Patents

Literature

56results about How to "Reduce hard work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

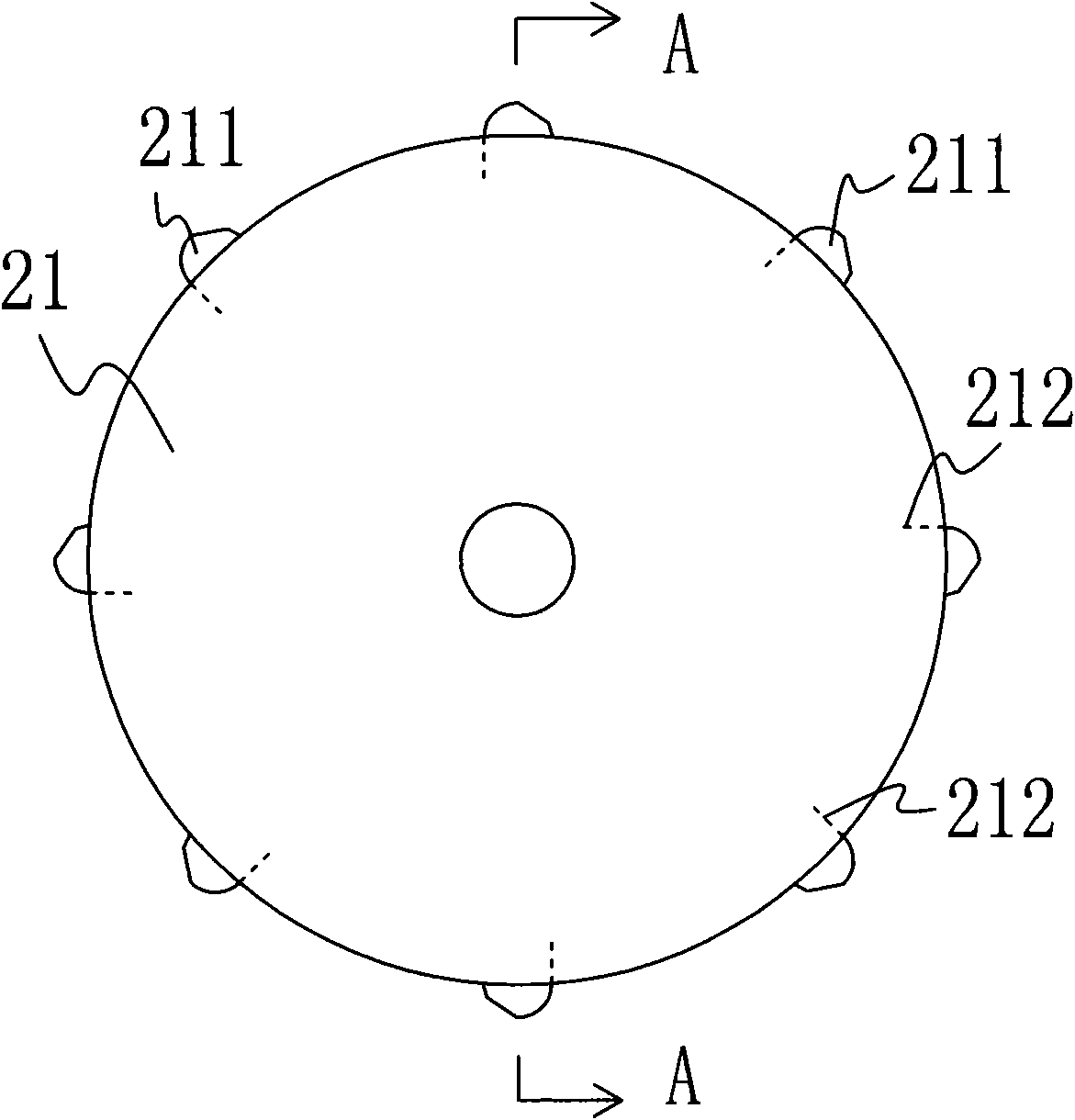

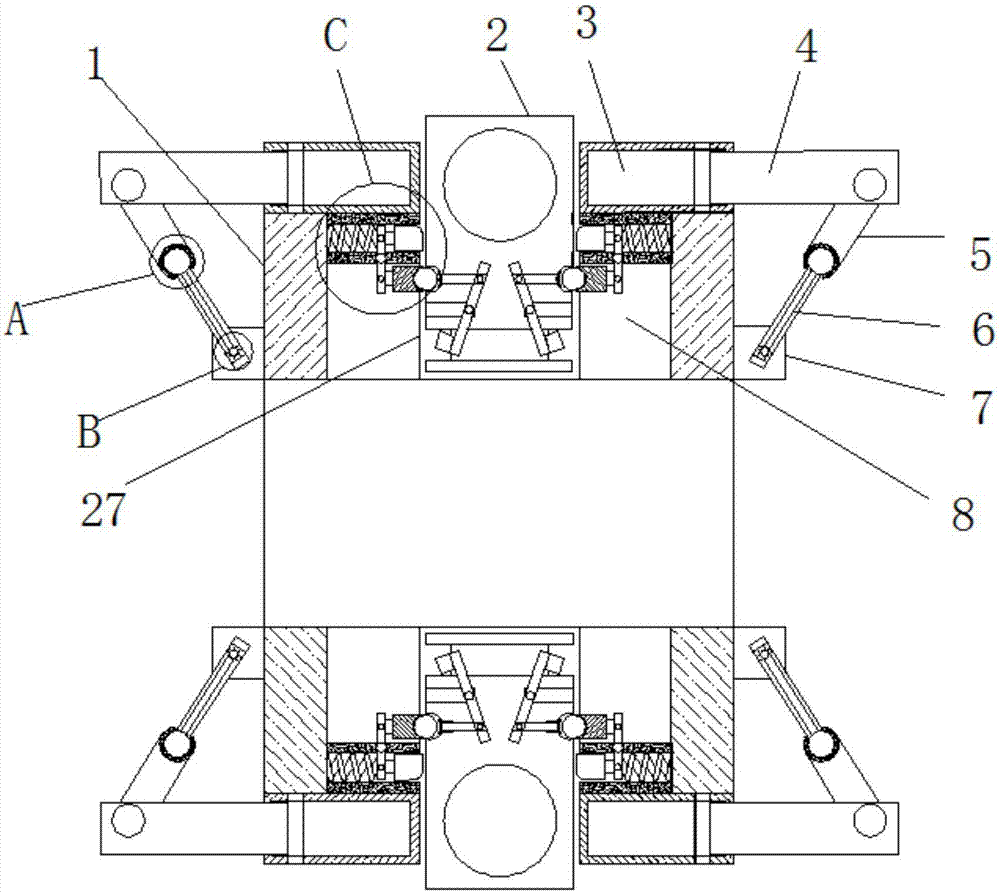

Marking device with automatic clamping and positioning function

ActiveCN104015498AWith automatic clamping and positioning functionAutomatic clamping and positioning are accurateTypewritersOther printing apparatusTransmission beltAirbag

The invention discloses a marking device with an automatic clamping and positioning function, which is accurate in positioning and can effectively improve the marking efficiency. The marking device with an automatic clamping and positioning function comprises a printing device, a transmission device is arranged right below the printing device, the transmission device comprises a transmission belt and an automatic clamping and positioning device, the automatic clamping and positioning device comprises inflatable airbags arranged at intervals at sides of the transmission belt, one inflatable airbag located at one side and the corresponding other inflatable airbag located at the other side form a clamp, one inflatable airbag of each clamp is provided with a starting end position sensor, the other inflatable airbag of each clamp is provided with an ending end position sensor, each inflatable airbag is internally provided with a sensing device used for sensing a workpiece, the inflatable airbag is connected with a pneumatic pump, the pneumatic pump is arranged at the side part of the support of the transmission device, and the starting end position sensors, the ending end position sensors and the sensing devices are connected with the controller of the pneumatic pump.

Owner:ABO BUILDING MATERIAL KUNSHAN CO LTD

Manufacturer, dealer and buyer linked transaction system and method

ActiveCN108428165AAdequate and effective managementEfficient managementBuying/selling/leasing transactionsManufacturing computing systemsE-commerceCloud data

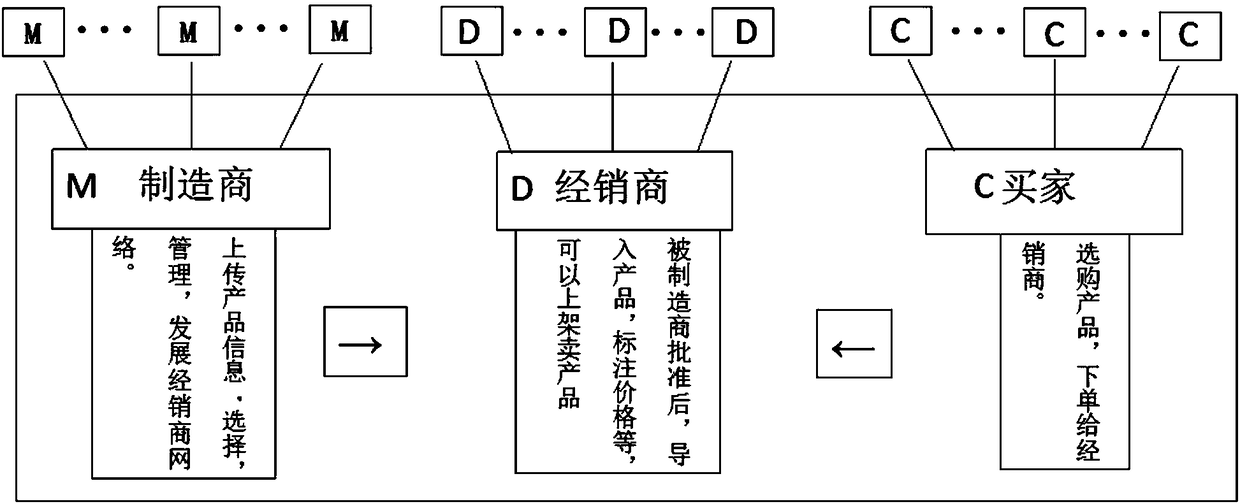

The invention discloses a manufacturer, dealer and buyer linked transaction system and method. The system comprises a manufacturer client, a dealer client, a buyer client and a cloud data server, wherein the cloud data server of the system respectively gives a manufacturer operation space, a dealer operation space and a buyer operation space for the manufacturer client, the dealer client and the buyer client; and buyers purchase products produced by manufacturers through dealers. According to the system and method, marketing channels of e-commerce and real industry and commerce are sufficiently and effectively combined, so that the problem that current popular B2C or B2B e-commerce modes seriously conflict with practical commercial ecological systems is solved, and manufacturers, deals andbuyers in the reality can easily realize e-commerce operation on the system.

Owner:SHANGHAI ANGE IND CO LTD

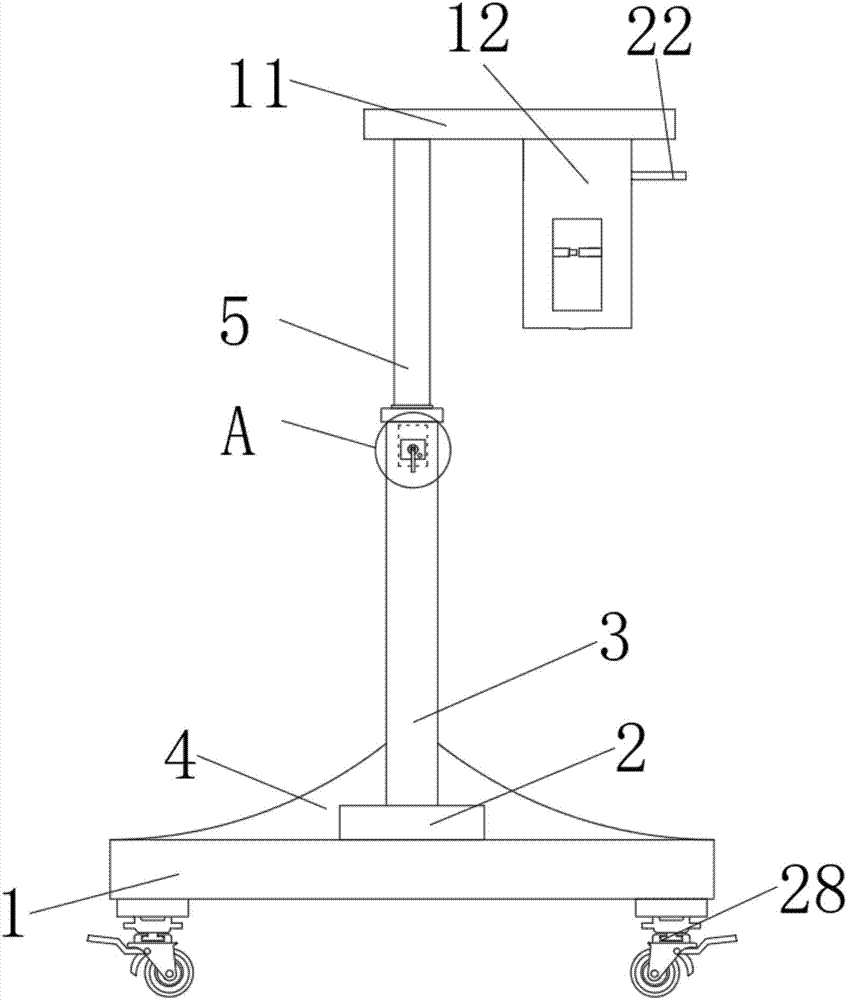

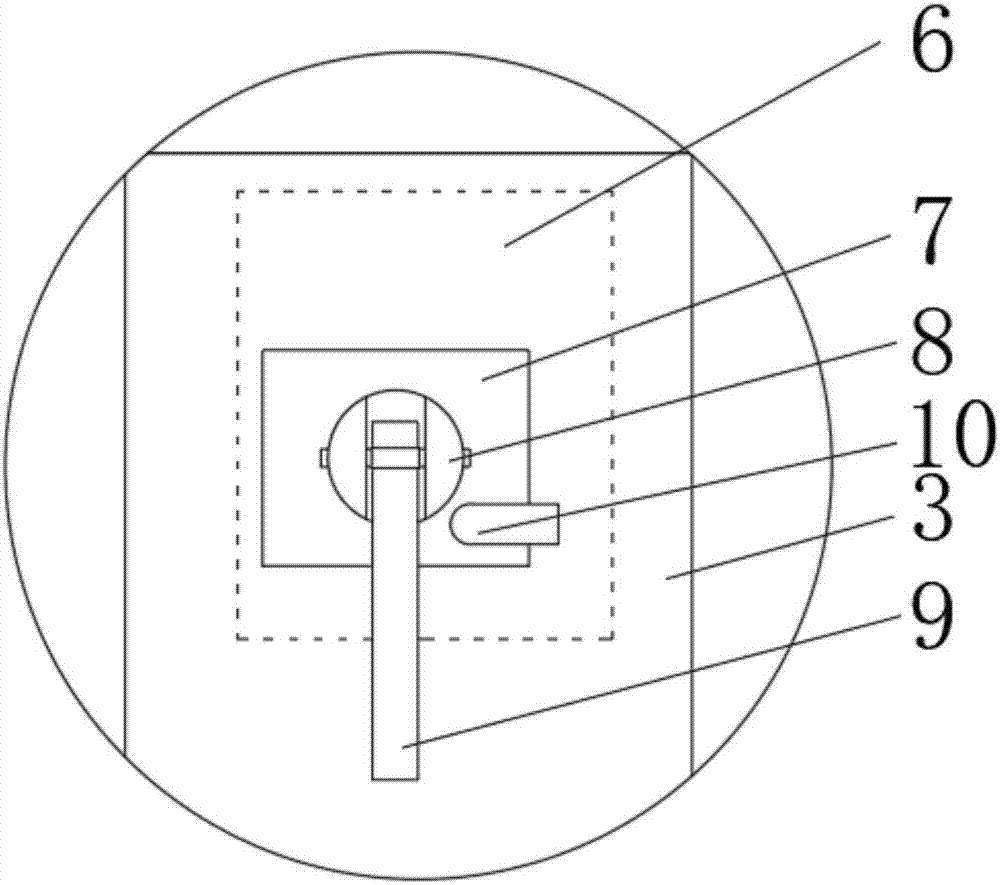

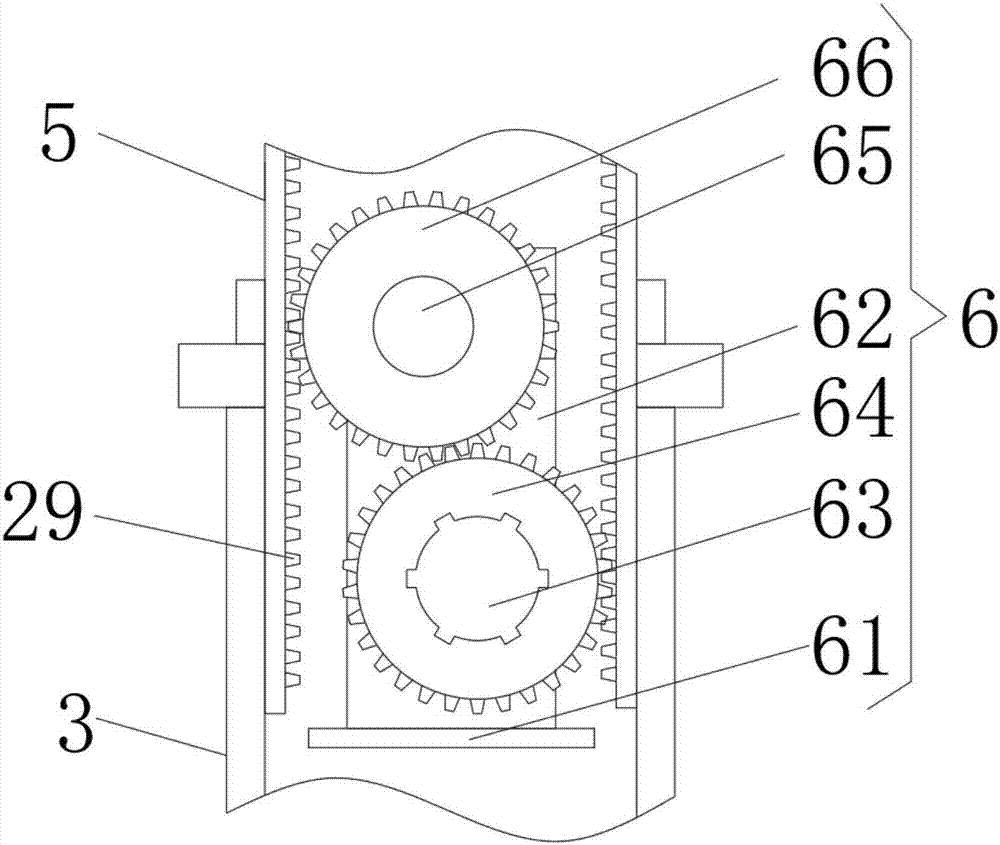

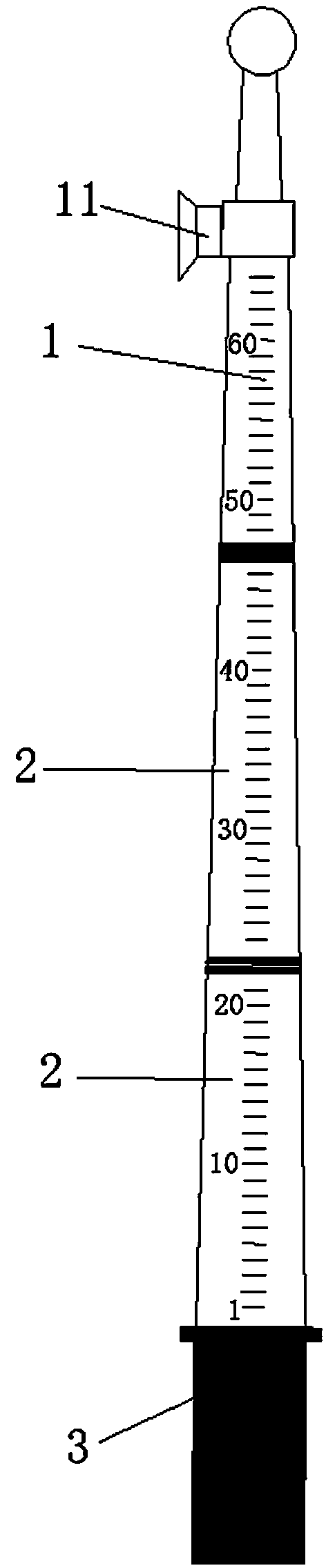

Infuse bottle holder for emergency department

The invention discloses an infuse bottle holder for the emergency department and relates to the technical field of medical instruments. The infuse bottle holder comprises a base, a fixing rod is fixedly connected to the top of the base through a fixing seat, a moving rod is slidably connected onto the inner wall of the fixing rod, a transmission gear is fixedly connected onto the inner wall of thefixing rod, a locking device is fixedly connected to the surface of the fixing rod as well as the position correspondingly to the transmission gear, a balance plate is fixedly connected to the top ofthe moving rod horizontally, an infusion kit is fixedly connected to one side of the bottom of the balance plate, a fixing hole is formed in the bottom of the infusion kit, and a pair of shock-absorbing universal wheels is fixedly connected to two sides of the bottom of the base. By the arrangement, the problem about an existing infusion bottle holder that an infusion bottle shakes during infusion is solved, the infusion bottle is effectively ensured not to shake during infusion, safety and rapidness during infusion are guaranteed, and meanwhile, convenience is brought to patients to move during infusion.

