Gas explosion-preventive spiral spray pipe bubbling stirring apparatus

The technology of a stirring device and spiral spray is applied in the field of bubbling and stirring of batching tanks, which can solve the problems of complex structure, low stirring efficiency, and dead corners of stirring, and achieve the effects of simple operation, simple structure and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

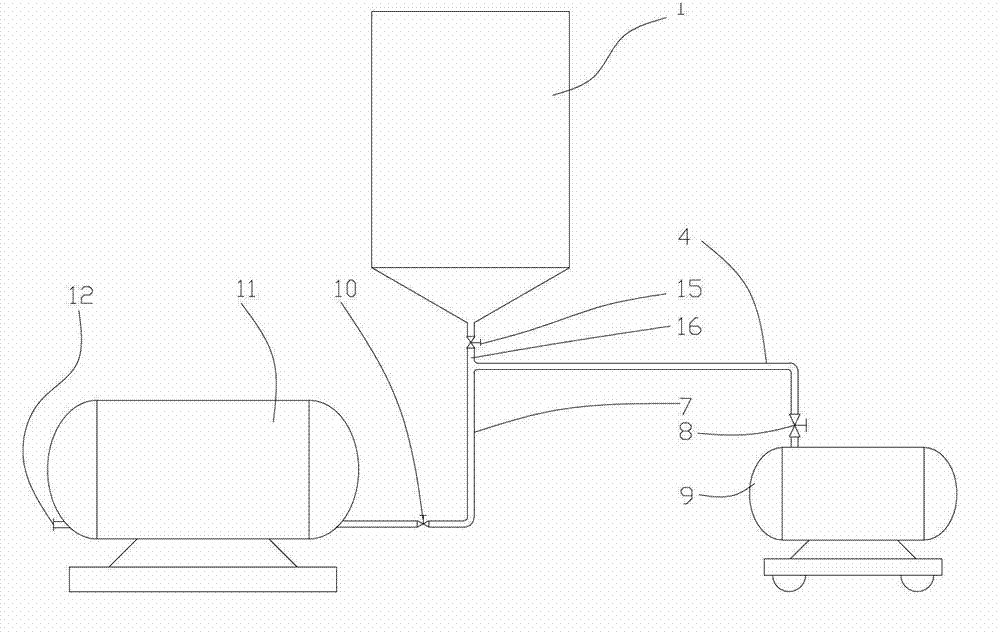

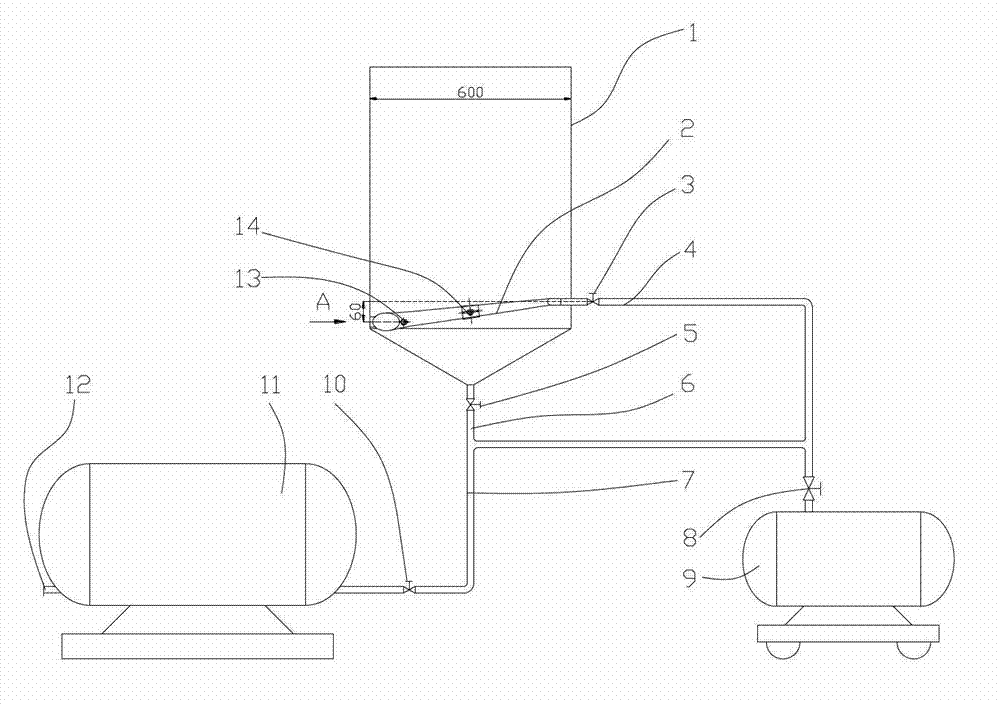

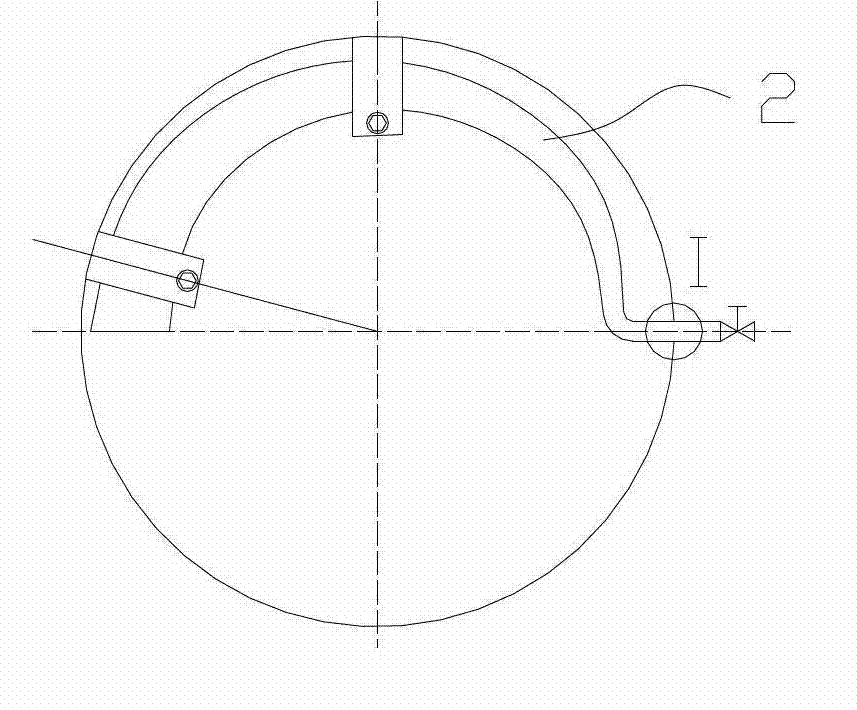

[0022] The present invention comprises: a batching tank 1, a spiral nozzle 2, an air intake valve 3, an air intake pipe 4, a discharge valve 5, a discharge pipe 6, a pressure tank air intake and feed pipe 7, a compressed air outlet valve 8, and an air compressor 9. Pressure tank inlet and feed valve 10, pressure tank 11, pressure tank discharge pipe 12, screw nozzle fixing card A13, screw nozzle fixing card B14, inner tightening nut 2.1, inner gasket 2.2, outer seal Pad 2.3, outer tightening screw nut 2.4, ordinary fine thread 2.5, tapered pipe thread 2.6; the bottom side of the batching tank 1 is equipped with a spiral nozzle 2, the bottom of the batching tank 1 is equipped with a discharge valve, the spiral nozzle 2 and There are inner tightening nuts 2.1 and inner gaskets 2.2 at the internal connection of batching tank 1, and outer tightening nuts 2.1 and outer gaskets 2.2 at the external connection between spiral nozzle 2 and batching tank 1; spiral nozzle 2 enters the batc...

Embodiment 2

