Flush-free toilet and excrement in-service treatment method

A fecal, non-flushing technology, used in household appliances, resistance to vector-borne diseases, sanitary equipment, etc., can solve the problems of large amounts of sewage, uneconomical, polluted flushing water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

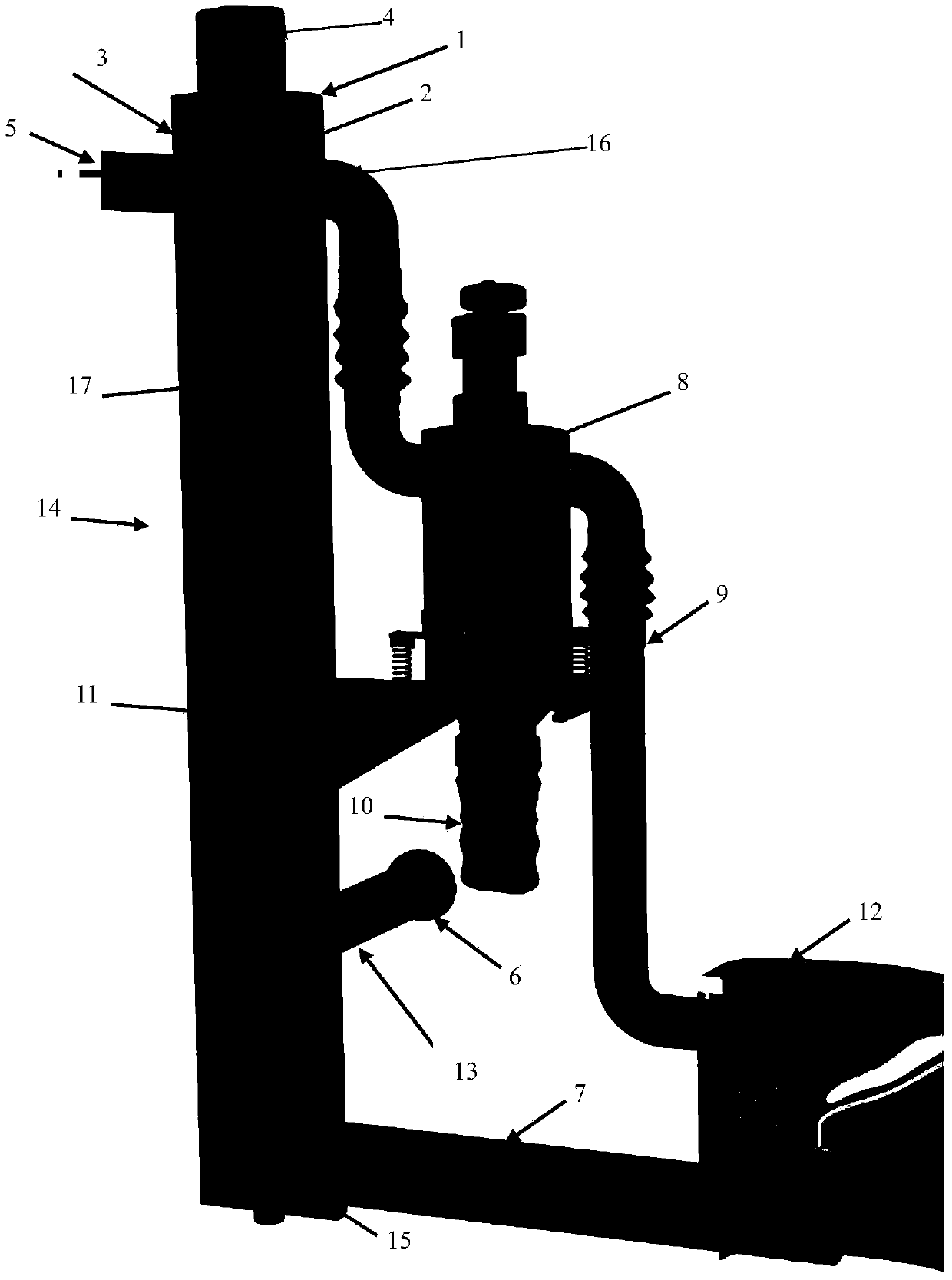

[0052] Example 1 - New flush-free toilet

[0053] The original intention of this invention is to meet the requirements of the Bill & Melinda Gates Foundation to "create the next generation of sanitation facilities" and "reinvent the toilet plan", and to design a toilet that can "operate without pipelines and kill pathogens; resources can be recycled." Utilize; the "next-generation toilet" with low price and easy promotion. For the new type of toilet in this example see figure 1 .

