Patents

Literature

43results about How to "Avoid gas explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

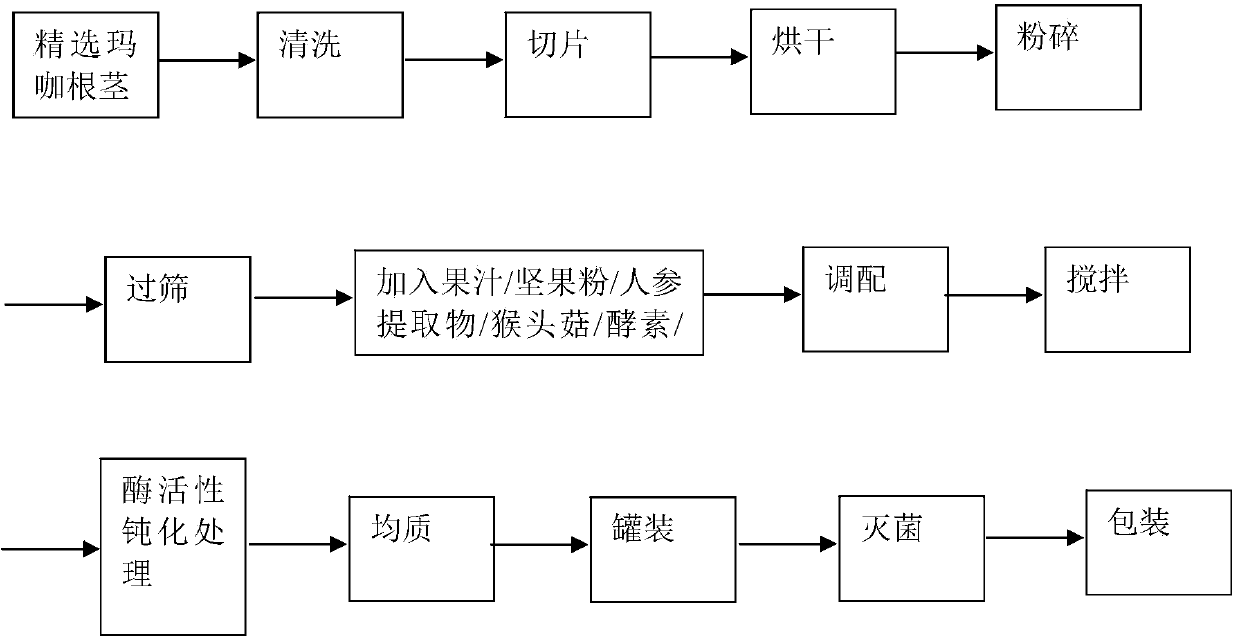

Maca functional beverage and preparation method thereof

InactiveCN103976435AImprove survival rateReduce lossesFood homogenisationFood ingredient functionsCitric acidFine powder

The invention discloses a maca functional beverage and a preparation method thereof. The maca functional beverage contains maca, citric acid and water. The preparation method comprises the following steps of crushing maca into fine powder, mixing the maca fine powder and other raw materials, and carrying out homogenization treatment on the mixture. The maca functional beverage has high biologically-active substance content, is conducive to direct absorption of functional and nutritive components by drinkers, realizes complete combination of maca functionality, naturality and safety and is a novel health food and drink having a plurality of functions.

Owner:赵之光 +1

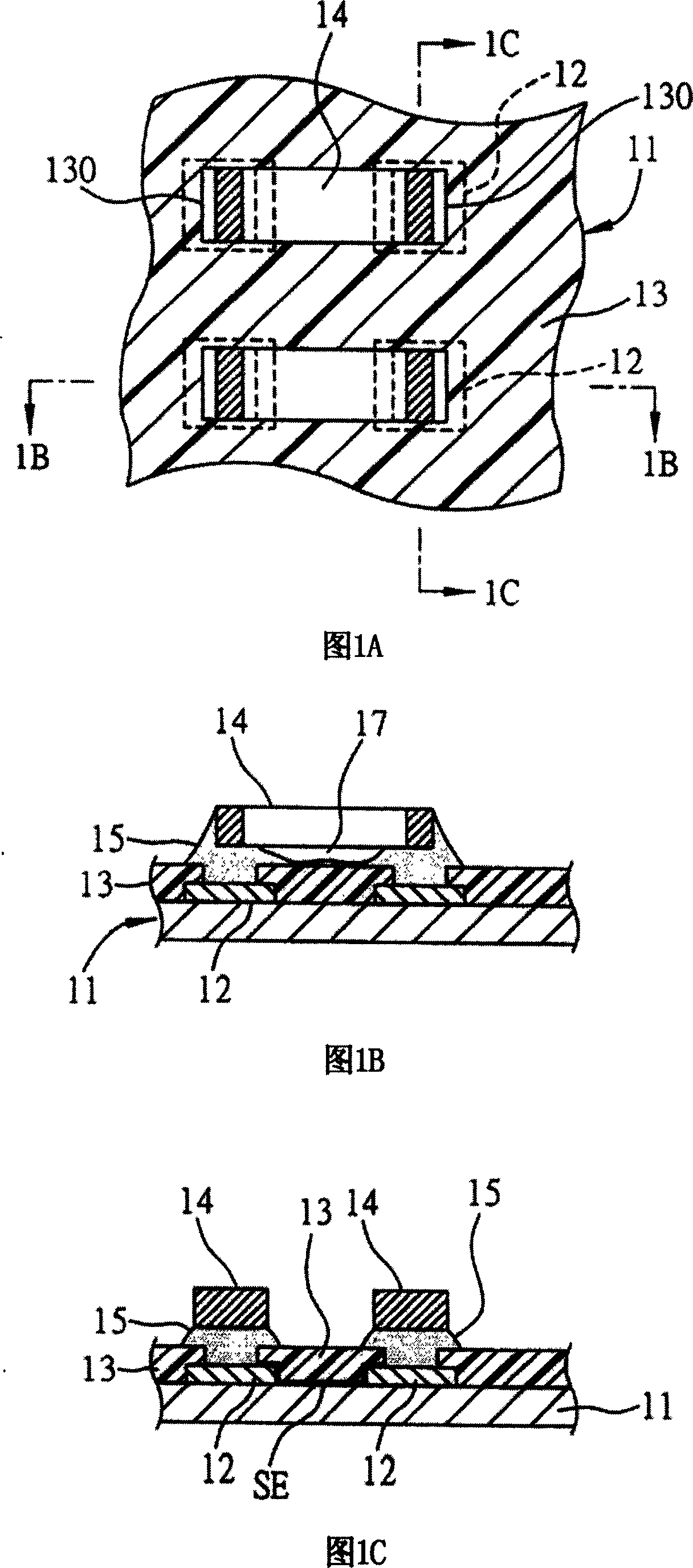

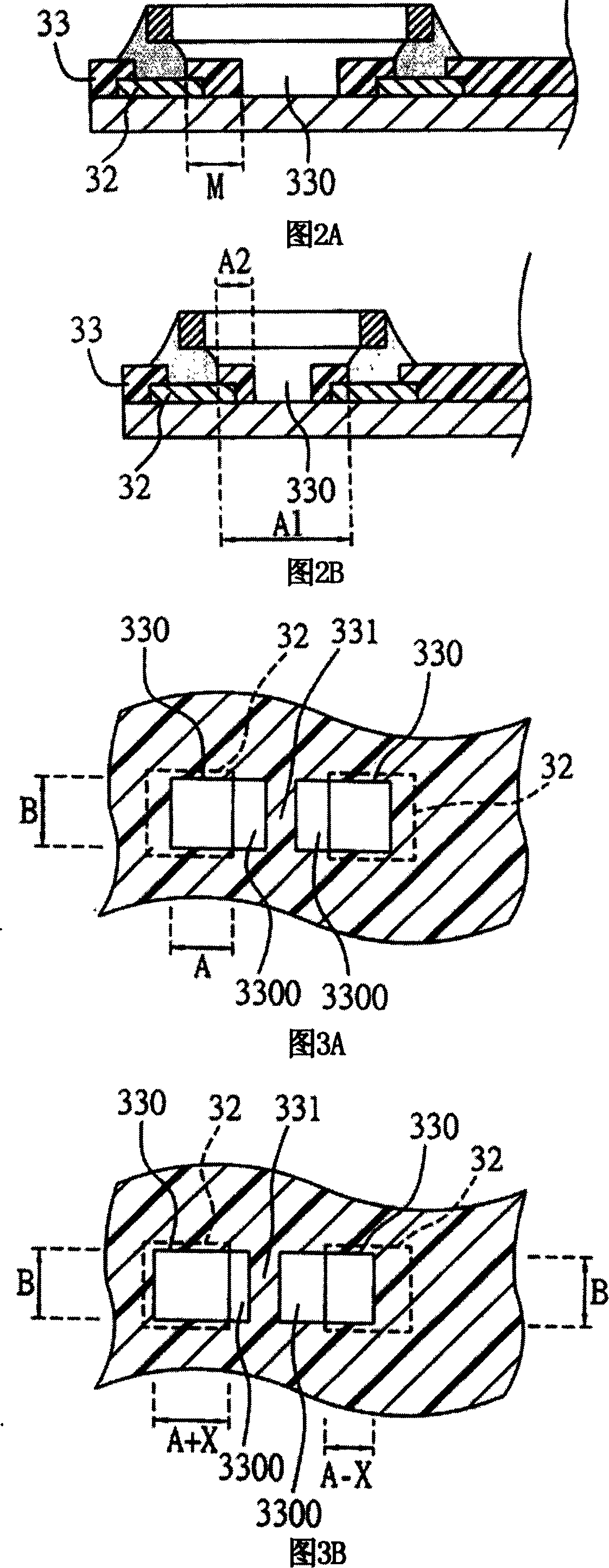

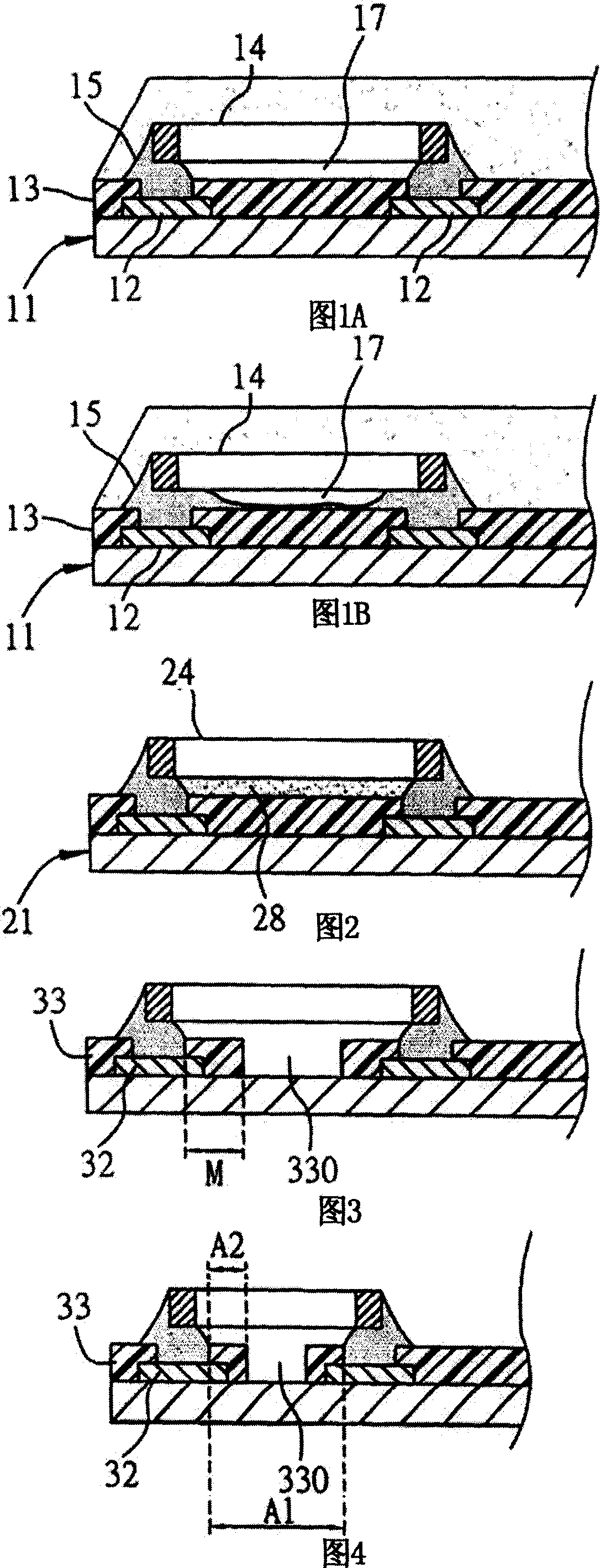

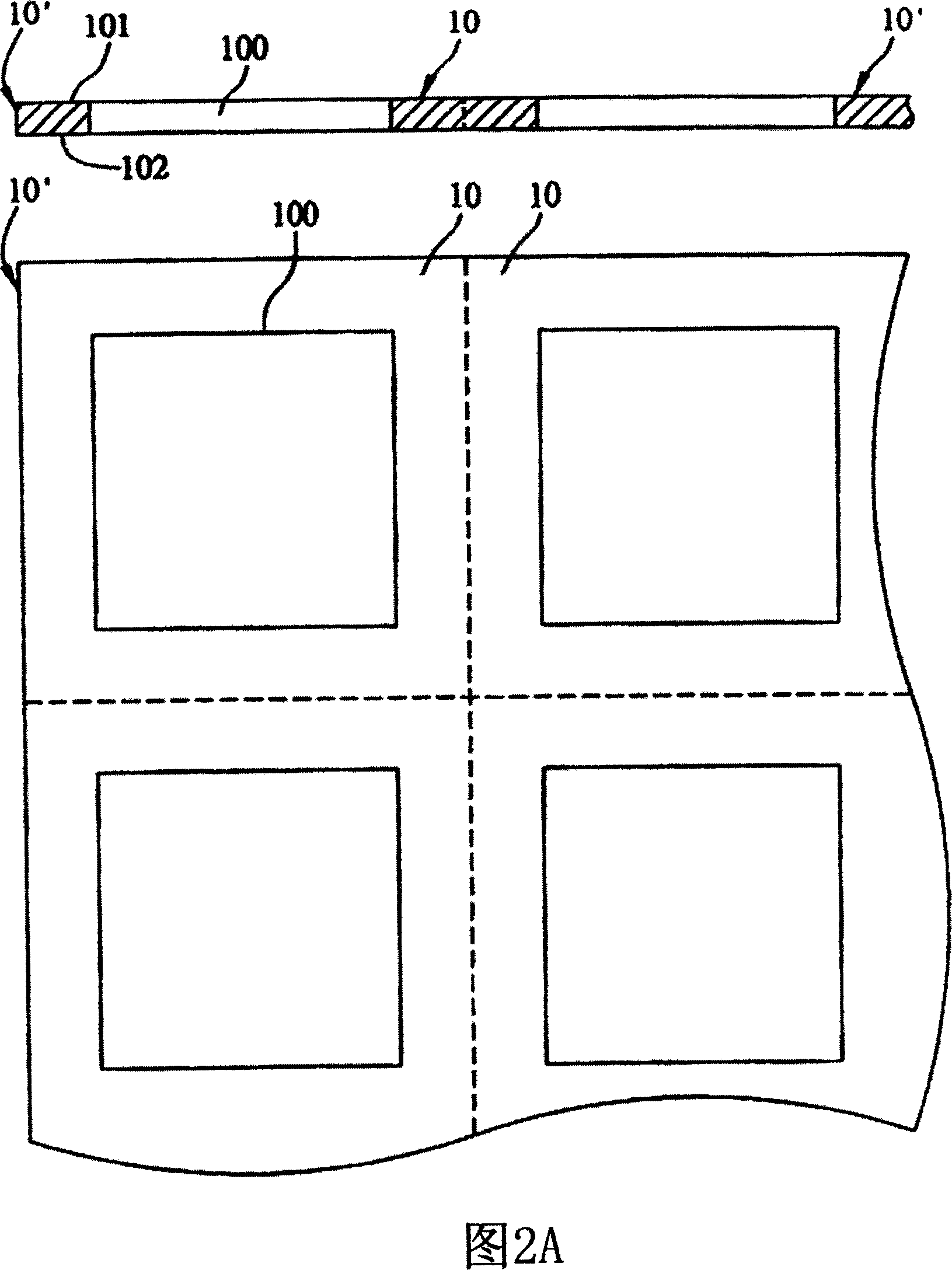

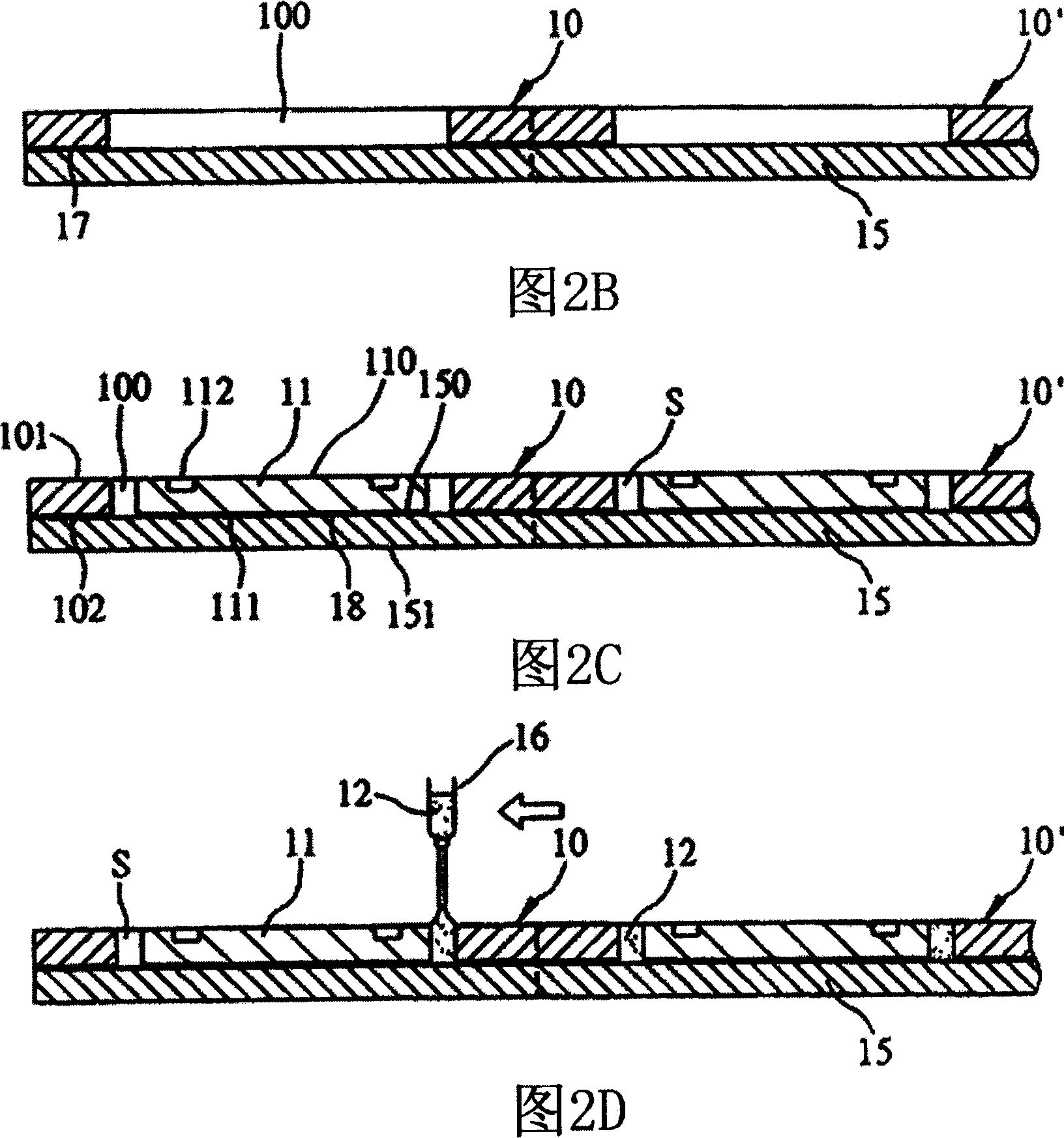

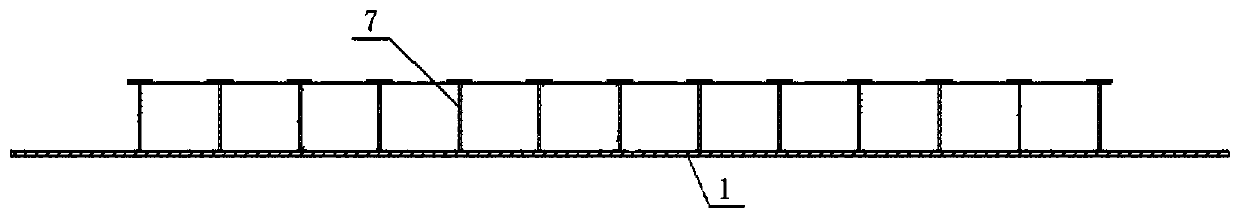

Electronic carrier board

InactiveCN101009968AAvoid different pad areasAvoid different areasPrinted circuitsElectrical componentsEngineeringElectronic board

The disclosed electric carrier plate comprises: a main body, at least two welding mats set on body surface in pairs, a protective layer covering body surface and forming an opening opposite to the mat position, wherein there are at least two same side walls on the opening to expose the mats, the first one is set vertically to the mat arrangement direction, while the second one is parallel. This invention can avoid different area of exposed mats, prevents electric element standing on the plate, fills insulation material between element and plate efficiently, and overcomes problem that it cannot form flow-in groove for package resin on small-size passive element bottom.