Owner:湖南丹尼尔智能科技有限公司

Bag-controlled sustained release fertilizer for mango tree and application method thereof

InactiveCN108271489AUnique methodEasy to implementFertilising methodsDirect liquid fertiliser deliveryFruit treeMaterial resources

The invention discloses a bag-controlled sustained release fertilizer for a mango tree and an application method thereof. The bag-controlled sustained release fertilizer for the mango tree specifically involves preparation of a fertilizer bag, compositions of a fertilizer, and a fertilizer application method. According to the bag-controlled sustained release fertilizer for the mango tree and the application method thereof, a package bag is made of paper; the package bag is started to decompose spontaneously two years after the fertilizer is applied; soil and air are not polluted, and a soil loosening effect is achieved. Meanwhile, the fertilizer efficiency of the bag-controlled sustained release fertilizer is long; the nutrient utilization rate is high. The effects of improving crop yieldand improving crop quality can be achieved. The manpower and material resources used for applying the fertilizer can also be saved effectively; the fertilizer is really applied quantitatively and accurately according to the requirement of the mango tree; meanwhile, the concentration of quick effective nutrients of the soil can be kept stable; the defect that the nutrient concentration of fertilizer applied soil fluctuates greatly is overcome; the nitrogen utilization rate is improved by 10 percent. In addition, the effects of protecting oil and reducing environment pollution are also achieved.By promoting and applying the bag-controlled sustained release fertilizer, safety and environment friendliness can be achieved; the bag-controlled sustained release fertilizer has long-term ecological benefits and remarkable social and ecological benefits, benefits the nation and the people, and has a very broad prospect.

Owner:田东县举家富现代农业开发有限公司

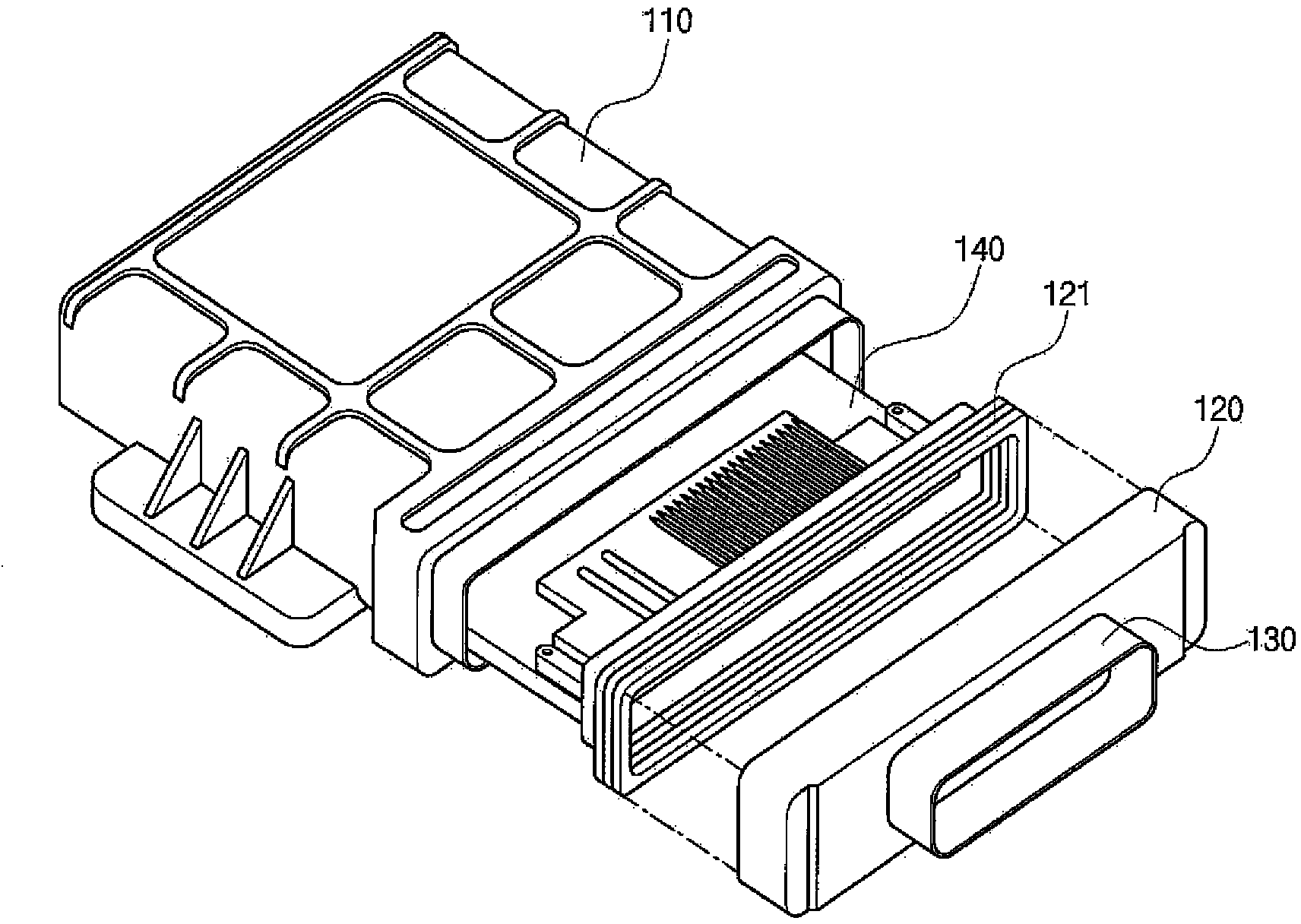

Electronic control apparatus for vehicle using water proof type housing sealing and method thereof

ActiveCN104125736AImprove waterproof performanceIncrease productivityPrinted circuit assemblingCasings with connectors and PCBEngineeringSealant

The present disclosure relates to an electronic control apparatus for a vehicle using waterproof type housing sealing and a manufacturing method thereof, in which when a connector cover including a sealing material injection hole formed on a front surface is coupled with a body coupling part, a sealing space is formed along a circumference of an inner surface of each of the coupled coupling parts and a preventive protrusion formed at a body coupling part, and a sealing material is injected through a sealing material injection hole so that a sealing space between the connector cover and a housing body is sealed, thereby improving waterproof performance between the connector cover and the housing body, and simplifying a process by replacing a process of manufacturing and mounting an O-ring in advance with a simple process of injecting the sealing material.

Owner:HYUNDAI KEFICO CORP

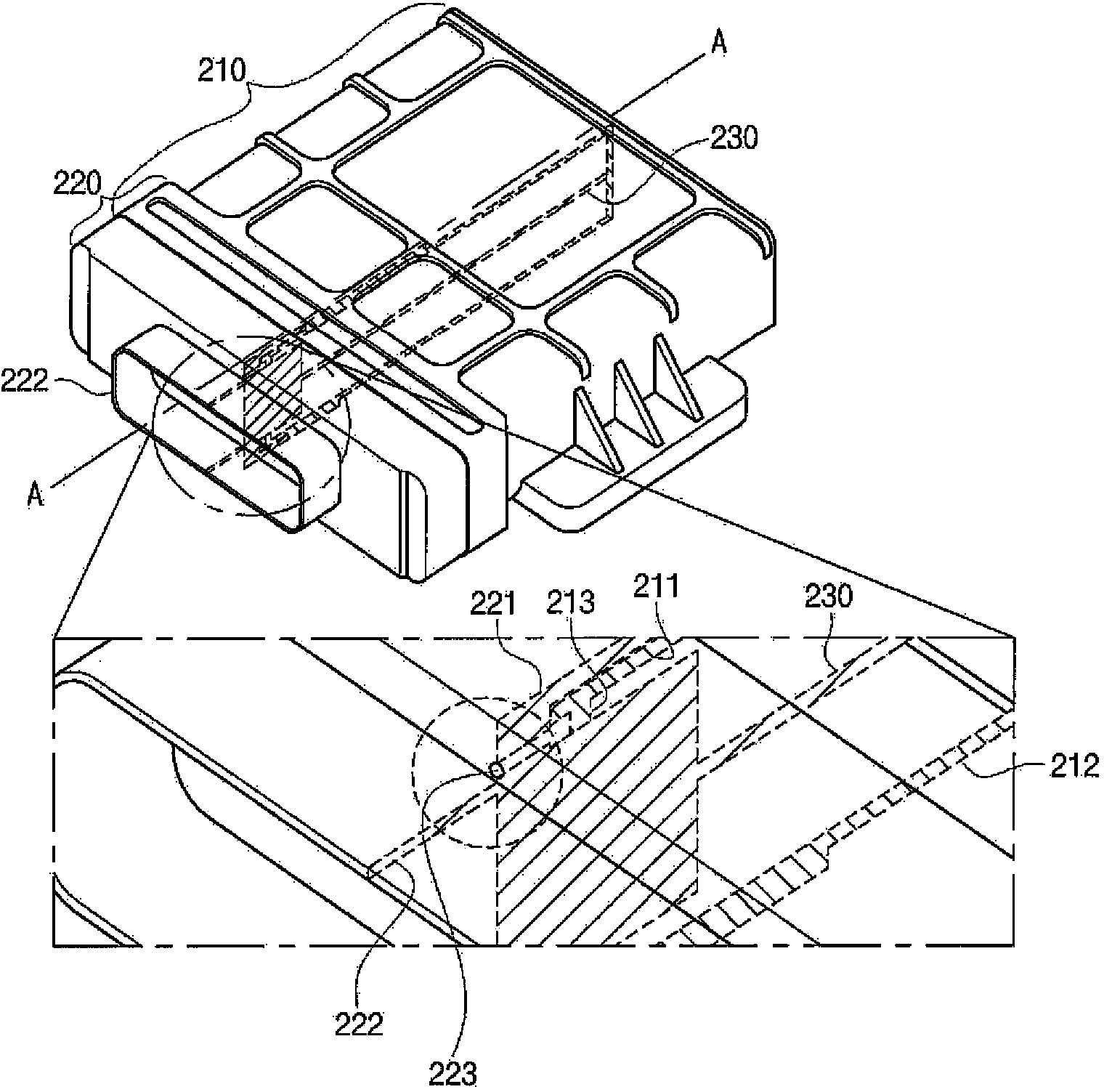

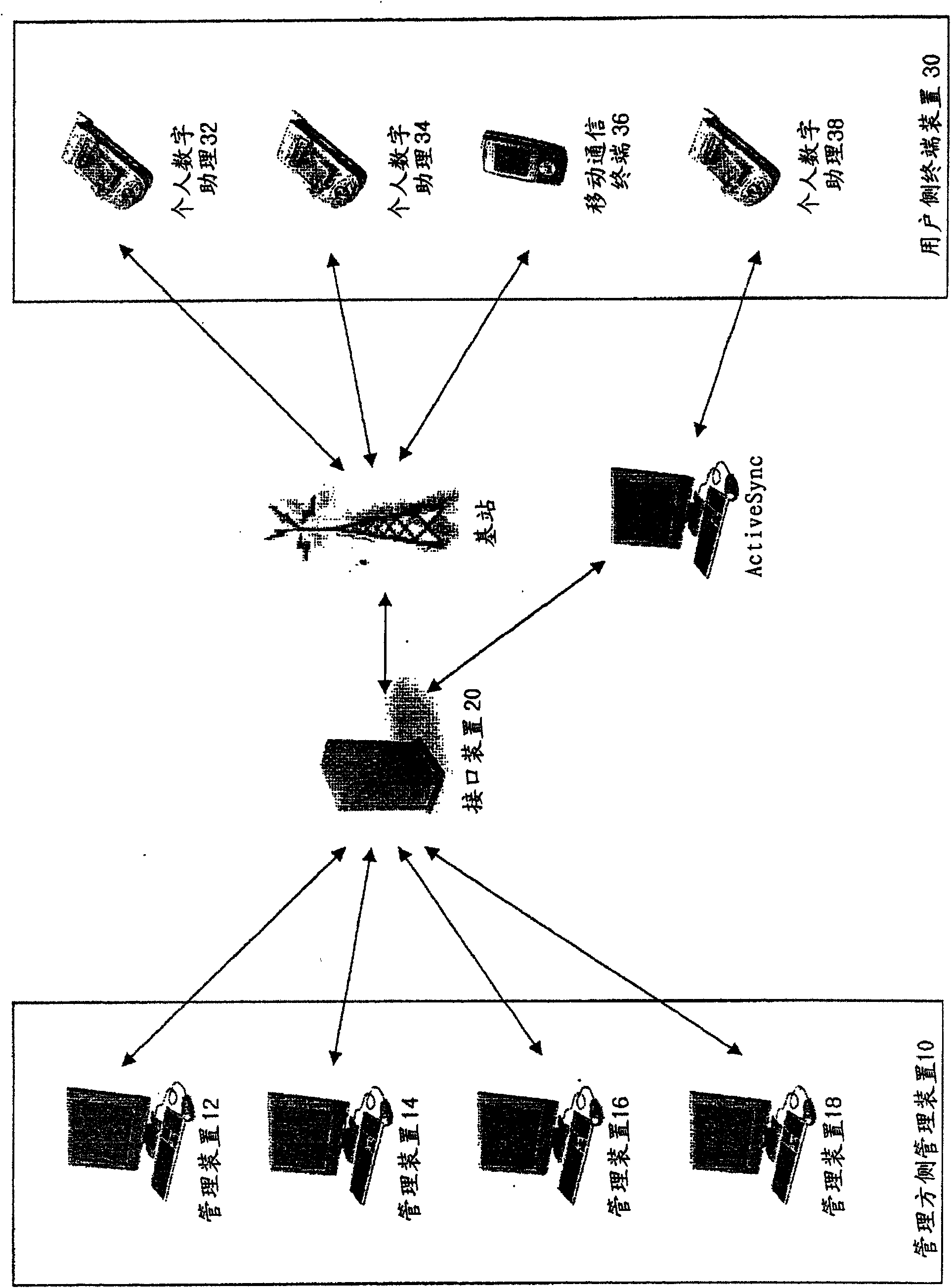

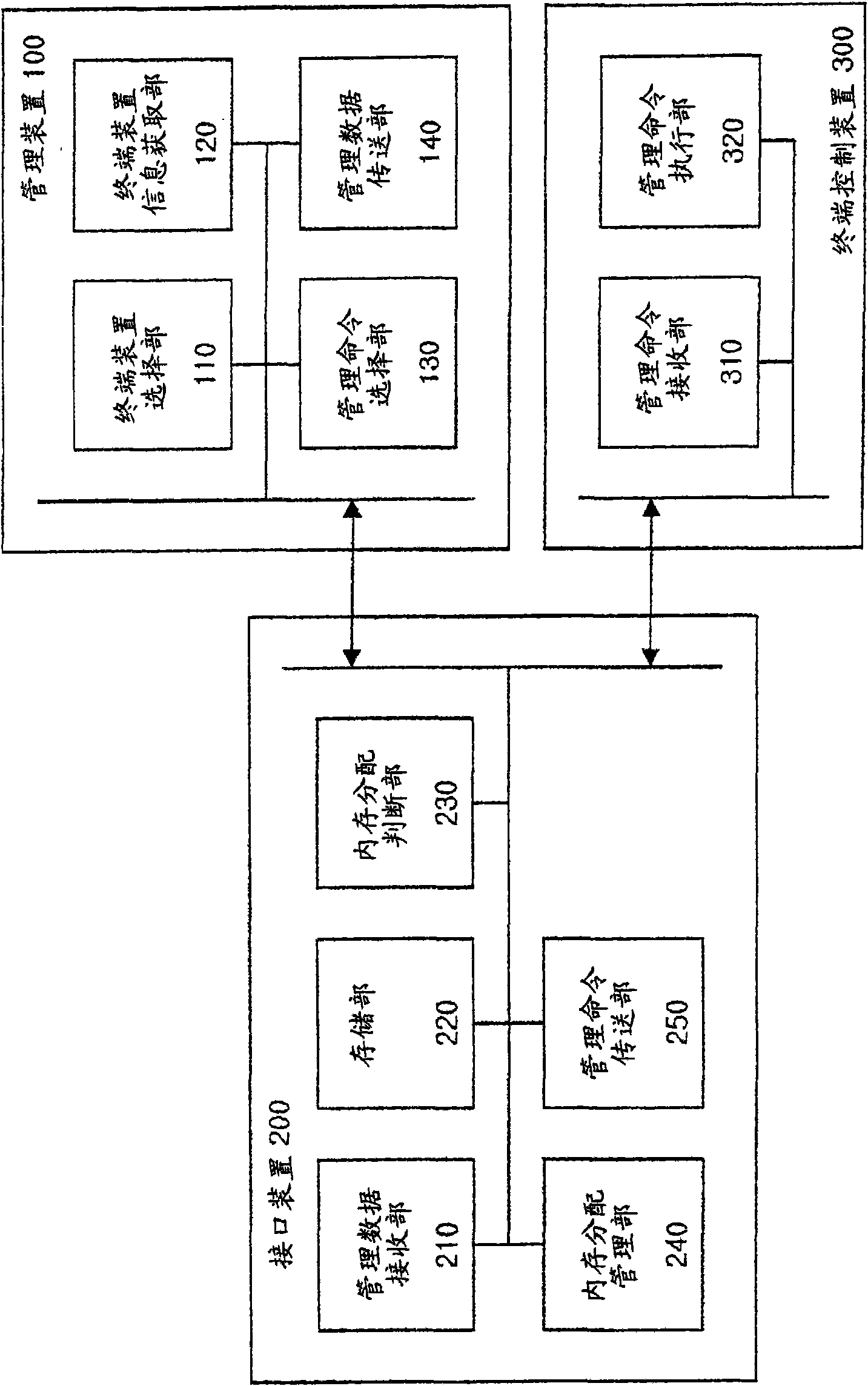

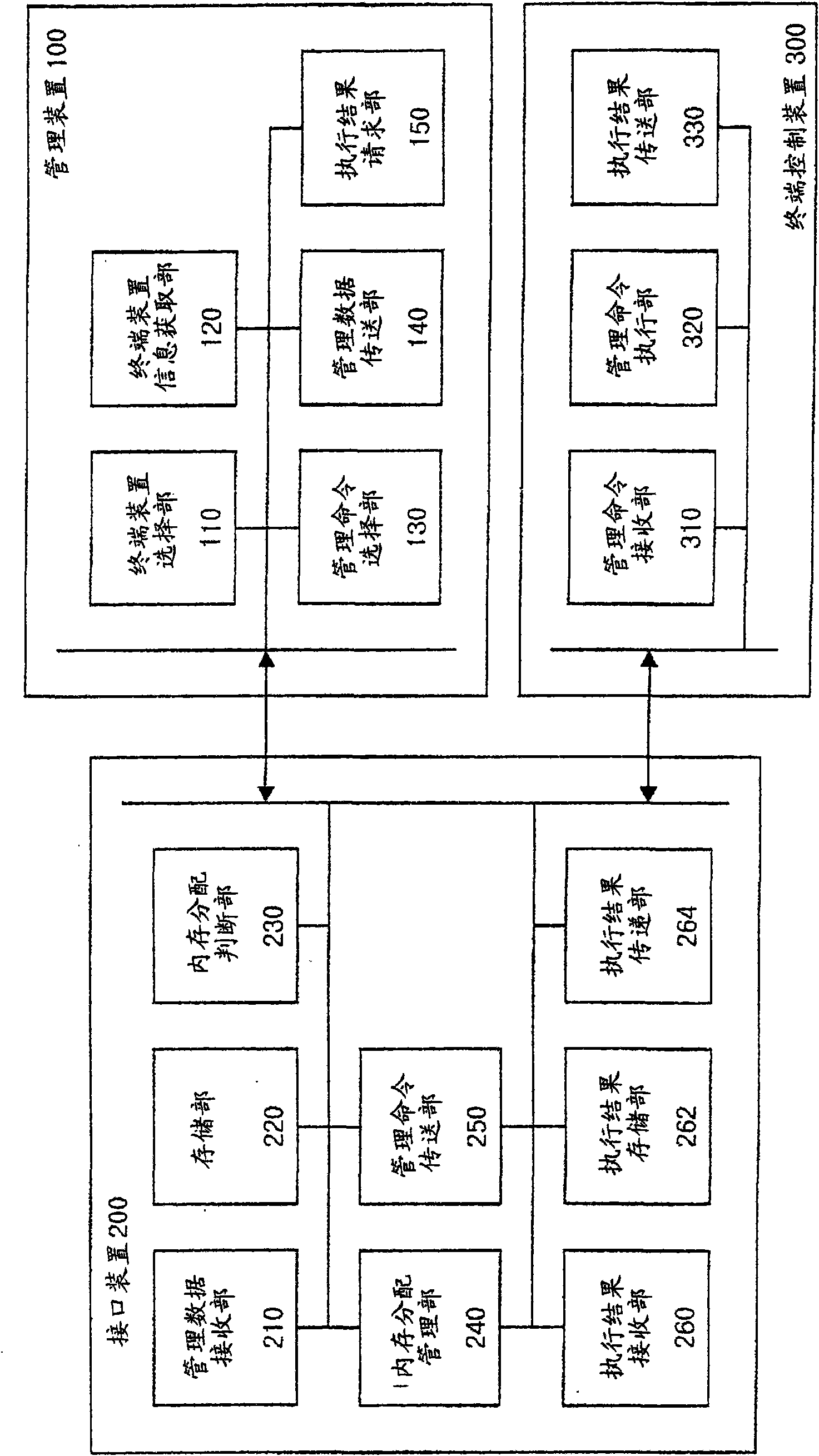

Terminating apparatus management system and an interface device and corresponding method, recording media

InactiveCN101594259AImprove satisfactionNo data shuffling will occurColor signal processing circuitsData switching networksComputer hardwareManagement unit

The invention relates to a terminating apparatus management system and an interface device and corresponding method, recording media, wherein the terminating apparatus management system manages to more than one user terminating apparatus in remote through wire or wireless communication, more specifically, utilize the interface device that connects with a plurality of management units and a plurality of terminating apparatus and control data transferring between them, and make the plurality of management units manage the plurality of terminating apparatus at the same time. The terminating apparatus management system in the invention comprises the following components: a management unit provided with a terminating apparatus selecting part, a terminating apparatus information acquisition part, a management command selecting part and a management data transferring part; an interface device provided with a management data receiving part, a storage part, a memory allocation judging part, a memory allocation management part and a management command transmitting part; and a terminal control device provided with a management command receiving part and a management command executing part.