[0054] The new toilet workflow is:

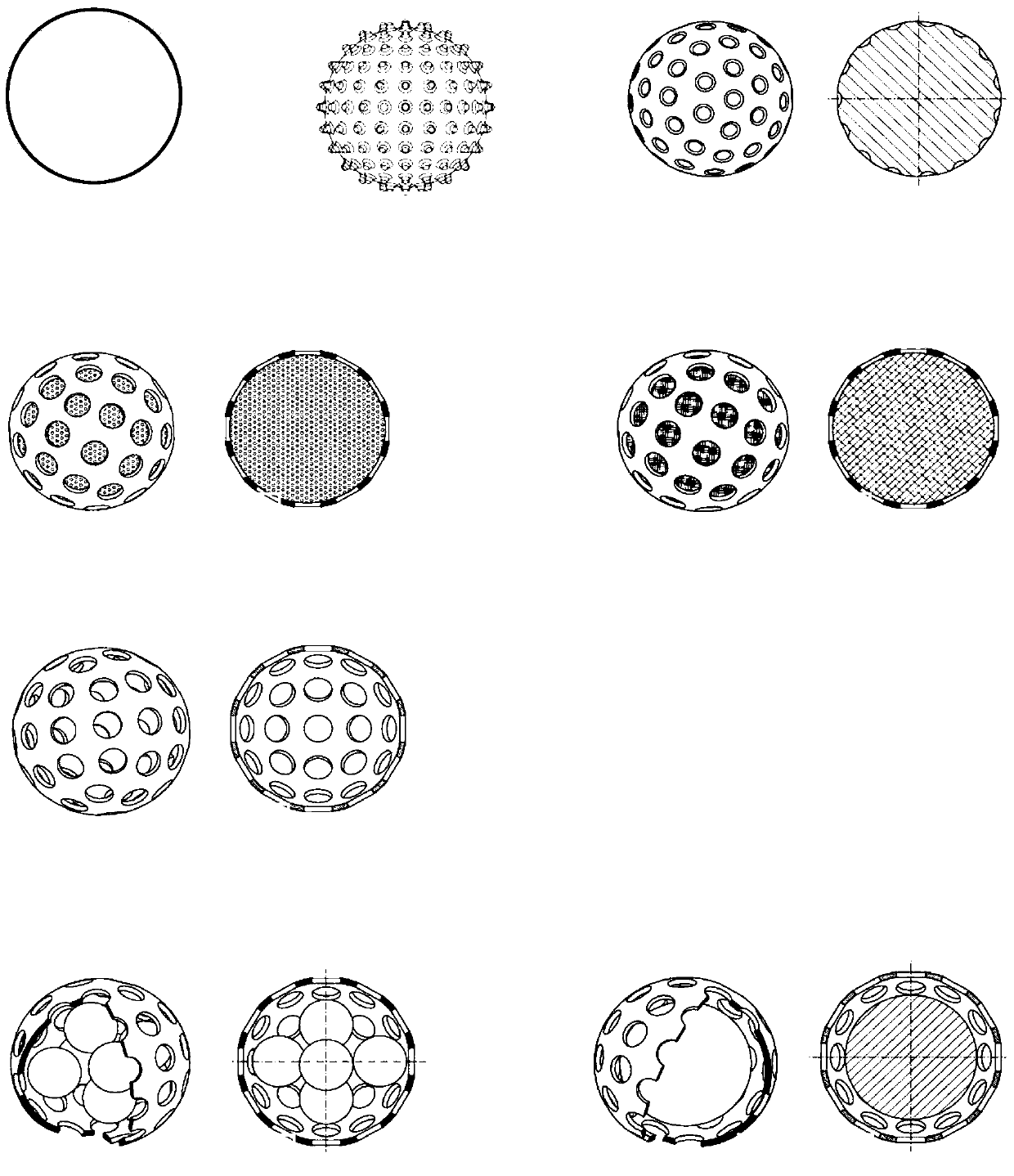

[0055] 1) In the toilet or squatting pan 12, many carrying balls are used to carry feces, and as the carrying balls are discharged from the toilet or squatting pan, the feces are also discharged at the same time, so as to avoid flushing;

[0056] 2) Stir and mix many balls 11 and feces in the agitator 7 (which is a screw conveyor), so that each ball carries a small amount of feces, and then is sent into the screw conveyor drier 14;

[0057] 3) The rotary driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com