Owner:SILICONWARE PRECISION IND CO LTD

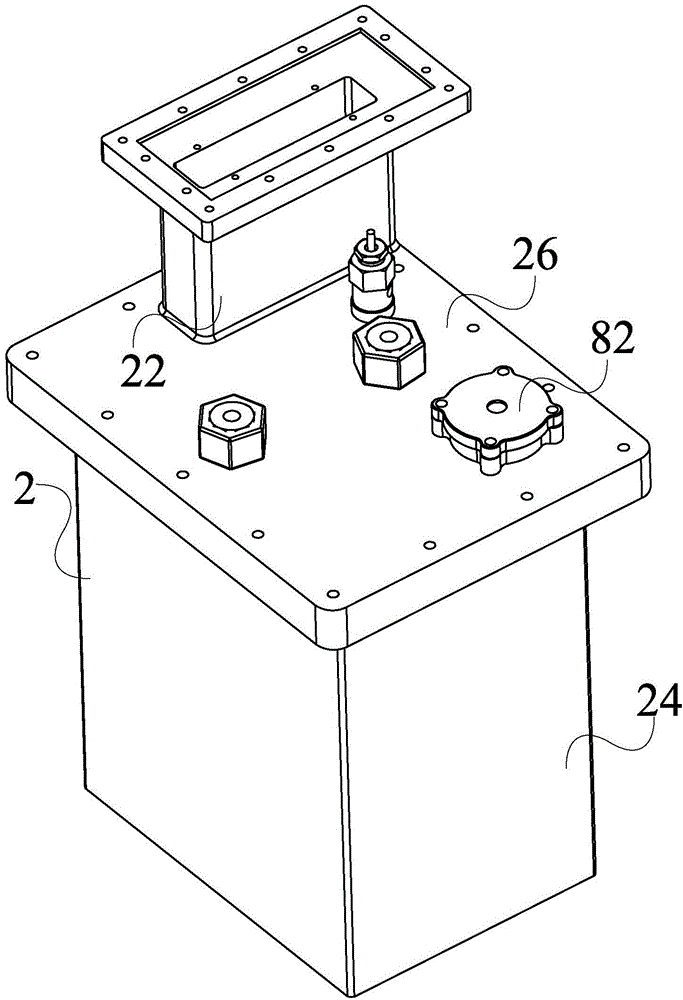

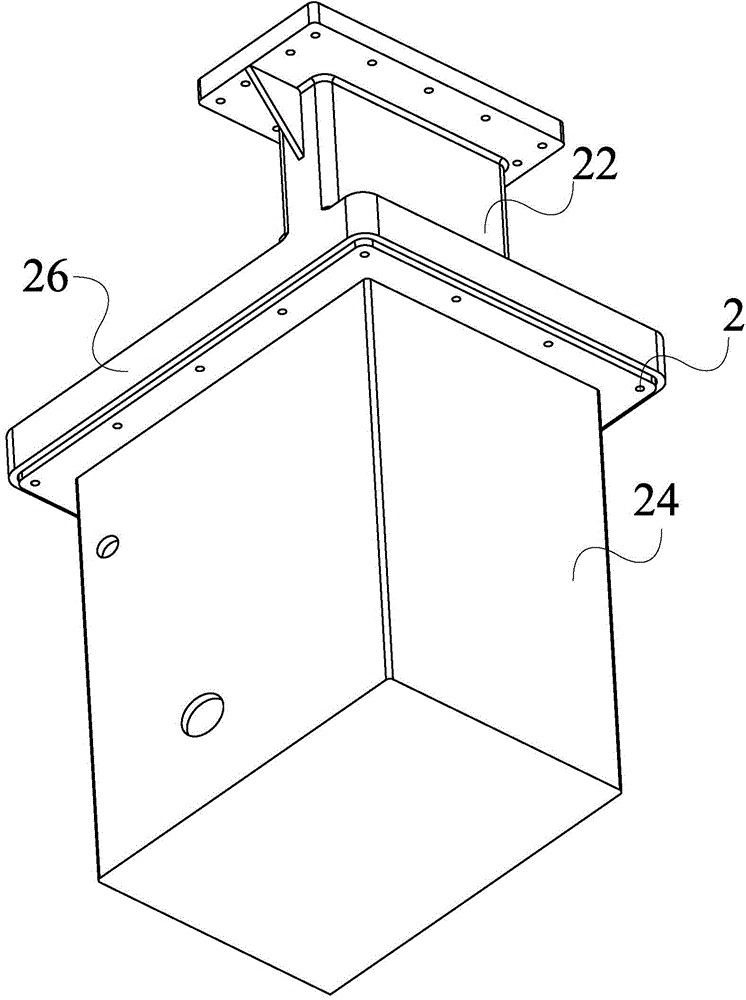

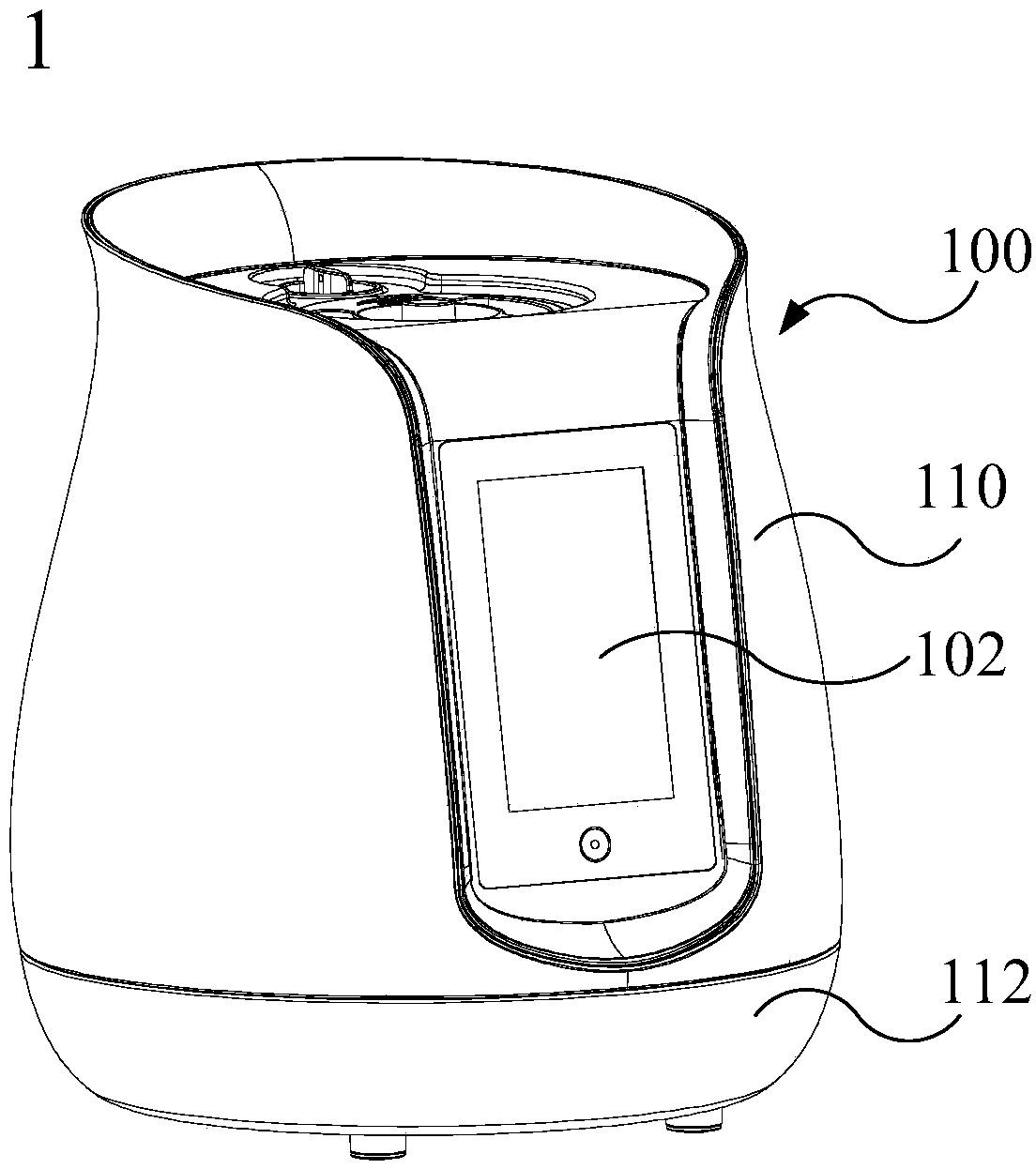

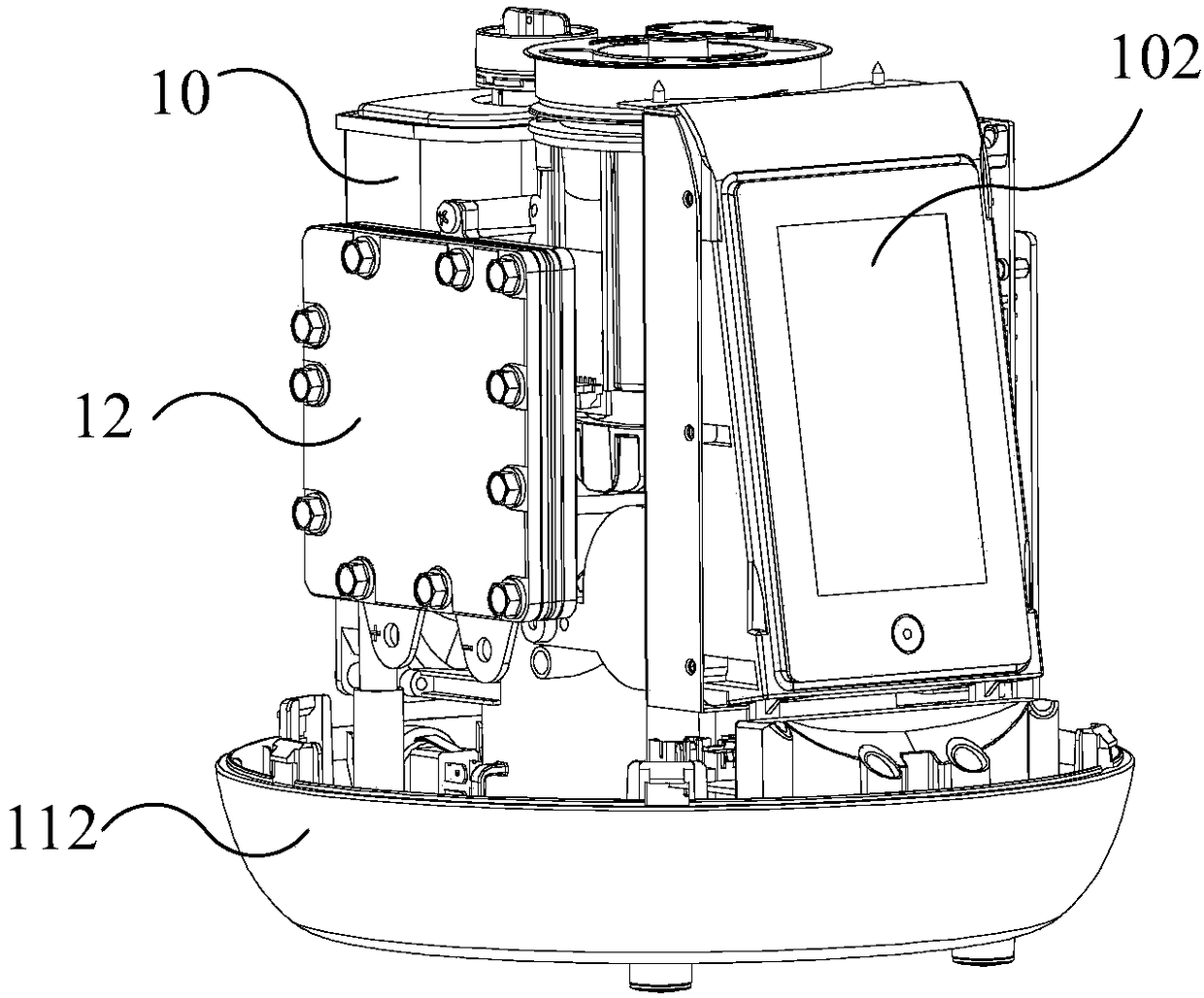

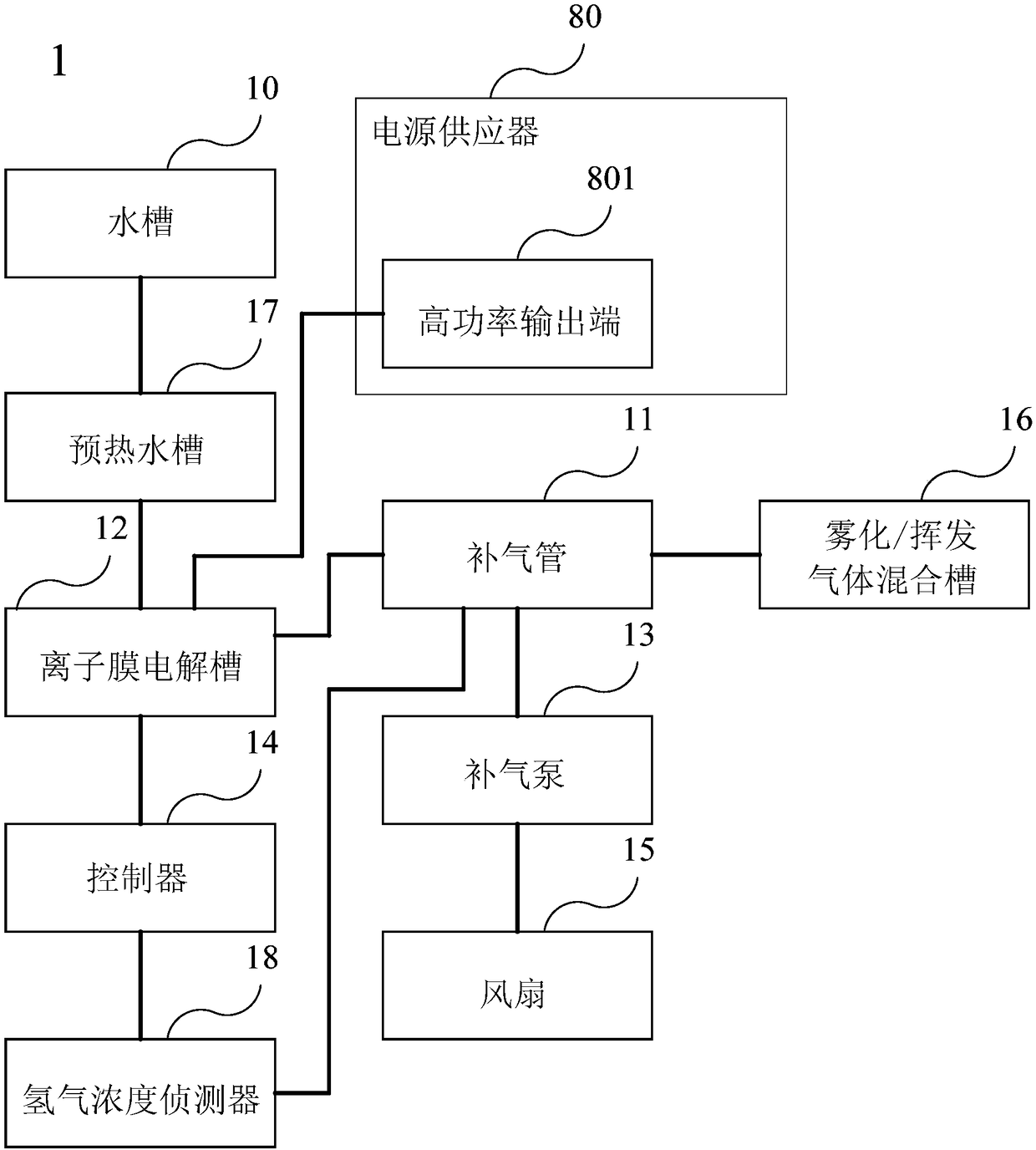

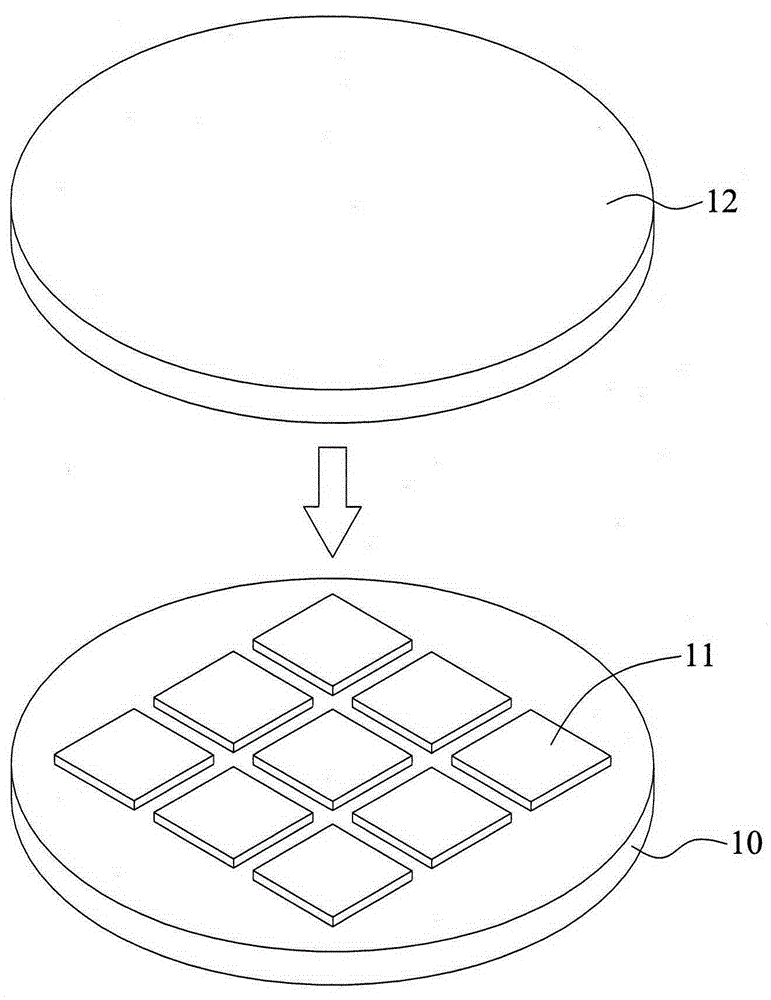

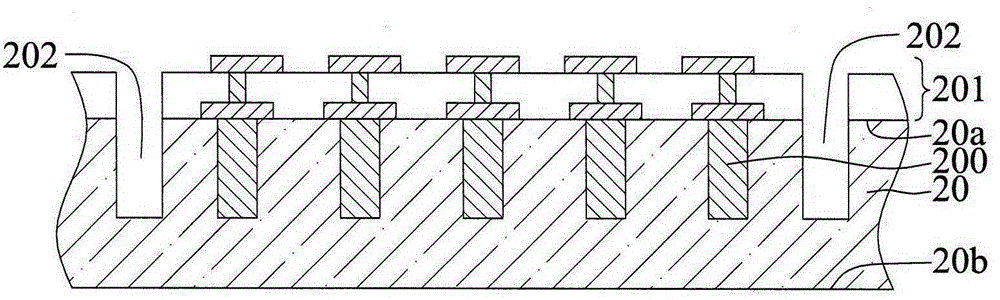

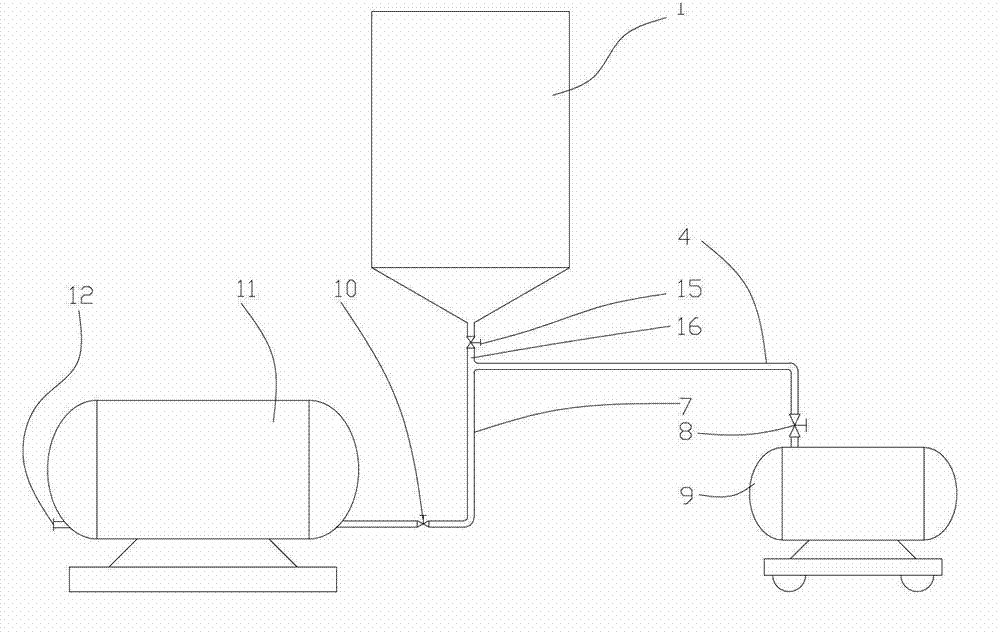

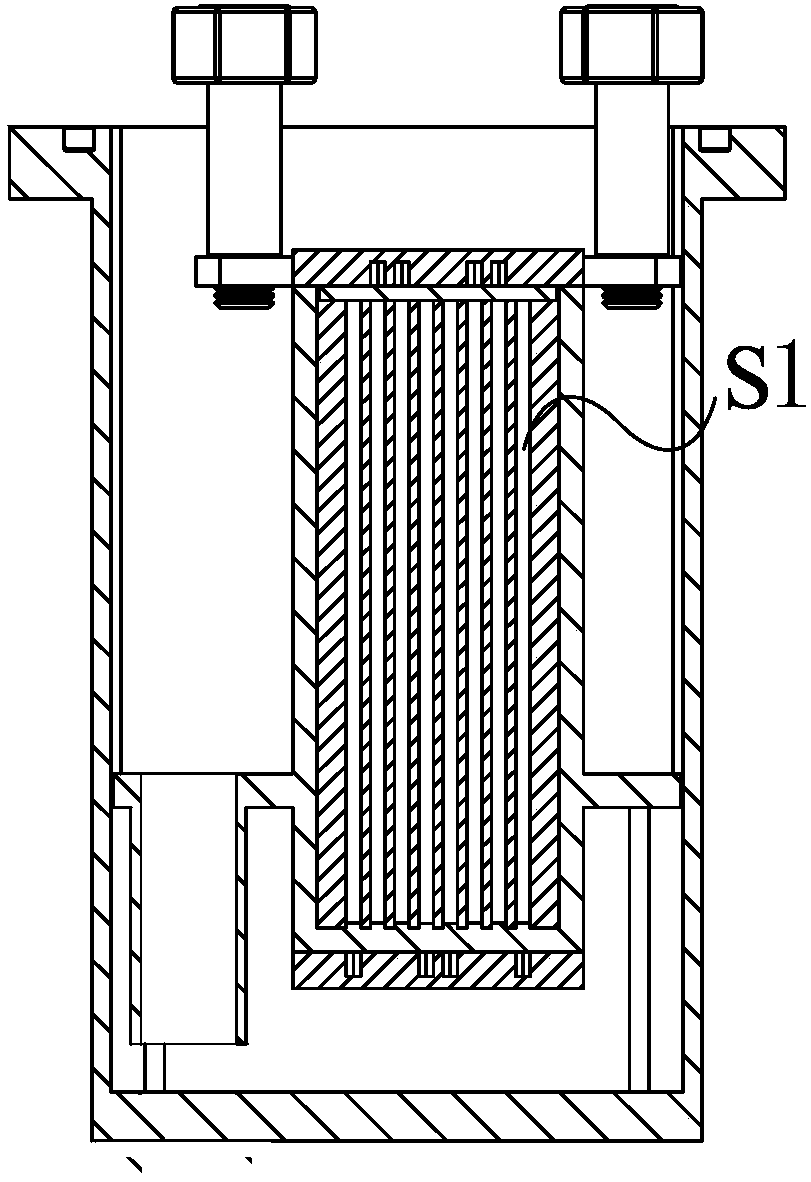

Gas generator

The present invention provides a gas generator comprising a water tank and an electrolysis device. The water tank has a first hollow portion for containing electrolyzed water. The electrolysis device is disposed inside the first hollow portion of the water tank for electrolyzing the electrolyzed water to generate a hydrogen-oxygen mixed gas. When the electrolysis device starts to electrolyze the electrolyzed water, the first hollow portion of the water tank is filled with the electrolyzed water for standing at a full level of water between 90 to 100%. The gas generator of the present invention provides the design for saving space and nearly a zero gas chamber to reduce the possibility of explosions resulting from hydrogen-oxygen mixed gas.