Owner:HANMI IT

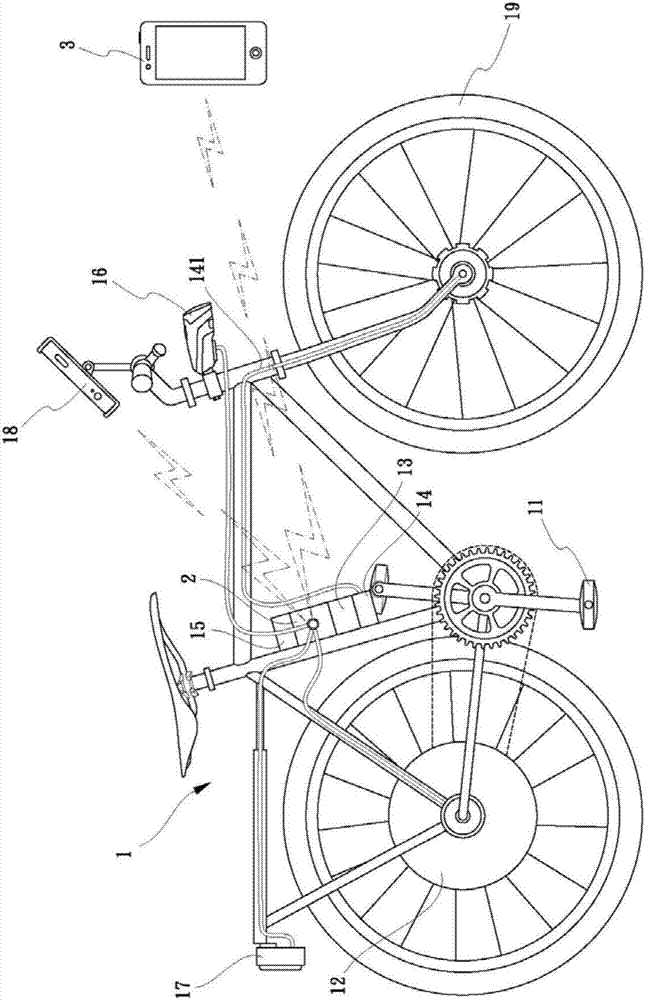

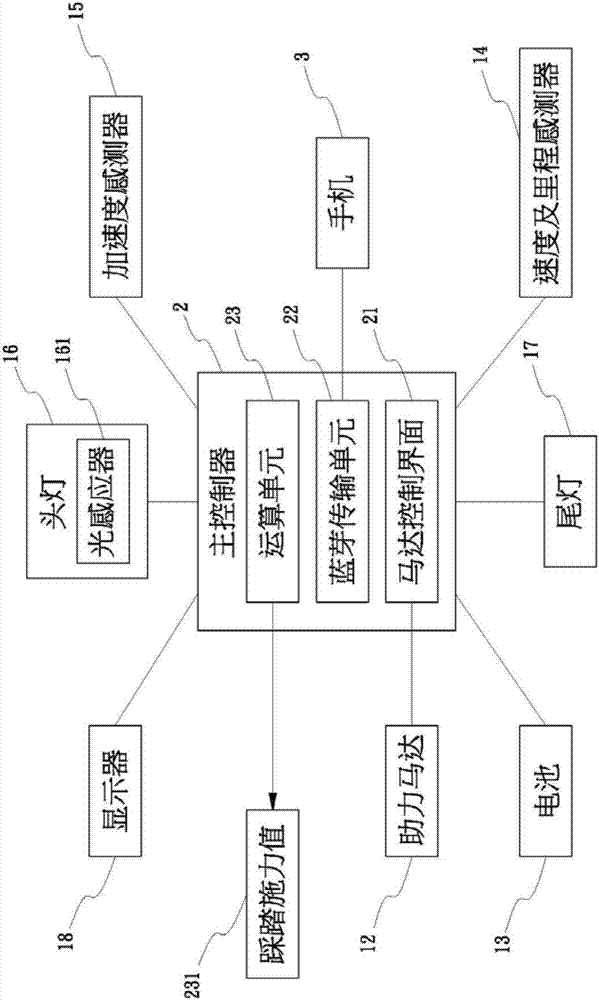

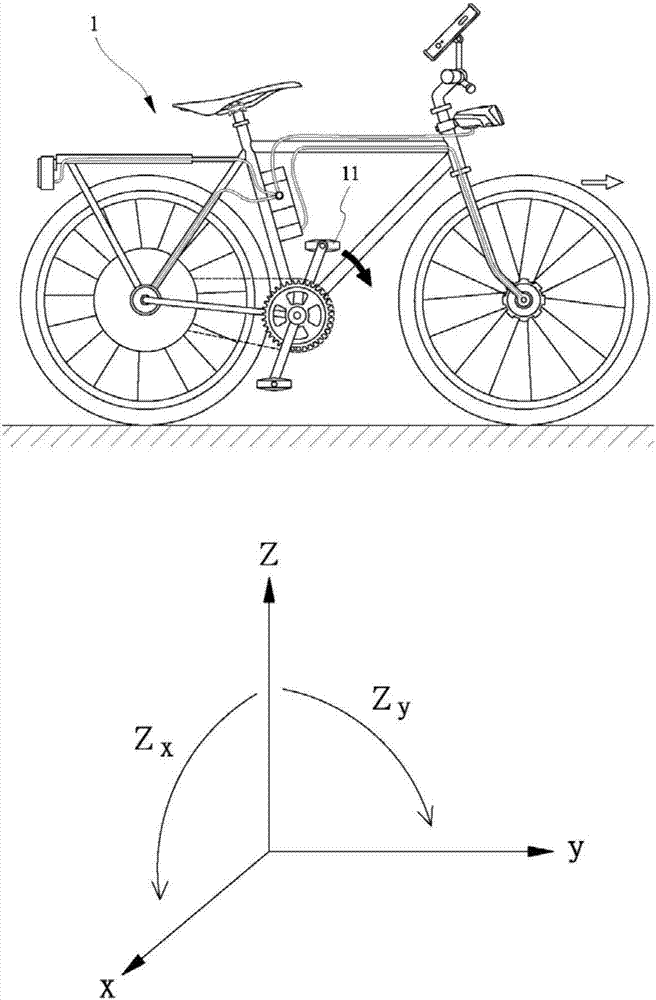

Control system of booster bike

ActiveCN106904242AAuxiliary power increaseOvercome driving resistanceOptical signalRider propulsionControl systemMaster controller

The invention discloses a control system of a booster bike. The control system of the booster bike comprises an acceleration sensor and a main controller, wherein the acceleration sensor is arranged on a booster bike body and used for detecting the running acceleration value of the booster bike and detecting the treading running acceleration value of pedals simultaneously; and the main controller is arranged on the booster bike and used for receiving the running acceleration value, detected by the acceleration sensor, of the booster bike, distinguishing, sensing and detecting the treading running acceleration value of the pedals, and outputting an adjusting signal to a booster motor and a battery so as to control output of the booster motor and the battery. When the running acceleration value of the pedals is larger than the running acceleration value of the booster bike, the main controller judges that the booster bike accepts increase of running resistance of the road condition or the wind power, and improves the output of the booster motor and the battery, the control system can effectively assist a rider in easily overcoming running resistance caused by tough road conditions without treading on the pedals hard, and labor and fatigue of the rider are relieved.

Owner:漳浦桂宏工业有限公司

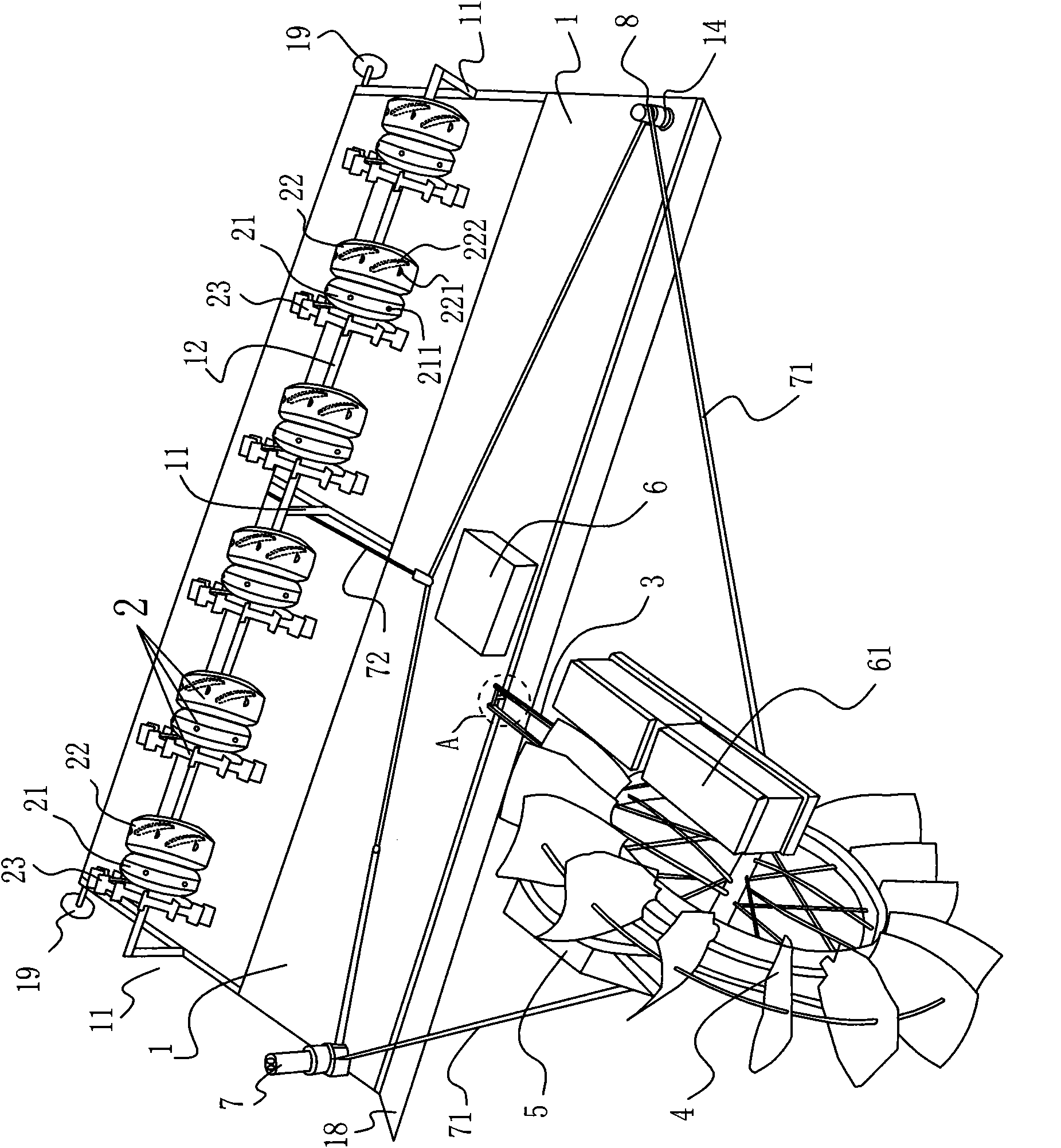

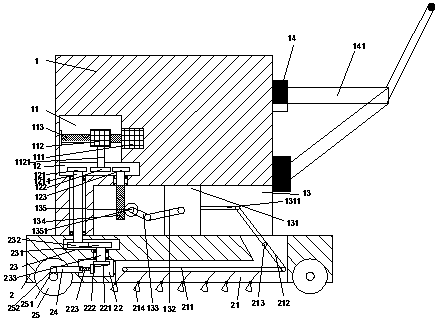

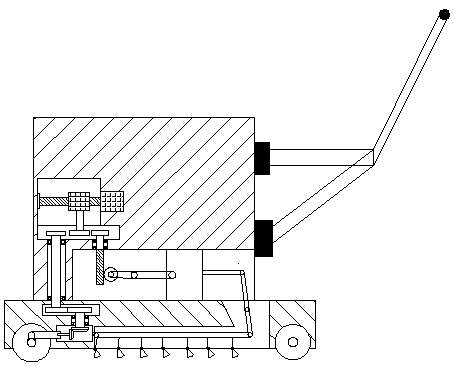

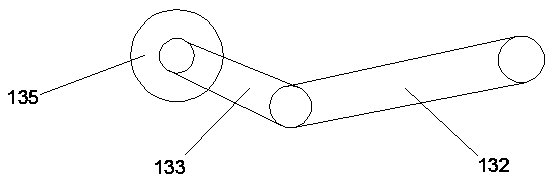

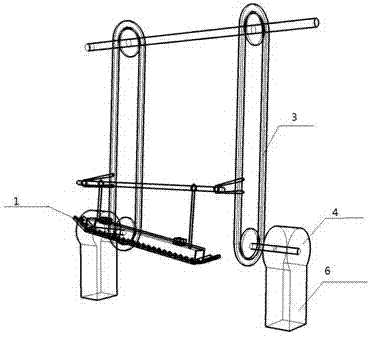

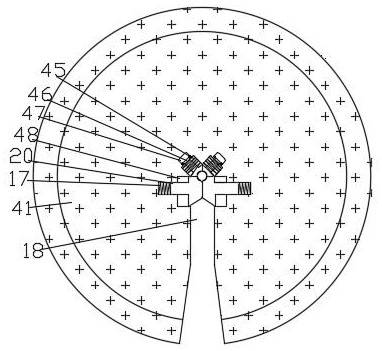

Remote control paddy direct seeding machine

InactiveCN101647339ASolve the seeding gapImprove seed uniformityAgriculture gas emission reductionSeed depositing seeder partsImpellerRemote control

The invention discloses a remote control paddy direct seeding machine. The middle of a base is provided with a movable circular shaft which is provided with a plurality of sets of seeding fertilization structures; each seeding fertilization structure comprises a seeding circular box, a fertilization circular box and a driven impeller; the circumference of each seeding circular box is provided witha plurality of small seedling outlet holes, and the seeding circular box is internally provided with seedling outlet regulating baffle pieces correspondingly; the circumference of each fertilizationcircular box is provided with a plurality of small fertilizer outlet holes, and each fertilization circular box is internally provided with flow diverting pieces correspondingly; a universal shaft atthe front side of the base is connected with a walking rack which is provided with a driving impeller and a transmission mechanism in transmission connection; one side of the front part of the base isprovided with a direction regulating motor, and the other side is symmetrically provided with a fixing rod with a small wheel; the transmission mechanism and the direction regulating motor are both connected with a controller; a transmission belt passes through the direction regulating motor and the small wheel and then is symmetrically fixed on both sides of the walking rack; the transmission belt between the direction regulating motor and the small wheel is connected with a regulating tension spring, and the other end of the regulating tension spring is fixed on the back side of the base. The invention has the advantages of low cost, convenient use and reliable action and is suitable for large-area application.