[0028] The present invention comprises: a batching tank 1, a spiral nozzle 2, an air intake valve 3, an air intake pipe 4, a discharge valve 5, a discharge pipe 6, a pressure tank air intake and feed pipe 7, a compressed air outlet valve 8, and an air compressor 9. Pressure tank inlet and feed valve 10, pressure tank 11, pressure tank discharge pipe 12, screw nozzle fixing card A13, screw nozzle fixing card B14, inner tightening nut 2.1, inner gasket 2.2, outer seal Pad 2.3, outer tightening screw nut 2.4, ordinary fine thread 2.5, tapered pipe thread 2.6; the bottom side of the batching tank 1 is equipped with a spiral nozzle 2, the bottom of the batching tank 1 is equipped with a discharge valve, the spiral nozzle 2 and There are inner tightening nuts 2.1 and inner gaskets 2.2 at the internal connection of batching tank 1, and outer tightening nuts 2.1 and outer gaskets 2.2 at the external connection between spiral nozzle 2 and batching tank 1; spiral nozzle 2 enters the batc...

Embodiment 3

[0034] The present invention comprises: a batching tank 1, a spiral nozzle 2, an air intake valve 3, an air intake pipe 4, a discharge valve 5, a discharge pipe 6, a pressure tank air intake and feed pipe 7, a compressed air outlet valve 8, and an air compressor 9. Pressure tank inlet and feed valve 10, pressure tank 11, pressure tank discharge pipe 12, screw nozzle fixing card A13, screw nozzle fixing card B14, inner tightening nut 2.1, inner gasket 2.2, outer seal Pad 2.3, outer tightening screw nut 2.4, ordinary fine thread 2.5, tapered pipe thread 2.6; the bottom side of the batching tank 1 is equipped with a spiral nozzle 2, the bottom of the batching tank 1 is equipped with a discharge valve, the spiral nozzle 2 and There are inner tightening nuts 2.1 and inner gaskets 2.2 at the internal connection of batching tank 1, and outer tightening nuts 2.1 and outer gaskets 2.2 at the external connection between spiral nozzle 2 and batching tank 1; spiral nozzle 2 enters the batc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com