Owner:SHANGHAI ASCLEPIUS MEDITEC CO LTD

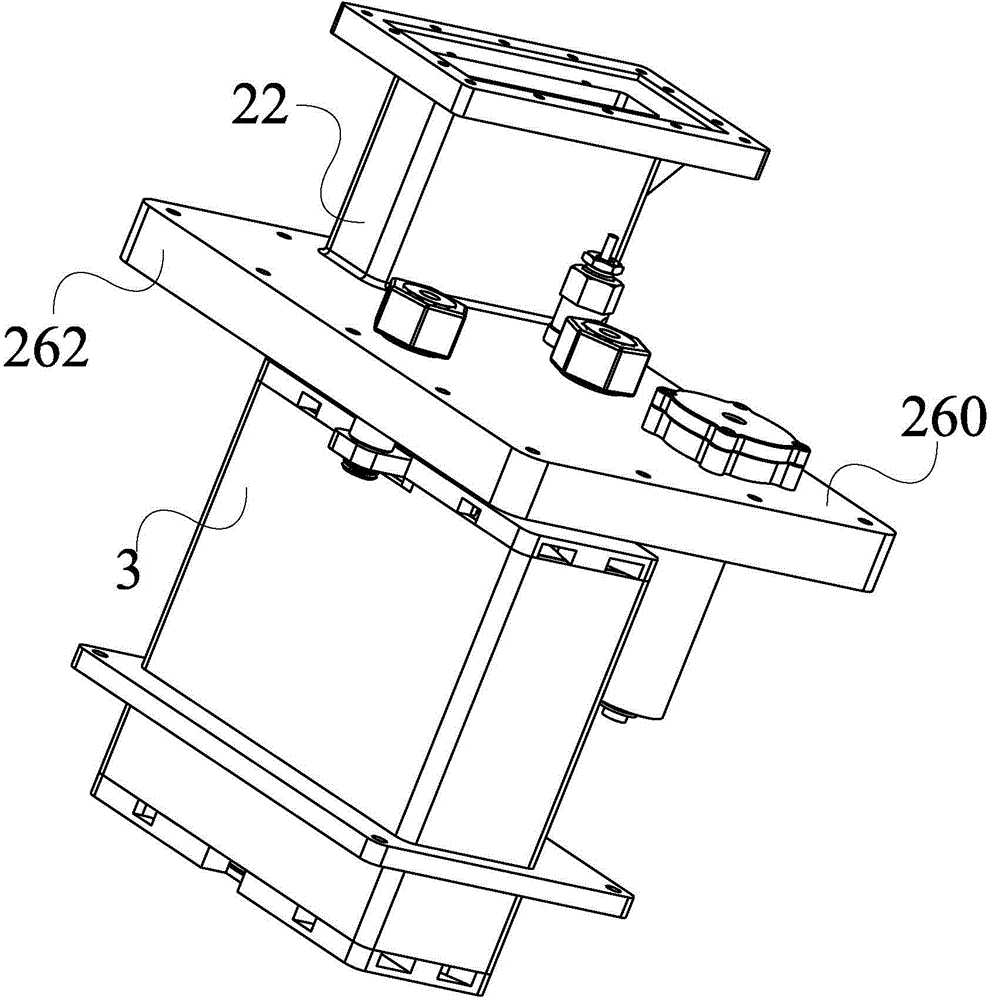

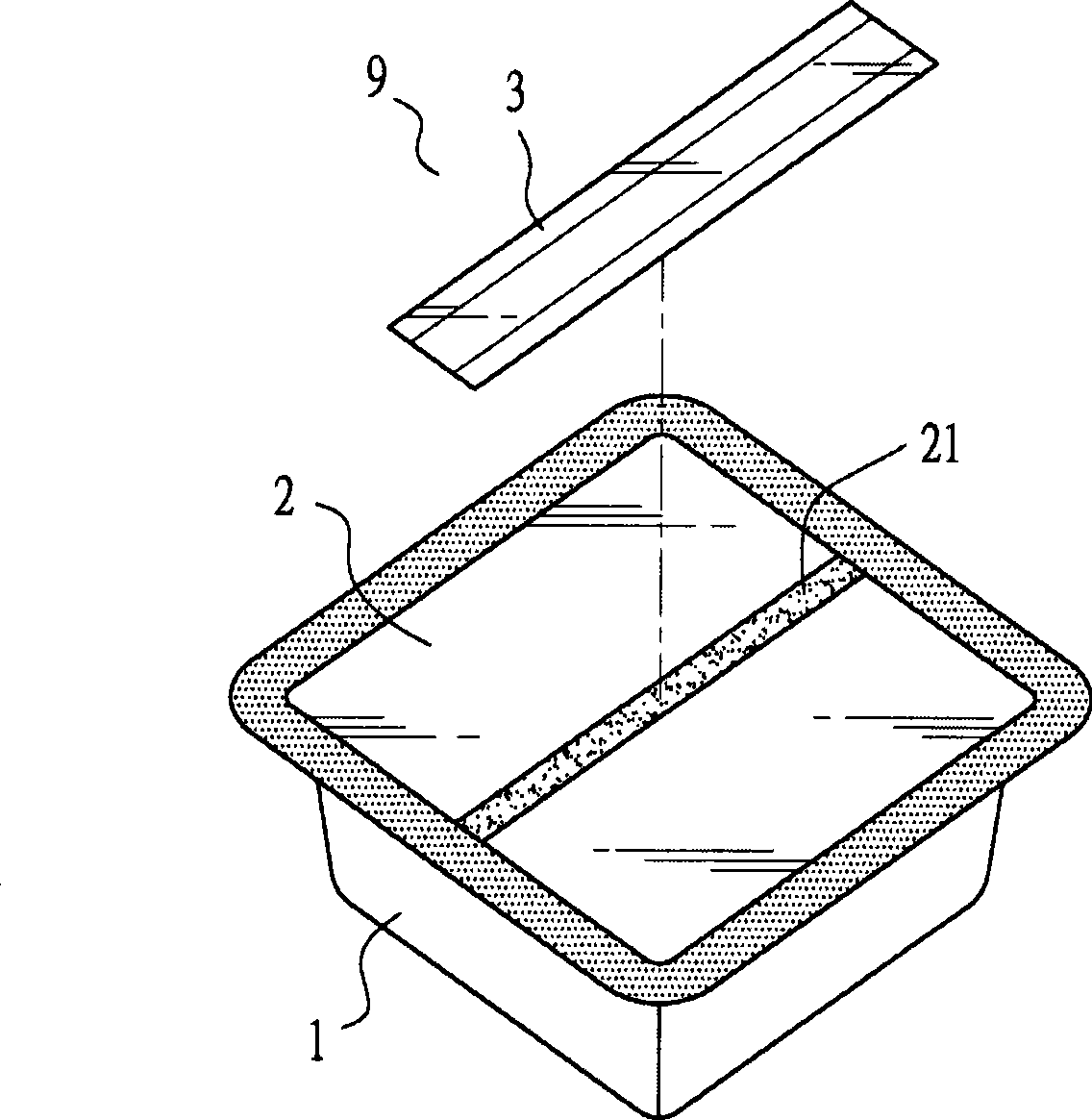

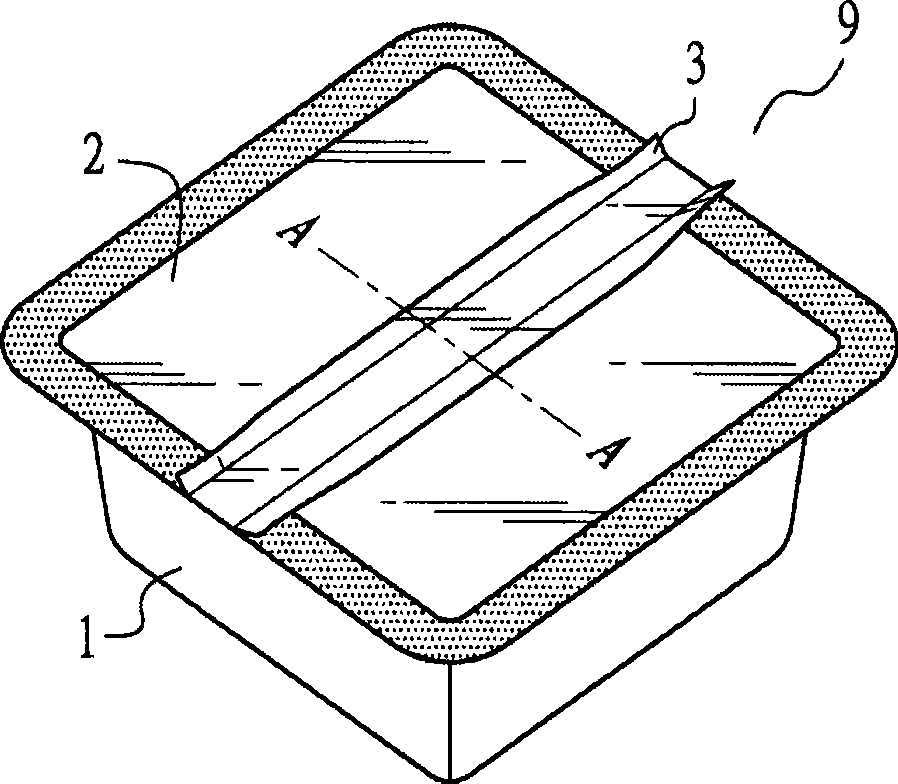

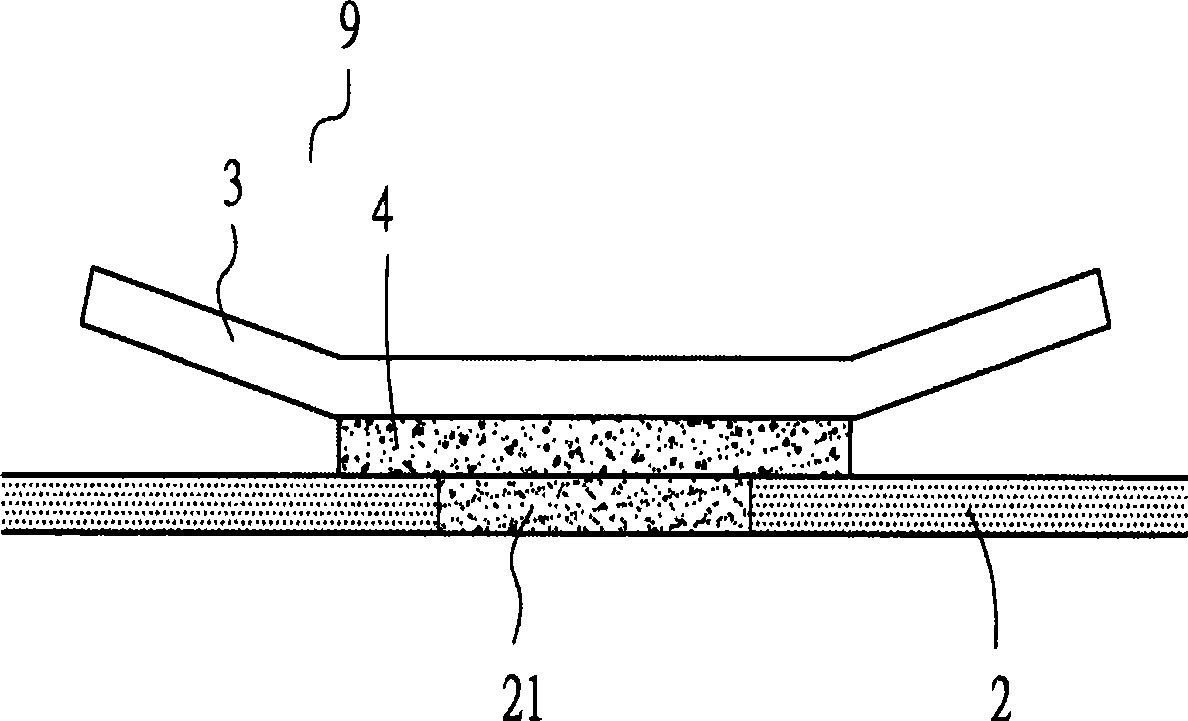

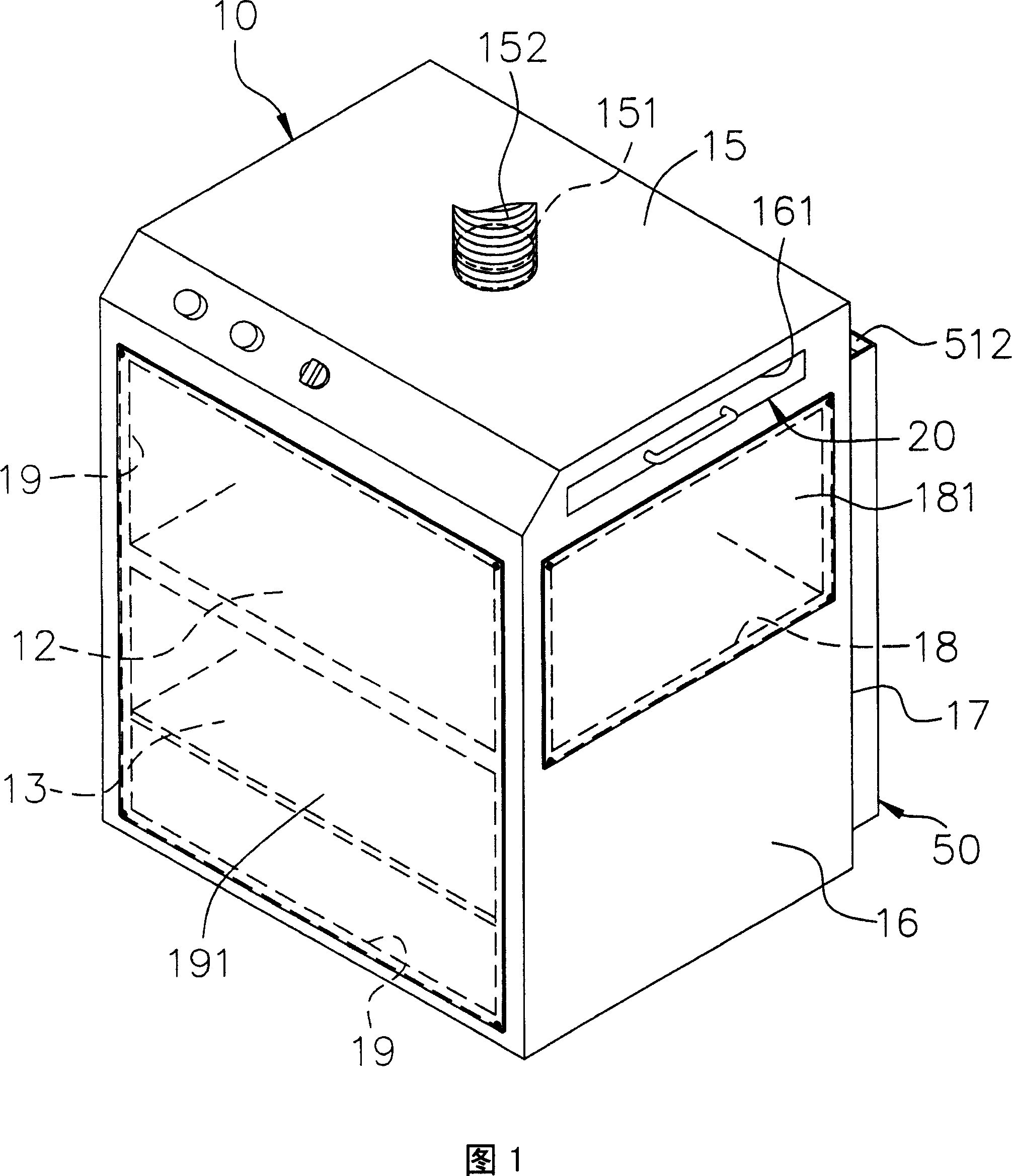

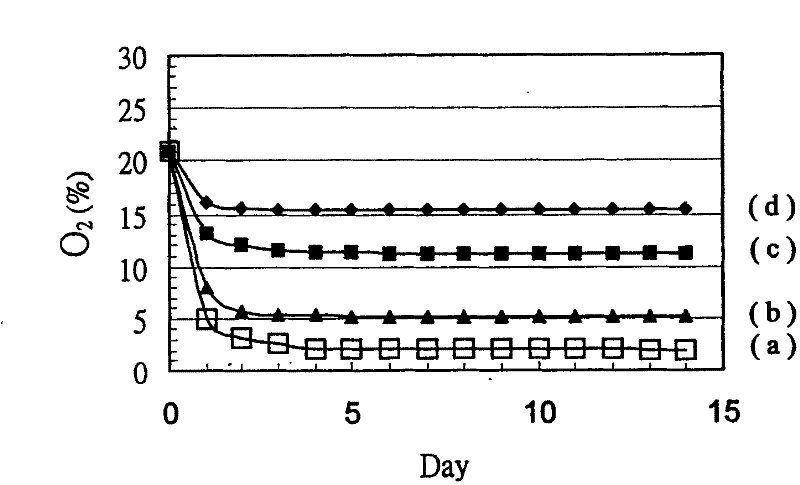

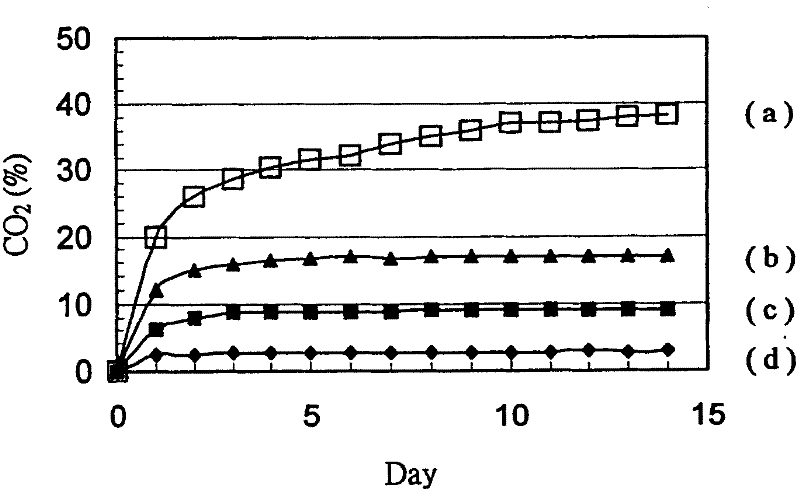

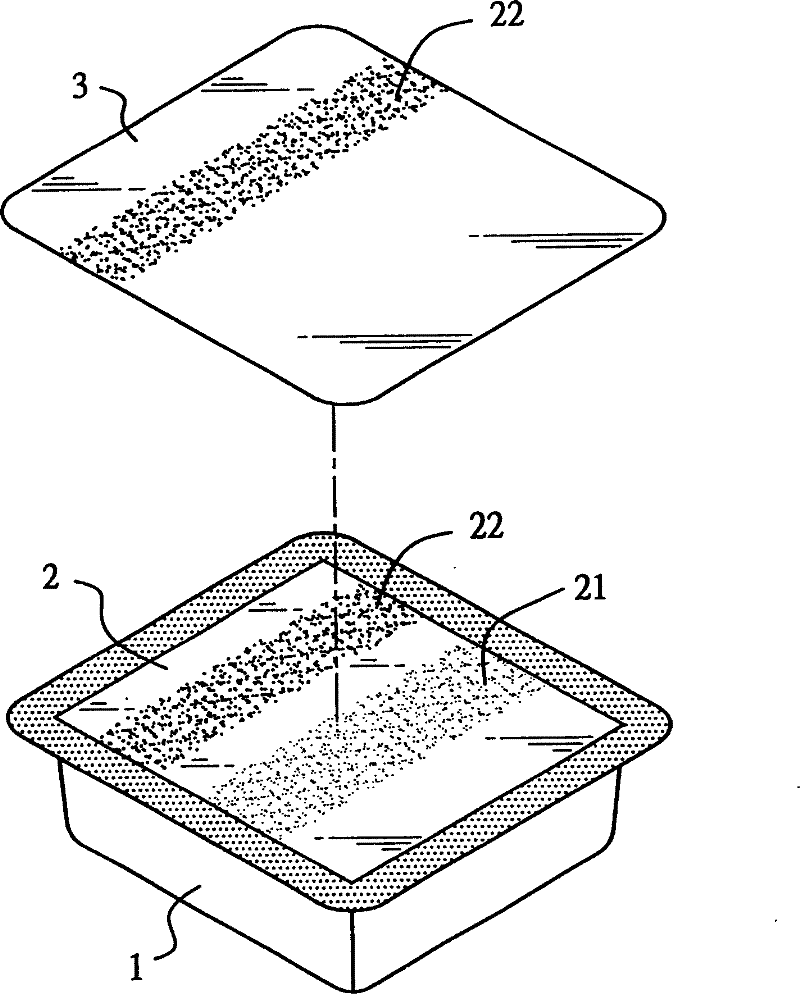

Composite film for hermetic food heating automatic pressure-regulation packaging device and manufacture method thereof

InactiveCN101423134AAvoid exposurePrevent bleachingFlexible coversWrappersComposite filmSteam pressure

The invention discloses a compound film used for an air-tight food-heating automatic pressure-regulating packing apparatus and a corresponding manufacturing method. The compound film is formed by a base film which is provided with a plurality of microcosmic clearance structure zones and on which an adhesive layer of an adhesive tape is coated to form a plurality of microcosmic clearance structure zones. The invention is especially used for various food packing boxes and bags, and after being packed and sealed, the food can be directly frozen in a sealed manner; when the food is to be cooked, the adhesive tape can be torn for a repeated use or the package containing the frozen food is directly put into a micro-wave oven for heating and the compound film is provided with the function of automatically regulating the high temperature and high steam pressure so as to prevent the explosion of the package in the heating process.

Owner:林大卫

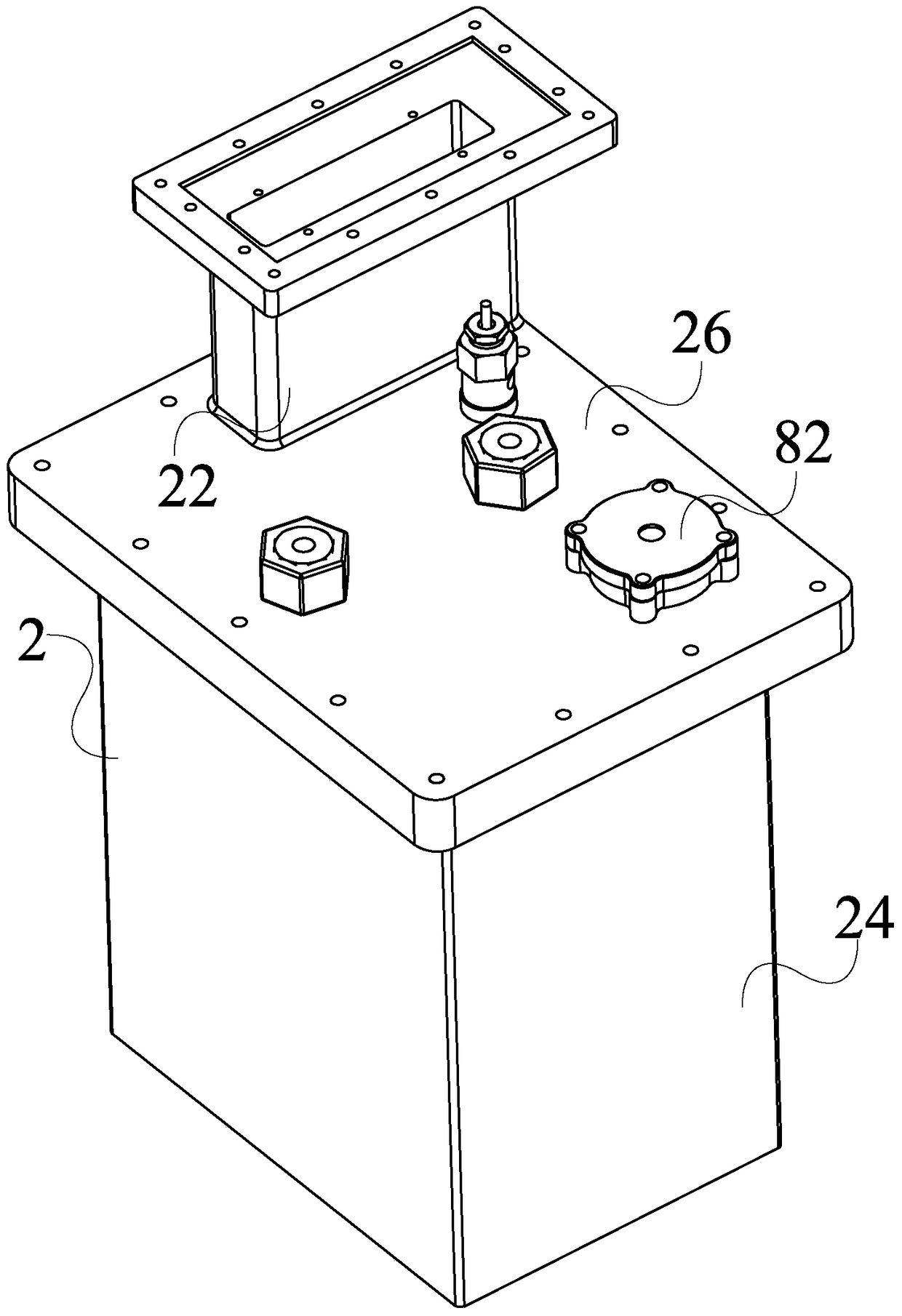

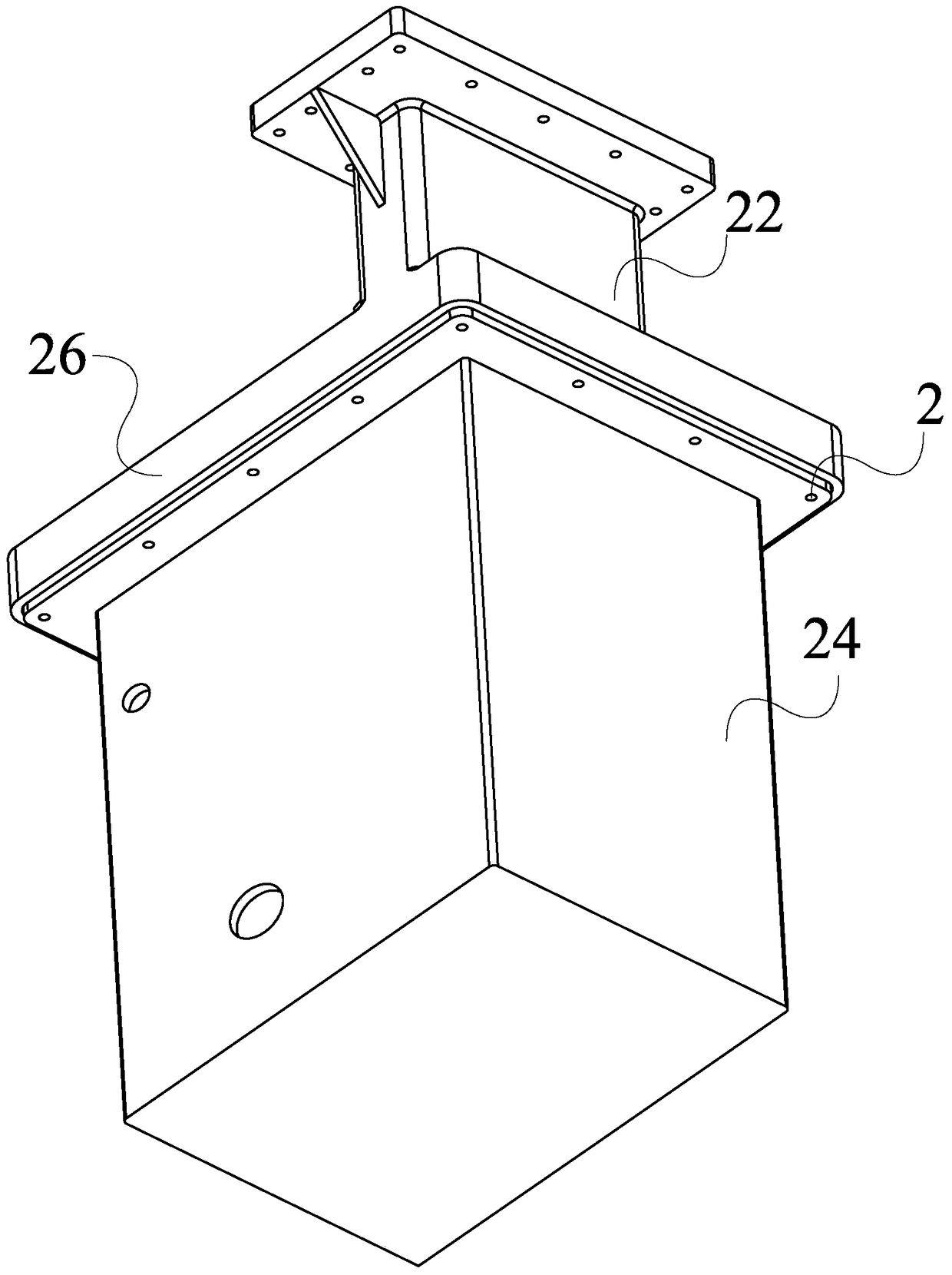

Water electrolysis device

Owner:林信涌

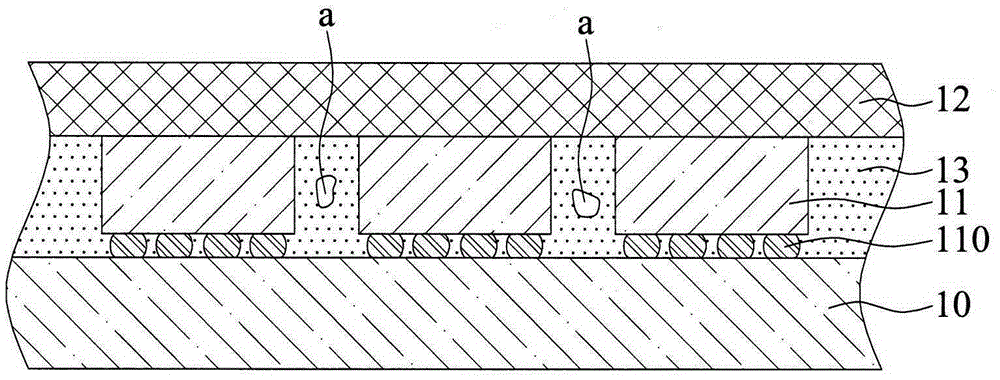

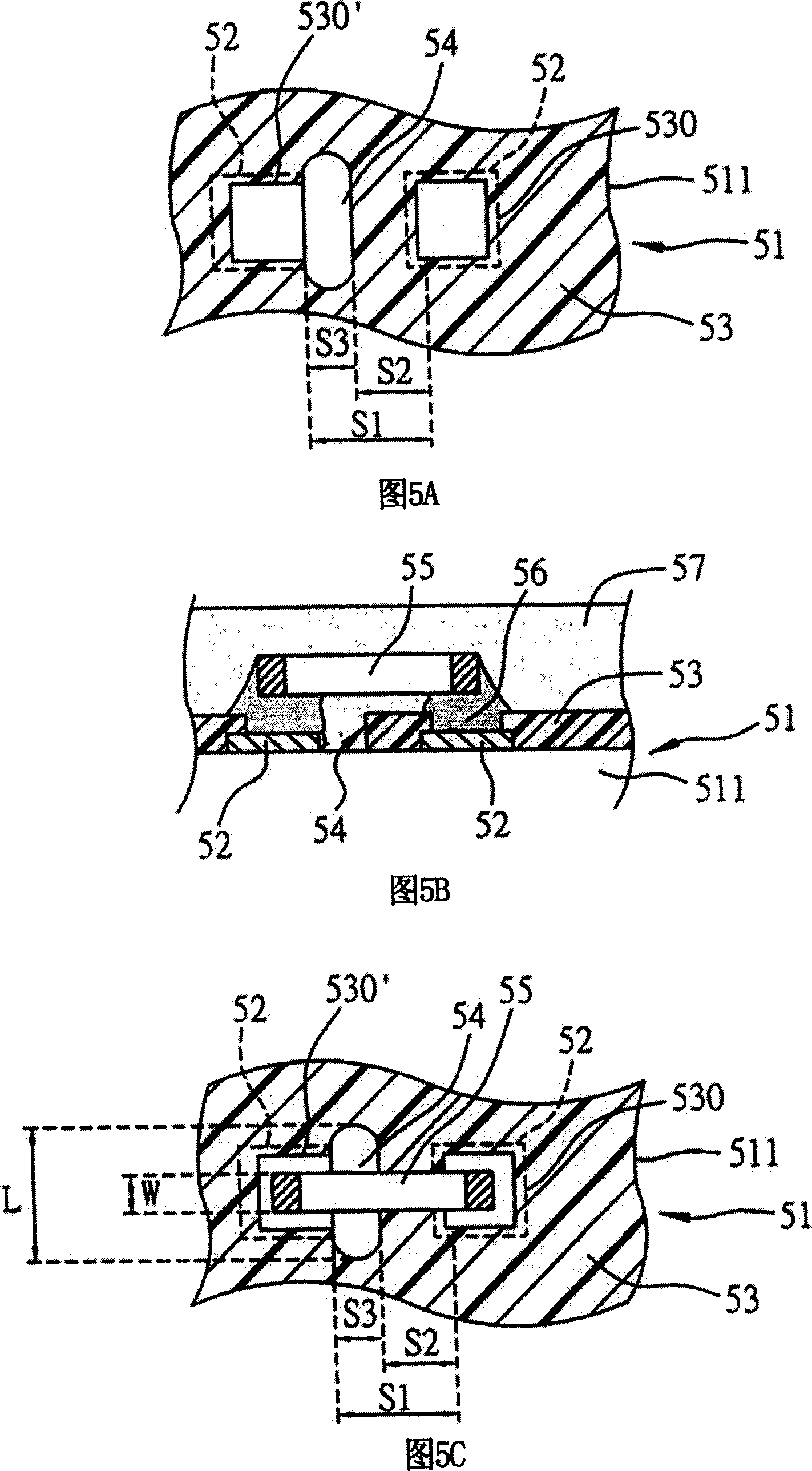

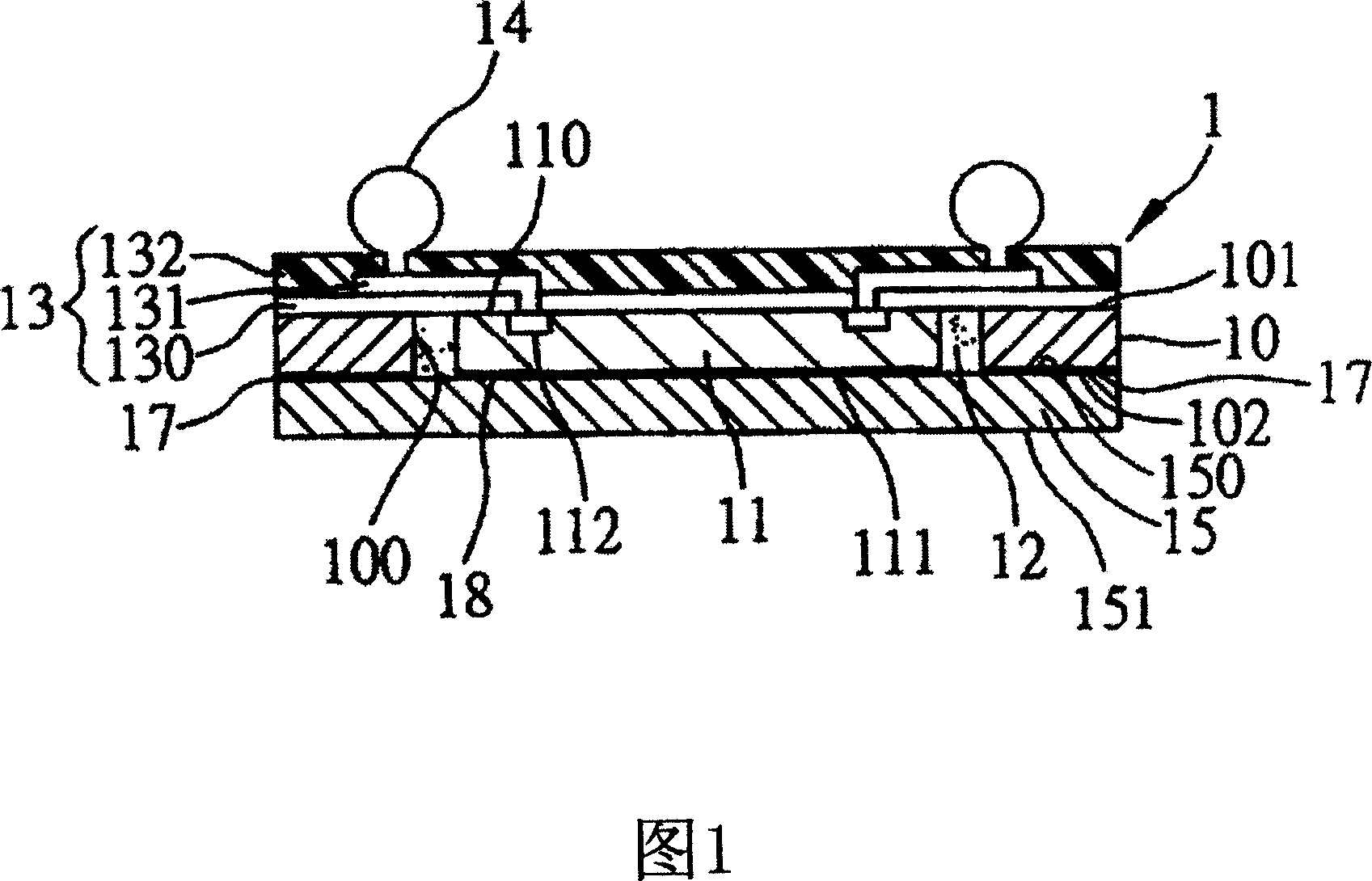

Electronic package and fabrication method thereof

ActiveCN106469712AAvoid formingAvoid gas explosionSemiconductor/solid-state device detailsSolid-state devicesInterposerElectronic component