Owner:RICE RES INST GUANGDONG ACADEMY OF AGRI SCI

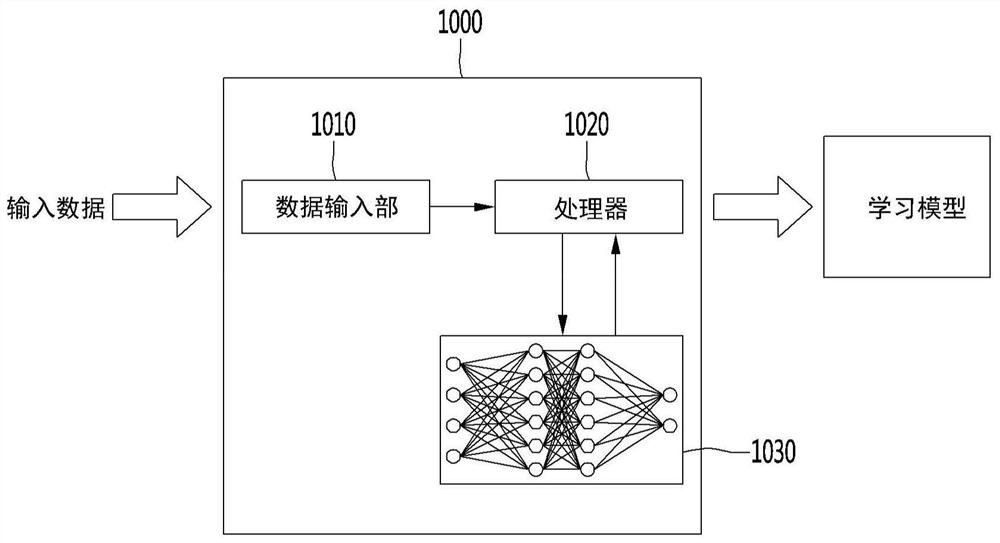

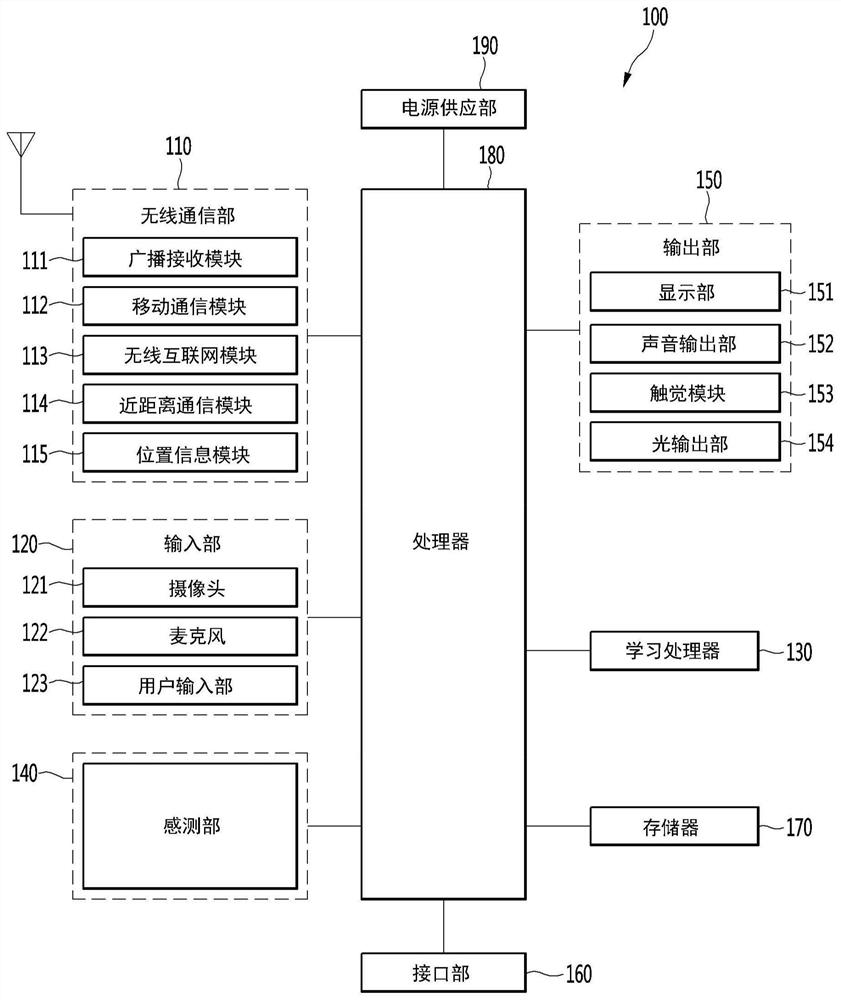

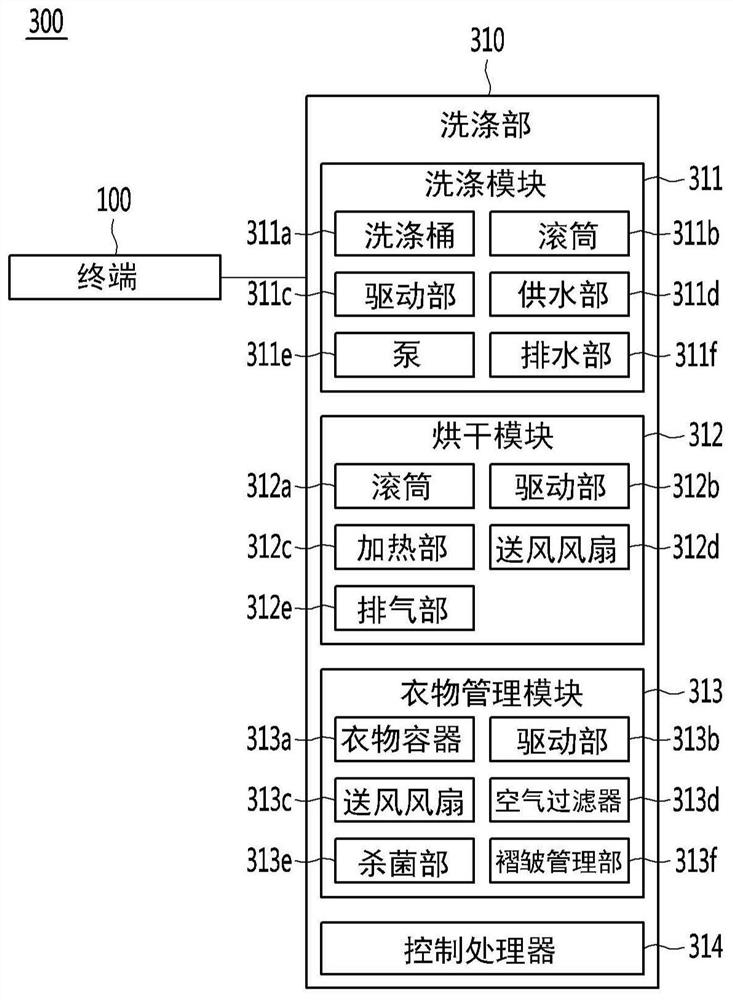

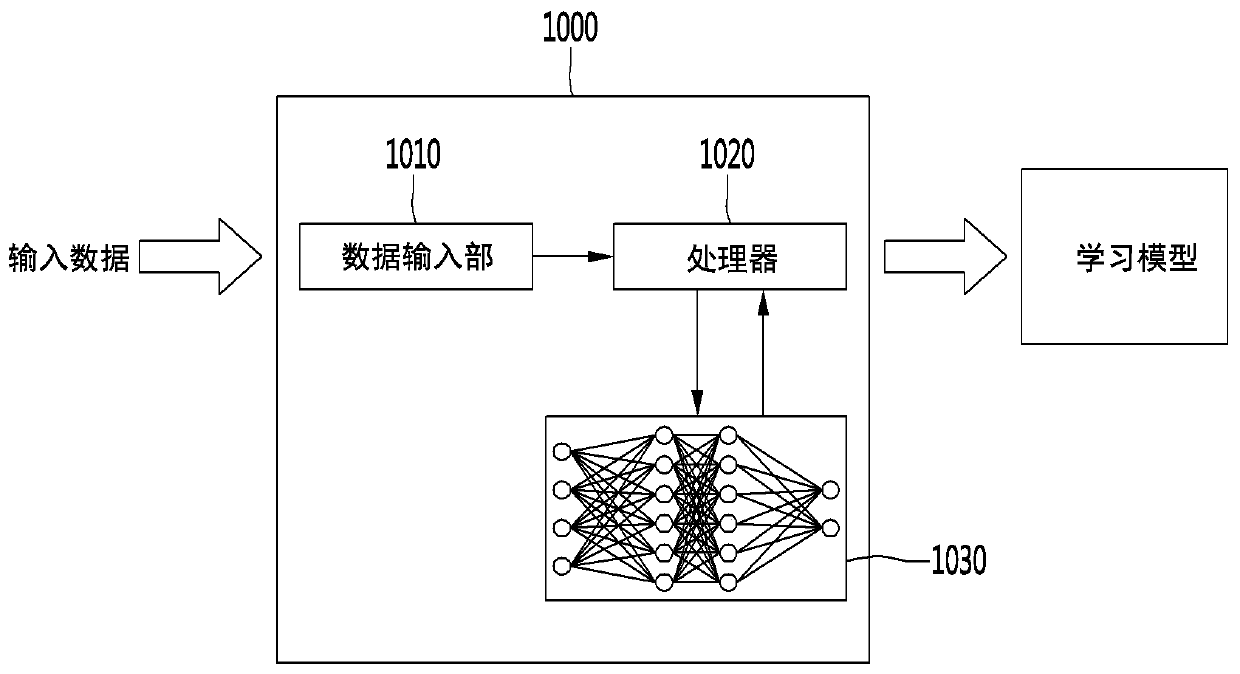

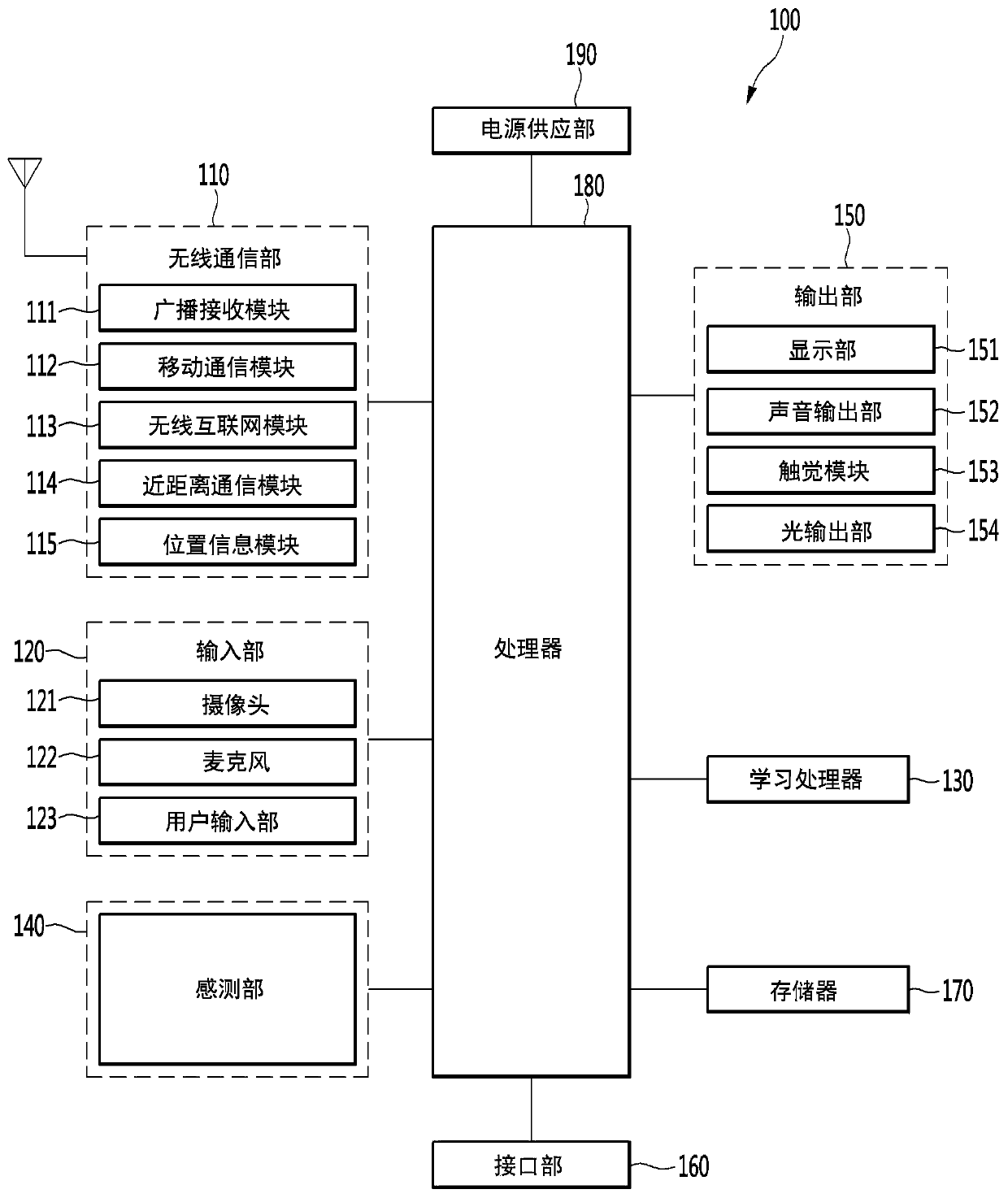

Artificial intelligence device and method for operating same

ActiveCN111663294ADamage minimizationMaximum washing powerOther washing machinesControl devices for washing apparatusProcess engineeringLaundry

An artificial intelligence device according to an embodiment of the present invention comprises a short-range communication module for detecting nearby multiple laundry processing devices, and a processor which: acquires laundry information relating to a laundry and feature information of each of detected multiple laundry processing devices; on the basis of the acquired laundry information, determines a laundry group to which the laundry belongs; according to a comparison between feature information of the determined laundry group and the feature information of each of the multiple laundry processing devices, determines a laundry processing device among the multiple laundry processing devices as a device for washing the laundry; and transmits the laundry information to the determined laundry processing device.

