sand mixer for foundry

A technology of sand mixer and cylinder, which is applied in the direction of casting molding equipment, cleaning/processing machinery of casting mold materials, manufacturing tools, etc. It can solve the problems that the mixing effect needs to be strengthened and does not move, so as to achieve the effect of rolling and mixing Good, uniform rolling effect, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

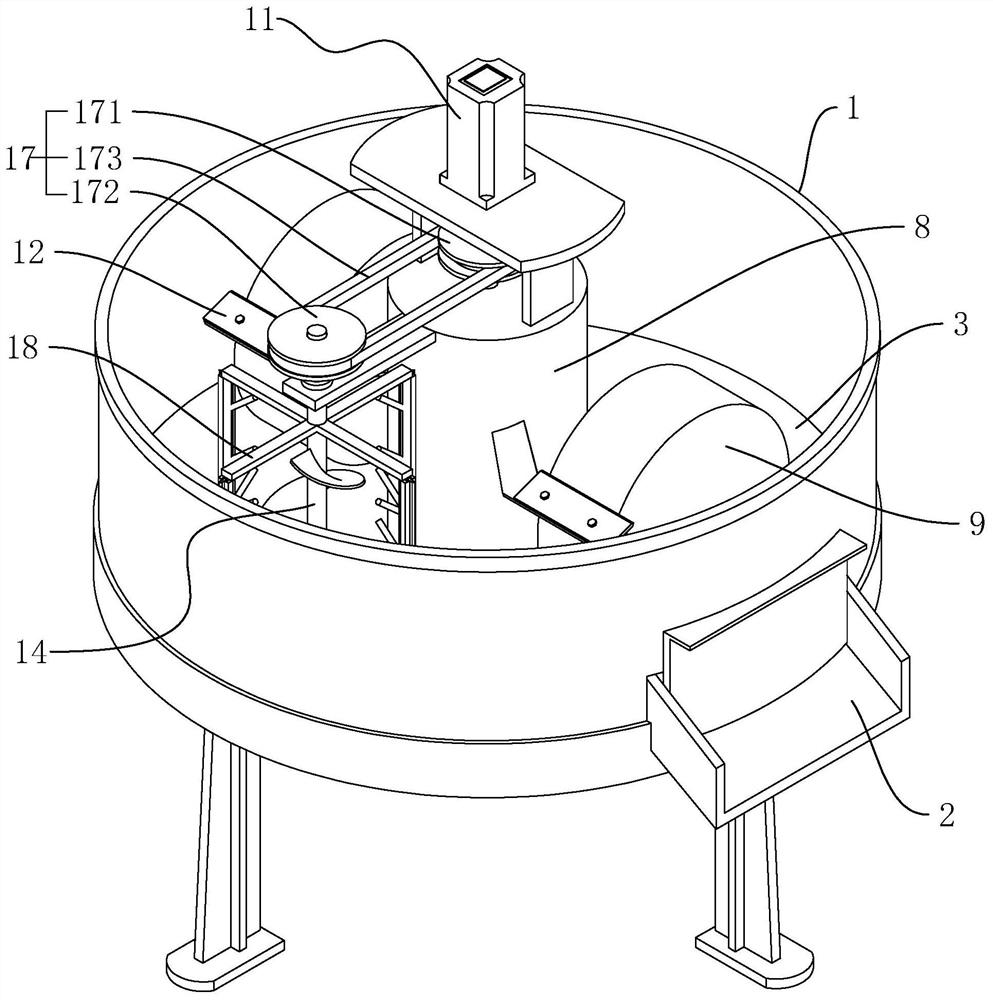

[0039] A sand mixer for foundry, such as figure 1 As shown, it includes a cylindrical cylinder body 1, the outer wall of the cylinder body 1 is provided with a discharge port 2 near the bottom, and a closing plate slides on the discharge port 2, and the closing plate is used to control the opening of the discharge port 2 and closed.