Owner:SILICONWARE PRECISION IND CO LTD

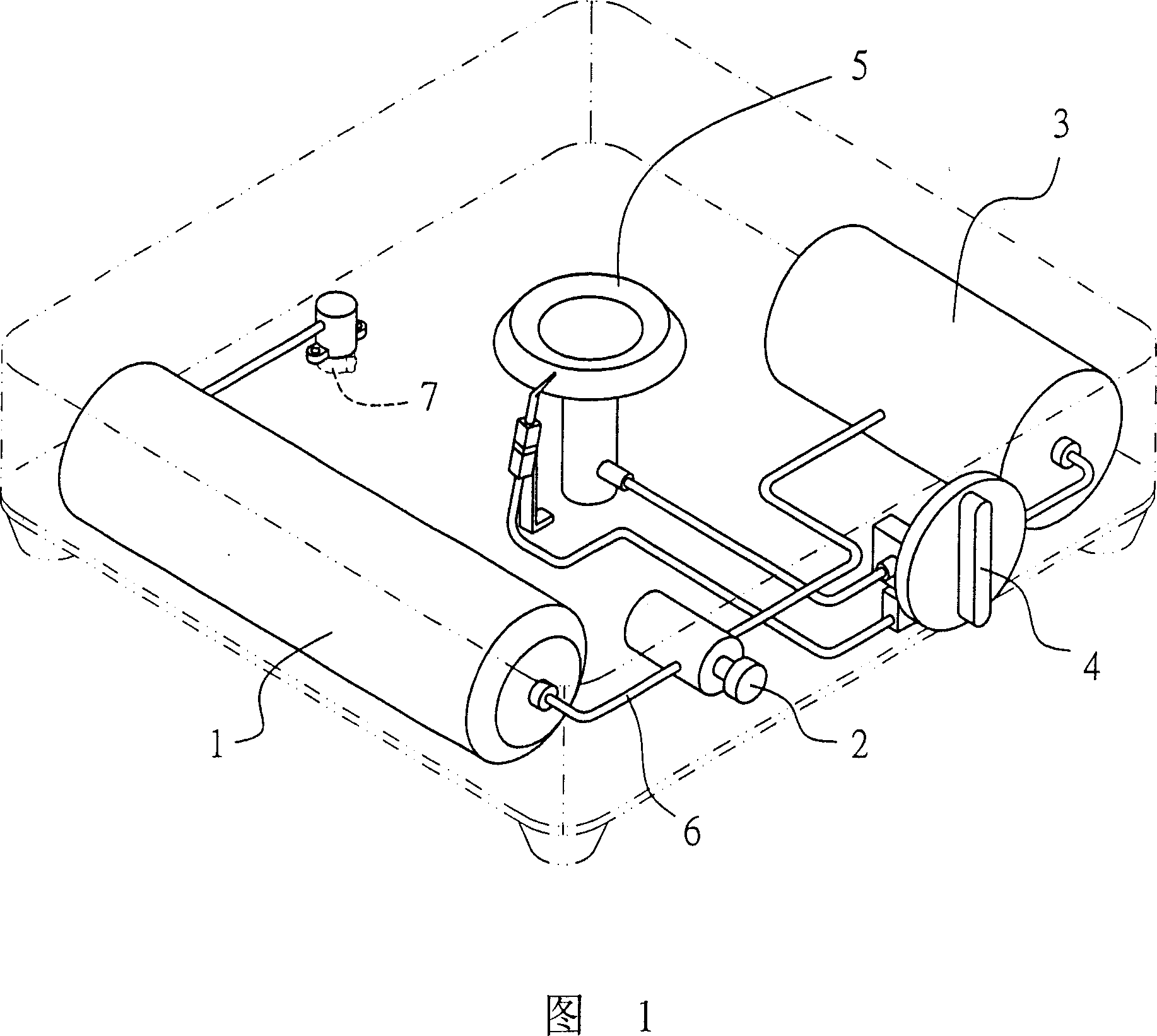

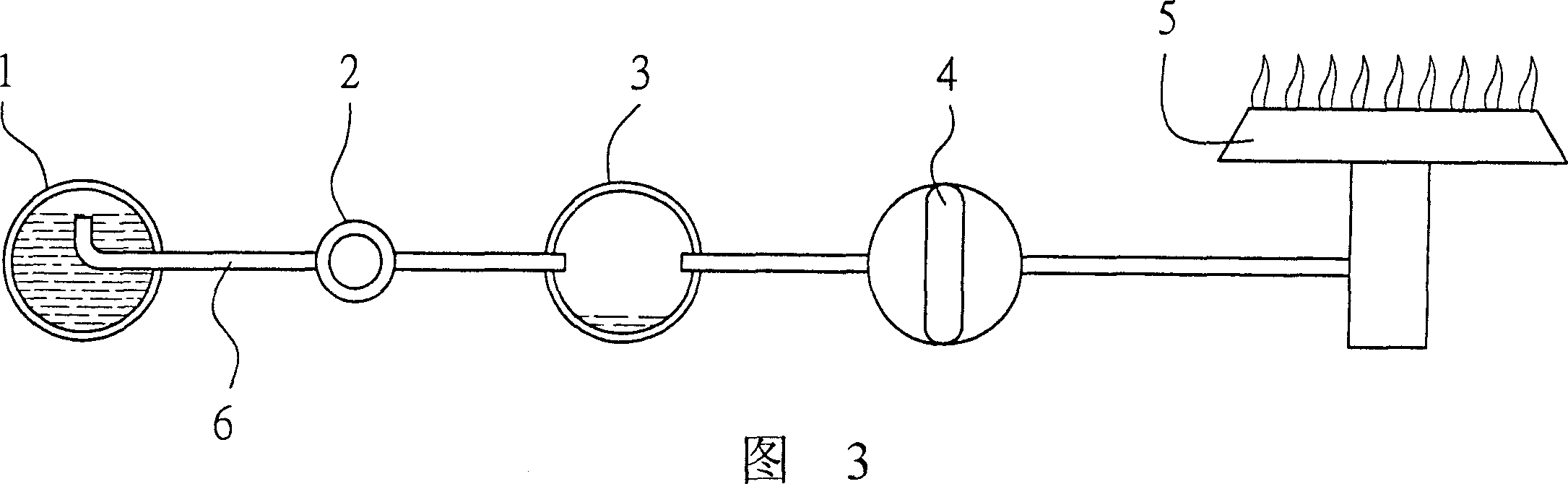

Gas-filled type gas oven

InactiveCN101063530AAvoid gas explosionDomestic stoves or rangesLighting and heating apparatusCombustionProcess engineering

The invention relates to an inflatable gas oven, comprising a gas storage slot, a gas switch, a oven core and a gas channel, wherein a gas storage cushion slot is arranged between the gas storage slot and the gas switch, with a switch at the front end of gas storage cushion slot, therefore, gas with high pressure in the gas storage slot can be charged to gas storage cushion slot to flow to the oven core and achieve complete combustion when hand presses the switch and turn the gas switch, to prevent from spreading flame or gas explosion caused by overheat of gas oven.

Owner:詹政通

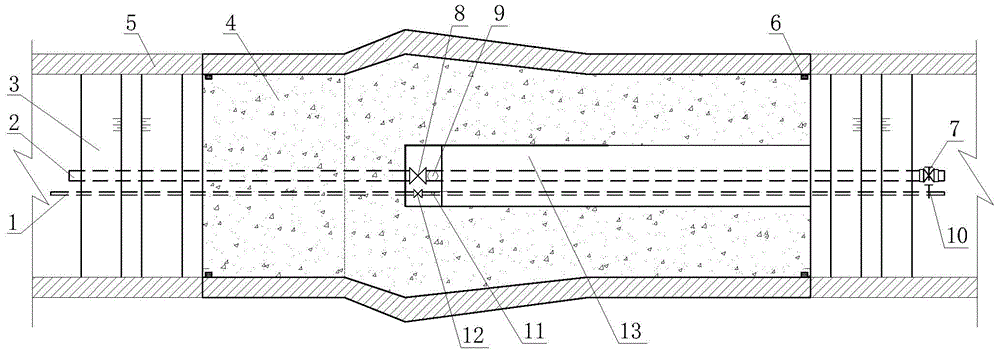

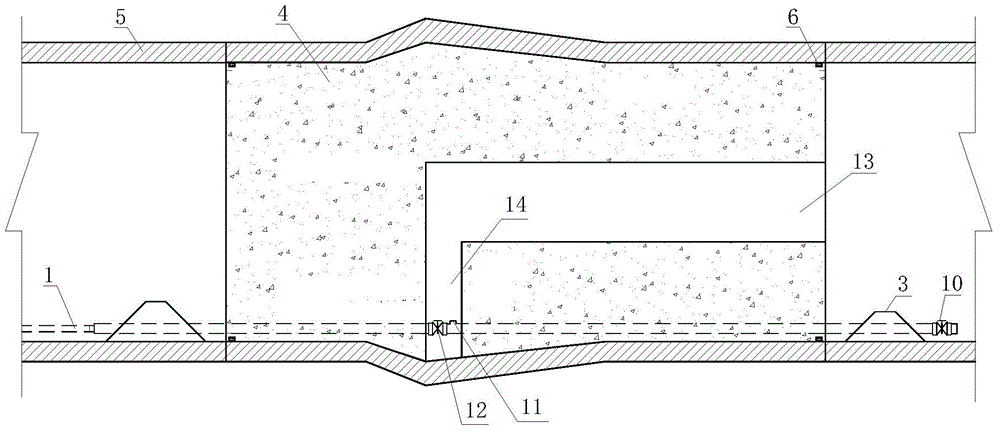

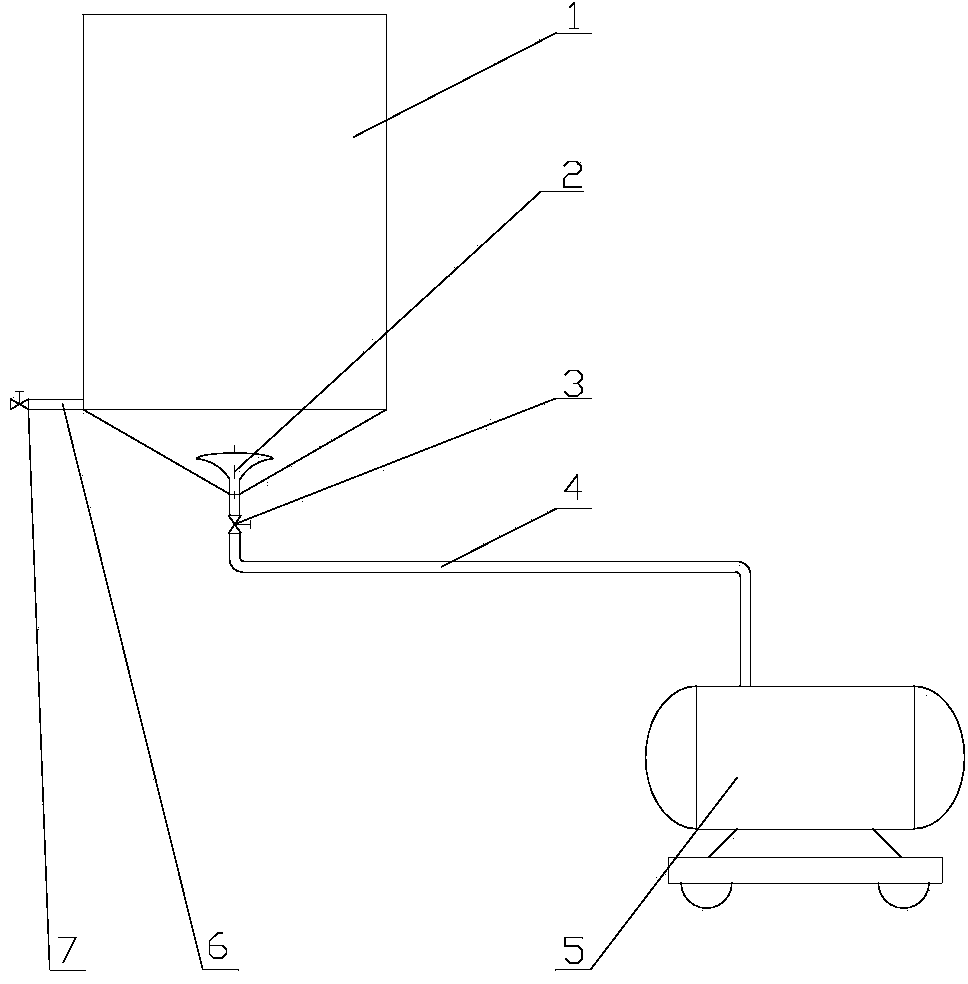

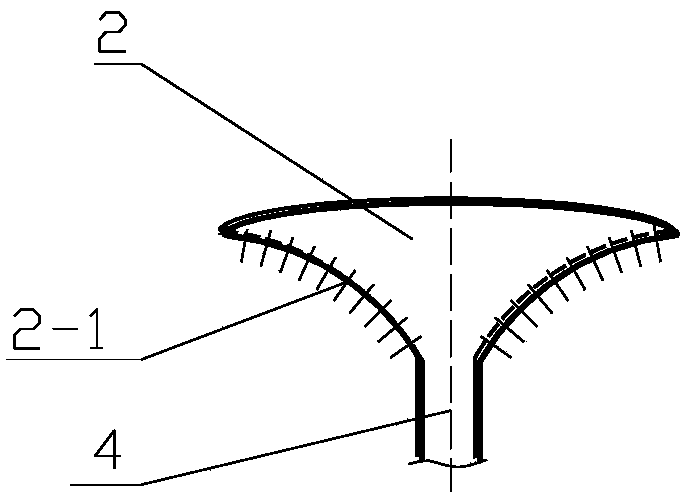

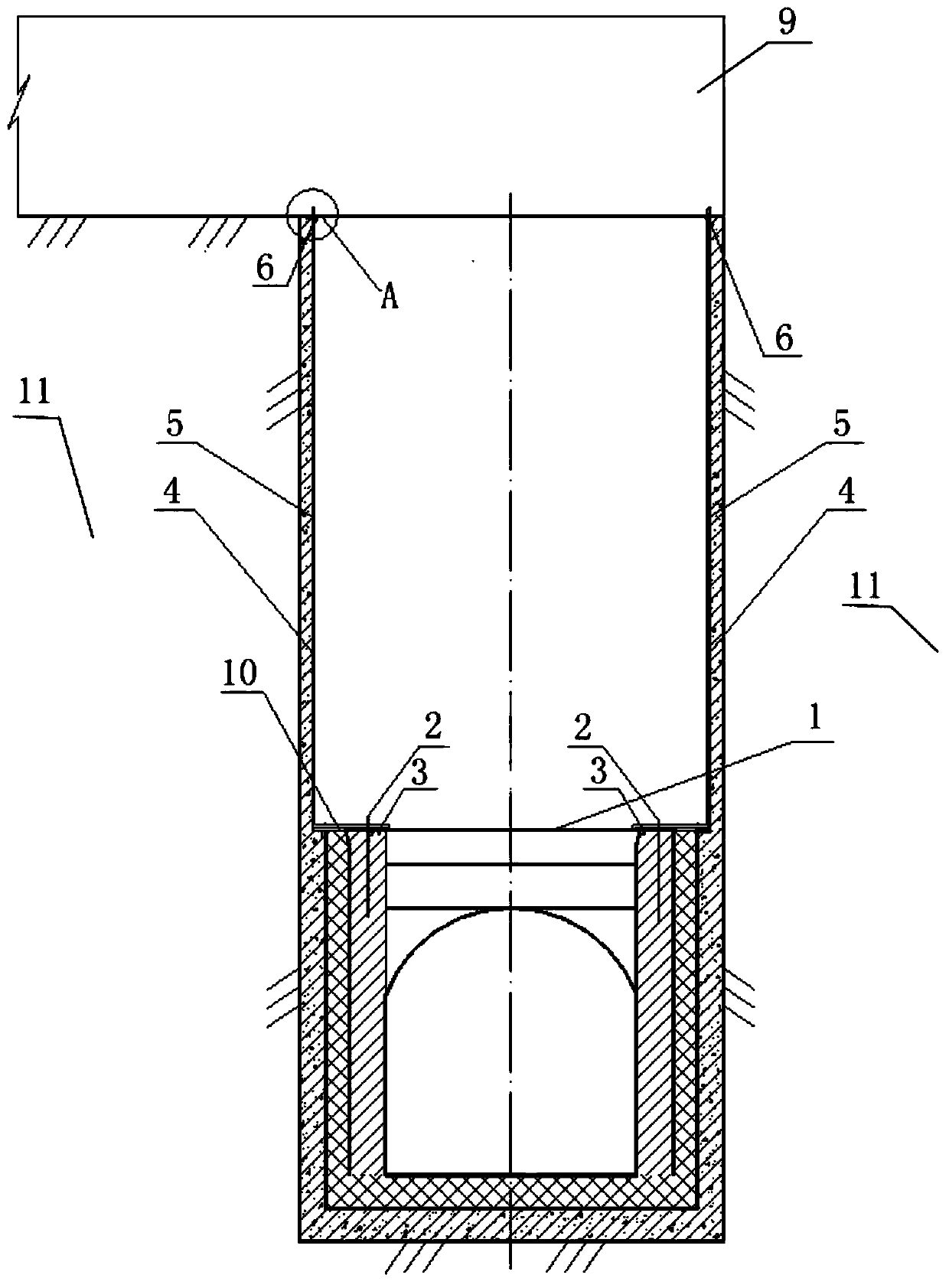

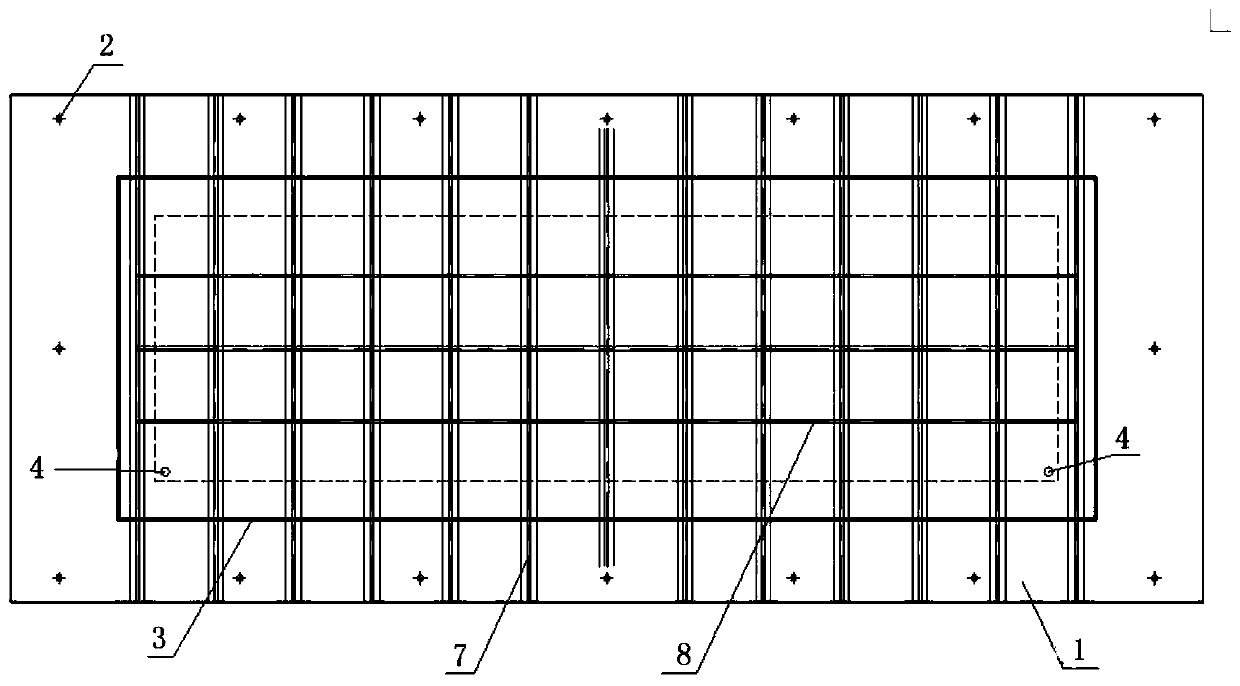

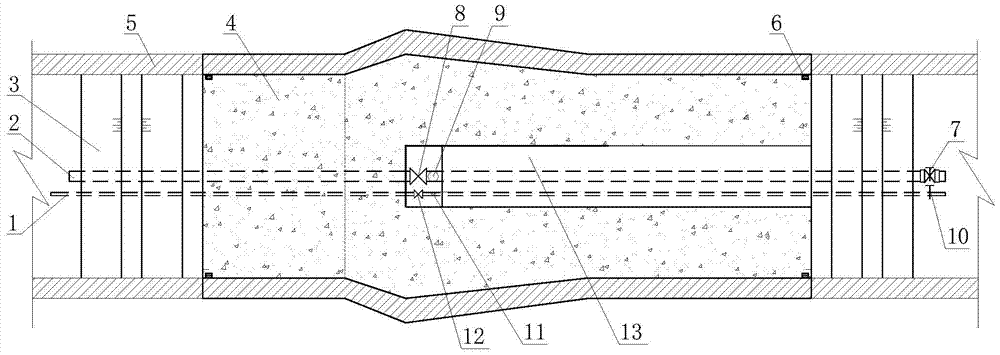

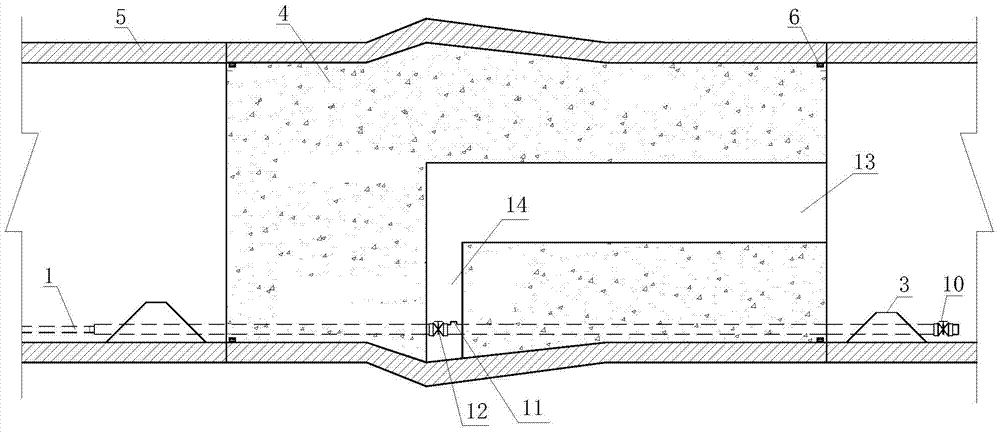

Diversion tunnel plug head exhaust structure and exhaust method thereof

ActiveCN104963324AEasy dischargeEnsure safetyWater-power plantsHydro energy generationWater dischargePipe water

The invention discloses a diversion tunnel plug head exhaust structure and an exhaust method thereof; the diversion tunnel plug head exhaust structure comprises a diversion cylinder and a concrete plug head arranged in a blocking segment in the diversion cylinder; the bottom of the concrete plug head is pre-buried with an air discharge pipe and a water discharge pipe; an upstream and a downstream of the concrete plug head in the diversion cylinder are respectively provided with a cofferdam; a grouting gallery and a gate well connected with the grouting gallery are arranged in the concrete plug head; the exhaust method comprises the following steps: 1, paving the air discharge pipe and the water discharge pipe; 2, building the cofferdams; 3, opening a water discharge butterfly valve; 4, casting the concrete plug head; 5, opening an air discharge butterfly valve; 6, observing air discharge pipe water discharge conditions. In certain regions, the diversion tunnel is deeply buried, the top is steep and no drilling construction road can be paved, and vent holes are hard to tap; the diversion tunnel plug head exhaust structure and the exhaust method can be applied to the diversion tunnel plugging construction process, thus fast discharging a cavity in the front segment of the diversion tunnel, preventing gas explosion caused by boosting pressure, and ensuring safety of the plug head structure.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Combustion installation

InactiveCN1430034AReduce the temperatureImprove combustion effectAir heatersHeating arrangementCombustion chamberPlate heat exchanger

A combustion apparatus is composed of an internal combustion furnace and an isolating cylinder surrounding said internal combustion furnace by a gap between them. Said fume has a top heat exchanger, a partition for dividing it intor primary and secondary combustion chamber and cooling chamber, and a load-bearing plate. Said isoalting cylinder has a hot air tube for heat exchanger and two reflux plates for circulating airflow in said gap. The material can be fully burnt and its ash is cooled in cooling chamber for discharging. It can also supply clean hot air by heat exchanger.