Owner:LG ELECTRONICS INC

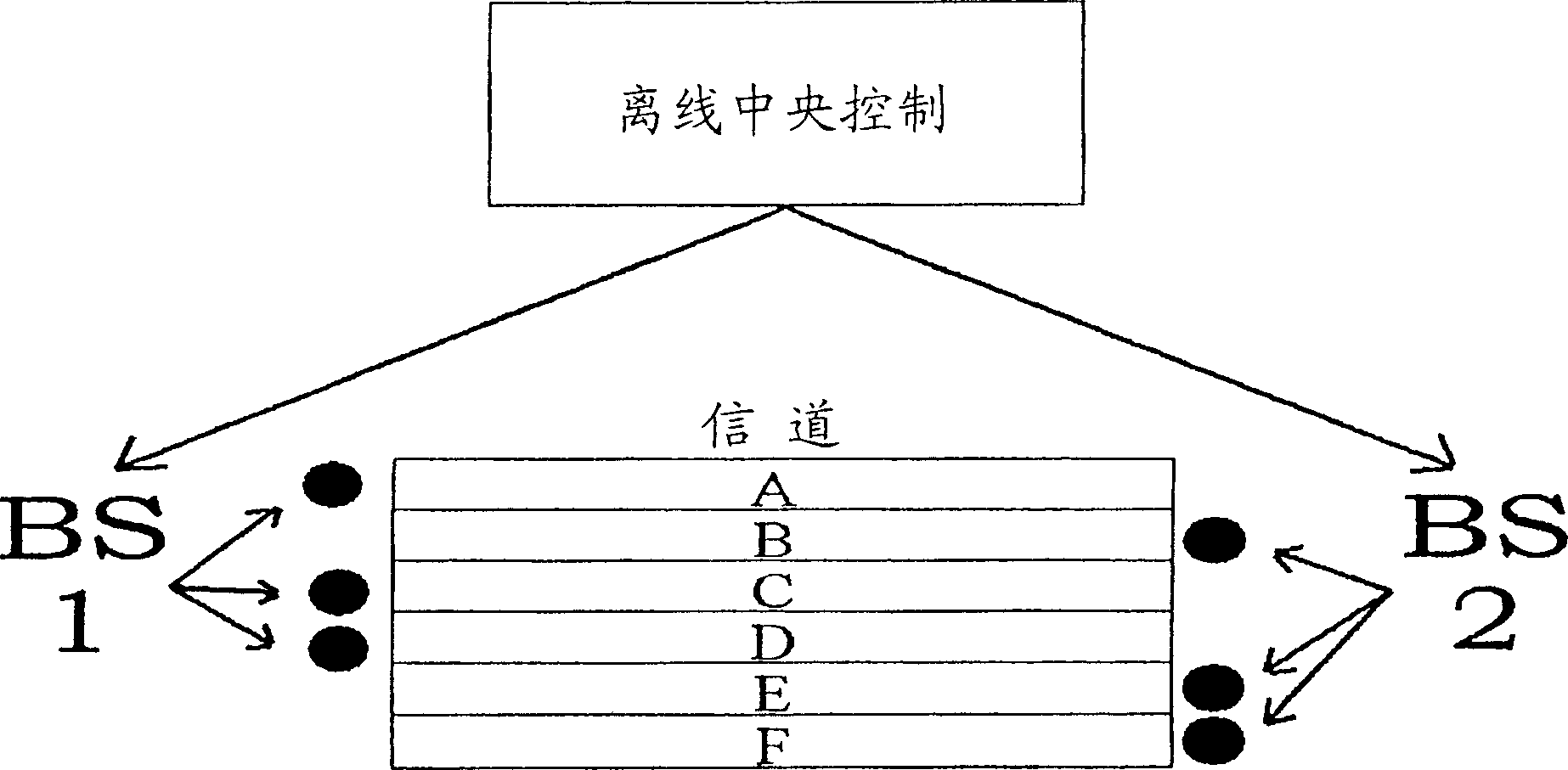

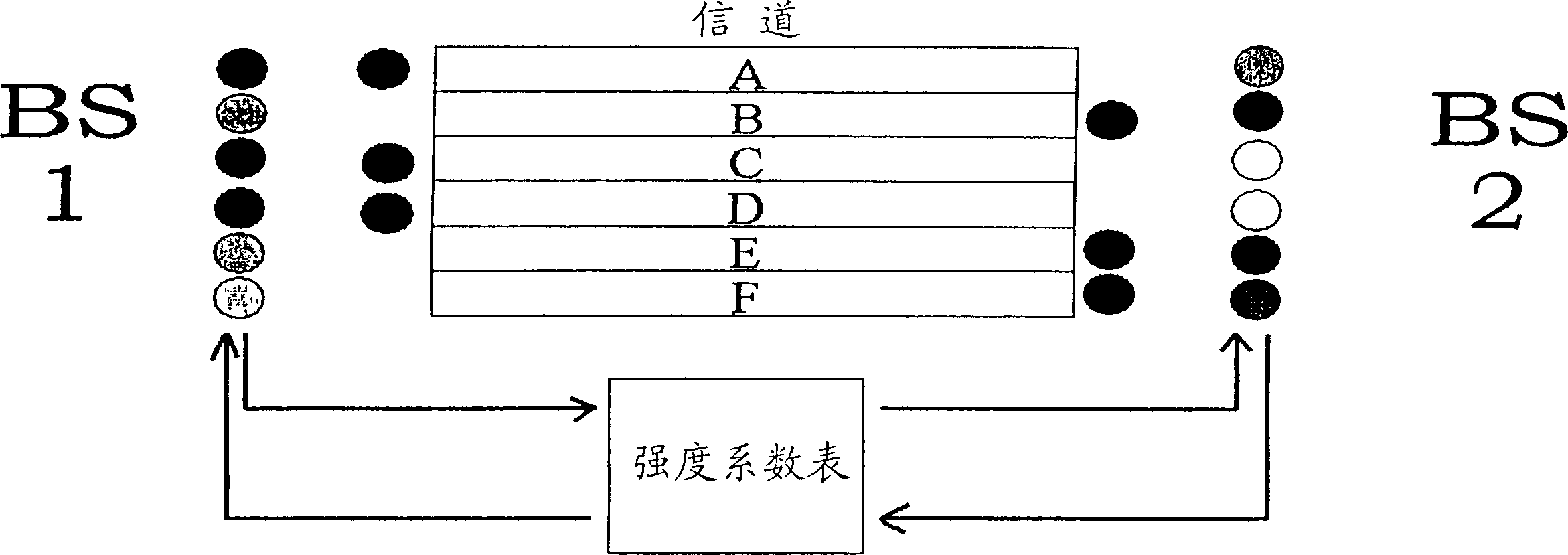

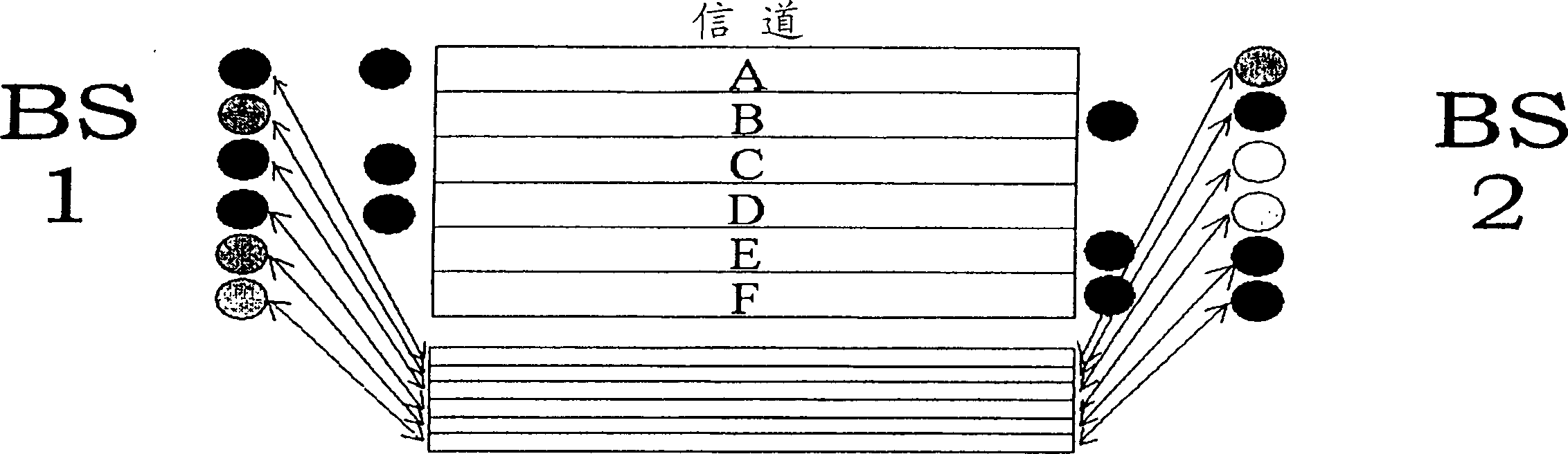

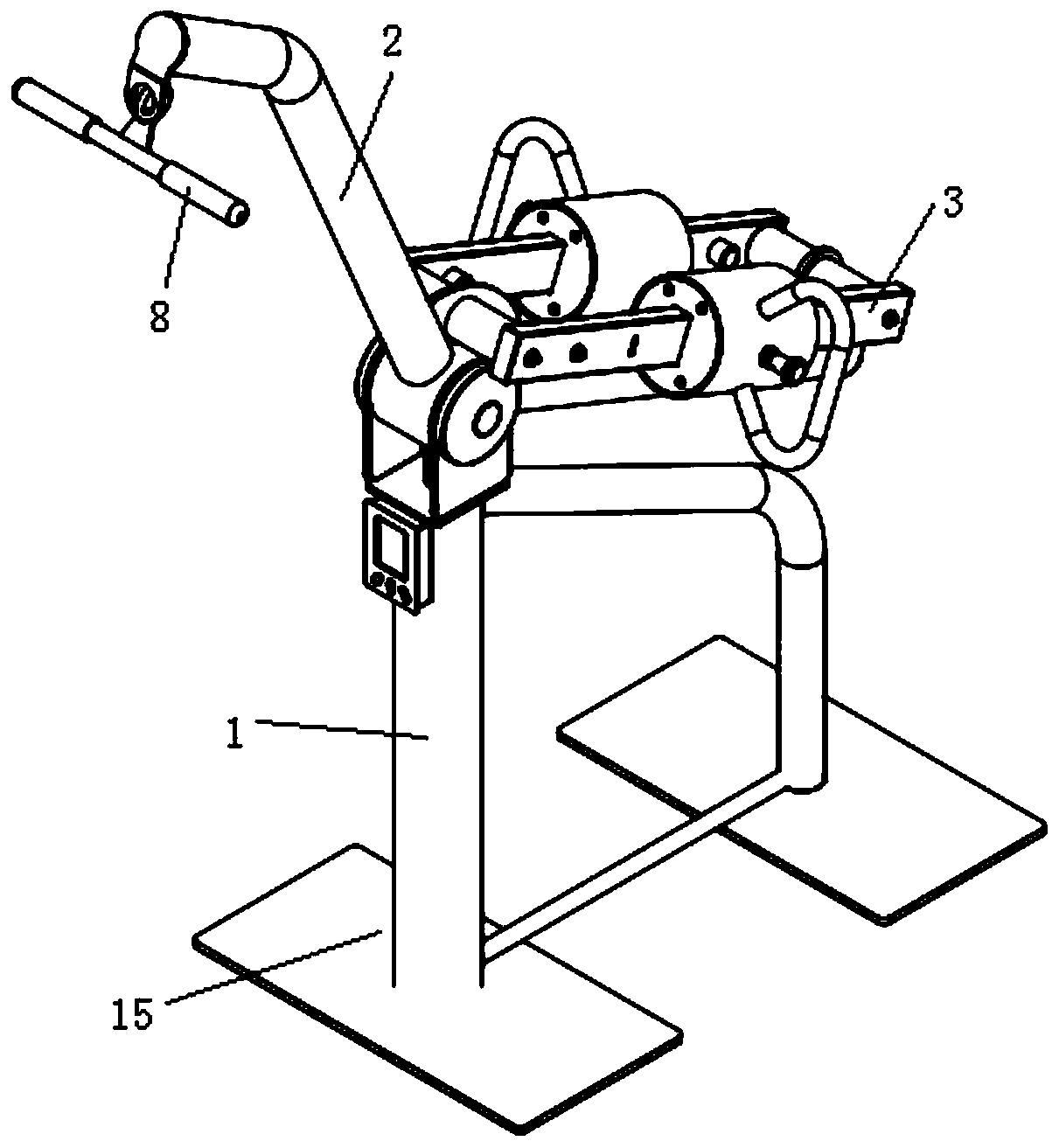

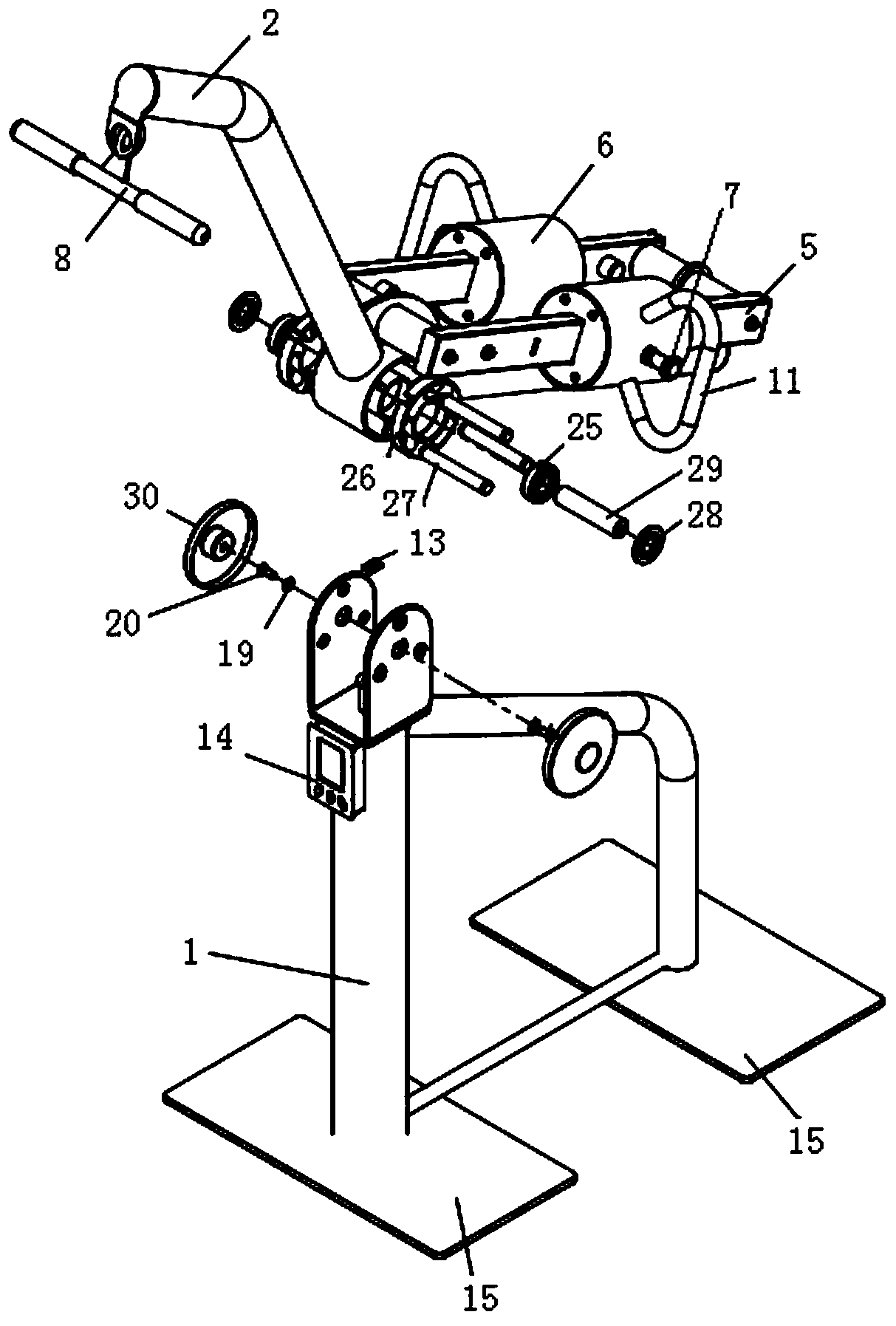

Allocation of channels to radio transceivers

InactiveCN1413423AEliminate dependenciesReduce hard workRadio/inductive link selection arrangementsTransmission monitoringTest channelTransceiver

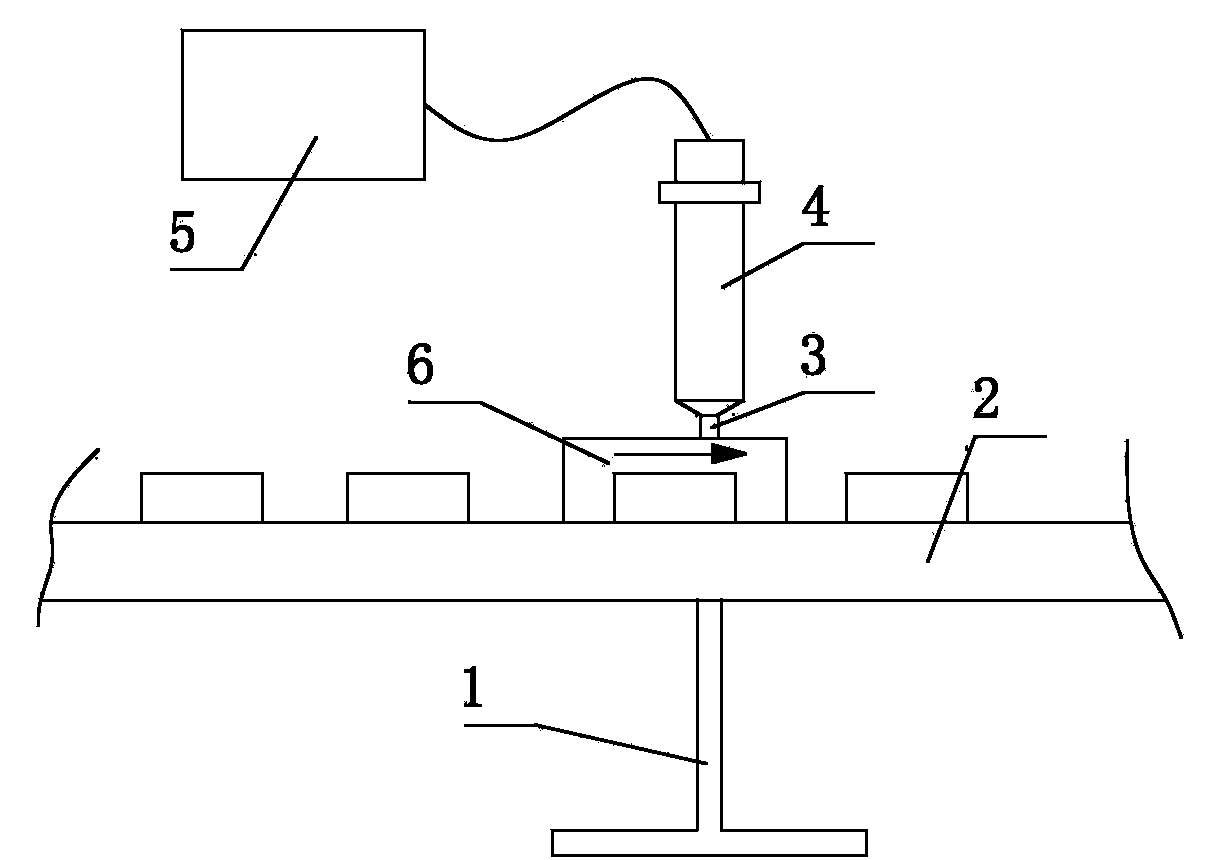

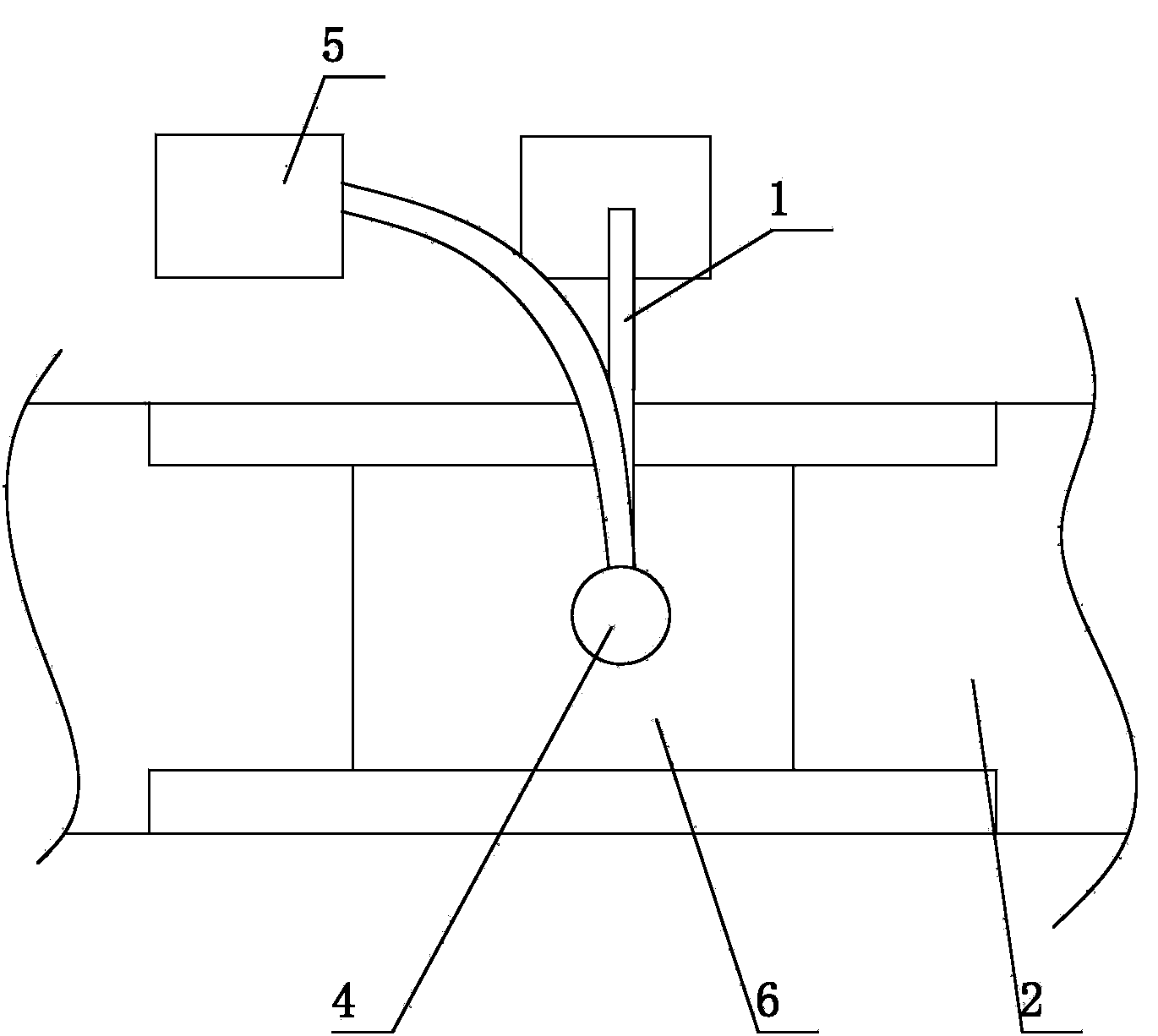

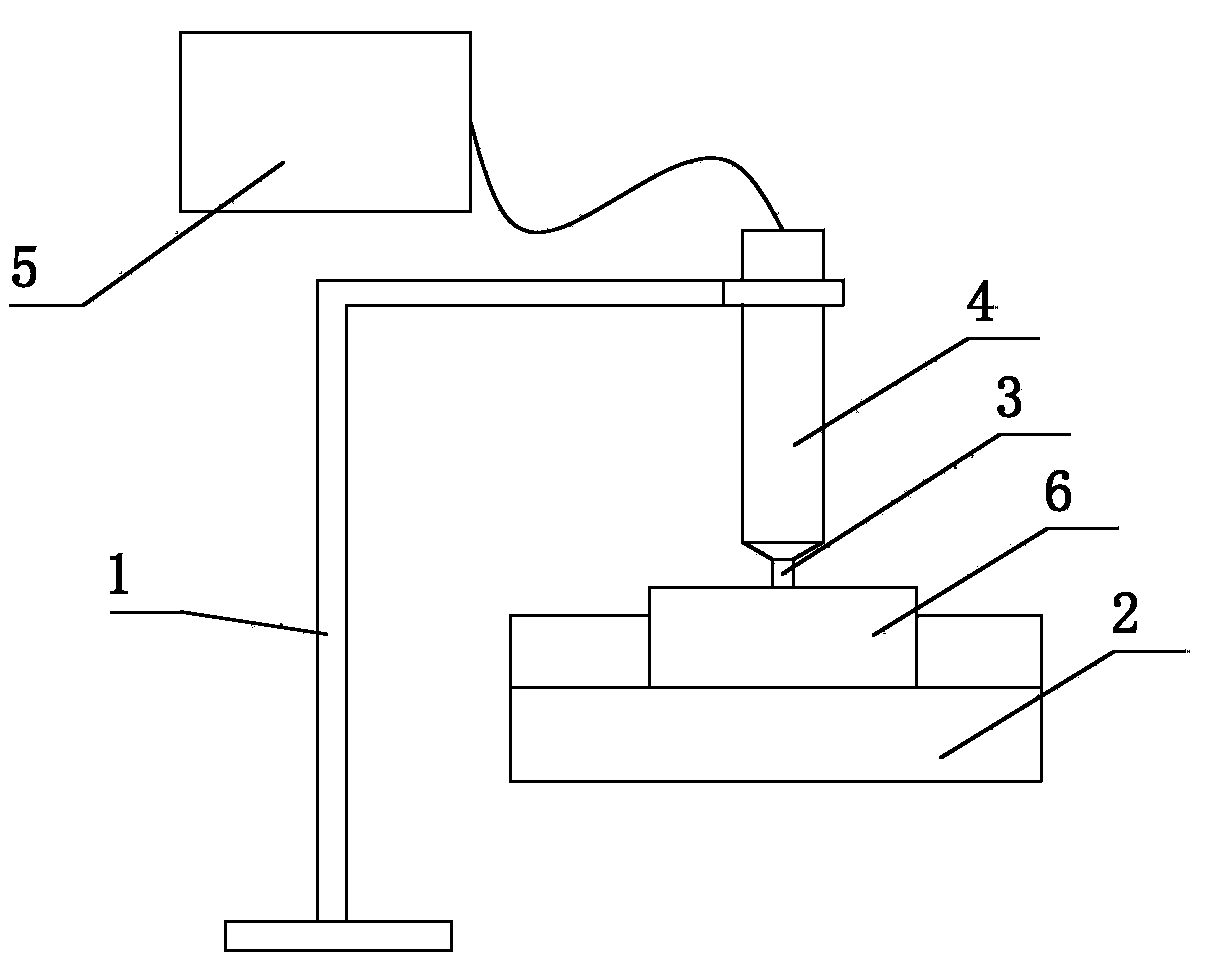

Each base station in a network has an antenna (1) which is connected in the conventional way to a transceiver (2) for handling normal call traffic on one or more radio channels. In addition there is another transmitter (3) which transmits a test signal on each of several test channels, one for each radio channel available for use by the main transceiver (2). The transceiver also has a receiver (4) for detecting the test channels. The system is controlled by a timer (5) which ensures that the transmitter (3) and receiver (4) do not operate at the same time. The receive times may be random, or may be co-ordinated between individual base stations. When the receiver is in operation, it will detect transmissions of the test signals from other base stations. The signal strength is measured (measurement system (6)) and the result is used by a control system (7) to determine a preference value for each channel: the stronger the signal detected, the lower the preference value. The preference value is used to control an amplifier system (8) which controls the signal strength of each channel transmitted by the transmitter (3). It is also used to control the traffic transceiver (2), by selecting which traffic channels are to be used in accordance with the preference values.

