Novel vertical shaft type planetary mixer with balance vibration exciter

A vibration exciter and balancing technology, used in the fields of mortar concrete, construction machinery and equipment, and cement slurry mixing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

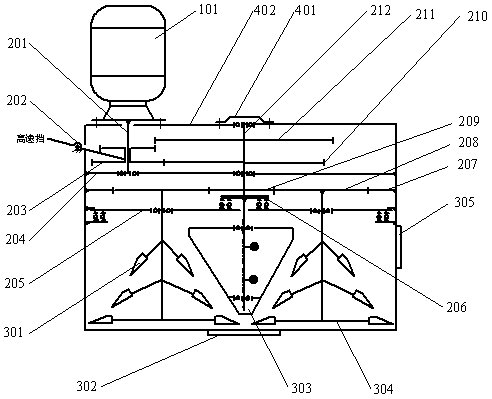

[0017] Embodiment 1, high-speed vibration stirring operation:

[0018] When the driving motor 101 is stopped, operate the shift mechanism 202 to make the large gear of the double gear 203 mesh with the pinion 210 on the second transmission shaft 212, and simultaneously engage the clutch 206;

[0019] Start the driving motor 101, drive the first transmission shaft 201 to rotate, drive the double row gear 203 to rotate through the spline, and then drive the second transmission shaft 212 to rotate through the pinion 210; wherein, the second transmission shaft 212 drives the dynamic planetary gear through the dynamic sun gear 209 all the way 208 rotates, through the force of the fixed ring gear 207, the dynamic planetary gear 208 drives the dynamic planetary carrier 205 to revolve while rotating, and then realizes the rotation and revolution of the agitator 301 (304), and the other transmission shaft 212 is driven by the clutch 206 Balanced vibrator 303;

[0020] Through the abov...

Embodiment 2

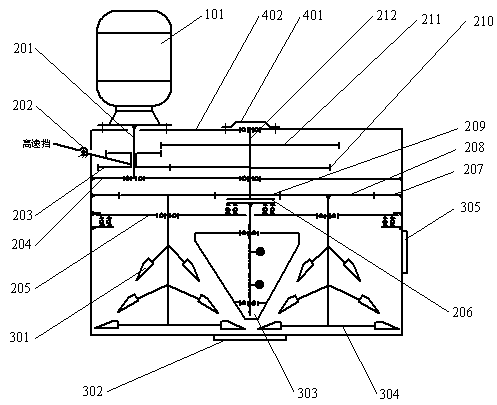

[0021] Embodiment 2, cement foaming high-speed mixing operation:

[0022] When the driving motor 101 is stopped, operate the shift mechanism 202 to make the large gear of the double row gear 203 mesh with the pinion 210 on the second transmission shaft 212, and simultaneously separate the clutch 206;

[0023] Start the driving motor 101, drive the first transmission shaft 201 to rotate, drive the double row gear 203 to rotate through the spline, and then drive the second transmission shaft 212 to rotate through the pinion 210, and the second transmission shaft 212 drives the dynamic planetary gear 208 to rotate through the dynamic sun gear 209, Through the force of the fixed ring gear 207, the dynamic planetary gear 208 drives the dynamic planetary carrier 205 to revolve while rotating, thereby realizing the rotation and revolution of the agitator 301 (304);

[0024] Through the above actions, under the action of the agitator 301 ( 304 ), the cement slurry and the foaming agen...

Embodiment 3

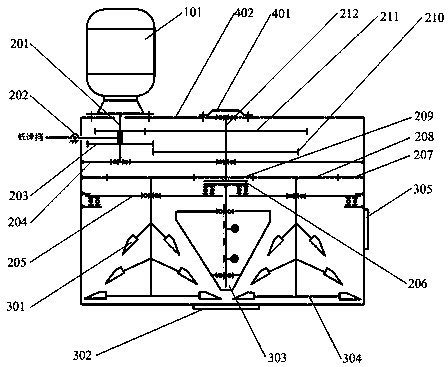

[0025] Embodiment 3, ease the slurry hydration reaction low-speed stirring operation:

[0026] When the drive motor 101 is stopped, operate the shift mechanism 202 to make the pinion gear 203 of the double row gear 203 mesh with the large gear 211 on the second transmission shaft 212, and simultaneously separate the clutch 206;

[0027] Start the driving motor 101, drive the first transmission shaft 201 to rotate, drive the double row gear 203 to rotate through the spline, and then drive the second transmission shaft 212 to rotate through the large gear 211, and the second transmission shaft 212 drives the dynamic planetary gear 208 to rotate through the dynamic sun gear 209, Through the force of the fixed ring gear 207, the dynamic planetary gear 208 drives the dynamic planetary carrier 205 to revolve while rotating, thereby realizing the rotation and revolution of the agitator 301 (304);

[0028] Through the above actions, under the action of the agitator 301 (304), the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com