Owner:林岱右

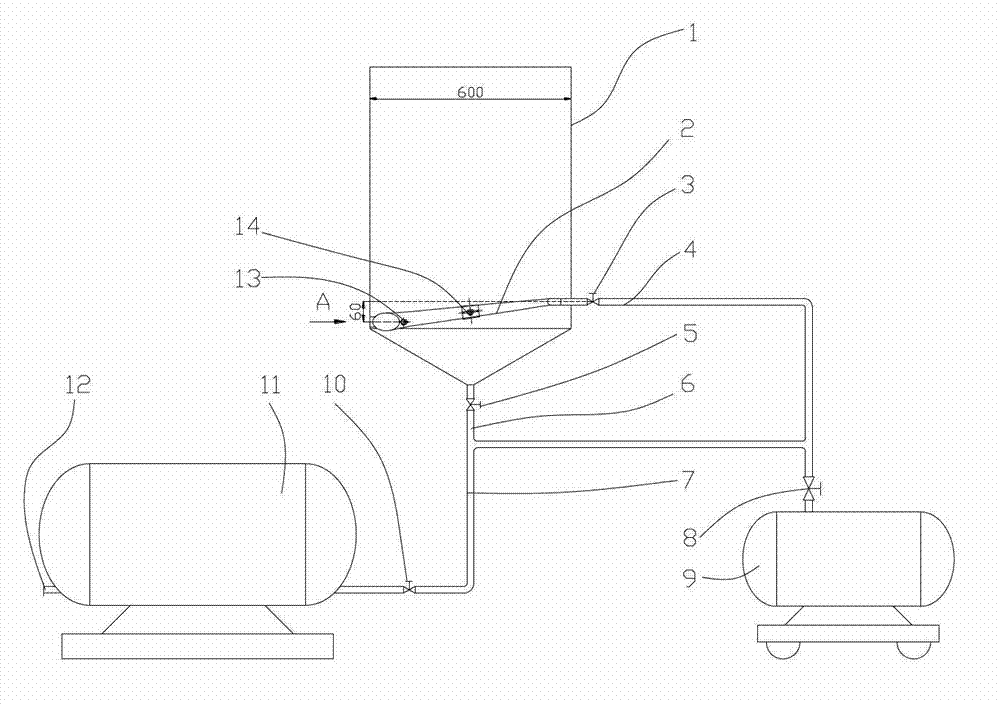

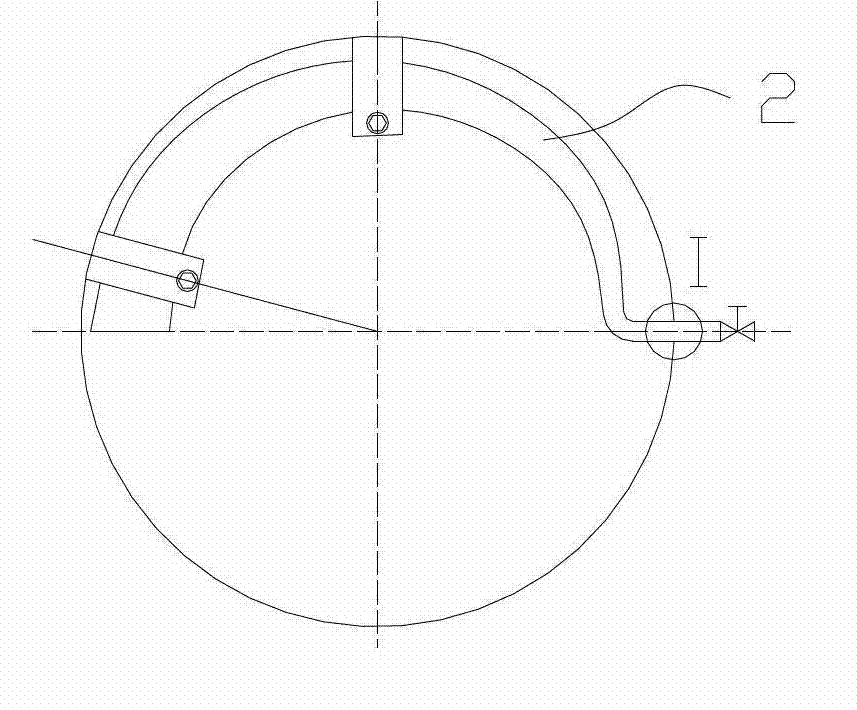

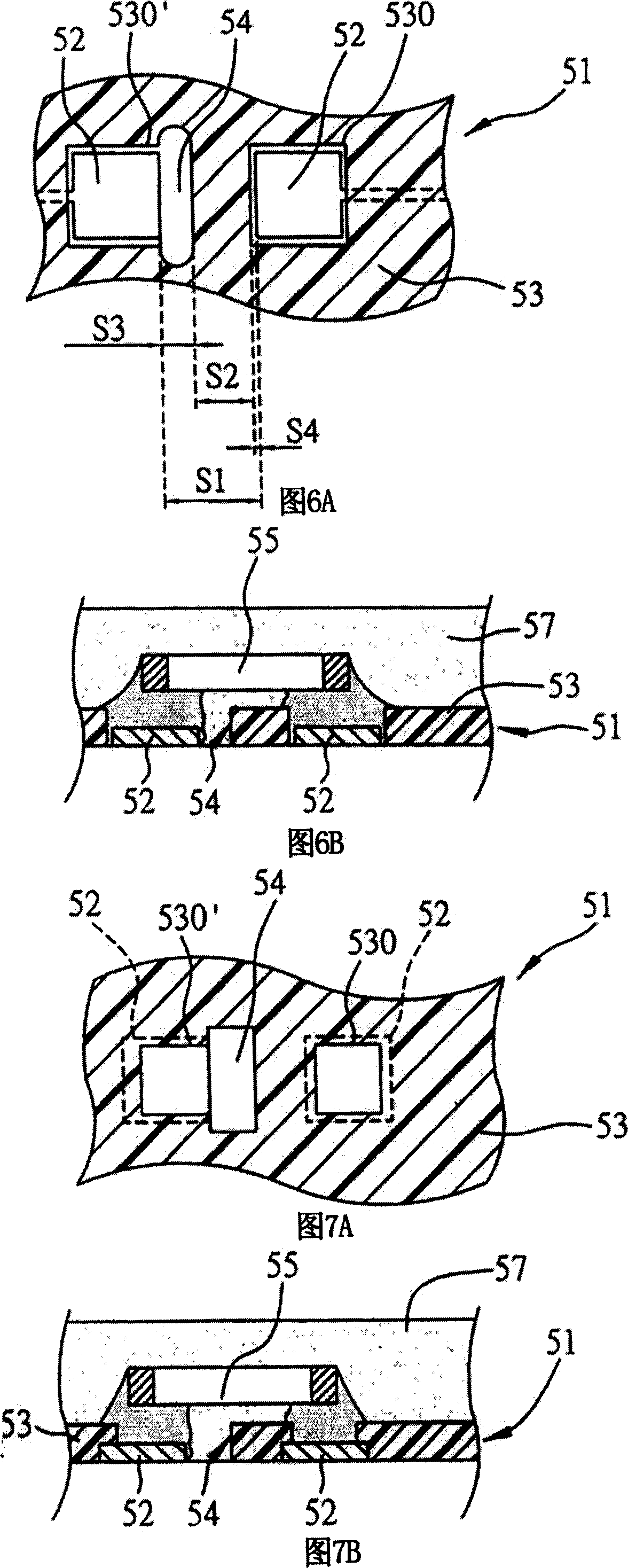

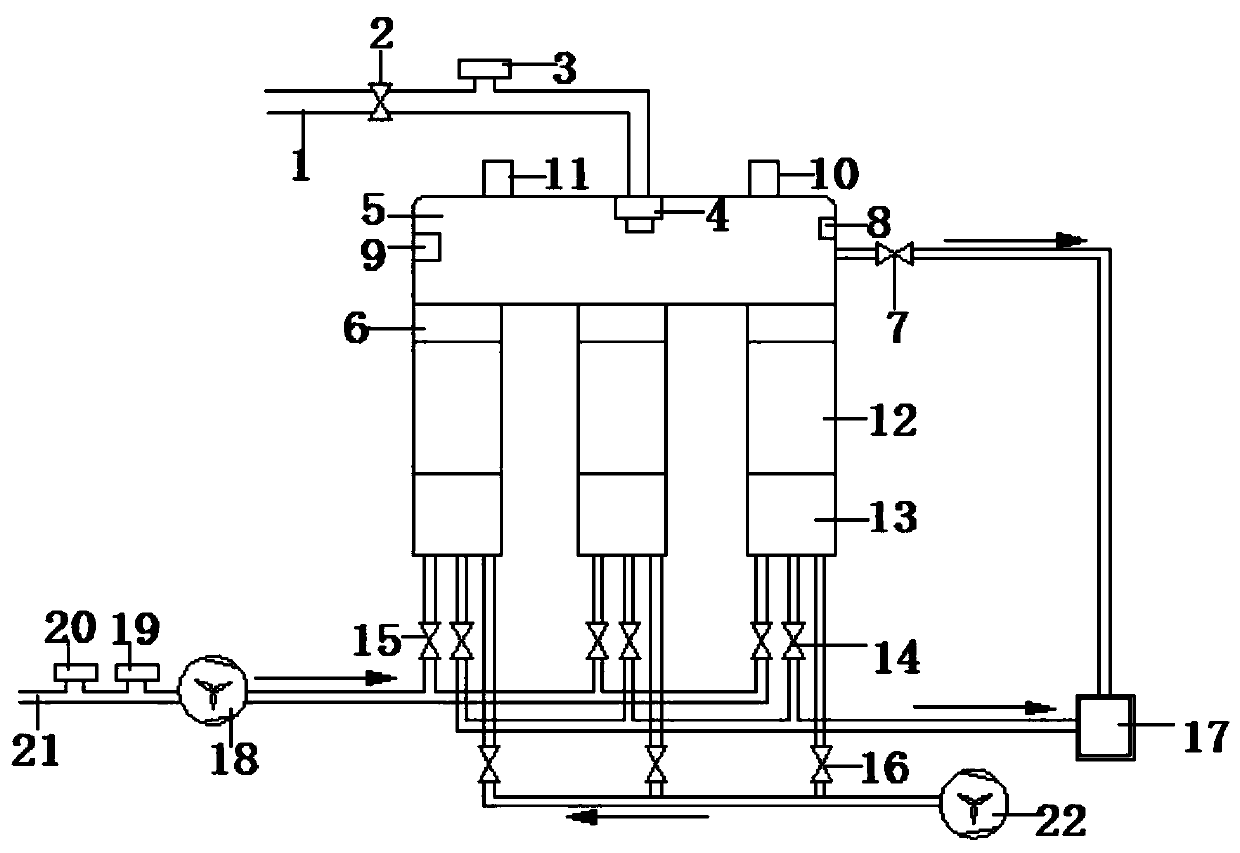

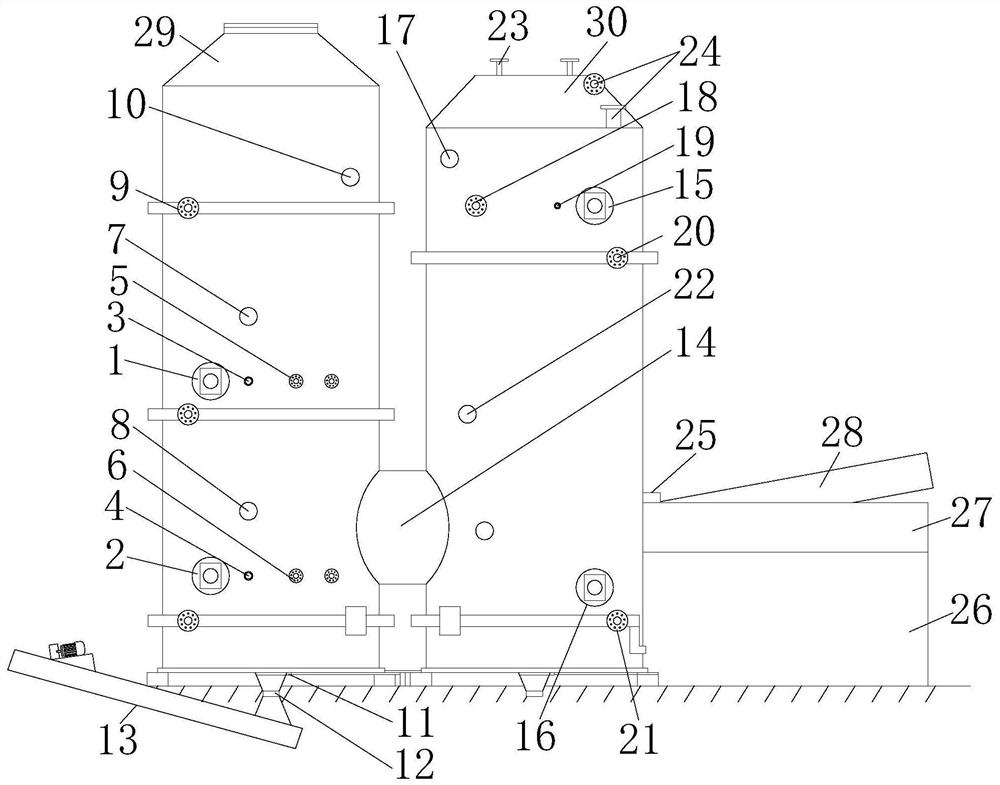

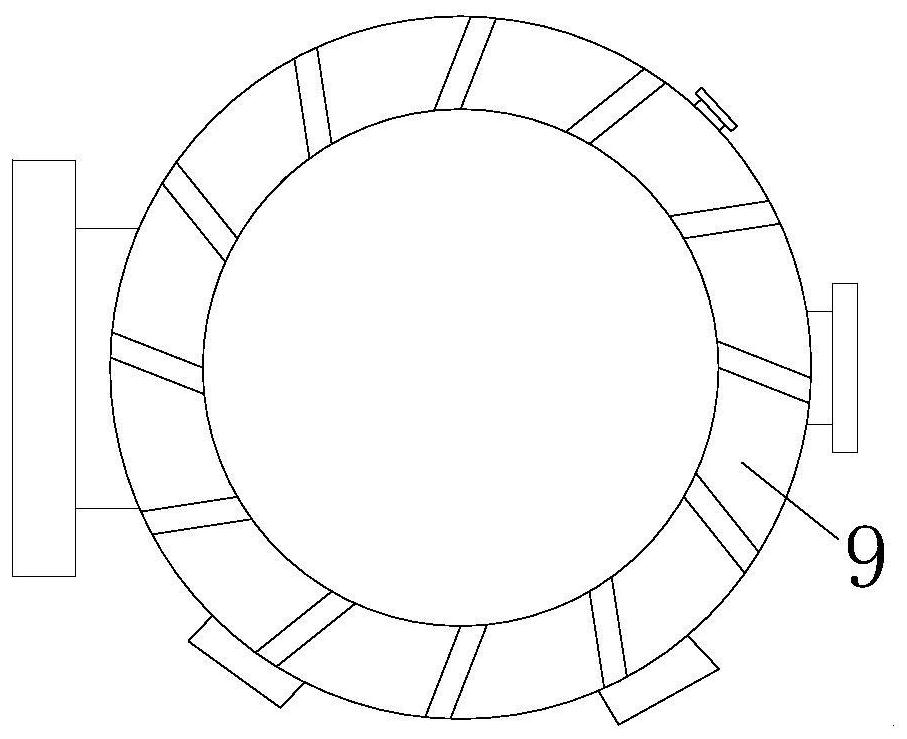

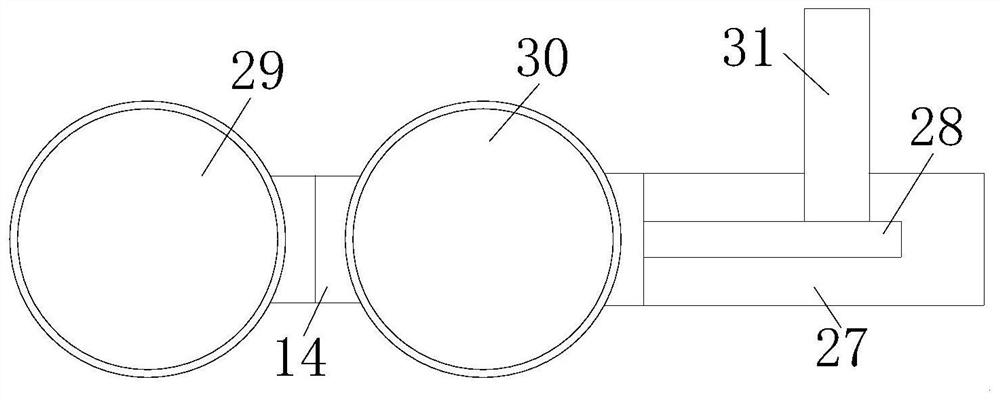

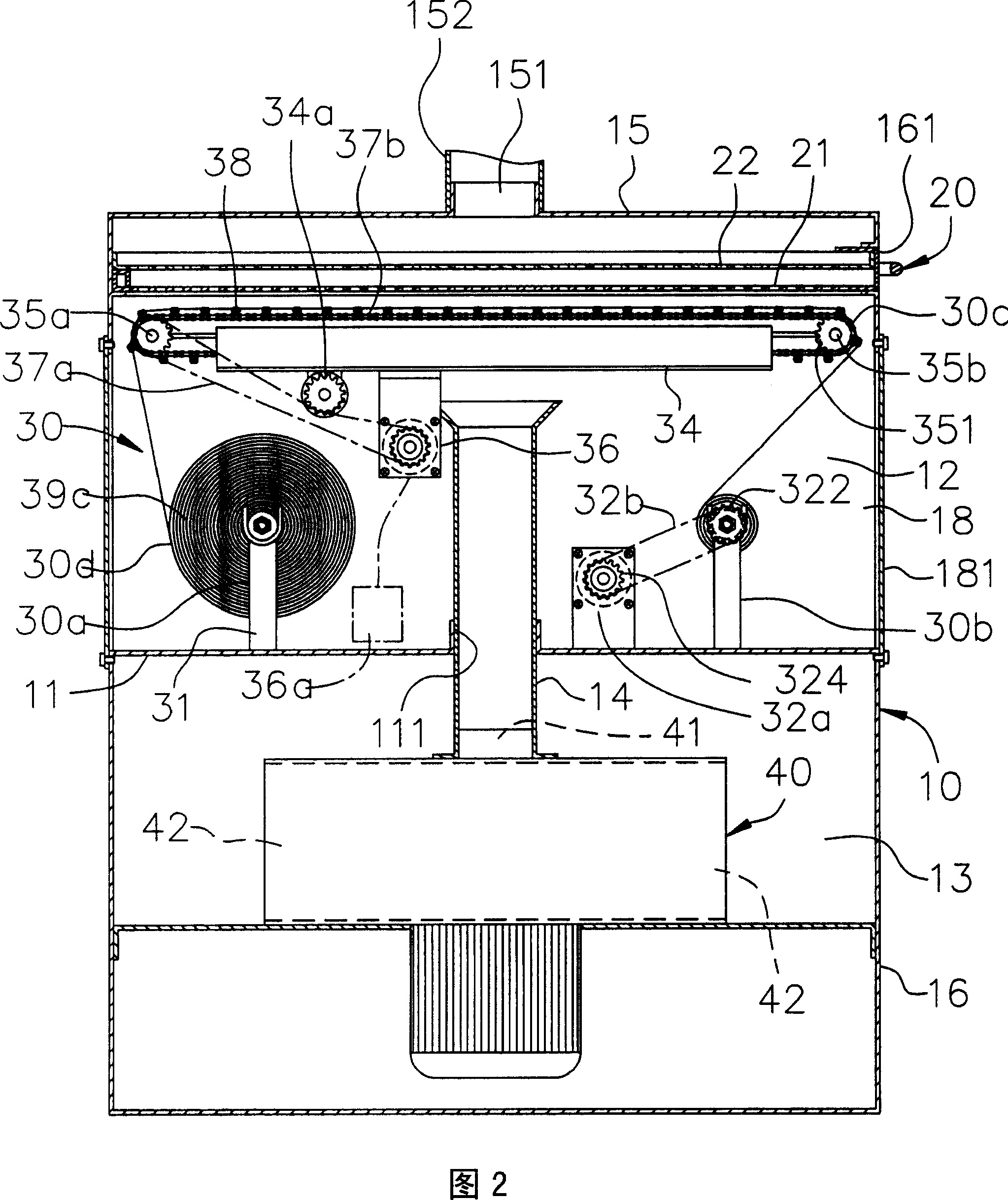

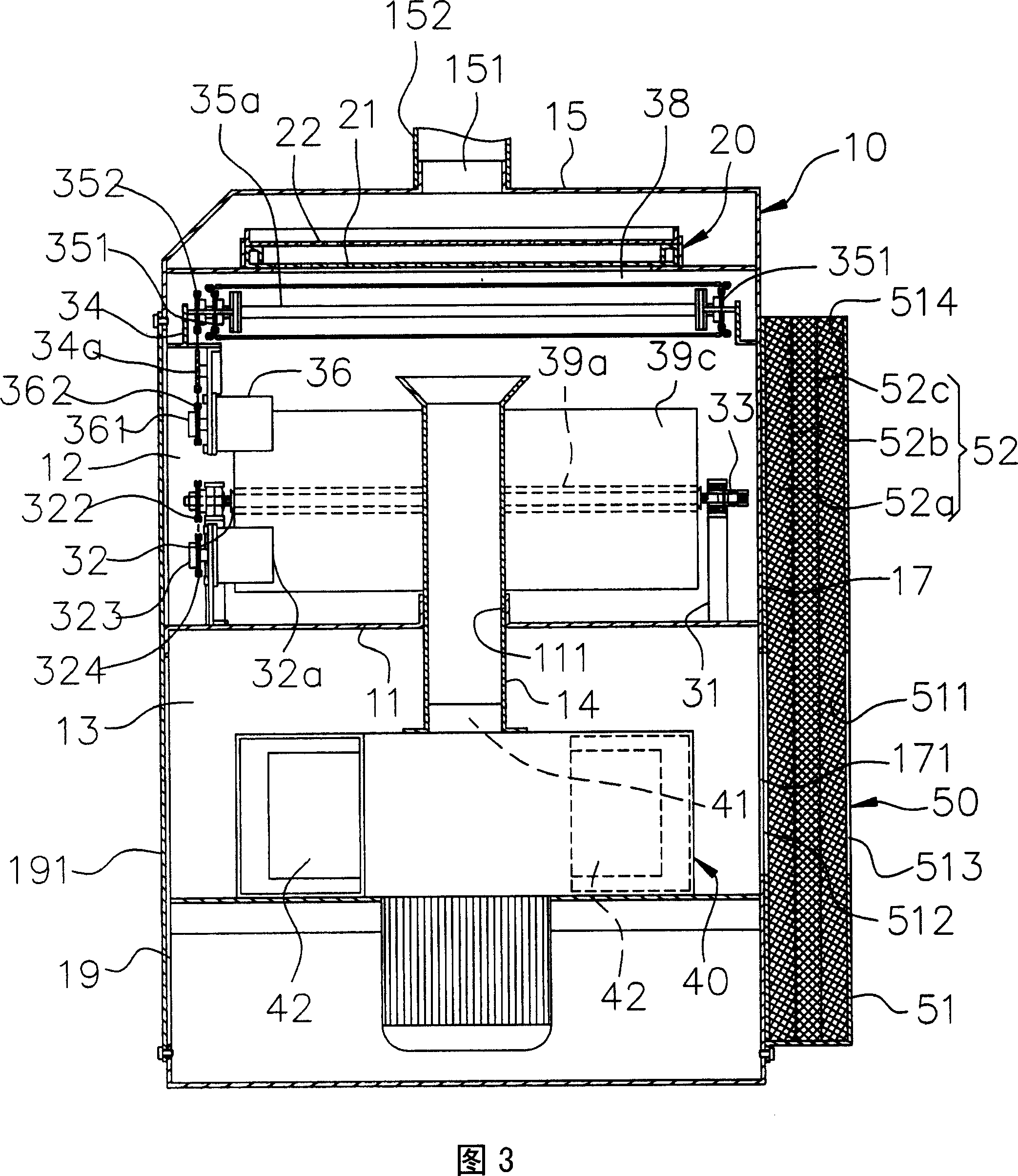

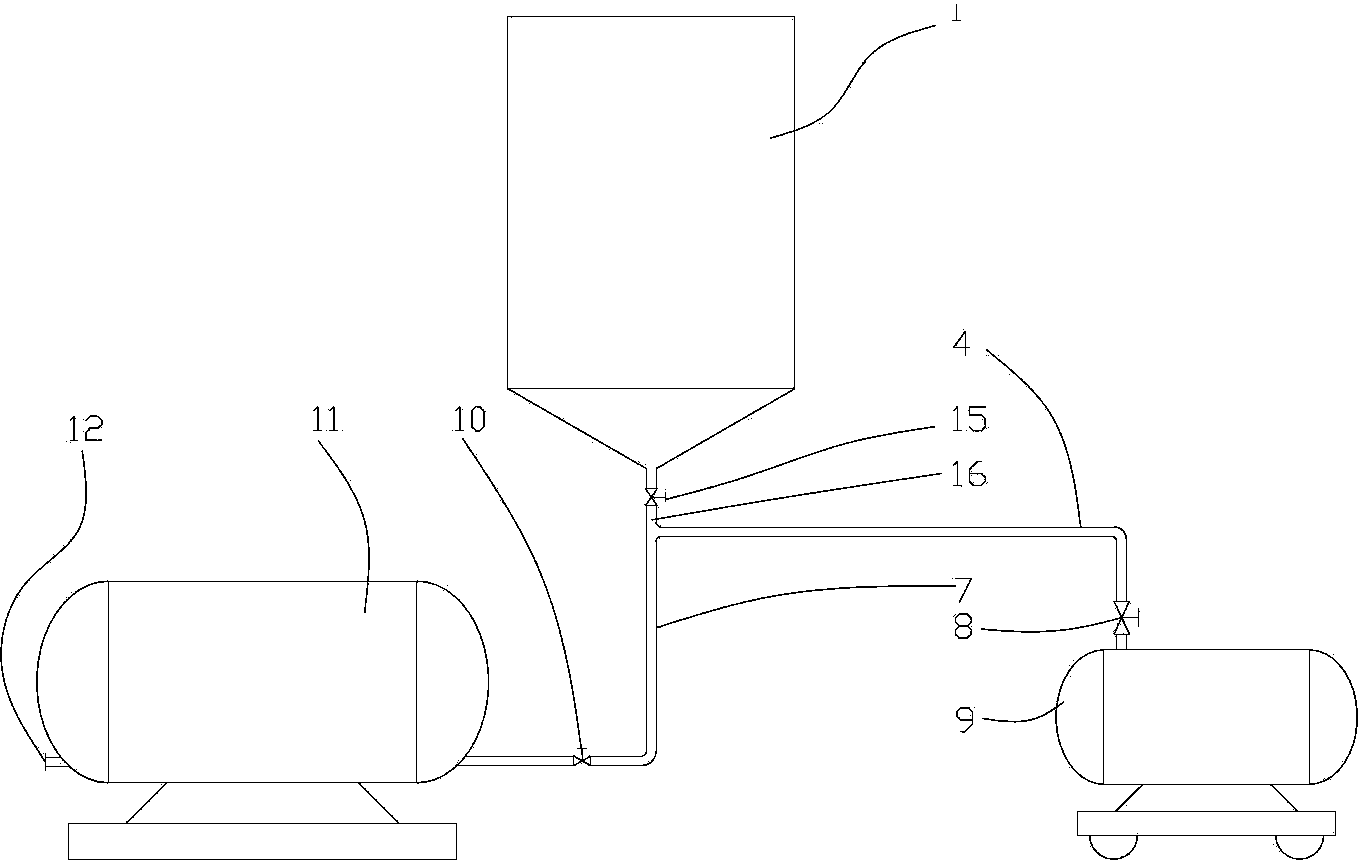

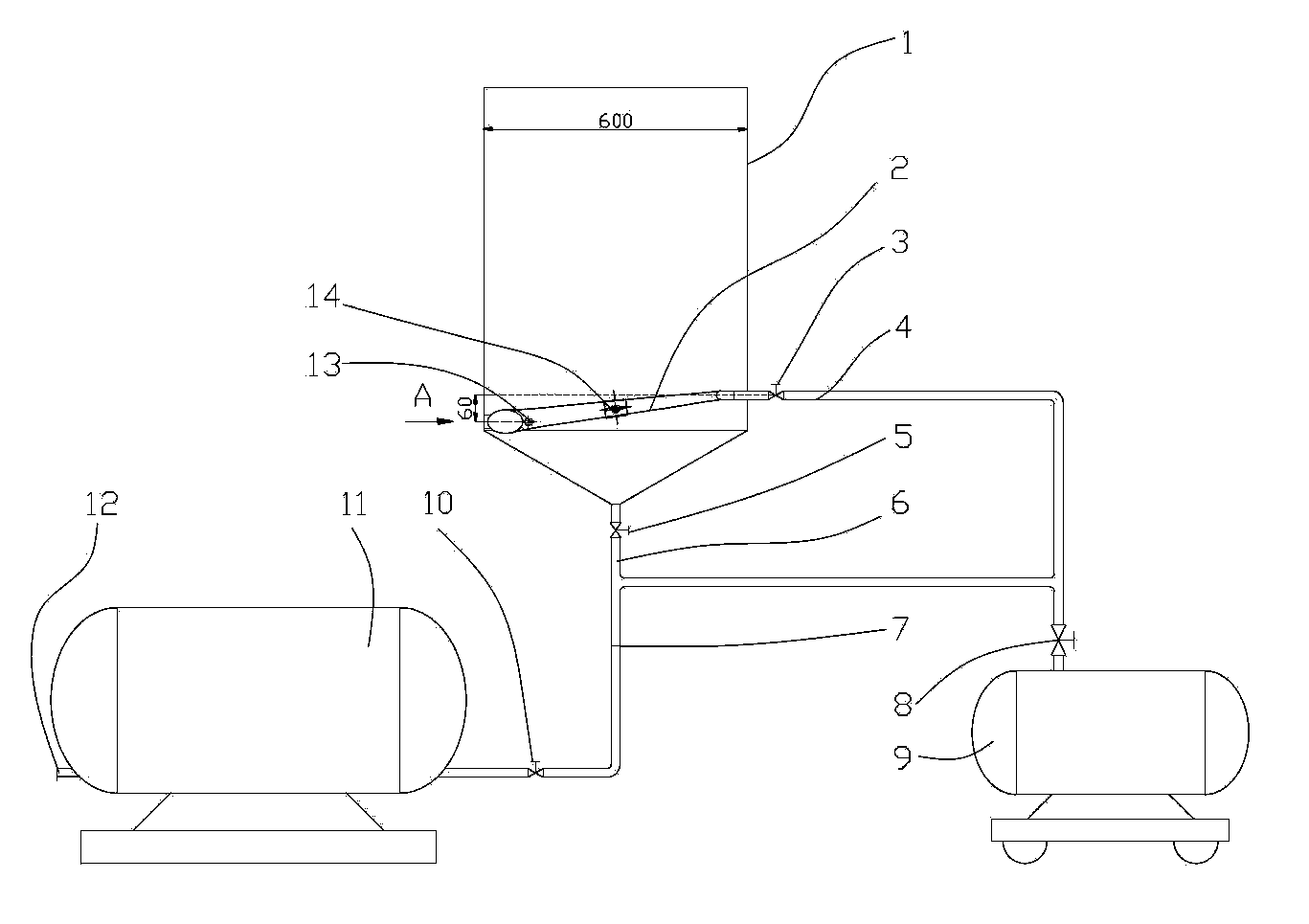

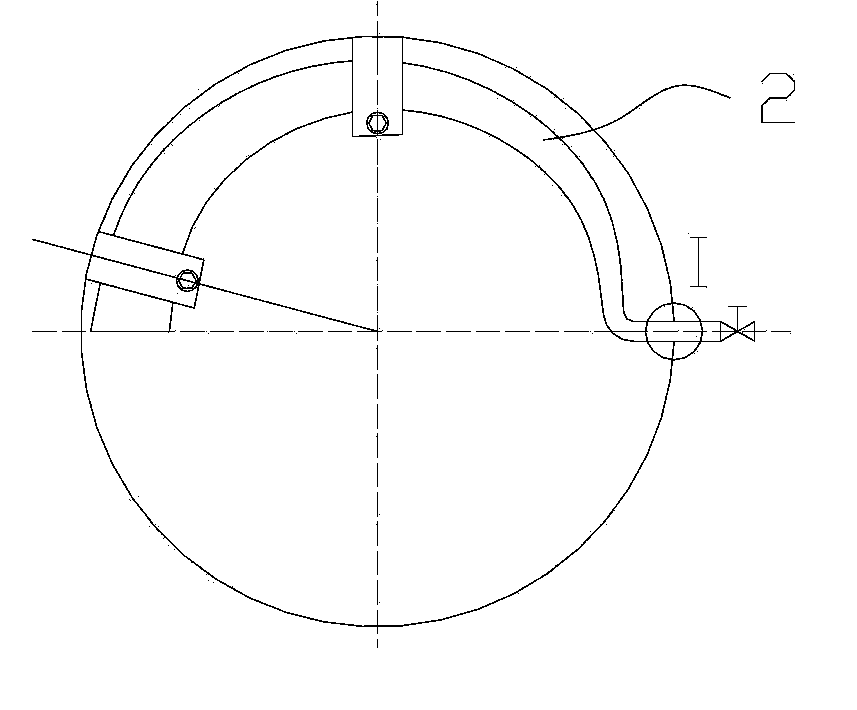

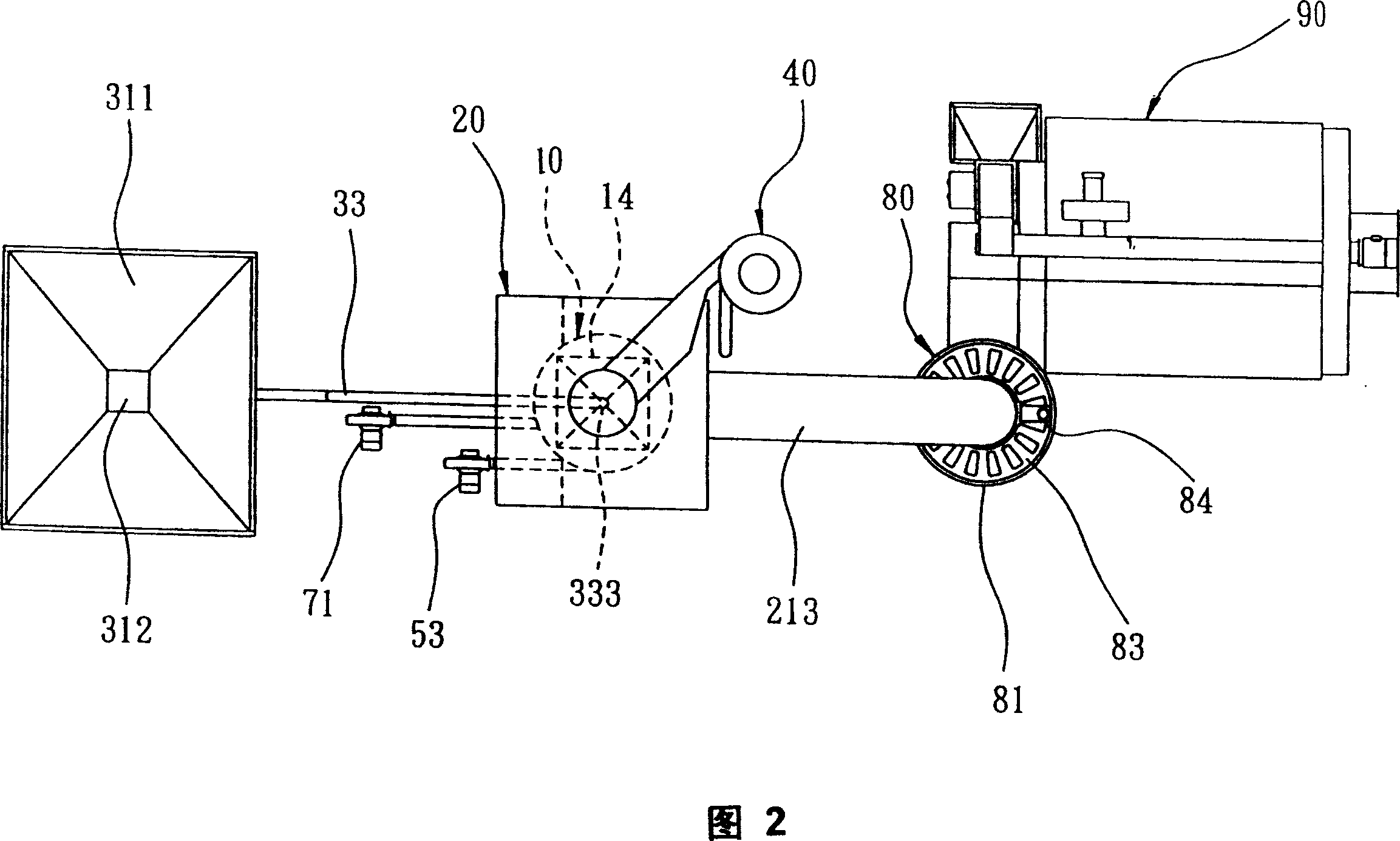

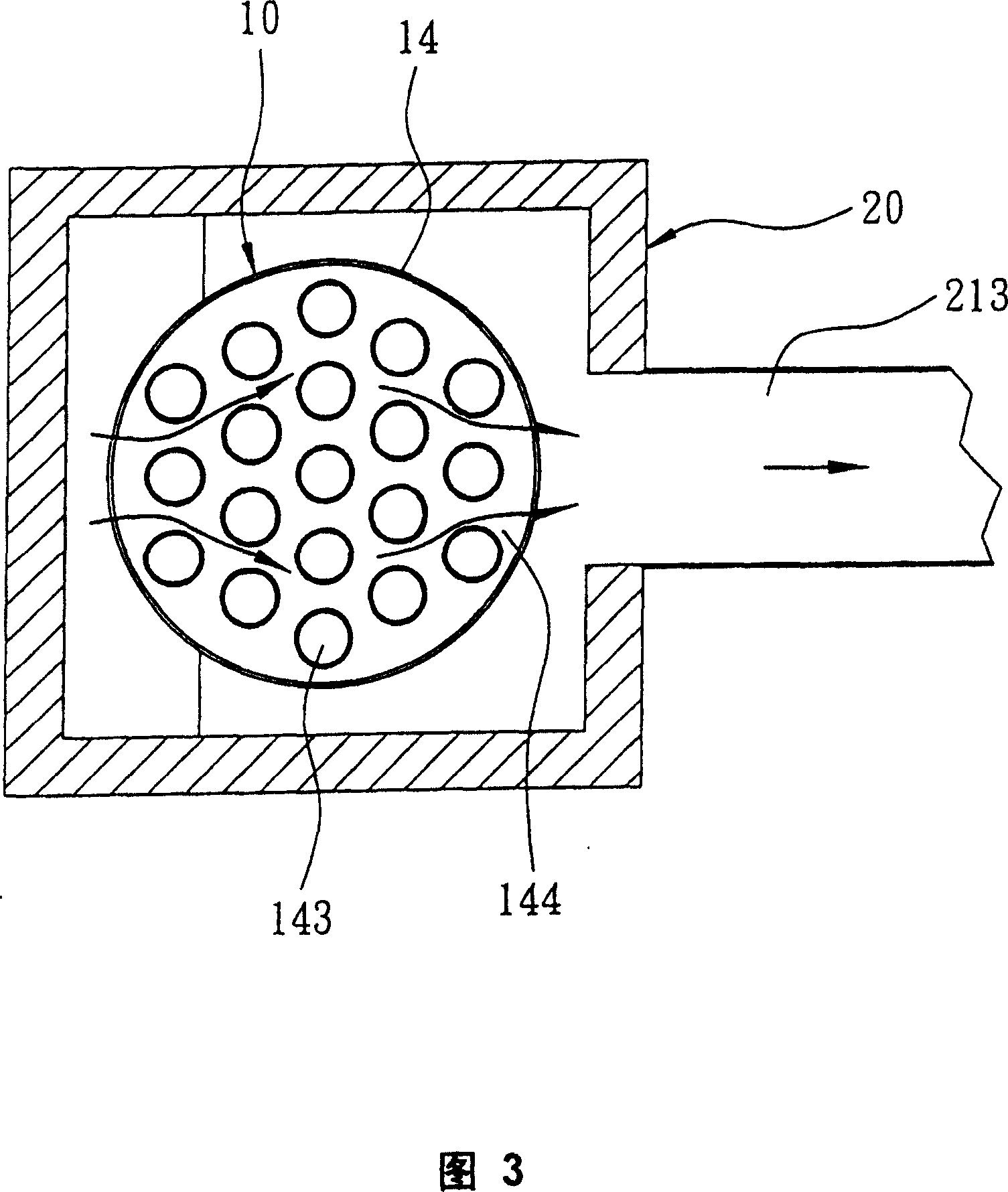

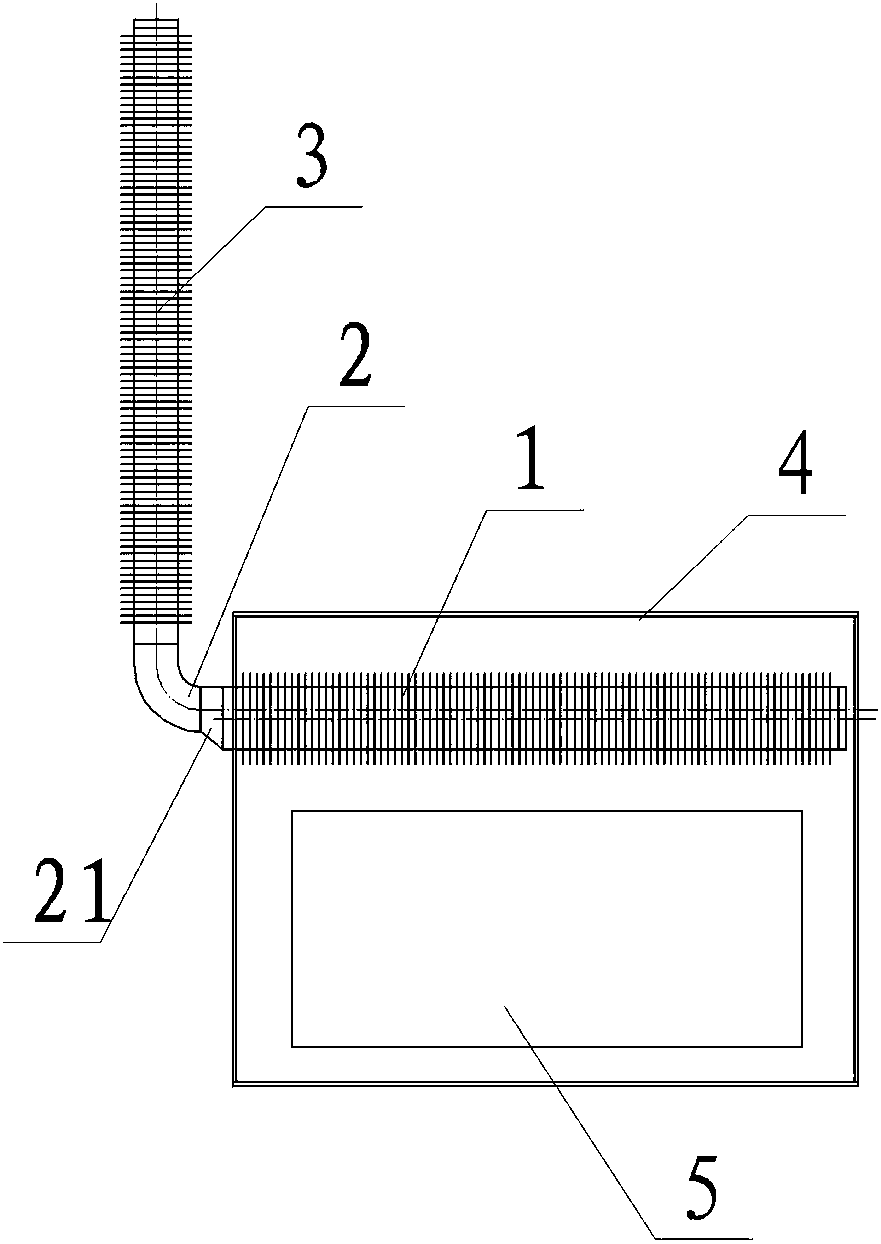

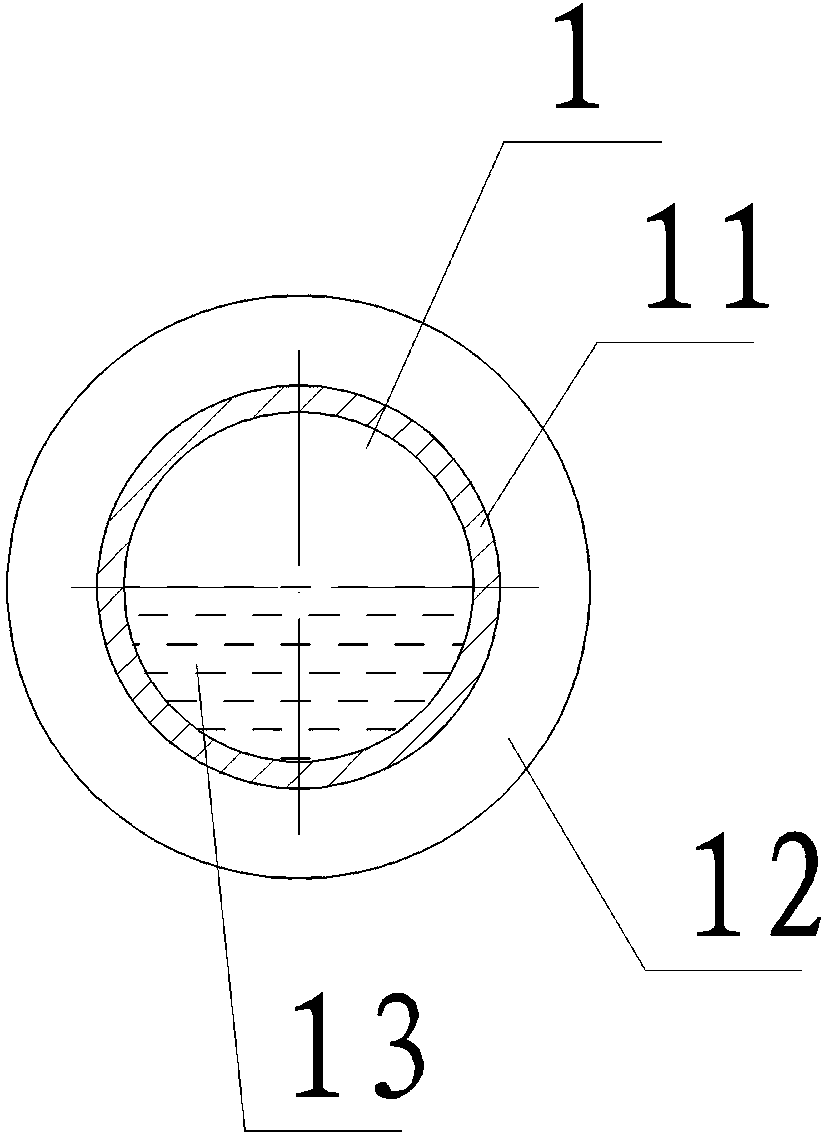

Gas explosion-preventive spiral spray pipe bubbling stirring apparatus

InactiveCN102755852ASimple structureEasy to operateTransportation and packagingMixer accessoriesInlet valveAir compressor

The invention relates to the field of bubbling stirring technology, in particular to a gas explosion-preventive spiral spray pipe bubbling stirring apparatus which comprises a make-up tank, a spiral spray pipe, a gas inlet valve, a gas inlet pipe, a gas outlet valve, a discharge valve, a discharge pipe, a pressure gas inlet feed pipe, a compressed air outlet valve, an air compressor, a pressure tank gas inlet feed valve, a pressure tank, a pressure tank discharge pipe, a spiral spray pipe fixed clamp A, a spiral spray pipe fixed clamp B and a spiral spray pipe fastening device; the spiral spray pipe is arranged at the bottom side part of the make-up tank, the discharge valve is arranged at the taper bottom of the make-up tank, and the spiral spray pipe and the make-up tank are fastened by a fastening nut and a sealing pad; the diameter of the spiral spray pipe is gradually increased after entering the make-up tank, and the spiral spray pipe is spirally downward slanted