Owner:BRITISH TELECOMM PLC

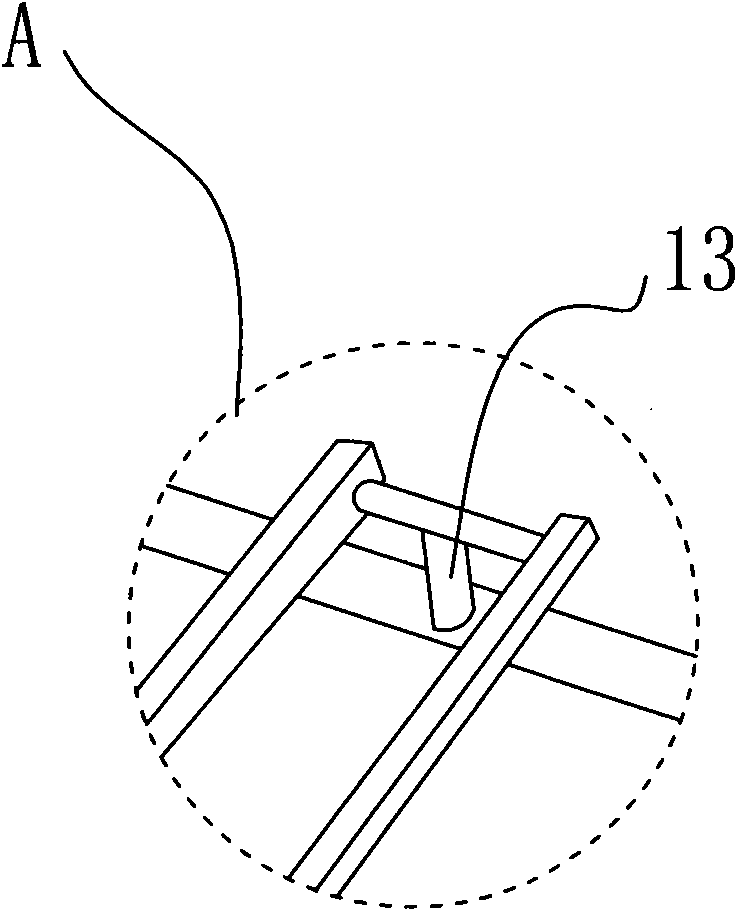

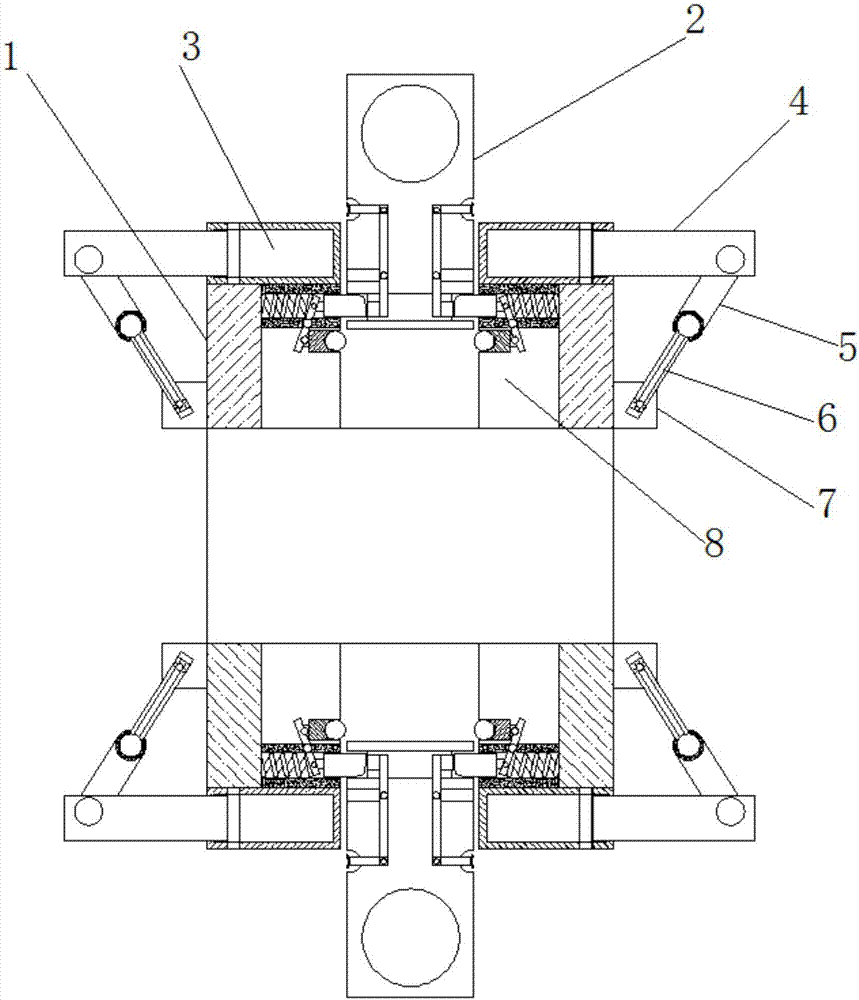

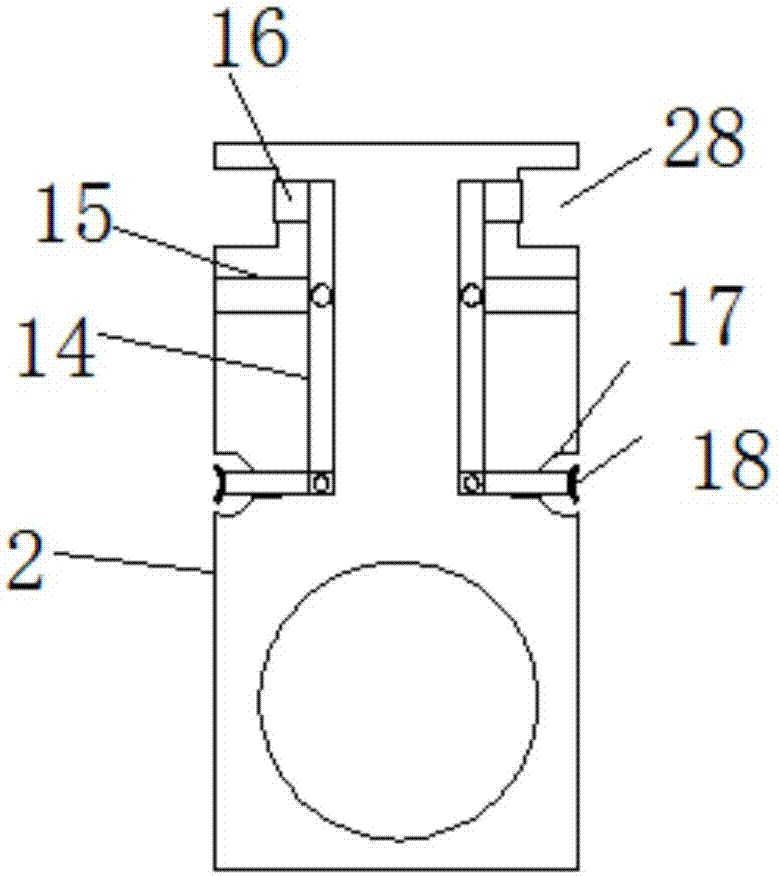

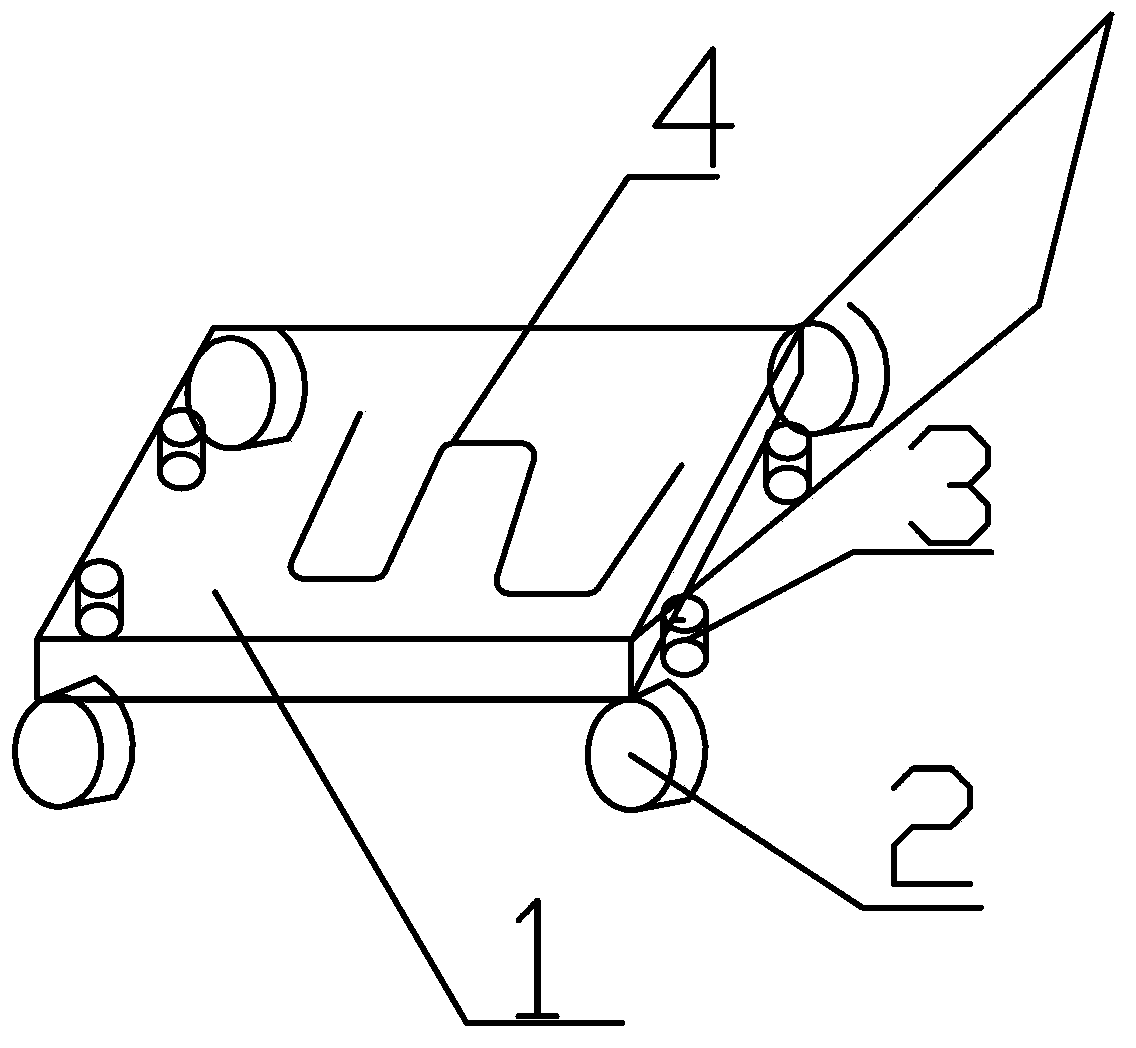

Optimized deep groove ball bearing

ActiveCN107448484APerformance is not affectedEasy to installBearing assemblyBall bearingStructural engineering

The invention belongs to the technical field of bearings, in particular to an optimized deep groove ball bearing. The disadvantages that the bearing is uneasy to install in use, and can not be installed by non-technical personnel, and an existing bearing is single in installation method and angle in the prior art are overcome; thus, the invention provides the optimized deep groove ball bearing. According to the following solution, the optimized deep groove ball bearing comprises a bearing head and a bearing inner ring; the bearing inner ring is of an circular structure, and the outer side of the bearing inner ring is provided with the bearing head along the shape of the outer side; and the sides, approaching to each other, of the bearing head and the bearing inner ring are provided with rolling bodies, and both sides of the bearing head are provided with fixing devices. The optimized deep groove ball bearing provided by the invention is novel in structure, and the fixing devices are arranged at both sides, which can effectively help users select fixed directions according to different conditions; the use convenience of the bearing and the using effect of the optimized deep groove ball bearing are improved, so that multiple directions can be selected during installation of the bearing, and the bearing can be installed by the non-technical personnel.

Owner:NINGBO KAILI HI TECH BEARING CO LTD

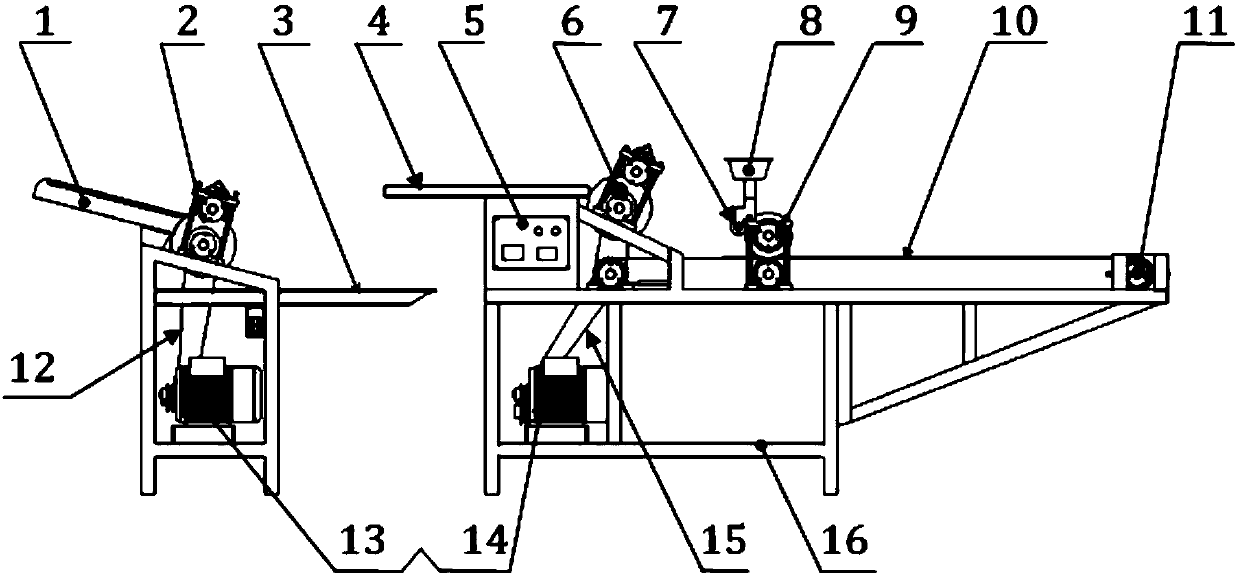

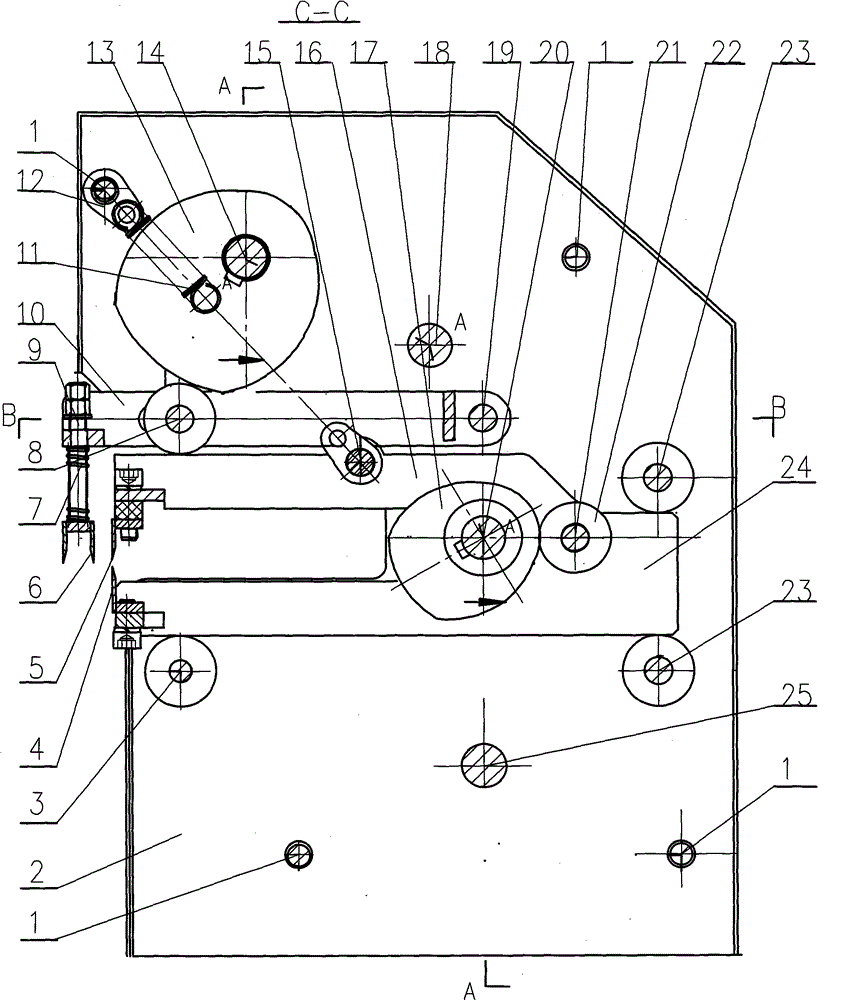

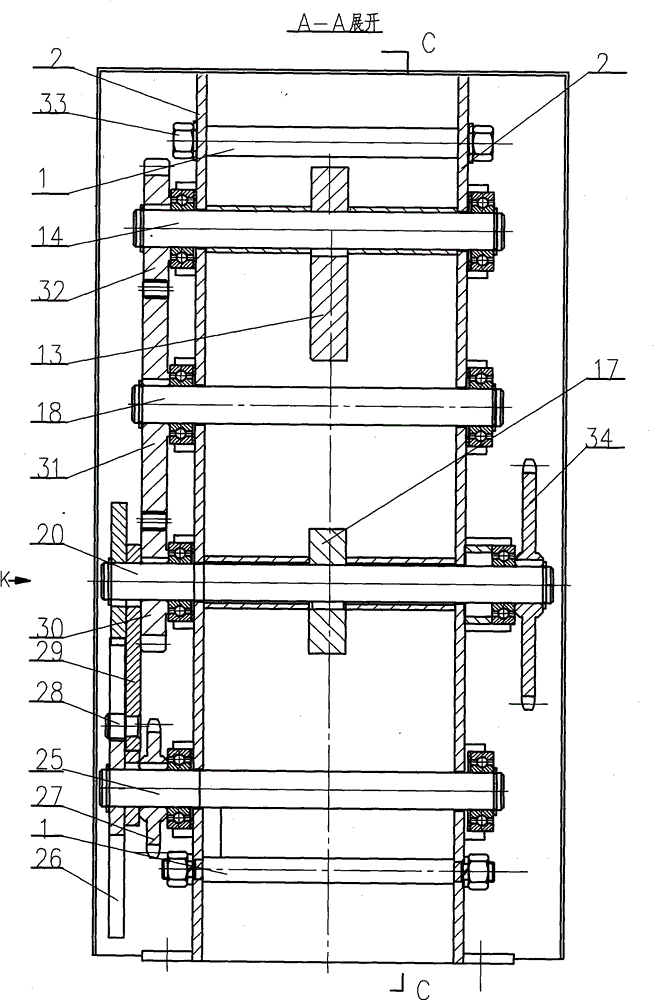

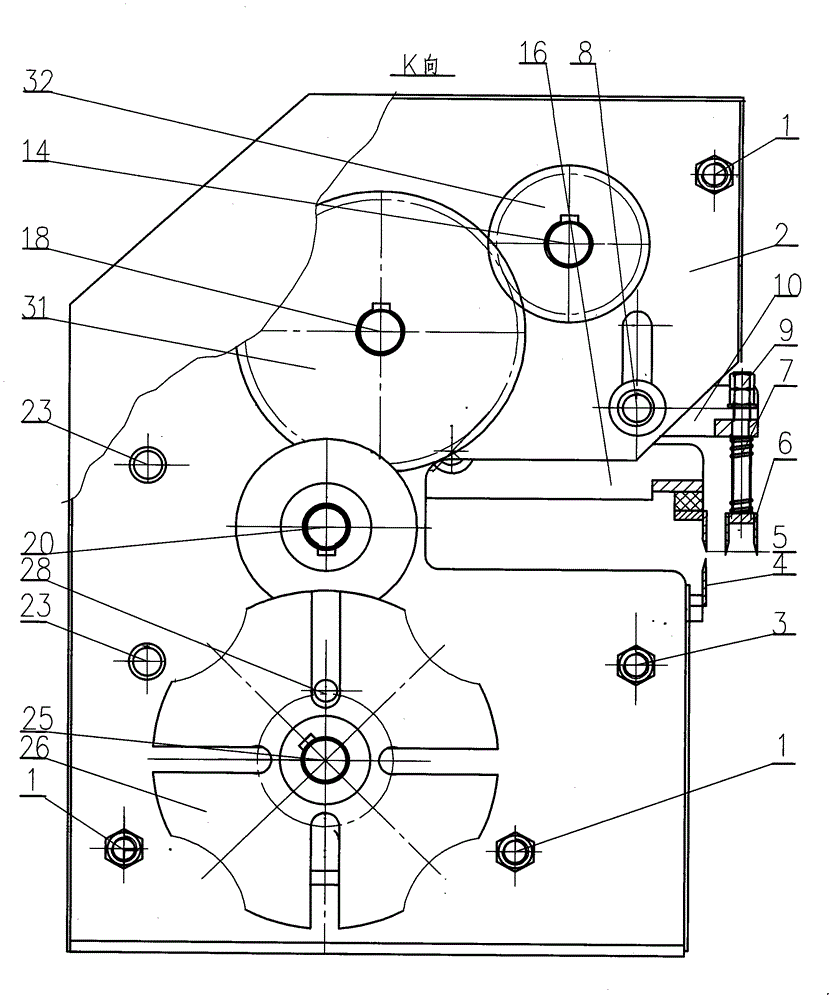

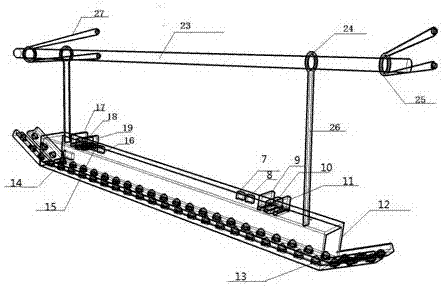

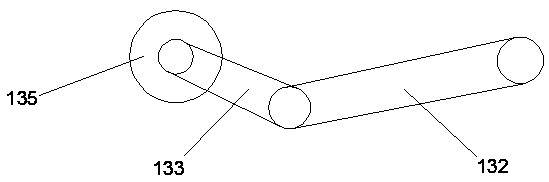

Wrapper forming machine imitating handmade wrapper rolling manner

InactiveCN107637618AFlat surfaceGreat tasteDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationEngineeringMaterial transport

The invention relates to a wrapper forming machine imitating a handmade wrapper rolling manner. The wrapper forming machine comprises a kneading and binding device and a forming device which are connected through a conveyor belt, wherein the forming device comprises a machine frame; a speed reducer is arranged under the machine frame; a finish rolling roller, a forming knife roller and a tension roller are sequentially arranged on the machine frame at a spaced manner; the finish rolling roller comprises a driven roller and a driving roller which are arranged up and down and connected through achain; the driving roller of the finish rolling roller is in power connection with a speed reducing motor through a second chain; a conveyor belt is arranged on the driving roller of the finish rolling roller; the forming knife roller comprises an upper roller and a lower roller which are arranged up and down and connected through a chain; the conveyor belt penetrates through a space between theupper roller and the lower roller of the forming knife roller, and the other end of the conveyor belt is wound on the tension roller; and a material transporting rolling wheel carrier is arranged at the front end of the finish rolling roller. According to the h wrapper forming machine disclosed by the invention, a kneading and binding roller and the finish rolling roller are arranged for repeatedly pressing dough, so that wrappers achieve a required thickness; and compared with a handmade wrapper rolling manner, the wrapper forming machine saves the hard work of manual rolling, and is time-saving and labor-saving.

Owner:BAOJI JINYU FOOD MACHINERY MFG CO LTD

Shrimp head remover

The present invention relates to a food processing machine, and provides a shrimp head remover which is mechanical processing equipment for removing heads of fresh shrimps. The shrimp head remover mainly comprises a gear motor, a lower frame, an upper frame, a shrimp head remover main unit, a rotary workbench, a hopper, a material discharging baffle and the like. Four sawteeth-shaped dental blades are used for imitating two hands of a person to remove shrimp heads. The two upper dental blades can be opened and closed in the vertical direction. The rotary workbench is used for intermittently conveying shrimps to a position between the two opened dental blades. After the two upper dental blades are closed, one pair of dental blades clamps the shrimp head, and the other pair of dental blades clamps the shrimp body. The dental blades clamping the shrimp body do not move, and the dental blades clamping the shrimp head move horizontally, so that the shrimp head and shrimp body can be separated.

