Continuous stirring device for cloth dyeing liquid

A stirring device and dyeing liquor technology, which is applied to the equipment configuration of textile materials, the treatment of textile materials, textiles and papermaking, etc., can solve the problems of incomplete stirring, uneven stirring, dead corners of stirring, etc., and achieve better color quality, Stirring is more uniform and the effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

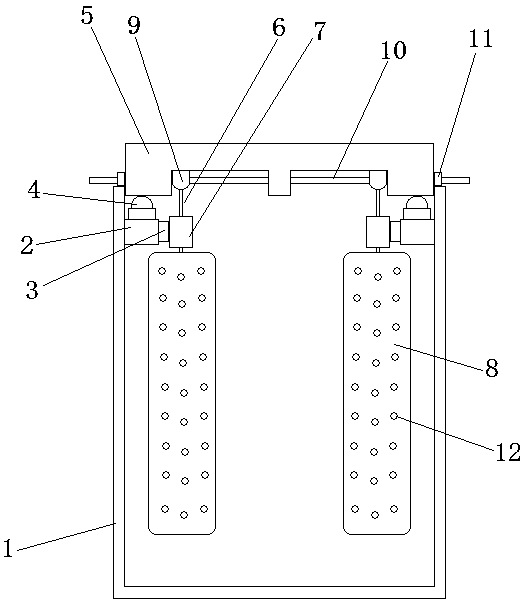

[0016] Such as figure 1 As shown, a continuous stirring device for fabric dye solution of the present invention comprises a mixing tank 1 with an opening at the top, a ring of bosses 2 are arranged near the opening of the mixing tank 1, and a ring of bosses 2 is arranged on the inner circle of the boss 2. The inner ring gear 3, the upper part of the boss 2 is limited with a rolling ball 4, the rolling ball 4 can rotate freely on the boss 2, a rotary plug 5 is installed above the boss 2, and the upper part of the rotary plug 5 has a Motor, the rotary plug 5 is placed on the rolling ball 4, the rotary plug 5 can rotate on multiple rolling balls 4, the diameter of the rotary plug 5 is the same as the inner diameter of the mixing tank 1, and the edge of the rotary plug 5 is matched with the inner wall of the mixing tank 1 , the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com