along with inner arc of the make-up tank; and the make-up tank is internally provided with the spiral spray pipe fixed clamp A13 and the spiral spray pipe fixed clamp B14 which are used for fixing the spiral spray pipes. The gas explosion-preventive spiral spray pipe bubbling stirring apparatus can reduce the gas flow rate through reducing the spiral spray pipe, and can effectively prevent gas explosion phenomenon due to overhigh gas speed, and has the advantages of being long in continuously stirring time, high in efficiency, low in energy consumption, simple in structure, easy to maintain and clean, and low in cost.

Owner:UNIV OF JINAN

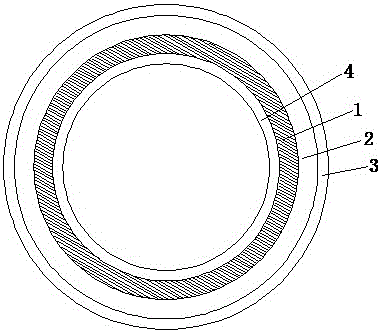

Flame-retardant and anti-static UPVC electrician tube

The invention discloses a flame-retardant and anti-static UPVC electrician tube comprising a UPVC electrician tube base layer, a flexible anti-seismic layer, a first anti-static layer, and a second anti-static layer. The flexible anti-seismic layer and the first anti-static layer are sequentially arranged on the outer surface of the UPVC electrician tube base layer from inside to outside. The second anti-static layer is arranged on the inner surface of the UPVC electrician tube base layer. The UPVC electrician tube base layer comprises the following raw materials, by weight, 50-70 parts of UPVC, 20-40 parts of butyl acrylate, 10-30 parts of maleic anhydride polymers, 6-17 parts of toughening modifier, 5-10 parts of cross-linking agent, 3-5 parts of halogen-free flame retardant, and 3-5 parts of smoke suppressor. Through the scheme, the flame-retardant and anti-static UPVC electrician tube is flame-retardant and anti-static, has durable and good shock resistance, is applicable to coal mines and other occasions, and can completely eradicate fire or gas explosion caused by electrostatic accumulation.