Owner:王智博

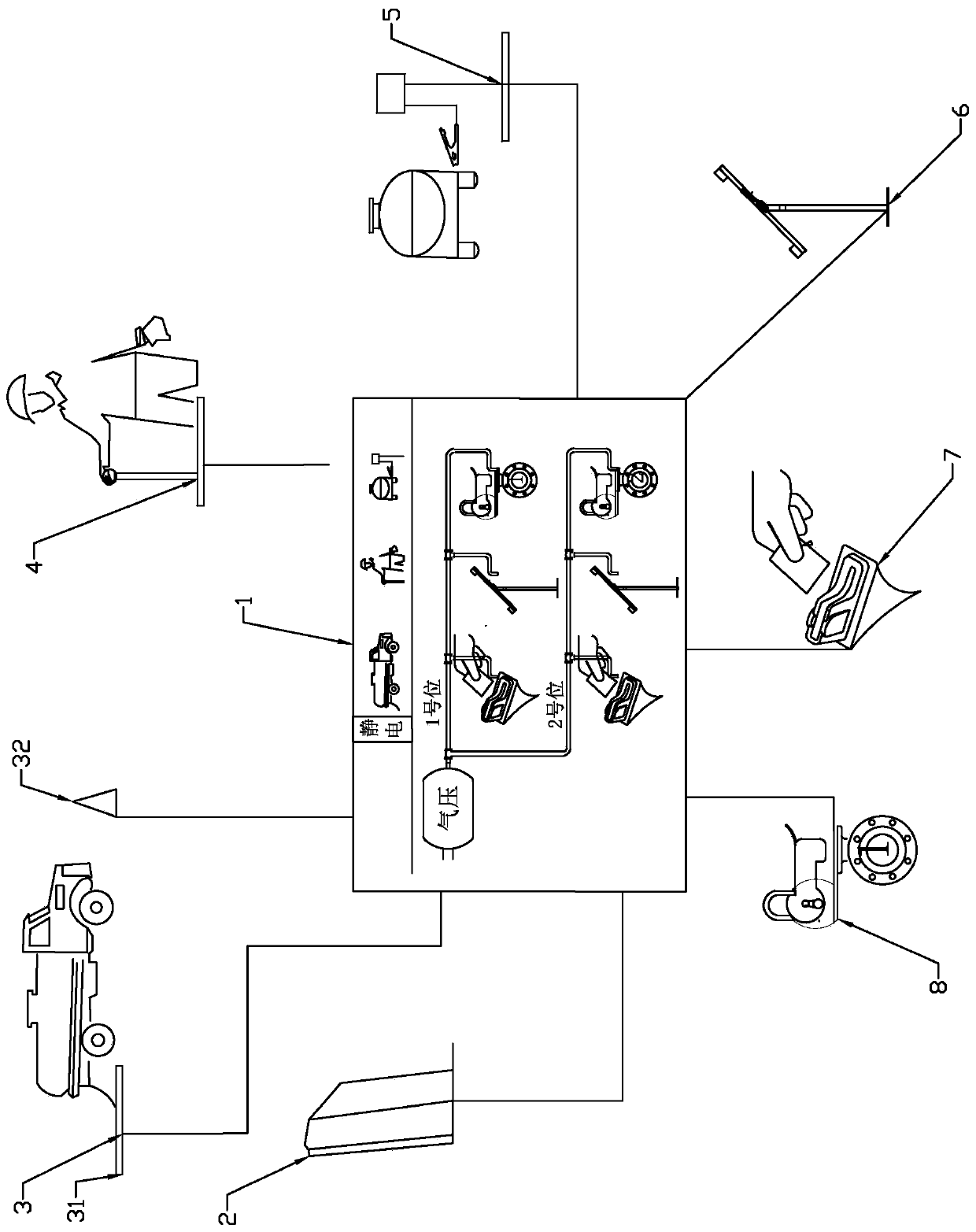

Oil depot and oil refinery oil loading and unloading management system

ActiveCN111252723AReduce hard workOvercoming various disadvantages of manual managementLiquid transferring devicesInformation CardProcess engineering

The invention discloses an oil depot and oil refinery oil loading and unloading management system. The system comprises a service host, an inlet terminal, a monitoring host, oil conveying pipe framesand oil conveying valves, wherein the service host is used for making a loading and unloading schedule and sending down the loading and unloading schedule to the monitoring host or the inlet terminal,and the loading and unloading schedule comprises oil loading and unloading vehicle numbers of each filling opening within every time period on the same day, to-be-authorized corresponding card ID numbers, the starting time and the end time; the inlet terminal is used for making and sending down electronic information cards according to the loading and unloading schedule, and each electronic information card comprises a vehicle number, an oil product, the quantity, the loading and unloading state, the running path and the arrival position; the monitoring host is arranged at the filling openings and used for monitoring the states of all procedures on the site according to the loading and unloading schedule; the oil conveying pipe frames are used for allowing oil conveying pipes to be placedand detecting the placement state of the oil conveying pipes; and the oil conveying valves are used for achieving valve opening and closing according to orders. All the procedures adopt the host to be monitored and checked in real time, potential safety hazards are completely eradicated, and mis-loading and mis-unloading are avoided.

Owner:山东奥克智能系统工程有限公司

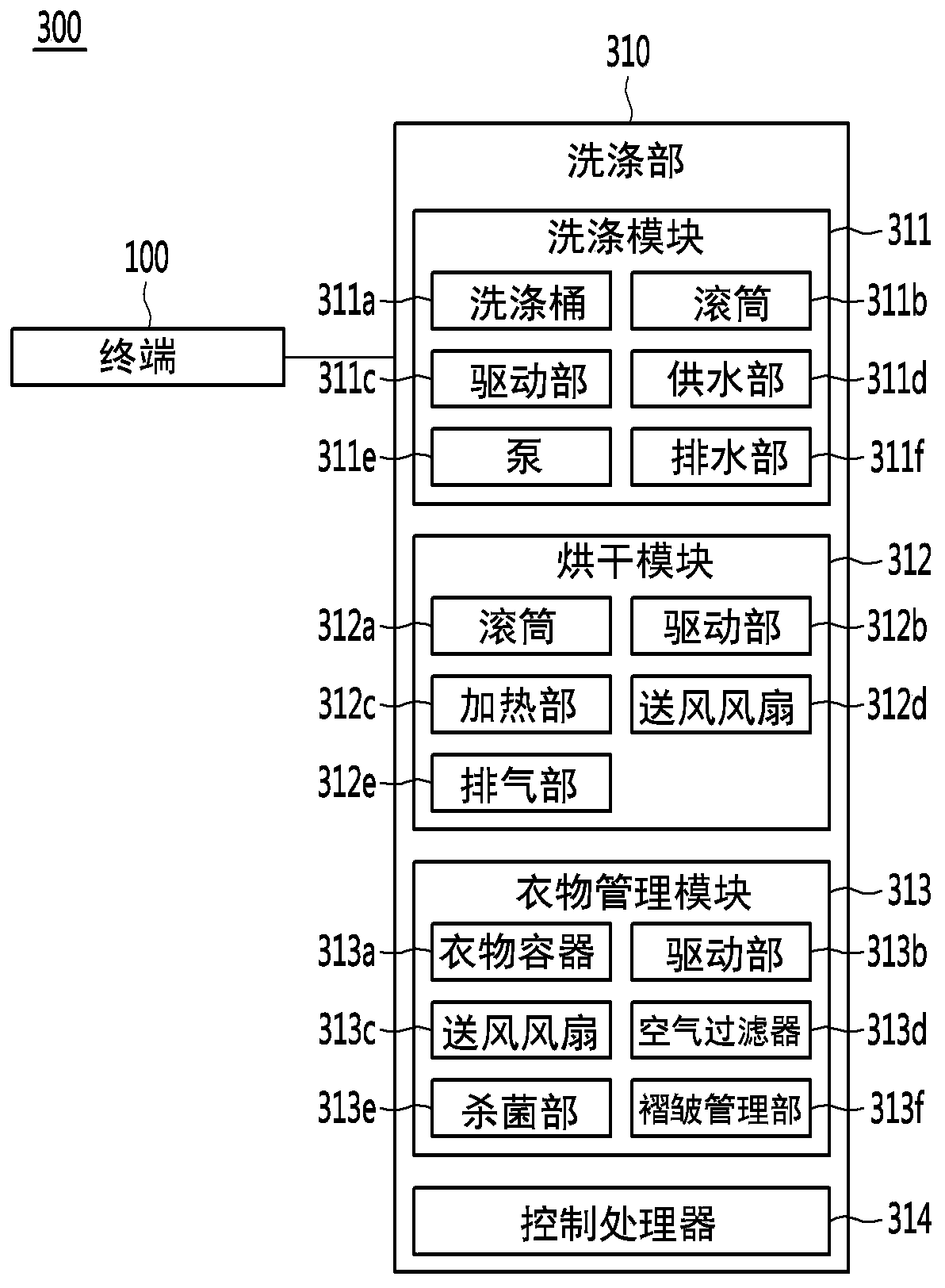

Laundry treatment device and method of determining laundry course thereof

ActiveCN111379119ADamage minimizationImprove washing effectOther washing machinesControl devices for washing apparatusProcess engineeringLaundry

A laundry treatment device according to one embodiment includes a washing module configured to perform operation related to washing, a camera configured to capture an image of a tag attached to a laundry, and a processor configured to acquire laundry information of a plurality of laundries, to convert the acquired laundry information into encoding data, and to acquire values of laundry control variables corresponding to the converted encoding data based on a laundry course learning model learned using a plurality of reference data through a deep learning algorithm.

Owner:LG ELECTRONICS INC

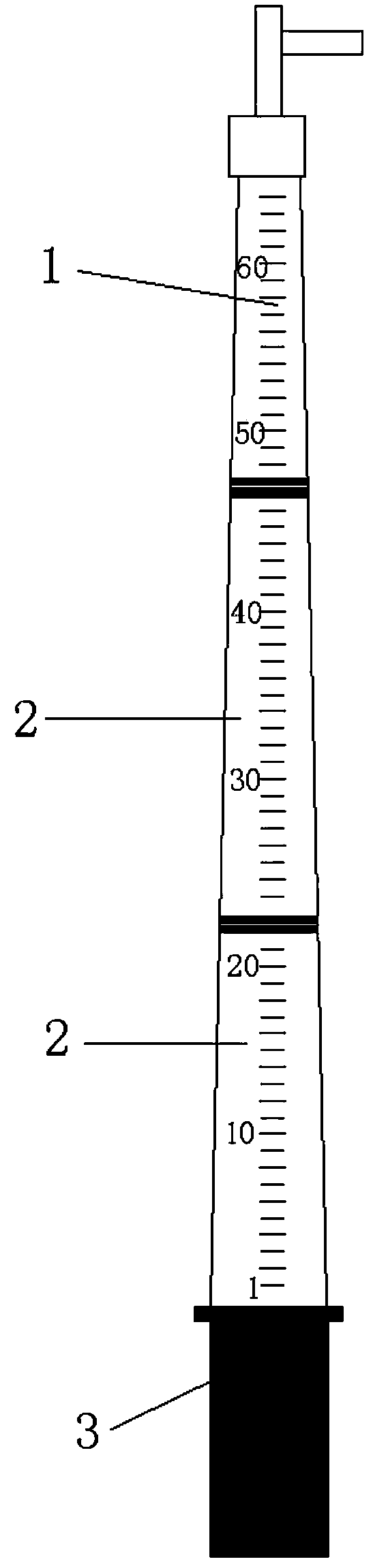

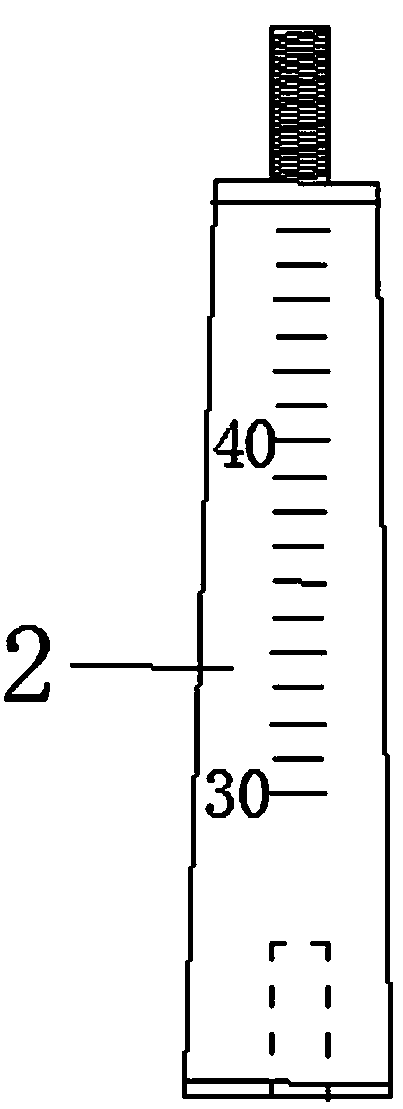

Multifunctional interface type insulation rod

InactiveCN104201608ASolve the inconvenience of communicationRealize the measurement functionCurrent/voltage measurementFluid speed measurementElectric power systemClassical mechanics

The invention belongs to the electric system auxiliary tool field, and particularly relates to a multifunctional interface type insulation rod which can be used as a scale ruler, a high altitude electricity test rod, a long pole sickle, an wind meter and a mobile phone signal amplifier. The multifunctional interface type insulation rod comprises a drag hook type work head, an insulating bar and a grab handle, and thread holes and screws matched with the thread holes are arranged on the lower end face of the work head, the upper end face and the lower end face of the insulating bar and the upper end face of the grab handle. The multifunctional interface type insulation rod is characterized in that scale marks are engraved on the outer faces of the insulating bar and the grab handle, and the work head further comprises an electricity test rod work head, a sickle work head, a wind meter work head and a signal amplifier work head. According to the multifunctional interface type insulation rod, the functions of measuring height, testing voltage, cutting braches, measuring wind speed and amplifying mobile phone signals are added based on functions of a common insulation rod, and functional diversification of the multifunctional interface type insulation rod is achieved.

Owner:JIYUAN POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

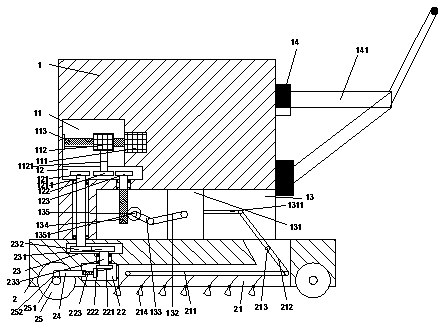

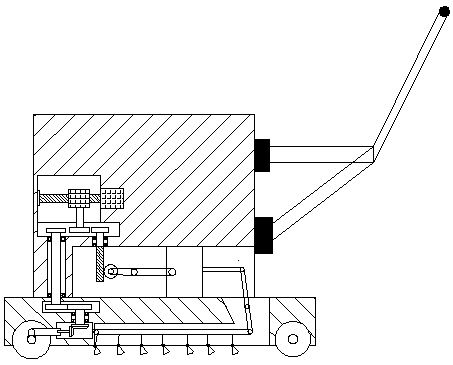

Novel and efficient agricultural grain tedding equipment

InactiveCN108375303AAchieve shakingReduce hard workSeed preservation by dryingDrying solid materialsAgricultural engineering

The invention discloses novel and efficient agricultural grain tedding equipment comprising a vehicle pushing frame and a machine body fixedly arranged on the upper portion of the vehicle pushing frame. The vehicle pushing frame is internally provided with a first space and a second space, a steering device is arranged in the first space, and swinging claws are arranged in the second space; the middles of the swinging claws are in rotating fit connection with the inner surface of the bottom of the vehicle pushing frame, and the top ends of the swinging claws are in rotating fit connection witha swinging connection rod mechanism through rotating rings; and the swinging claws are horizontally and evenly distributed on a horizontal connecting rod, a fixing connection rod is in rotating fit connection with the inner wall of the vehicle pushing frame, and the tail of the swinging connection rod mechanism is in fit connection with a crank sliding block mechanism. The novel and efficient agricultural grain tedding equipment is simple in structure and convenient to operate, and is suitable for most of grain tedding in the agricultural life; and the situation that farmers ted grains in thehot weather is not needed, the hardship of the farmers is reduced, the farmers are librated from the labor of manually tedding the grains, and great convenience is provided for the farmers.

Owner:王晨亮

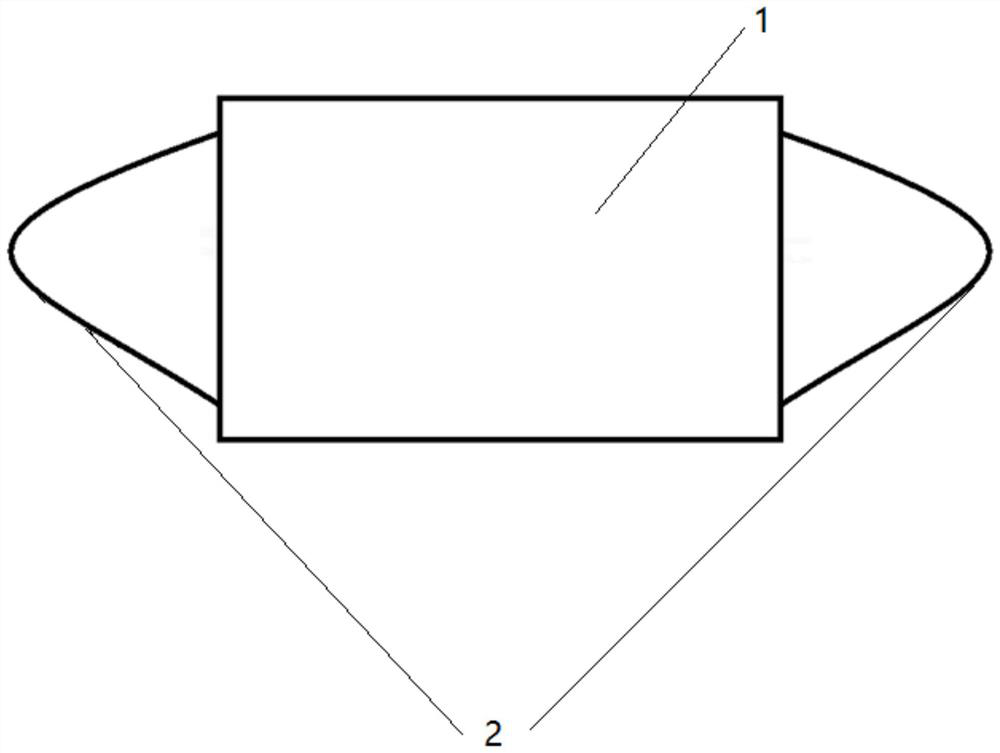

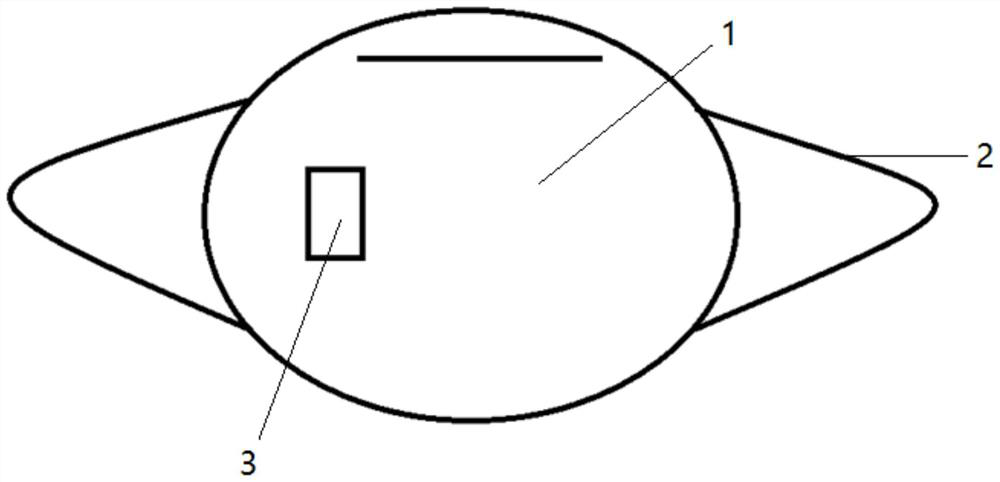

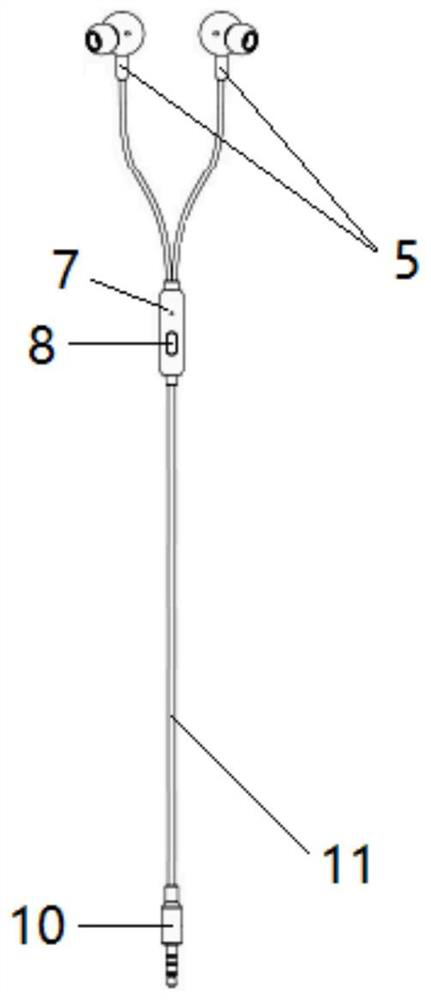

Mask with earphones

PendingCN114403525AEasy to clear voicePromote disseminationMicrophonesLoudspeakersEngineeringHeadphones

The invention discloses a mask with earphones, and belongs to the technical field of wearable equipment. The mask is provided with a position 0 for installing the earphones. An earphone can be installed at the position; the hangers are used by human ears, the microphone or the wireless transceiving device and the like are mounted on the mask body, and the loudspeaker 5 and the like are mounted outside the mask body or are used by human ears in a wireless manner; the mask can be opened, and the microphone 7 can be detached from the mask. A gasket is further included. According to the invention, people can wear the mask individually due to haze, epidemic situation, or sanitation, without speaking or working, or even in order to be good-looking in life. The distance between the microphone and the mouth can be shortened through the hanging lugs, the mask can prevent voice from diffusing to the surrounding environment during communication and affecting others, and the sound energy of a phone-making person can be focused on the microphone; a release hand; mobile phone conversation and the like can be clearly carried out without taking off the mask; the functions of the system support each other, and a new technical effect is achieved. The product is a new category / new product; the market prospect is wide.