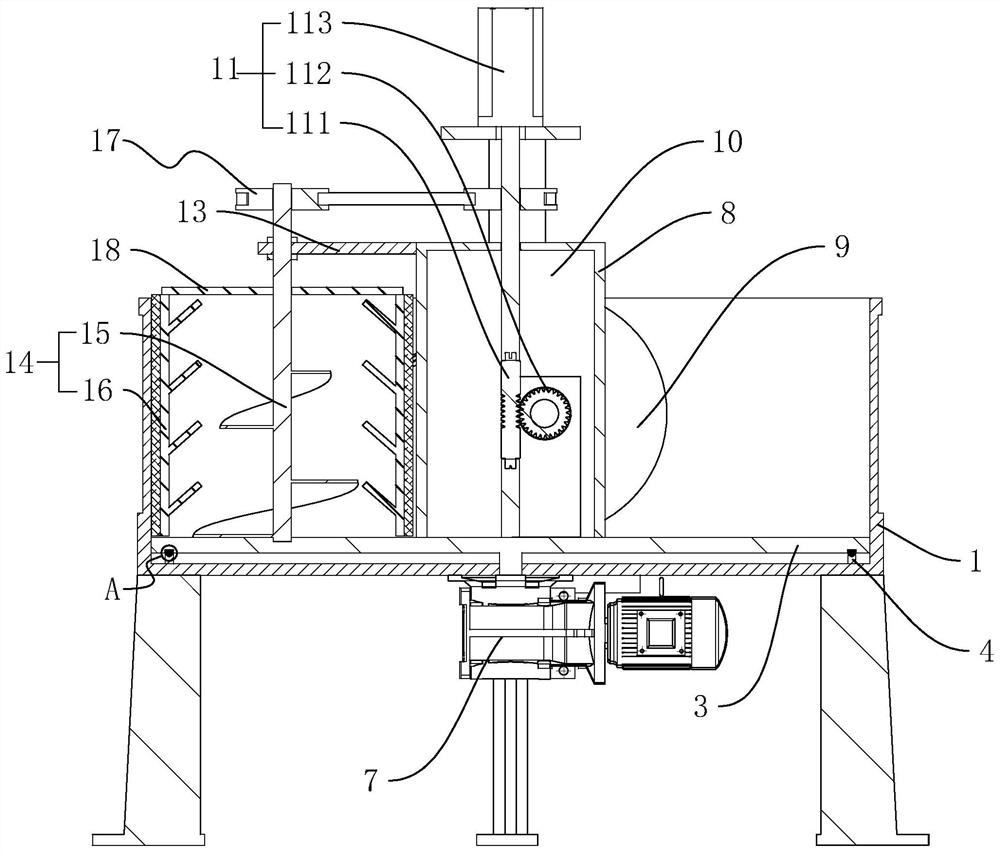

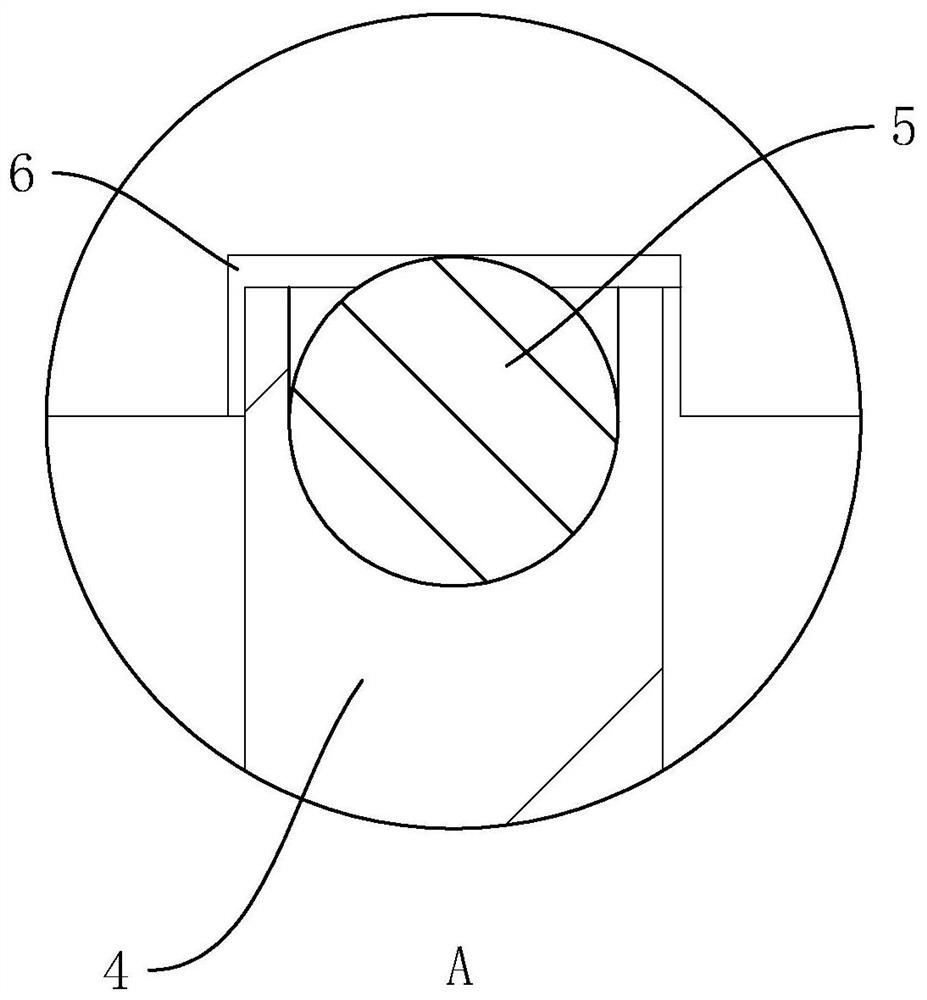

[0040] Such as figure 2 , image 3As shown, a mounting plate 3 is connected to the cylinder body 1 for coaxial rotation, and the mounting plate 3 is arranged near the bottom of the cylinder body 1 . The mounting plate 3 is arranged in a circular plate shape, the axis of the mounting plate 3 coincides with the barrel 1, and the outer wall of the mounting plate 3 is set against the inner wall of the barrel 1, and the inner wall of the bottom of the barrel 1 is provided with a positioning ring 4 for positioning. The upper end surface of the ring 4 is rotatably embedded with a roller 5 . The end face of the mounting plate 3 corresponds to the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com