Air filter machine special for electric welding

A filter and air technology, which is applied to welding accessories, dispersed particle filtration, cleaning methods and appliances, etc., can solve problems such as gas explosion, affecting welding operation and welding quality, and burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

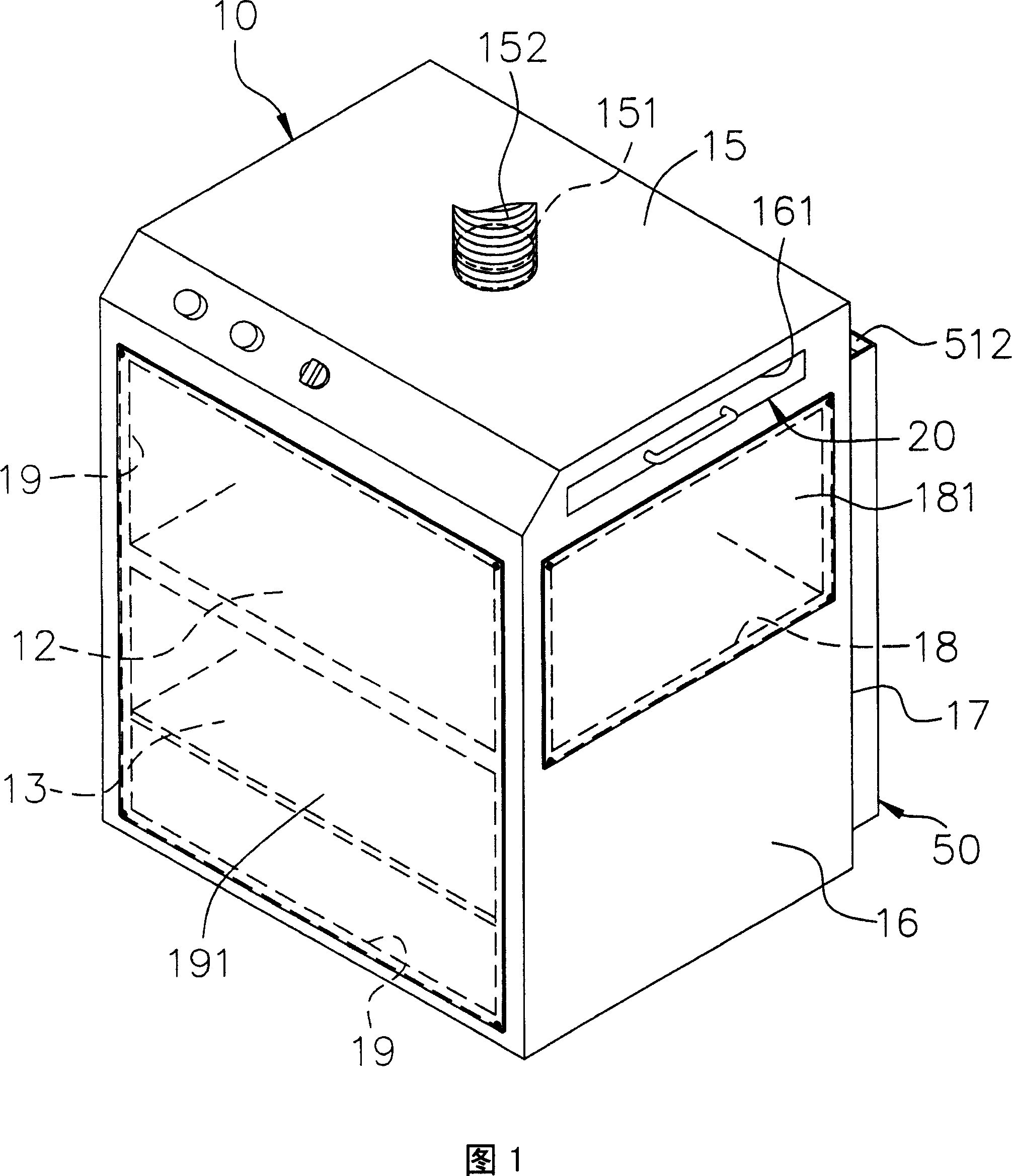

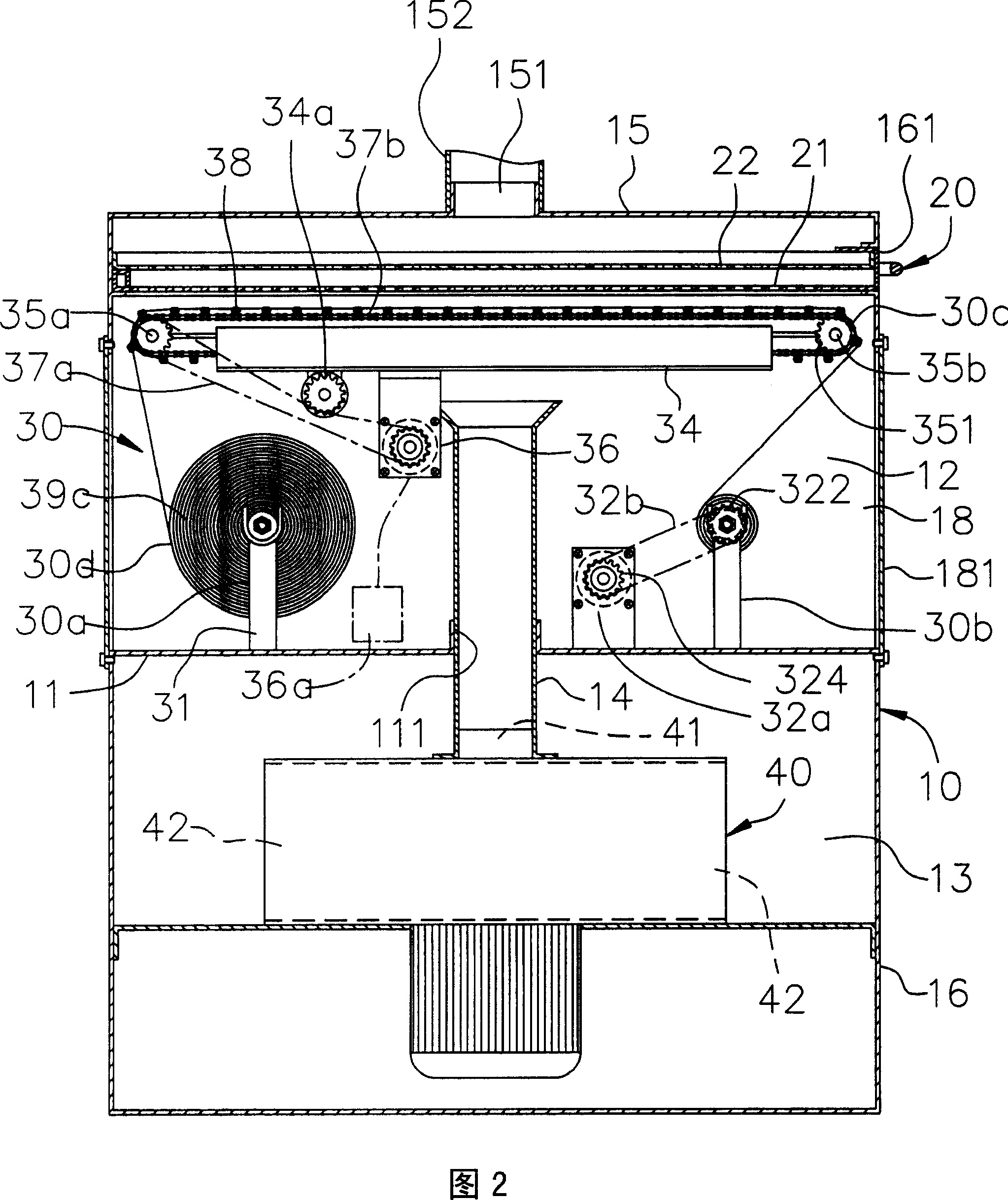

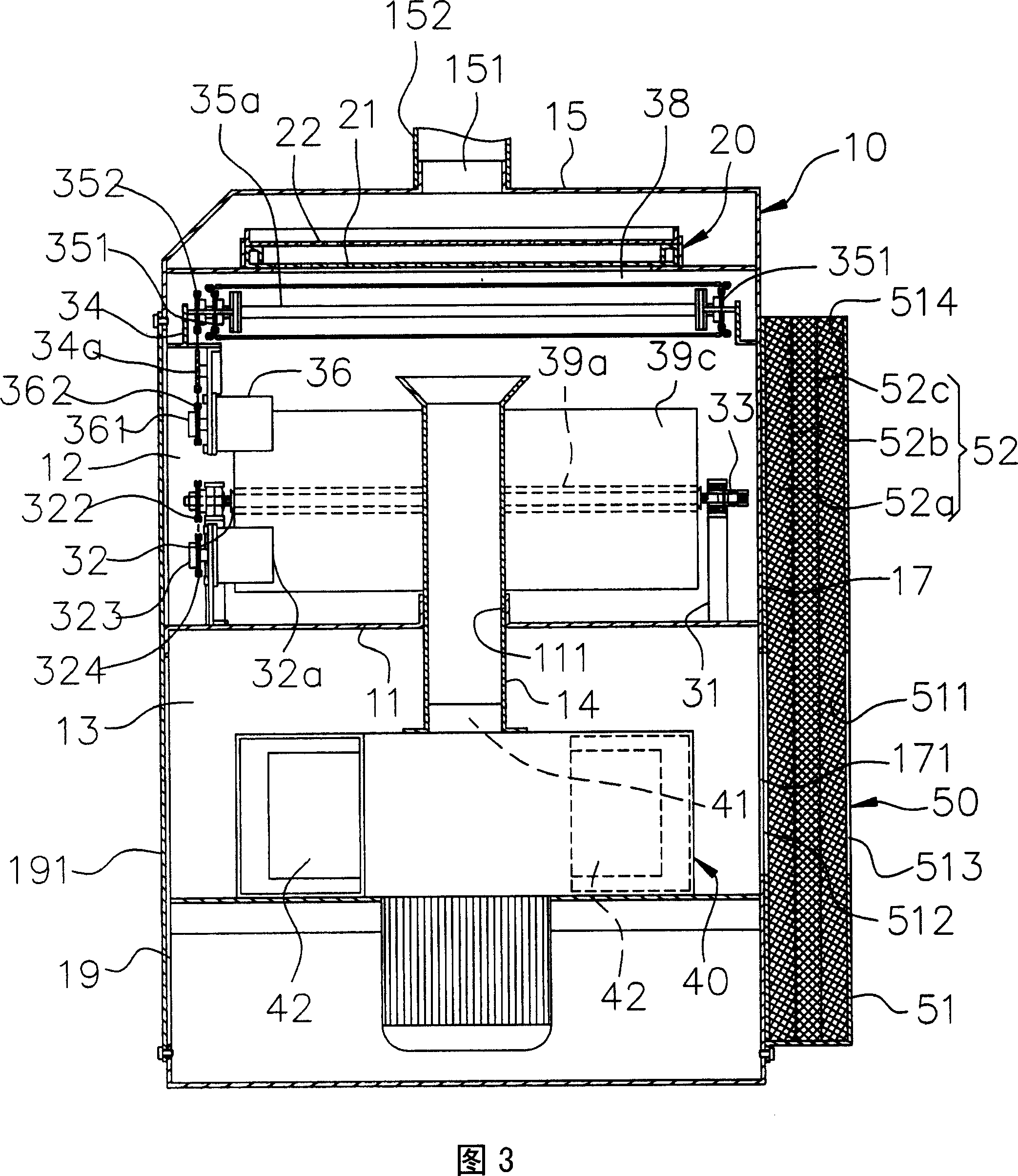

[0052] First of all, referring to Fig. 1 to Fig. 3, the present invention is a preferred embodiment of a special air filter for electric welding, the special air filter for electric welding mainly includes a cabinet 10, a spark ash blocking device 20, A movable filter cloth device 30, a blower 40, and an extractable filter device 50; wherein:

[0053] The chassis 10 is rectangular, and an upper chamber 12 and a lower chamber 13 are defined inside by a middle partition 11, and a perforation 111 is provided in the center of the middle partition 11, and a hole 111 is formed in the center of the middle partition 11. A pipe body 14 is fixedly connected to the inside through the sleeve, and extends to the inside of the upper and lower chambers 12 and 13 respectively; in addition, a through opening 151 is provided in the center of the top plate 15 of the chassis 10, which can be connected to a suction pipe 152. The air suction pipe 152 can be arbitrarily bent to adjust the air suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com