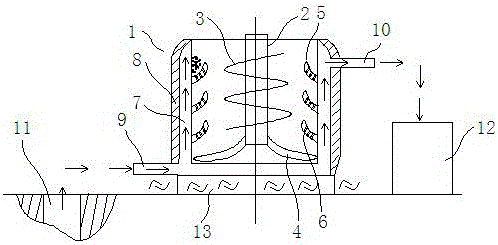

[0013] Accompanying drawing is a kind of specific embodiment of the present invention.

[0014] like figure 1 As shown in , this embodiment includes a stirring tank 1, a stirring shaft 2 is arranged in the stirring tank, a propeller blade 3 is arranged on the stirring shaft, and a turning paddle 4 positioned at the bottom of the propeller blade is also arranged on the stirring shaft, the turning paddle The leaves extend from the stirring shaft to the edge of the bottom of the stirring tank so as to turn up the feed at the bottom of the stirring tank; the inner wall of the stirring tank is also evenly distributed with sieve teeth 5, and the tooth surface of the sieve teeth is provided with sieve holes 6. The feed turned up by the turning blades and propeller blades falls on the sieve teeth, and the impurities can be screened out through the sieve holes; the outer ring of the mixing tank is provided with a low-temperature interlayer 7, and the outer ring of the low-temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com