Self-cleaning vertical stirring machine

A vertical mixer, self-cleaning technology, applied to mixer accessories, mixers with rotating agitation devices, mixers, etc., can solve the problem of easy entanglement of fiber materials, affecting the physical or chemical process of the mixed liquid, and the unfavorable service life of the mixer Influence and other problems, to achieve the effect of no mixing dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

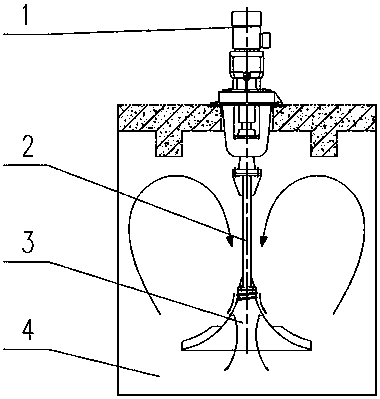

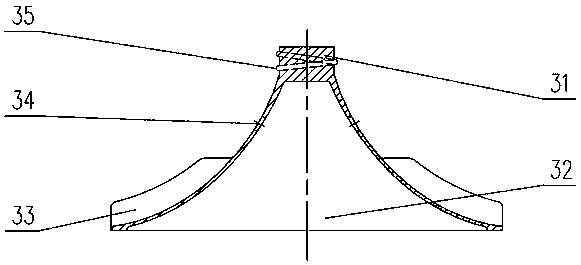

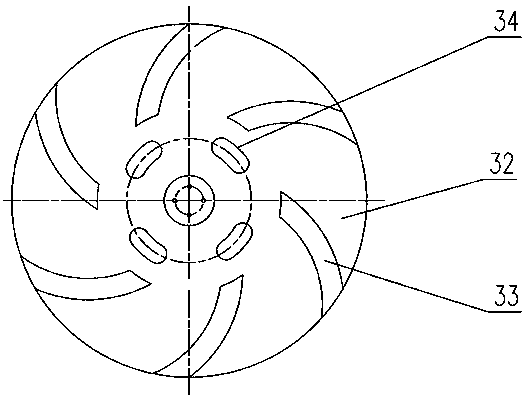

[0023] Such as Figure 1 to Figure 3 As shown, a self-cleaning vertical mixer according to an embodiment of the present invention includes a driving device 1 , a transmission shaft 2 and an impeller 3 . The upper end of the transmission shaft 2 is connected with the lower end of the driving device 1 , and the impeller 3 is assembled on the lower end of the transmission shaft 2 . The impeller 3 comprises a hub, main blades 33 and return grooves 34 . The hub is connected to the lower end of the transmission shaft 2, and the main blade 33 is connected to the outer surface of the hub. The return groove 34 is located on the hub and runs through the hub.

[0024] In the agitator of the above embodiment, the reflux groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com