Owner:CHANGZHOU TUOYUAN CABLE ASSEMBLY

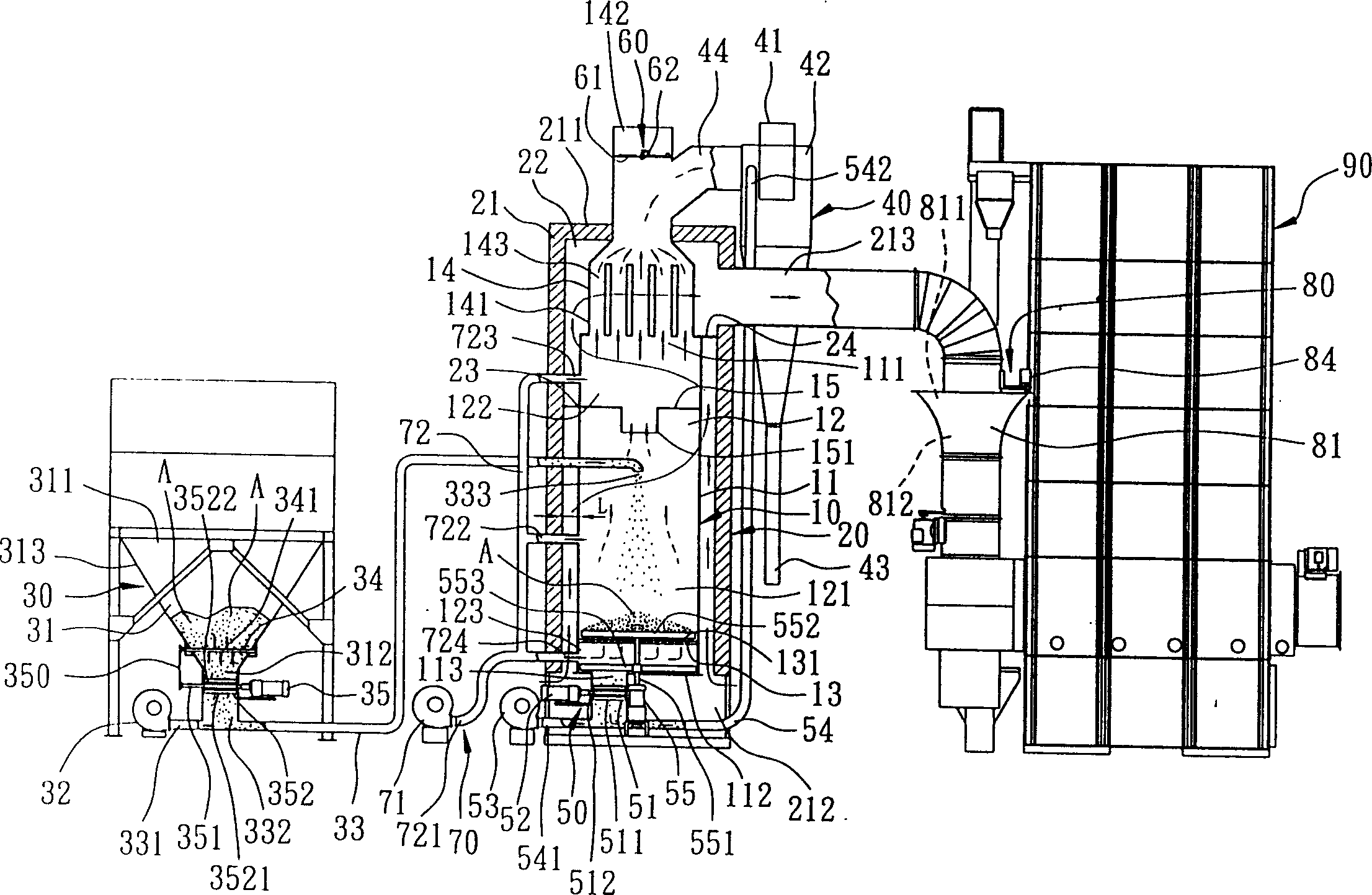

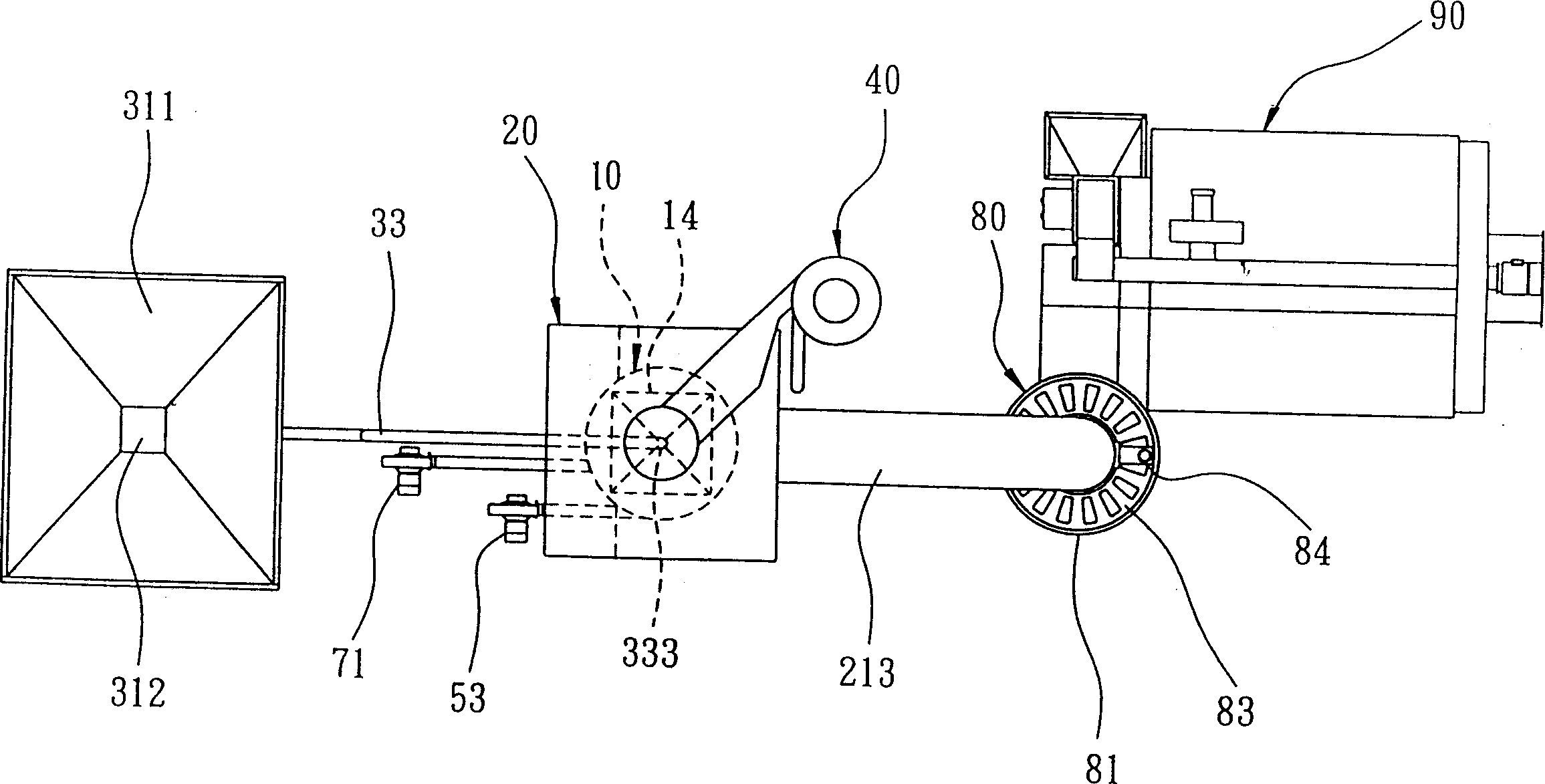

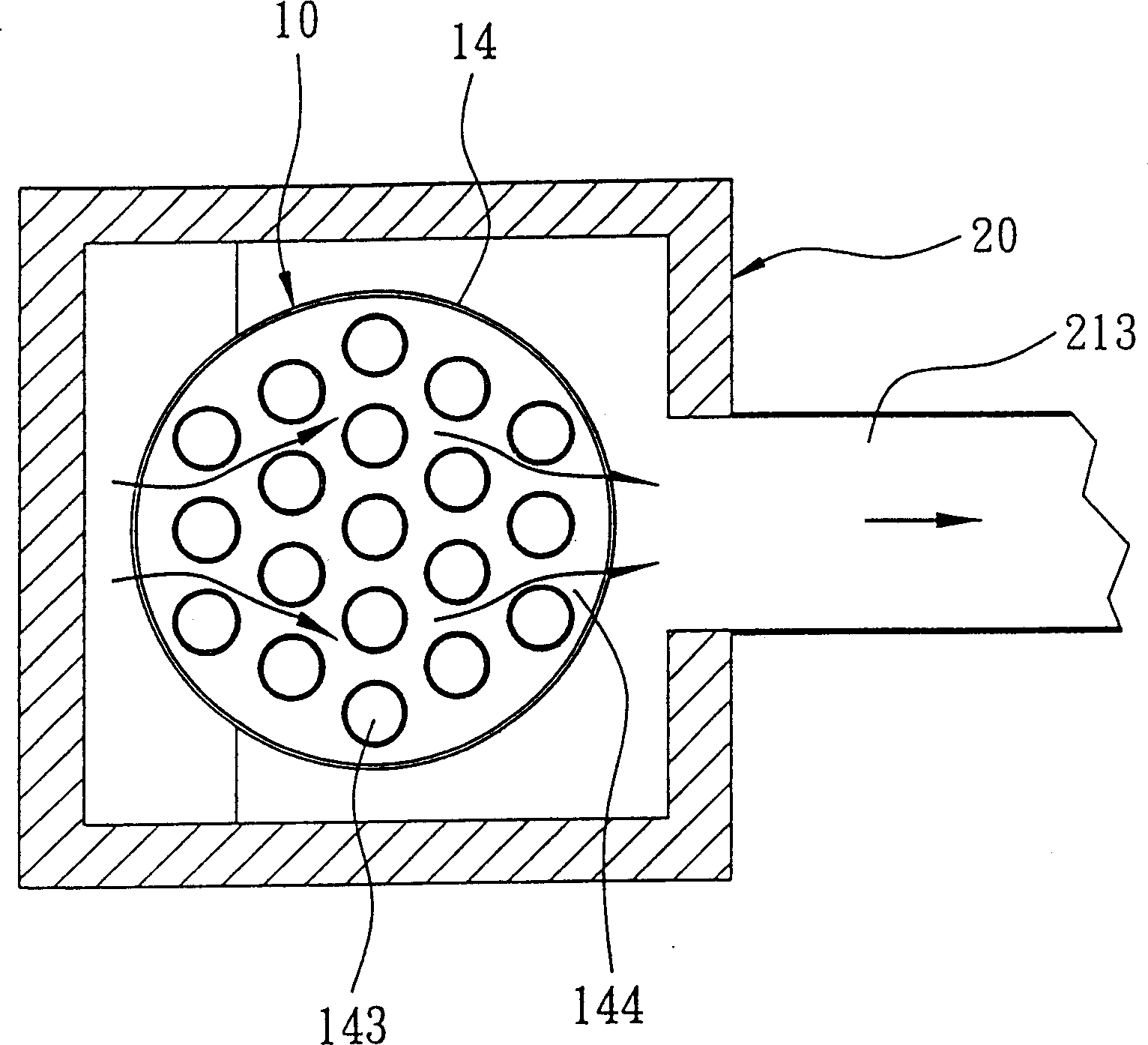

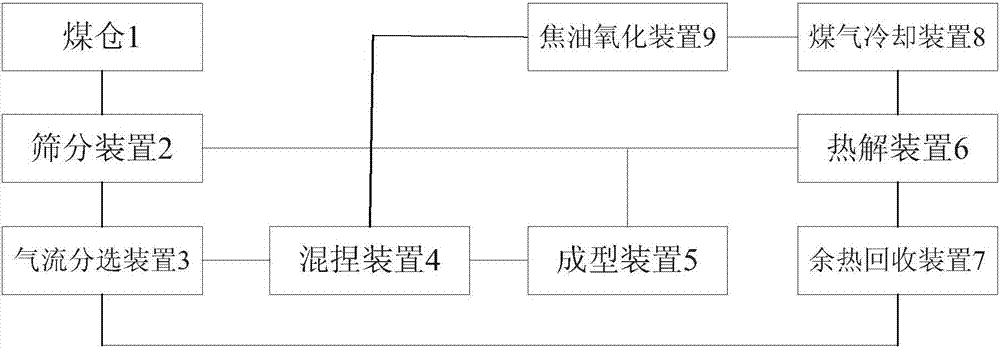

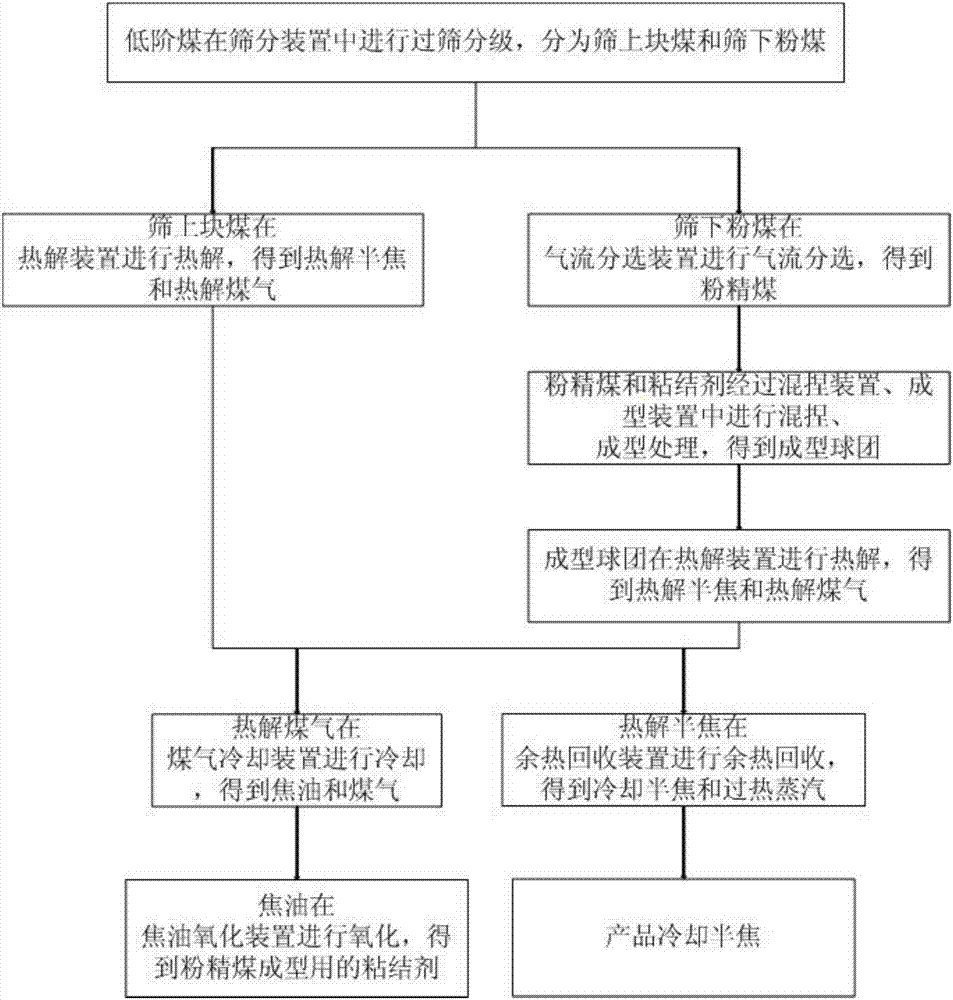

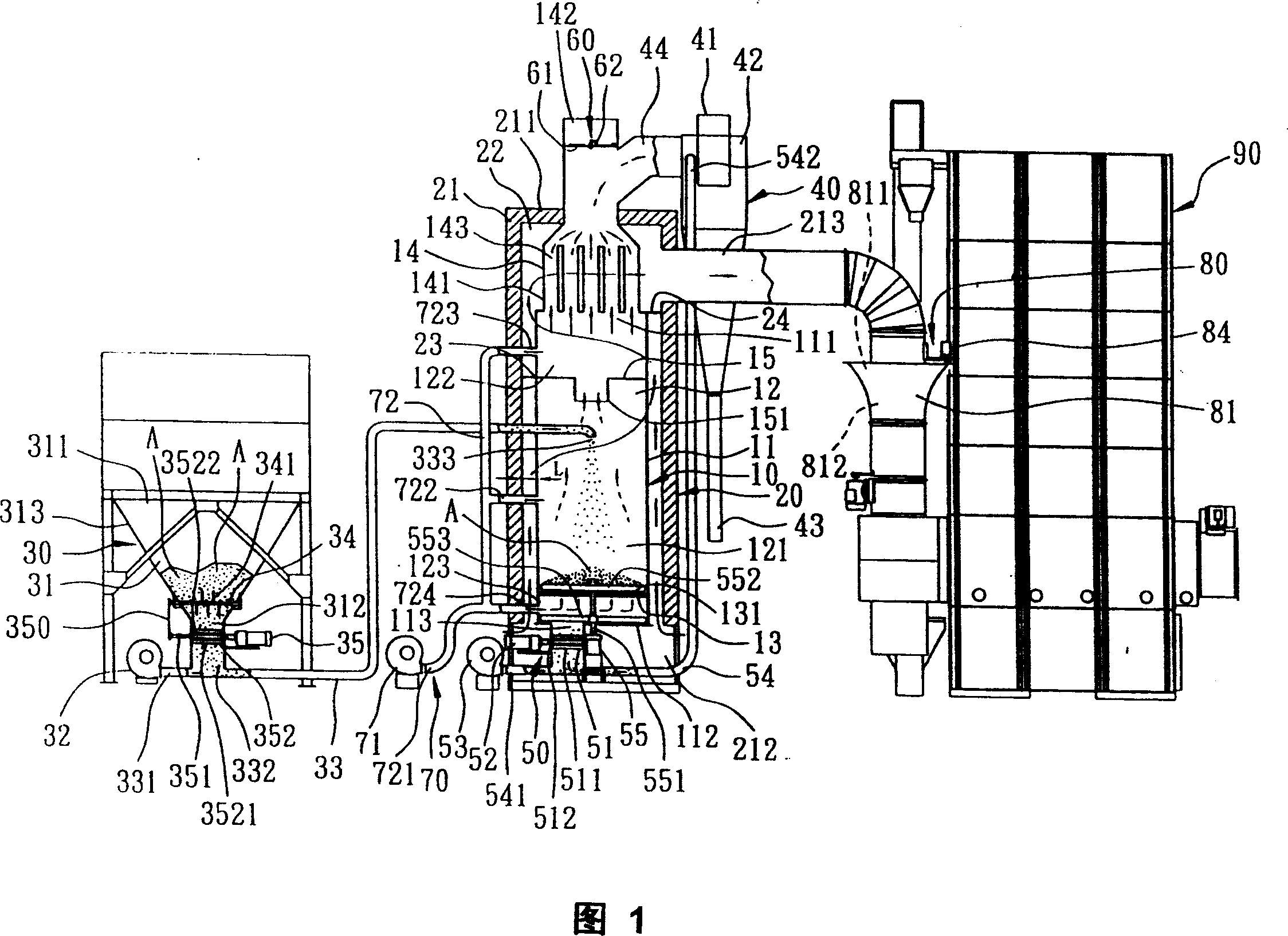

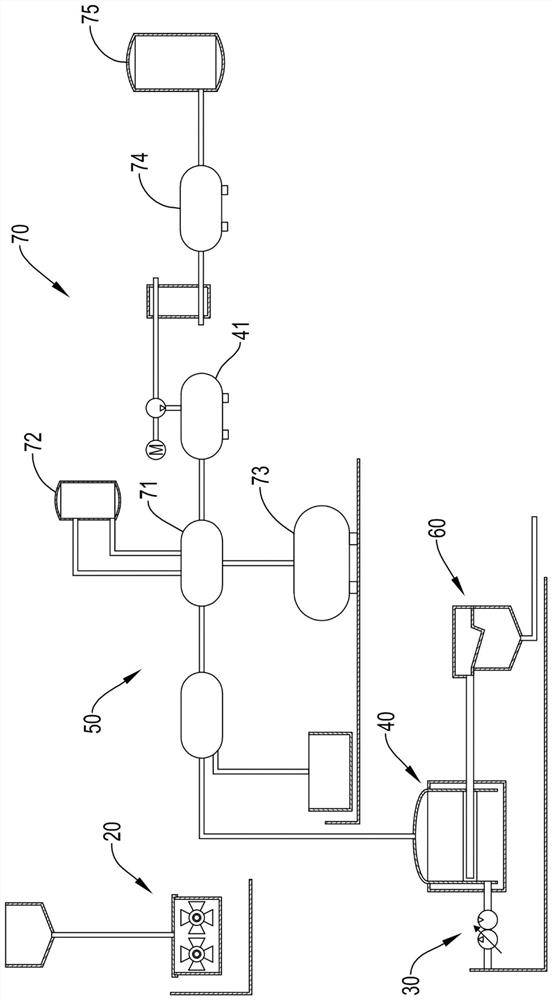

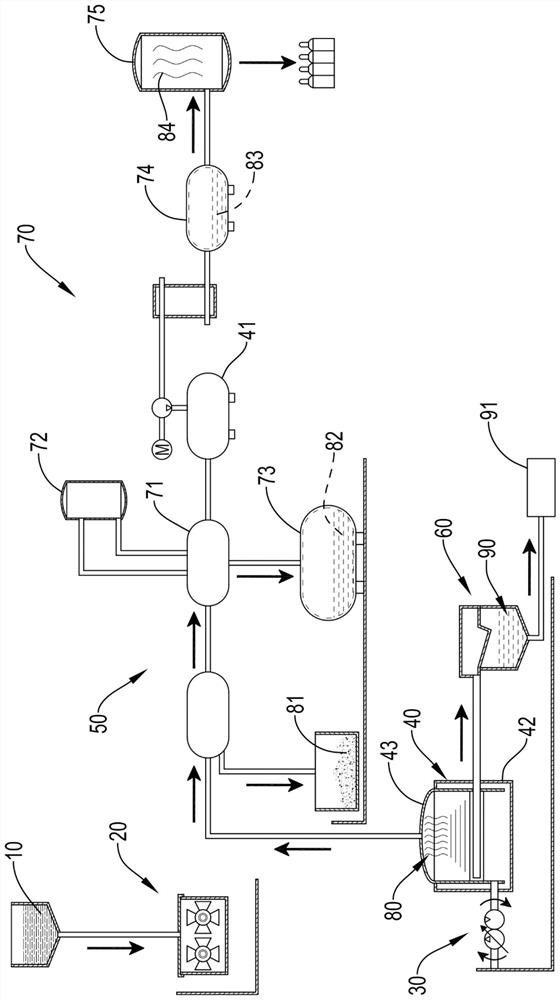

System for preparing semi-coke from low-rank coal and method for preparing semi-coke

The invention relates to a system for preparing semi-coke from low-rank coal. The system comprises an air classification unit, a kneading unit, a tar oxidation unit, a screening unit, a shaping unit,a pyrolysis unit, a coal gas cooling unit, and a residual heat recovery unit. The invention further relates to a method for preparing semi-coke by using the system. The method and the system disclosedby the invention can solve the problems of low pulverized coal ball formation rate, low ball strength, severe gas explosion and a lot of half balls, and thus, the utilization rate of powder can be increased; and moreover, the yield and quality of pyrolytic tar and gas and semi-coke obtained by the method are high.

Owner:SHENWU TECH GRP CO LTD

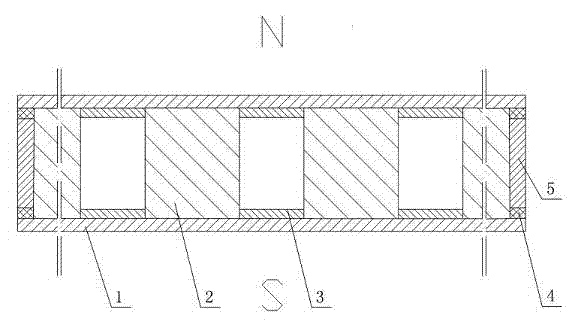

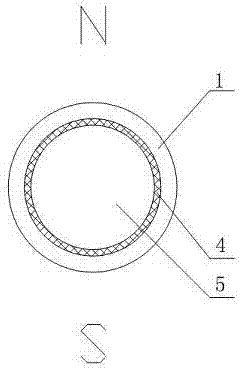

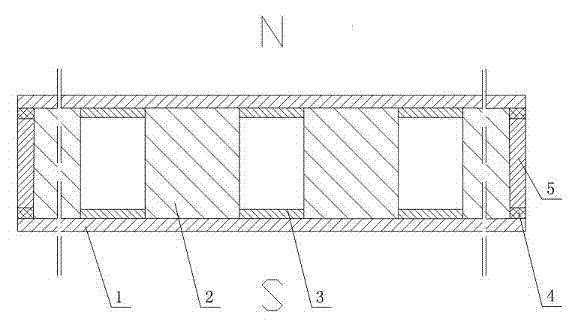

Permanent magnet filter stick and method for preparing permanent magnet material thereof

InactiveCN102228760AStrong magnetismEasy to removeInorganic material magnetismFiltration separationMagnetic polesEngineering

The invention provides a permanent magnet filter stick, comprising an outer sleeve and segmented permanent magnet sticks in the outer sleeve, wherein all segments of permanent magnet stick are separated and connected by common steel tube segments; gaps exist between the outer sleeve and the segmented permanent magnet sticks as well as between the outer sleeve and the common steel tube segments in a radial direction; two ends of the outer sleeve are closed by iron sheets respectively and sealed by seal rings; the segmented permanent magnet sticks are made from NdFeB (neodymium iron boron); the outer sleeve is a stainless steel pipe; the segment number of the permanent magnet sticks is within the range of 4-29; the length and the diameter of the permanent magnet is 20-100mm and 6-30mm respectively; two magnetic poles of each segment of permanent magnet stick are arranged in a radial direction of the permanent magnet stick respectively; the length and the diameter of a common steel tube is 8-10mm and 6-30mm respectively; and the thickness of the iron sheets is 2-3mm. The permanent magnet filter stick is simple in structure, easy to manufacture, simple and easy in application method, wide in use and suitable for large-scale promotion and application.

Owner:WUXI GUANGXU STEEL SHEET +1

Electronic carrier board and its packaging structure

ActiveCN1997261AFully distributedAvoid gas explosionPrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringElectronic component

This invention discloses one electron load board and its form structure, wherein, the electron load board comprises one body, multiple pairs of weld pads on body surface and one protection layer to cover on body surface. Comparing with current technique, this electron load board and its structure forms insulation resin channel space between weld pads to distribute insulation resin materials onto electron load board gaps.

Owner:SILICONWARE PRECISION IND CO LTD

Agitated reactor without dead angle

InactiveCN103418322ASimple structureEasy to installTransportation and packagingMixersInlet valveCircular cone

The invention discloses an agitated reactor without a dead angle, and belongs to the technical field of reaction kettles. The agitated reactor without the dead angle comprises a reactor body, a bubble agitator, an air inlet valve, an air inlet pipe, an air compressor, a discharging pipe, a discharging valve and bubble overflowing holes. The agitated reactor without the dead angle is characterized in that the reactor body is a cone-base reactor, the bubble agitator is of an inverted-cone shape, the bubble overflowing holes are formed in the side face of a conical body of the bubble agitator, the bubble agitator is arranged at the bottom of the reactor body, the conical top of the bubble agitator is connected with the air inlet pipe, the air inlet valve is installed on the air inlet pipe, the air inlet valve is connected with the air compressor, the conical side face of the bubble agitator is an inwards-concave cambered surface, the equal-hole-diameter bubble overflowing holes are formed in the conical side face of the bubble agitator, the diameter of each bubble overflowing hole is 2-5mm, and the bubble overflowing holes are evenly distributed along the inwards-concave side face of the conical body. The agitated reactor without the dead angle has the advantages of being simple in structure, convenient to install and maintain and low in power consumption.

Owner:薛应东

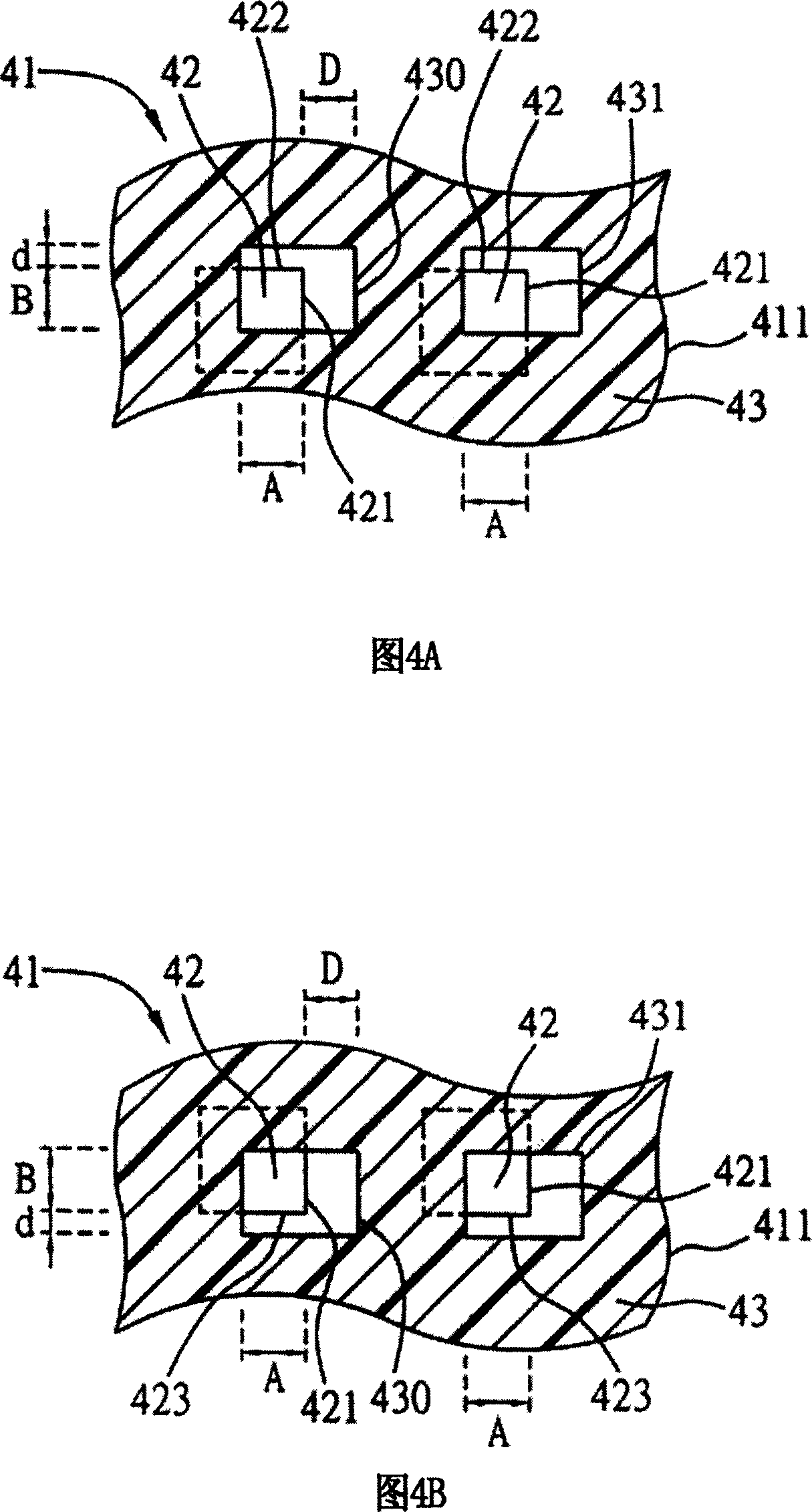

Semiconductor package device with layer-increasing structure and making method thereof

ActiveCN1316604CImprove protectionNot easy to absorb moistureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageGas explosion

The capsulation piece comprises following parts: hard base, hard frame possessing through hole fixed on the hard base, at least one chip accommodated in the through hole of hard frame, medium filled in gap between chip and hard frame, addition layer structure formed on the chip and hard frame and connected to the chip electrically, multiple pieces of conducting subassemblies soldered on addition layer in use for connecting the chip to external devices electrically. Since the hard base and hard frame are adopted, the disclosed capsulation piece can prevent problems of structural warp, fragmentation, delamination and gas explosion etc. from happening. The invention discloses method for preparing the capsulation piece of semiconductor in wafer level further.

Owner:SILICONWARE PRECISION IND CO LTD

Incineration equipment for coking industry

InactiveCN110081446AEasy to control temperatureEfficient removalIncinerator apparatusGas explosionExhaust gas

The invention discloses incineration equipment for a coking industry. The incineration equipment comprises a gas inlet pipeline, the gas inlet pipeline is sequentially connected with a fuel gas inletvalve, a fuel gas flow detector and a combustor, the combustor is fixed above a combustion chamber, the lower end of the combustion chamber is provided with a heat storage chamber, the two sides of the combustion chamber are provided with a temperature relief valve, a thermocouple and a pressure intensity detector, the thermocouple and the pressure intensity detector are respectively connected with a temperature alarm and a pressure intensity alarm, a heat accumulator and a residue collecting tank are arranged in the heat storage chamber, the residue collecting tank is provided with an air outlet valve, an exhaust gas inlet valve and a blowing valve, the temperature relief valve and the air outlet valve are connected with a high-temperature mixing tank, the waste gas inlet valve is sequentially connected with a RTO main fan, a waste gas concentration detector and an air access device, the air access device is connected with a waste gas inlet pipeline, and the blowing valve is connectedwith a blower. According to the equipment, the temperature of the incinerating equipment can be controlled, the gas explosion phenomenon caused by VOC in the waste gas can be avoided, and the VOC inthe waste gas can be efficiently removed.

Owner:吴起英

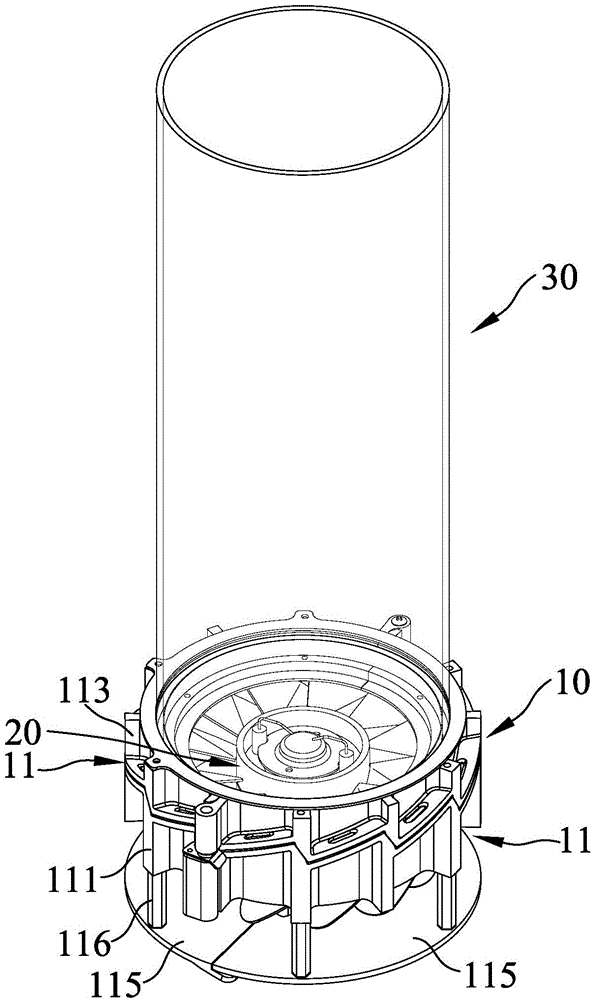

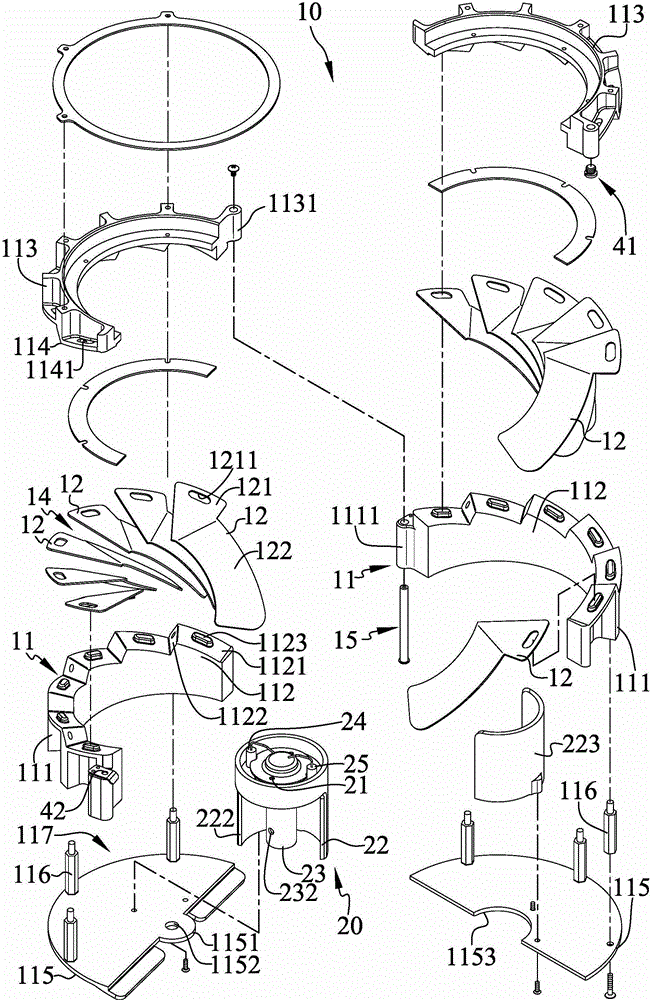

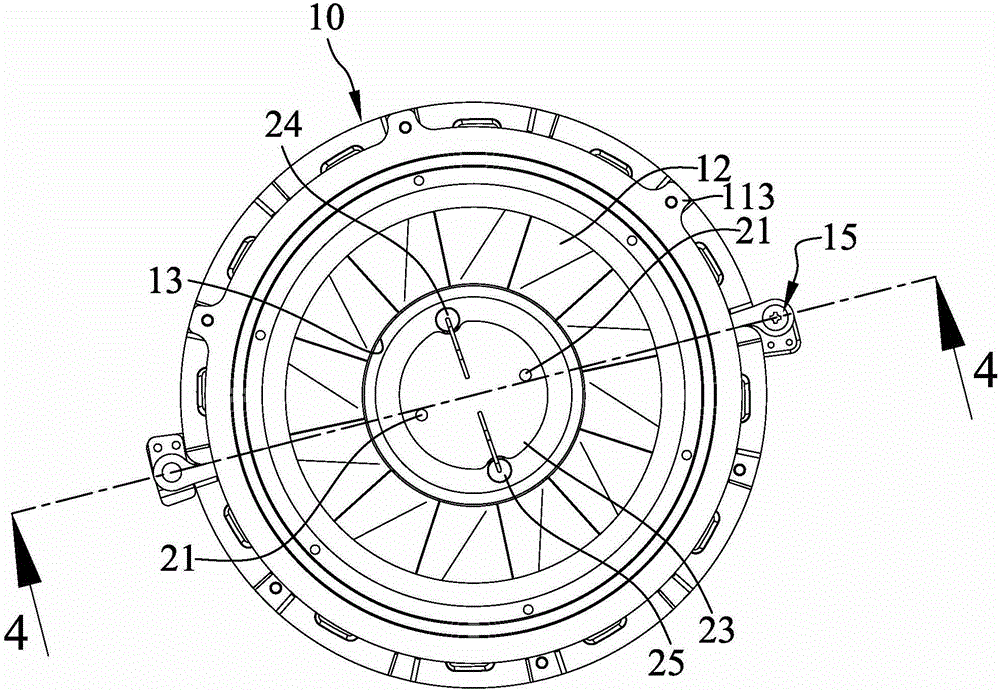

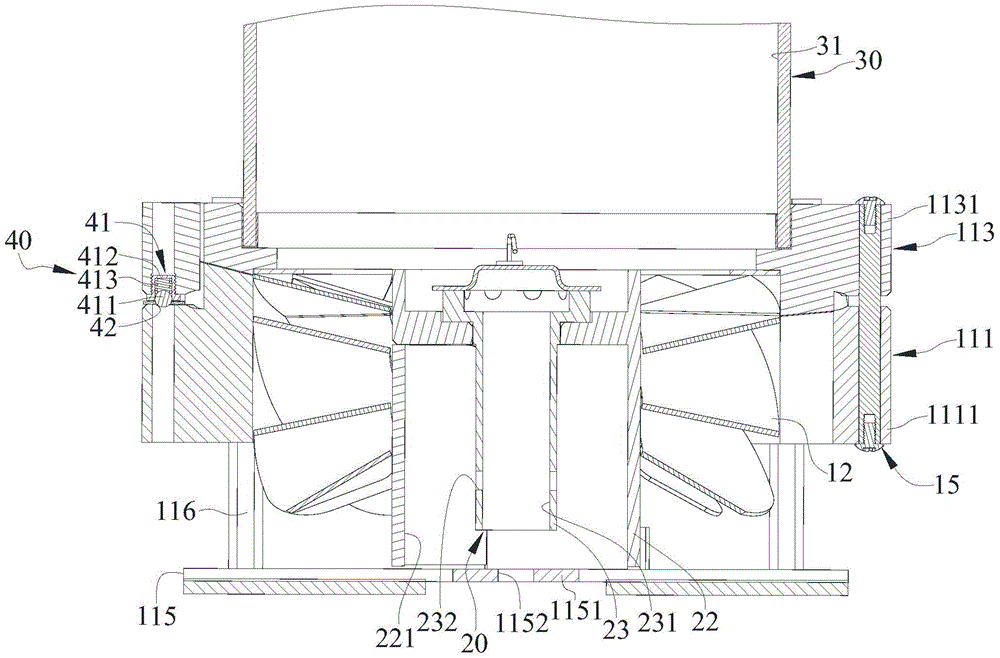

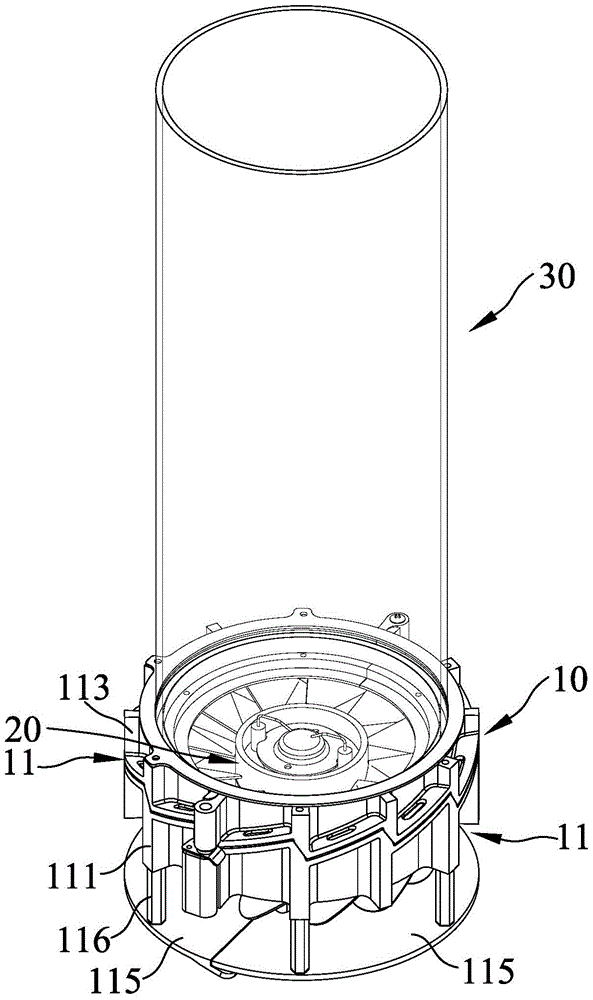

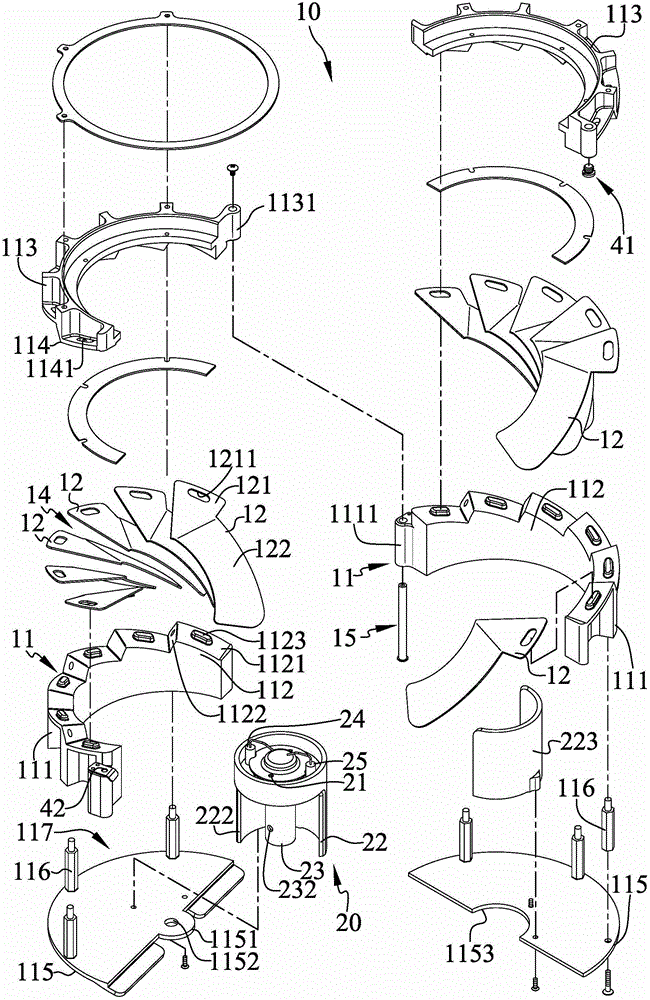

Scroll type flame combustion device with safety manual ignition

ActiveCN104654282AVisibly rotating fire effectAvoid gas explosionGaseous fuel burnerCombustion apparatusCombustionFuel tank

The invention relates to a scroll type flame combustion device with safety manual ignition. The device comprises a deflector group, a nozzle and a cover body. The deflector group can be connected with a fuel tank and contains two frame bodies and several blades. The two frame bodies are pivoted to each other. Each of the blades is spirally distributed on the two frame bodies. An air guide channel for letting the air pass through is formed between each two adjacent blades. The nozzle is arranged inside the deflector group and contains at least a vent hole which lets fuel inside the fuel tank pass through. One end of the deflector group, far away from the nozzle, is connected with the cover body. The cover body is prepared from a nonopaque material. The cover body encloses to form a limit space which is communicated with the vent hole of the nozzle.

Owner:PRO IRODA INDS

Vertical type incinerator capable of incinerating waste liquids, waste gases and solid waste simultaneously

The invention discloses a vertical type incinerator capable of incinerating waste liquids, waste gases and solid waste simultaneously. The vertical type incinerator comprises a connecting pipe, fire-observing windows, a first combustion mechanism, a second combustion mechanism, a feeding mechanism and discharging mechanisms. The first combustion mechanism comprises a second incinerator body. According to the vertical type incinerator capable of incinerating the waste liquids, waste gases and solid waste simultaneously, the discharging mechanisms are arranged on bottom positions of a first incinerator body and the second incinerator body, ash discharging is conducted by adopting a scraper slag discharging machine at the bottom, the operation is convenient, and trouble and hard work of manual labor are reduced; besides, burning ports are formed in the bottoms of the first incinerator body and the second incinerator body, solid waste can be incinerated while the waste liquids and waste gases are incinerated, and incineration diversity of the incinerator device is increased; through peculiar oxygen-supplementing wind ports, the solid waste is blown away and soars, the contact area of the solid waste and flames is increased, it is guaranteed that the solid waste combusts fully, and it is avoided that gas explosion occurs after certain concentration is reached by accumulated organicgases because of incomplete combustion of solid waste at the bottom; and the incinerator has the advantages of high-efficiency incineration and complete incineration.

Owner:宜兴市华瑞焚烧炉科技发展有限公司

Air filter machine special for electric welding

InactiveCN101015756ABlocking inhalationAvoid blockingDispersed particle filtrationDirt cleaningAir filtrationAir filter

The invention provides an air filter used in electric welding, substantially comprising a cabinet with a through opening at the top to connect an aspiration channel and an upper chamber and a lower chamber in the cabinet, while the upper chamber is communicated with the top through opening, a spark ash baffle device and a movable filter cloth respectively mounted at upper and lower sides inside. The movable filter cloth is provided with a filter cloth rotating some degree while the lower chamber is mounted with a blower inside and an extraction filter device outside to communicate with the lower chamber, to absorb the object air via the aspiration channel when the blower operates, to pass through the spark ash baffle device, the movable filter cloth, the blower and the extraction filter device to be discharge, to baffle the spark ash and filter air effectively.

Owner:郑渊太

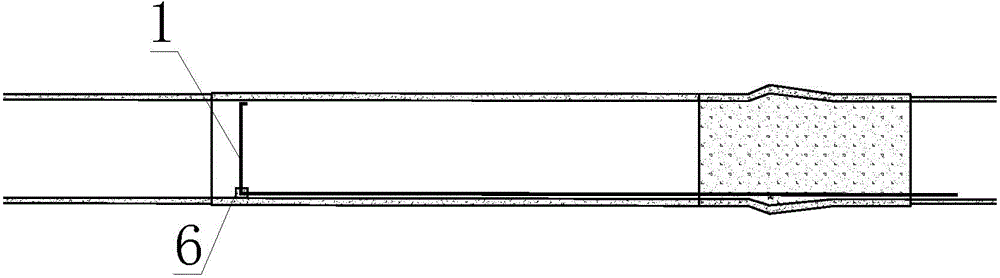

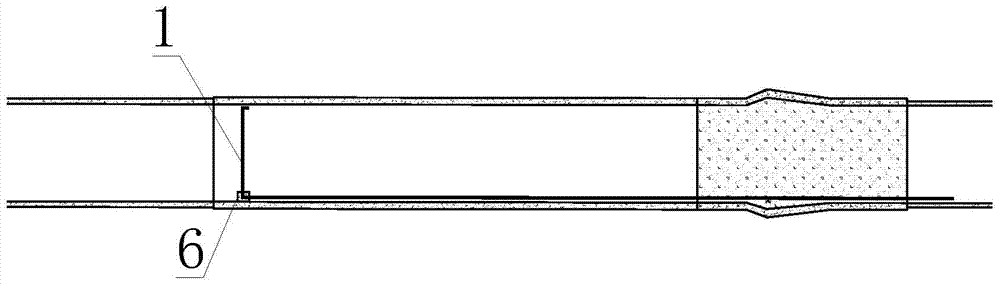

Diversion tunnel body gate wellbore temporarily sealing and blocking method and device

PendingCN109853495AIncrease volumePrevent floodingWater-power plantsHydro energy generationWater flowEngineering

The invention discloses a diversion tunnel body gate wellbore temporarily sealing and blocking method and device, which comprises a sealing and blocking steel plate arranged on a diversion tunnel gatewell wellbore, the outer end of the sealing and blocking steel plate is connected with diversion tunnel gate well wellbore concrete in a diversion tunnel sealing and blocking gate locking platform byanchor bolts, and rubber sealing is arranged at the joint; an air exhaust steel pipe is arranged in the upward direction of the sealing and blocking steel plate and extends to a lock chamber sectionconstruction branch tunnel, and a check valve is arranged in the position where the top of the air exhaust pipe reaches the lock chamber section construction branch tunnel. According to thediversiontunnel body gate wellbore temporarily sealing and blocking method and device,by sealing and blocking the tunnel body gate well wellbore andinterceptingapressure diversion tunnel gate well wellbore air inlet passage, leakage of the diversion tunnel is increased;the sealing and blocking wellbore prevents the high water head water from flowing through the wellbore to other downstream caverns;under theaction of the diversion tunnel high water head, the sealing and blocking device of the diversion tunnel body gate wellbore temporarily sealing and blocking method and device can be automatically vented to prevent the air of the lock chamber section from generating a gas explosion under high pressure; and at the same time, the air can be depressurized through the check valve, and the pressure on the outside and the inside of the steel plate is identical after the water is passed.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Gas explosion-preventive spiral spray pipe bubbling stirring apparatus

InactiveCN102755852BAvoid gas explosionImprove efficiencyTransportation and packagingMixer accessoriesInlet valveGas explosion

The invention relates to the field of bubbling stirring technology, in particular to a gas explosion-preventive spiral spray pipe bubbling stirring apparatus which comprises a make-up tank, a spiral spray pipe, a gas inlet valve, a gas inlet pipe, a gas outlet valve, a discharge valve, a discharge pipe, a pressure gas inlet feed pipe, a compressed air outlet valve, an air compressor, a pressure tank gas inlet feed valve, a pressure tank, a pressure tank discharge pipe, a spiral spray pipe fixed clamp A, a spiral spray pipe fixed clamp B and a spiral spray pipe fastening device; the spiral spray pipe is arranged at the bottom side part of the make-up tank, the discharge valve is arranged at the taper bottom of the make-up tank, and the spiral spray pipe and the make-up tank are fastened by a fastening nut and a sealing pad; the diameter of the spiral spray pipe is gradually increased after entering the make-up tank, and the spiral spray pipe is spirally downward slanted along with inner arc of the make-up tank; and the make-up tank is internally provided with the spiral spray pipe fixed clamp A13 and the spiral spray pipe fixed clamp B14 which are used for fixing the spiral spray pipes. The gas explosion-preventive spiral spray pipe bubbling stirring apparatus can reduce the gas flow rate through reducing the spiral spray pipe, and can effectively prevent gas explosion phenomenon due to overhigh gas speed, and has the advantages of being long in continuously stirring time, high in efficiency, low in energy consumption, simple in structure, easy to maintain and clean, and low in cost.

Owner:UNIV OF JINAN

Vortex flame combustion device with safety manual ignition

ActiveCN104654282BVisibly rotating fire effectAvoid gas explosionGaseous fuel burnerCombustion apparatusCombustionFuel tank

Owner:PRO IRODA INDS

Combustion installation

InactiveCN100343609CReduce the temperatureImprove combustion effectAir heatersHeating arrangementPlate heat exchangerCombustion chamber

A combustion apparatus is composed of an internal combustion furnace and an isolating cylinder surrounding said internal combustion furnace by a gap between them. Said fume has a top heat exchanger, a partition for dividing it intor primary and secondary combustion chamber and cooling chamber, and a load-bearing plate. Said isoalting cylinder has a hot air tube for heat exchanger and two reflux plates for circulating airflow in said gap. The material can be fully burnt and its ash is cooled in cooling chamber for discharging. It can also supply clean hot air by heat exchanger.

Owner:林岱右

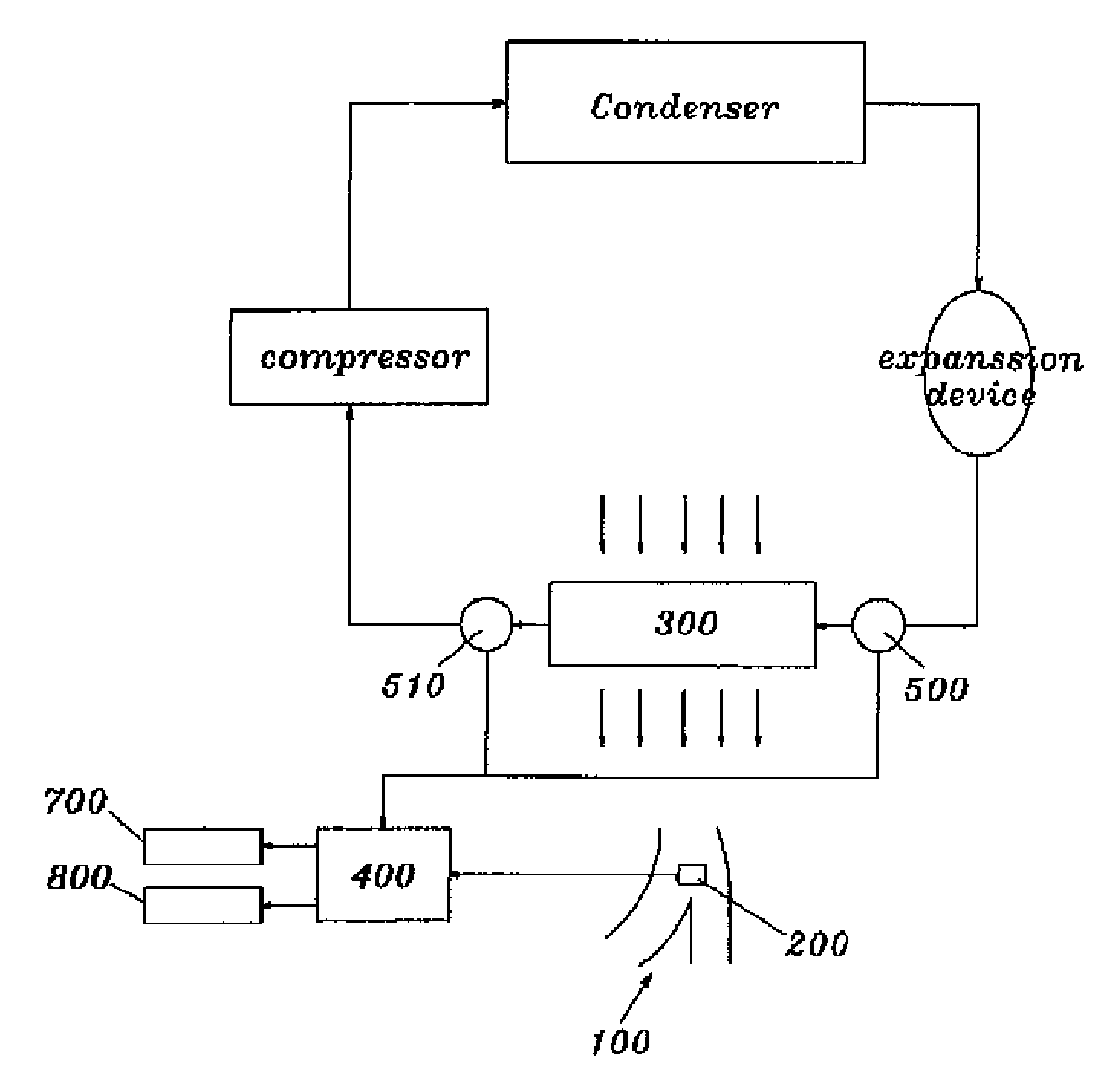

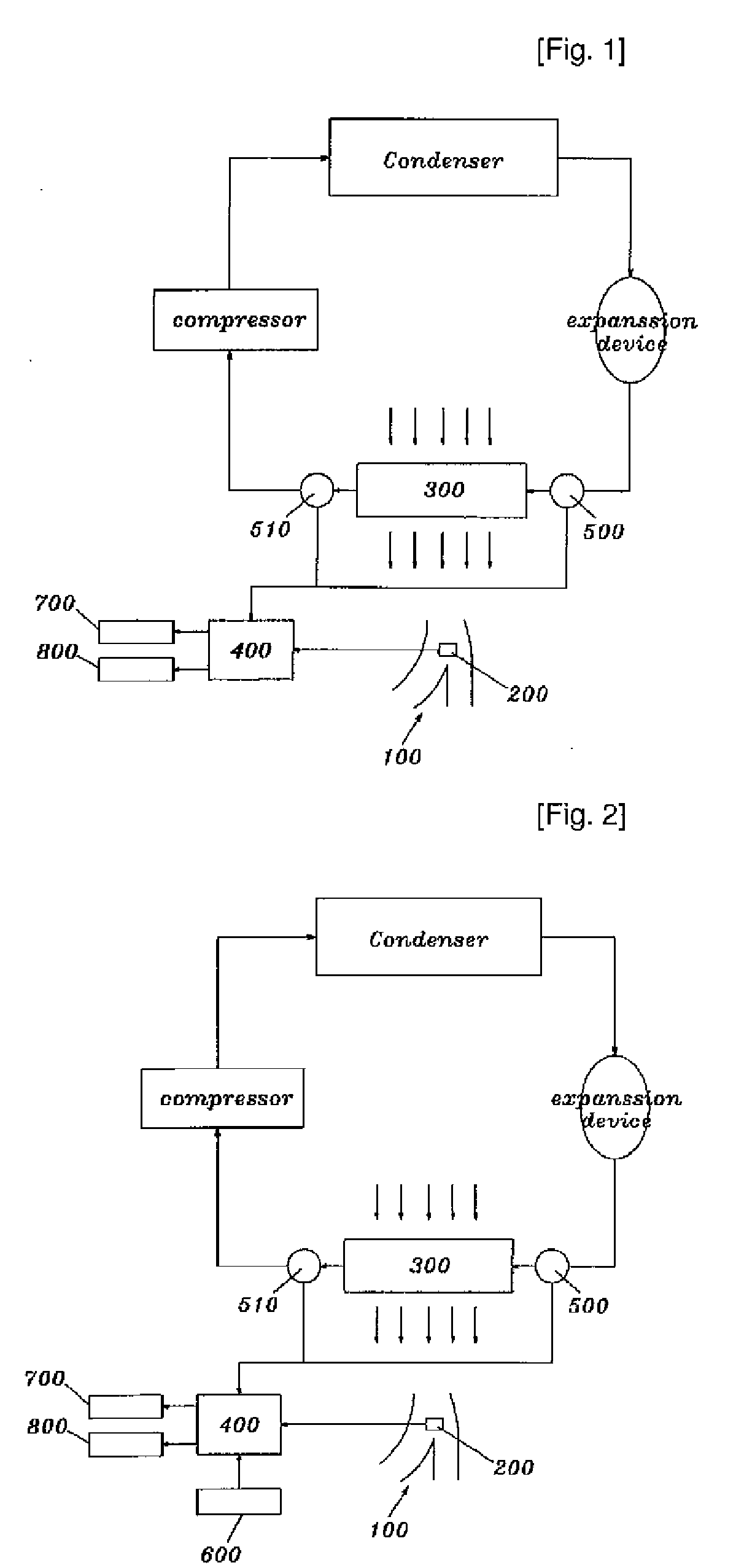

Gas safety device and the control method of heating ventilating and air conditioning system

InactiveUS20090158753A1Avoid gas explosionAvoid accidentsAir-treating devicesDomestic cooling apparatusRefrigerantEvaporator

Disclosed is a gas safety device of a heating, ventilating, and air conditioning system for vehicles. The gas safety device includes a gas sensor installed at an air inlet connecting an engine room and the inside of a vehicle; and refrigerant cutoff valves installed at lines of an evaporator at the sides of refrigerant inlet or outlet for restricting the flow of a refrigerant by means of the operation of a control unit according to a sensing signal value of the gas sensor. In the gas safety device, when gas is leaked in the engine room after a starting switch of the vehicle is turned on, the gas sensor installed at the air inlet connecting the engine room and the inside of the vehicle senses the gas leakage, and outputs a corresponding signal value to the control unit. Then, the control unit determines whether or not gas is leaked through the signal value, and operates the refrigerant cutoff valve installed at the line of the evaporator at the side of the refrigerant inlet, thus controlling the flow of the refrigerant.

Owner:METACHEM

Heat-recycle L-shaped heat tube of horizontal finned tube externally connected with vehicle finned tube

InactiveCN108131972AAvoid gas explosionRealize heat exchangeIndirect heat exchangersButt jointEvaporation

The invention discloses a heat-recycle L-shaped heat tube of a horizontal finned tube externally connected with a vehicle finned tube. The L-shaped heat tube comprises an evaporation-segment heat tubebody, a balance-segment heat tube body and a cooling-segment heat tube body; the evaporation-segment heat tube body is horizontally distributed in a furnace body with a heat medium, the cooling-segment heat tube body is distributed outside the furnace body with a cold medium, and the balance-segment heat tube body is a bent tube between the evaporation-segment heat tube body and the cooling-segment heat tube body; a working medium which volatilizes when heated and condenses into liquid after cooled is arranged in the evaporation-segment heat tube body; the inner tube diameter of the evaporation-segment heat tube body is larger than that of the cooling-segment heat tube body; the balance-segment heat tube body is connected with the evaporation-segment heat tube body through a large connection and a small connector in a tube top butt joint mode. The heat-recycle L-shaped heat tube is compact in structure, the functions of horizontal tube distribution and heat exchange are achieved, thedistribution space is saved, and heat exchange is frequent and smooth.

Owner:合肥宽信机电有限公司

Composite membrane with air-adjusting fresh-keeping and microwave heating automatic pressure-adjusting package device and its production method

InactiveCN1807086BAvoid the risk of blowoutExtended shelf lifeLayered productsComposite filmMicrowave oven

The invention relates to a composite film for a packing device with controlled atmosphere fresh-keeping and microwave self-venting and a method for manufacturing the same. The composite film includes: a substrate film layer provided with a first group of micro-gap structure area of which the adjacent edges physically contacted to each other; a sealing film layer covering one side of the first group of micro-gap structure area, and connected to the substrate film layer having the first group of micro-gap structure area through an adhesive layer, and then forming a second group of micro-gap structure area along the thickness direction on the composite film integrating the sealing film layer, the adhesive layer and the substrate film layer. The composite film has the function for regulating the high-temperature and high steam pressure, and avoids the packing device from blasting during the heating process, and prolongs the fresh-keeping and storing time for fresh vegetable and fruit. Besides, the composite film can be directly put in to a microwave oven for heating and regulating, which can not generate the problem of dry and hard food caused by huge drain of high temperature steam.

Owner:林启祥

gas generator

The present invention provides a gas generator comprising a water tank and an electrolysis device. The water tank has a first hollow portion for containing electrolyzed water. The electrolysis device is disposed inside the first hollow portion of the water tank for electrolyzing the electrolyzed water to generate a hydrogen-oxygen mixed gas. When the electrolysis device starts to electrolyze the electrolyzed water, the first hollow portion of the water tank is filled with the electrolyzed water for standing at a full level of water between 90 to 100%. The gas generator of the present invention provides the design for saving space and nearly a zero gas chamber to reduce the possibility of explosions resulting from hydrogen-oxygen mixed gas.

Owner:SHANGHAI ASCLEPIUS MEDITEC CO LTD

A kind of diversion hole plugging head exhaust structure and exhaust method

ActiveCN104963324BEasy dischargeEnsure safetyWater-power plantsHydro energy generationPipe waterWater discharge

The invention discloses a diversion tunnel plug head exhaust structure and an exhaust method thereof; the diversion tunnel plug head exhaust structure comprises a diversion cylinder and a concrete plug head arranged in a blocking segment in the diversion cylinder; the bottom of the concrete plug head is pre-buried with an air discharge pipe and a water discharge pipe; an upstream and a downstream of the concrete plug head in the diversion cylinder are respectively provided with a cofferdam; a grouting gallery and a gate well connected with the grouting gallery are arranged in the concrete plug head; the exhaust method comprises the following steps: 1, paving the air discharge pipe and the water discharge pipe; 2, building the cofferdams; 3, opening a water discharge butterfly valve; 4, casting the concrete plug head; 5, opening an air discharge butterfly valve; 6, observing air discharge pipe water discharge conditions. In certain regions, the diversion tunnel is deeply buried, the top is steep and no drilling construction road can be paved, and vent holes are hard to tap; the diversion tunnel plug head exhaust structure and the exhaust method can be applied to the diversion tunnel plugging construction process, thus fast discharging a cavity in the front segment of the diversion tunnel, preventing gas explosion caused by boosting pressure, and ensuring safety of the plug head structure.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

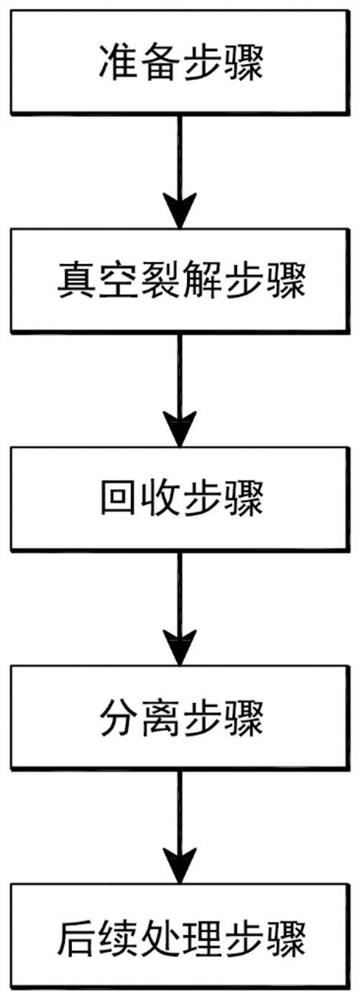

Disposal method and device for waste electronic products

ActiveCN109504418BImprove practicalityKeep healthyLiquid hydrocarbon mixture productionToxic gasPlastic materials

The invention relates to a discarded electronic product treatment method and device. A plurality of discarded electronic products to be treated are conveyed to a vacuum cracking device, and plastic materials in the discarded electronic products are subjected to low-temperature vacuum cracking to generate gaseous oil gas, so that the production of toxic gas and gas explosion phenomena are avoided,the cost is lowered during use, and safety and environment protection are achieved. Then, metal materials are heated and molten into liquid metal in a high-temperature vacuum cracking manner, and thegaseous oil gas and the liquid metal are respectively treated by a filtering device and a separation device to obtain liquid oil products, liquid hydrogen chloride, gaseous auxiliary fuel and the like, so that the practicability of the discarded electronic products is improved greatly. The discarded electronic product treatment method and device have the advantages of safety in use, environmentalfriendliness and full recovery.

Owner:陈宣荣 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com