Owner:北京驰座汽车科技有限公司

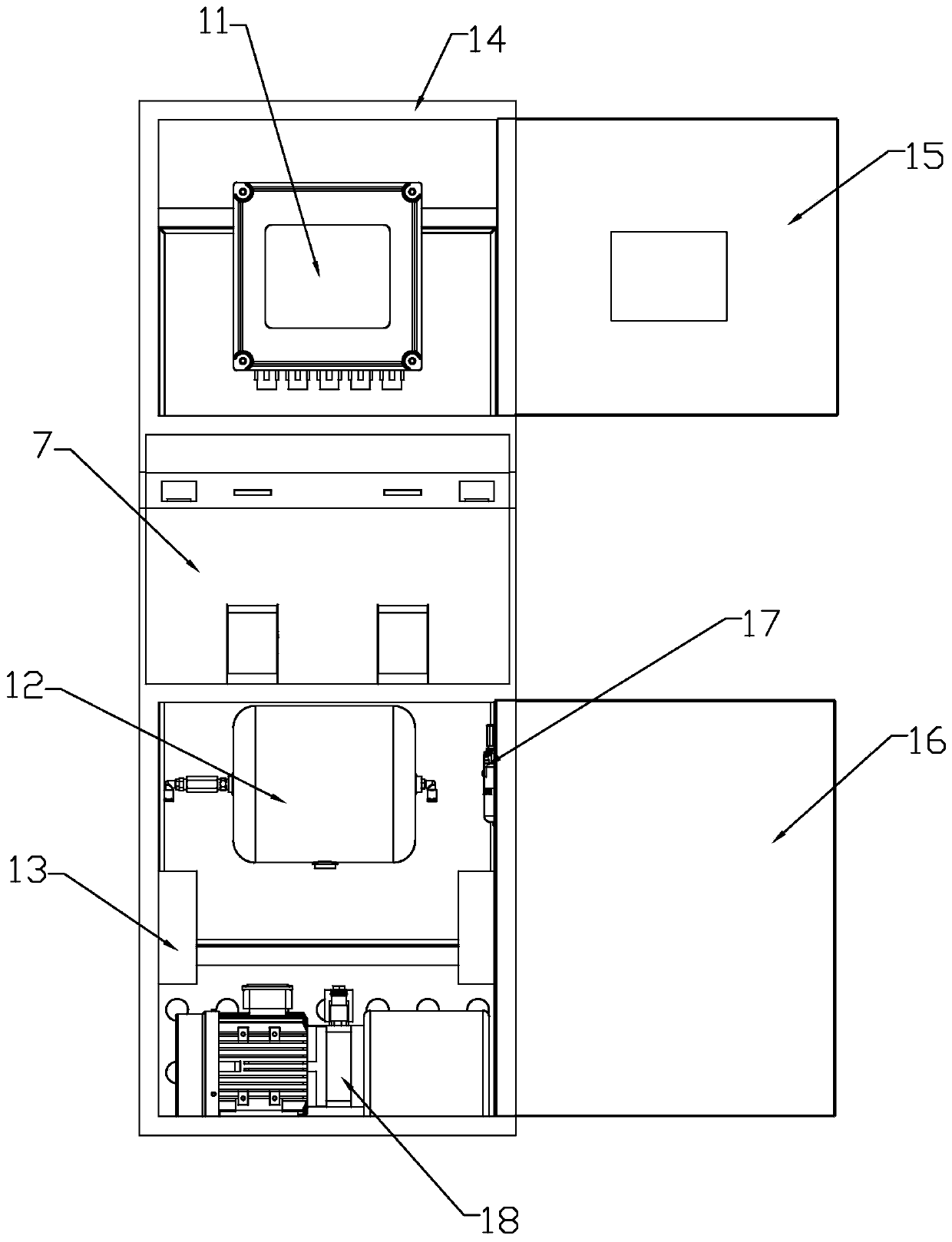

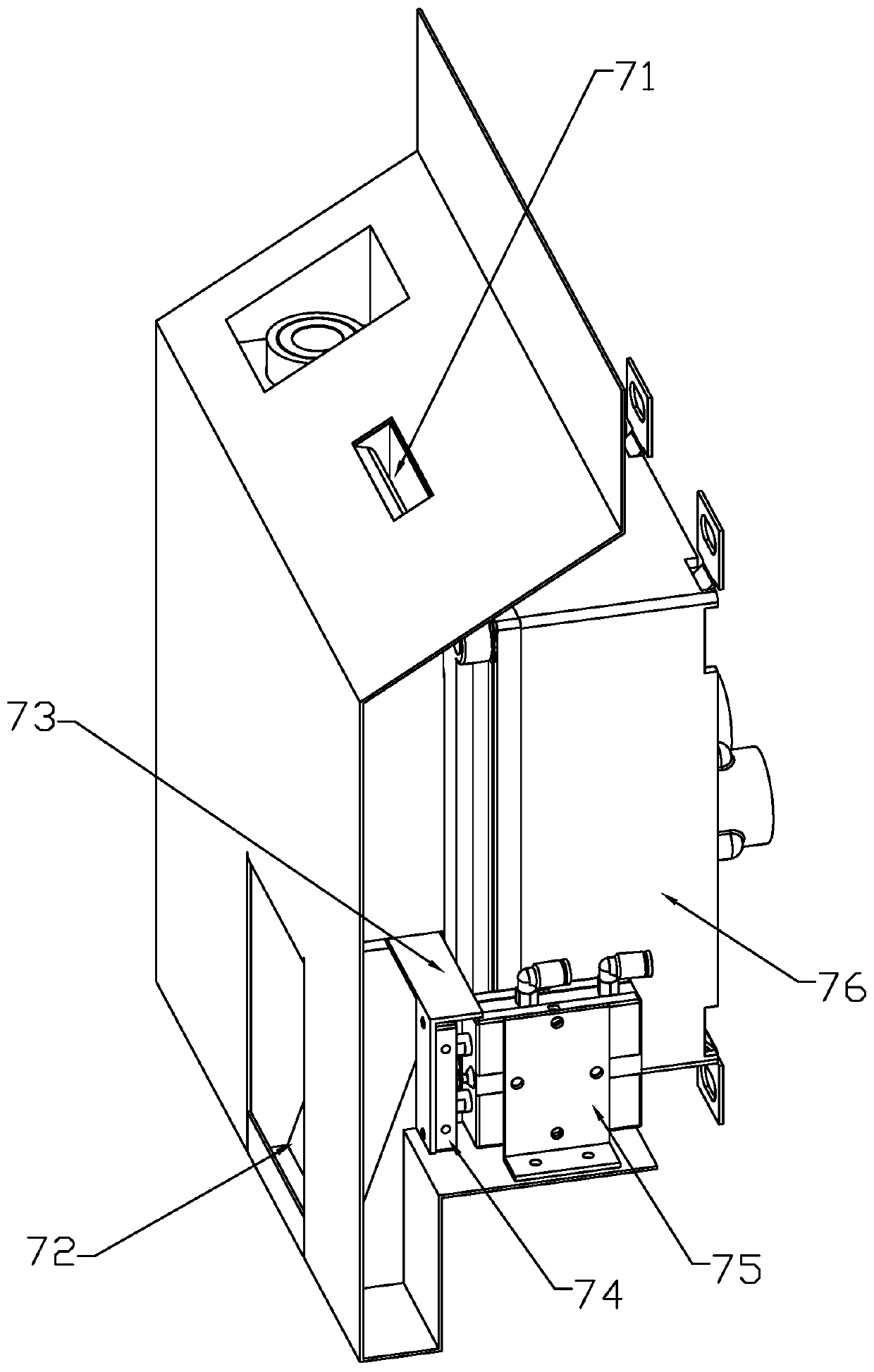

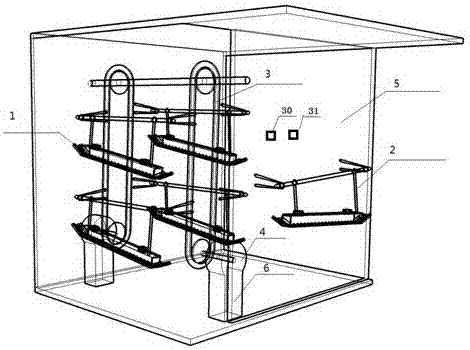

Borrowing and returning terminal for nonlocal seat borrowing and returning system

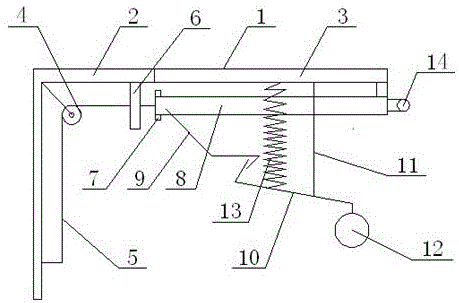

InactiveCN107346588ASimple structureEasy to useApparatus for meter-controlled dispensingElectric machineryEngineering

The invention discloses a borrowing and returning terminal for a nonlocal seat borrowing and returning system. The borrowing and returning terminal comprises a bearing cabinet body and a borrowing and returning unit, wherein the borrowing and returning unit is driven by circulating equipment driven by a motor; reciprocating circulation is carried out on the circulating equipment; the borrowing and returning unit comprises a lease terminal, a return terminal and a sliding rail groove; a pulley is arranged at the bottom end of the sliding rail groove; a slide block is arranged on the pulley; the slide block is provided with seat identification information; a seat is arranged on the lower surface of the slide block; a return terminal post-switch is arranged on the sliding rail groove; a return terminal pre-switch is arranged on the sliding rail groove; a seat identification device B is arranged on the sliding rail groove; a lease terminal post-switch is arranged on the sliding rail groove of the lease terminal; a lease terminal pre-switch is arranged on the sliding rail groove; and a seat identification device A is arranged on the sliding rail groove. By using the borrowing and returning terminal for the nonlocal seat borrowing and returning system, the hard work of queuing or long-time standing travel of people is relieved.

Owner:韩璐

Movable kiln

InactiveCN103727787AIncrease profitIncrease flexibilityFurnace componentsFurnace typesEngineeringMechanical engineering

The invention discloses a movable kiln. The movable kiln is composed of a movable platform and a kiln body formed by stacking. Four wheels are installed below the movable platform, so that the platform moves flexibly and conveniently, the amount of labor is reduced, and the work efficiency is improved easily. Small pillars are used for fixing the platform and prevent the platform from sliding. The kiln body is provided with independent heating wires and independent electrifying devices, adjustment can be carried out according to the size of a fired product, the production requirement is well met, and the problems in firing in the past are solved well. The movable kiln is simple in structure, convenient to operate and beneficial for the production requirement.

Owner:陈明忠

High-efficient agricultural grain tedder

InactiveCN108112692AAchieve shakingReduce hard workSeed preservation by dryingAgricultural engineeringSlider crank

The invention discloses a high-efficient agricultural grain tedder, which comprises a trolley pushing frame and a machine body fixedly arranged above the trolley pushing frame. A first space and a second space are arranged in the trolley pushing frame; a steering device is arranged in the first space; rocking jaws are arranged in the second space; the middle parts of the rocking jaws and an innersurface of the bottom part of the trolley pushing frame are connected in a rotation fit way; the top ends of the rocking jaws and a swinging connecting rod mechanism are connected in a rotation fit way through a rotating ring; the rocking jaws are horizontally and uniformly distributed on a horizontal connecting rod; a fixed connecting rod and an inner wall of the trolley pushing frame are connected in a rotation fit way; the tail part of the swinging connecting rod mechanism is connected with a slider crank mechanism in a matching way. The high-efficient agricultural grain tedder provided bythe invention is simple in structure, convenient to operate, and applicable to tedding most grains in an agricultural life, farmers have no need to ted grains under the sun, hard work of the farmers is reduced, the farmers are liberated from tedding the grains by hand, and great convenience is provided for the farmers.

Owner:王晨亮

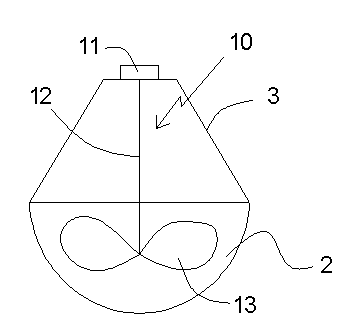

Domestic oven for roasting chestnuts with sugar

The invention provides a domestic oven for roasting chestnuts with sugar. The oven comprises an oven body and a stirring component, wherein the stirring component is arranged above the oven body; the stirring component comprises a stirrer and supporting frame; the supporting frame is of a conical structure; the stirrer is arranged on the top of the supporting frame; the bottom of the supporting frame is fixedly arranged on the oven body; a stirring rod of the stirrer stretches out of the supporting frame; a stirring blade arranged on the top end of the stirring rod is located inside a concave face of the oven body. According to the domestic oven for roasting the chestnuts with the sugar provided by the invention, the chestnuts can be automatically roasted in a turning way without being roasted in the turning way by manpower; therefore, the labor intensity is decreased for a chestnut roasting person, and the physical harm caused by smoke generated in the course of roasting in the turning way to a turning person is reduced.

Owner:SHANGHAI HANGTOU SCHOOL

Irrigator capable of automatically switching water flow direction

PendingCN106416954ASolve the problem of staring at the post and being exposed to the scorching sunReduce hard workWatering devicesCultivating equipmentsWater flowWater resources

The invention discloses an irrigator capable of automatically switching the water flow direction. The irrigator comprises an irrigator body, wherein the irrigator body is provided with a front main body structure and a rear main body structure; the front main body structure is provided with a pulley, a rope, a rubber buffer block, convex parts on the two sides of a metal rod, and the metal rod; and the rear main body structure is provided with a metal rod upper hook, a spring warping plate, a spring warping plate fixing rod, a buoy, a spring and a metal rod pull ring. The irrigator is simple and reasonable in structure and convenient to use, can automatically change the water flow direction and automatically irrigate, effectively solves the problem that a farmer is in sun exposure to monitor during crop irrigation, reduces the hard work of the farmer, improves the irrigation efficiency, saves water resource to a certain degree, and meets the requirements of economy and environmental protection.

Owner:任叶飞

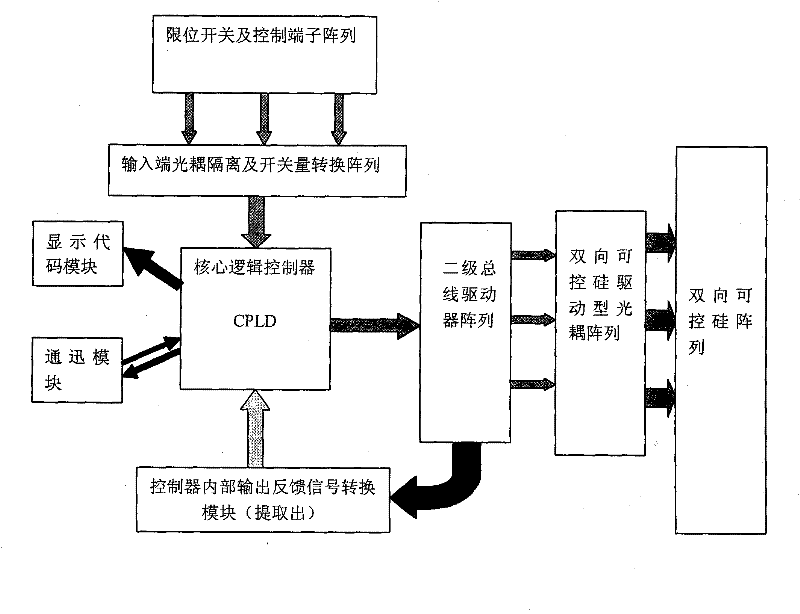

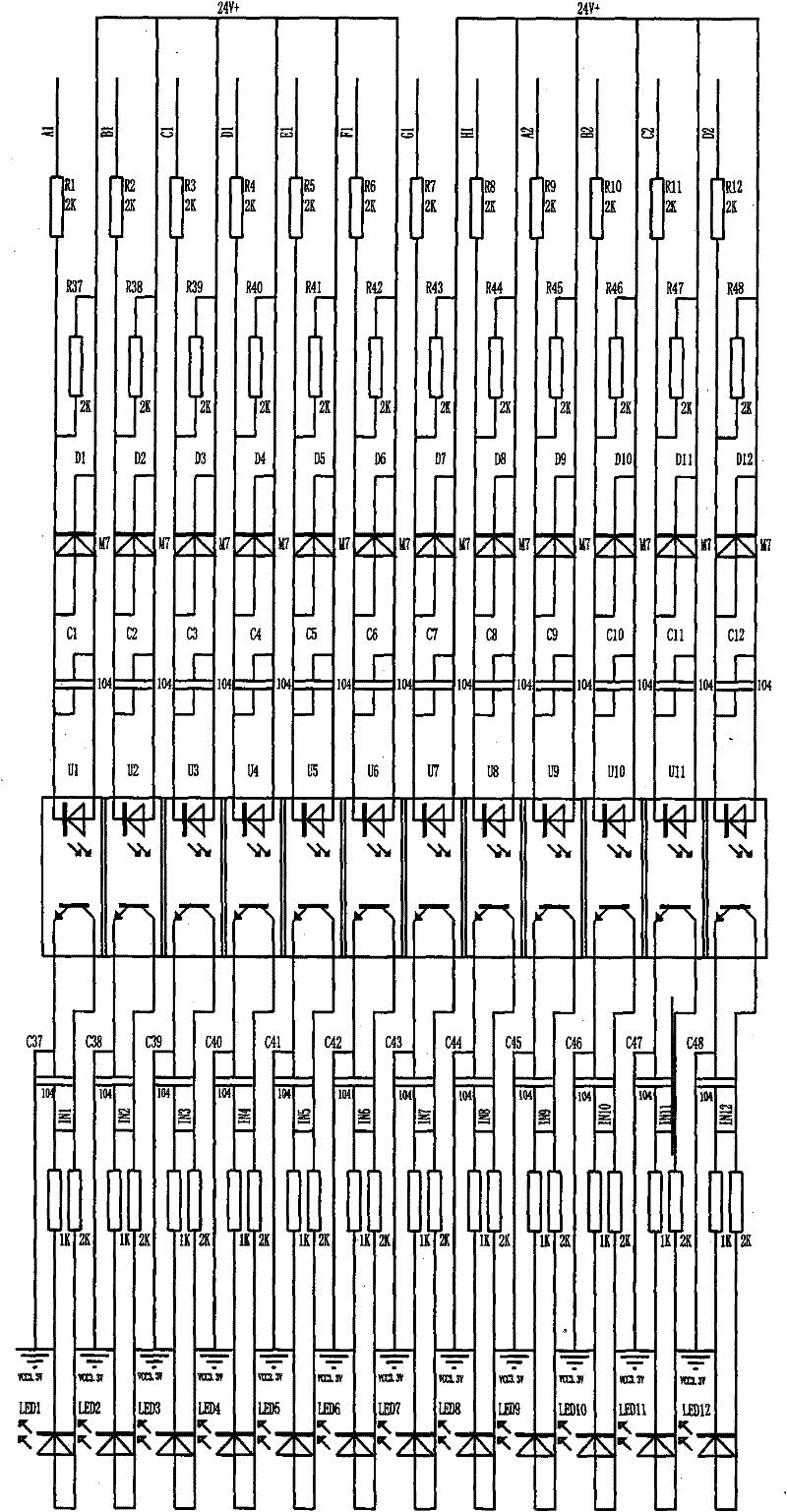

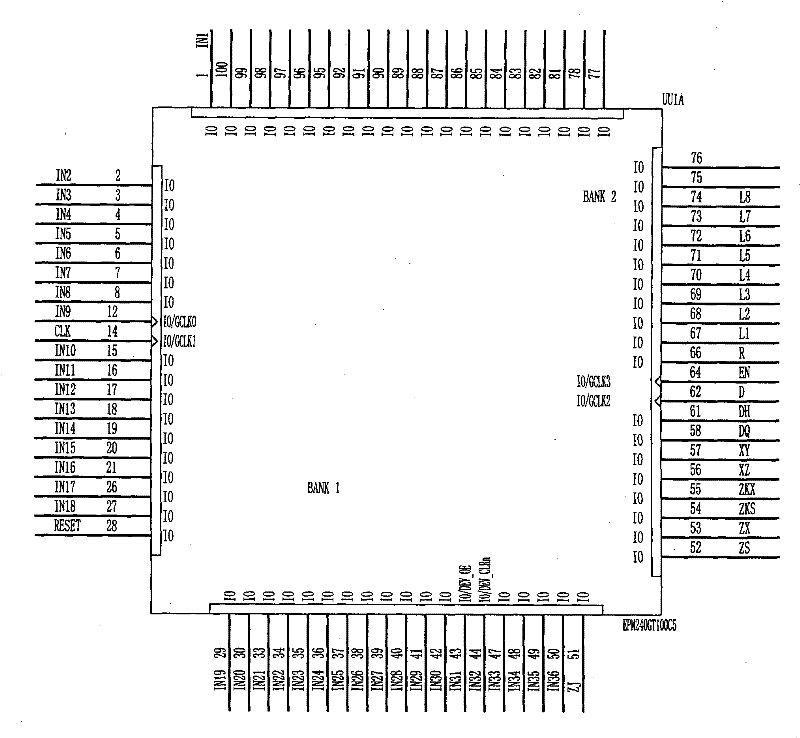

Electric control system for crane

InactiveCN102234066AReduce hard workShorten production timeLoad-engaging elementsDIACElectric control

The invention relates to an electric control system for a crane. The system comprises a limit switch and control terminal array, an input end optical coupling isolation and switch quantity conversion array, a core logic controller, a controller internal output feedback signal conversion module, a secondary bus driving module, a bidirectional controlled silicon driven optical coupling array, a bidirectional controlled silicon array, a communication module and a display code module, wherein the limit switch and control terminal array is connected with the core logic controller through the input end optical coupling isolation and switch quantity conversion array; the core logic controller is connected with the controller internal output feedback signal conversion module and the output intensity electric isolation and secondary bus driving module respectively; the controller internal output feedback signal conversion module is connected with the output intensity electric isolation and secondary bus driving module; and the output intensity electric isolation and secondary bus driving module is connected with a contactor coil control terminal connecting end through a terminal solid state relay driving array.

Owner:HANGZHOU HOISTING MACHINERY

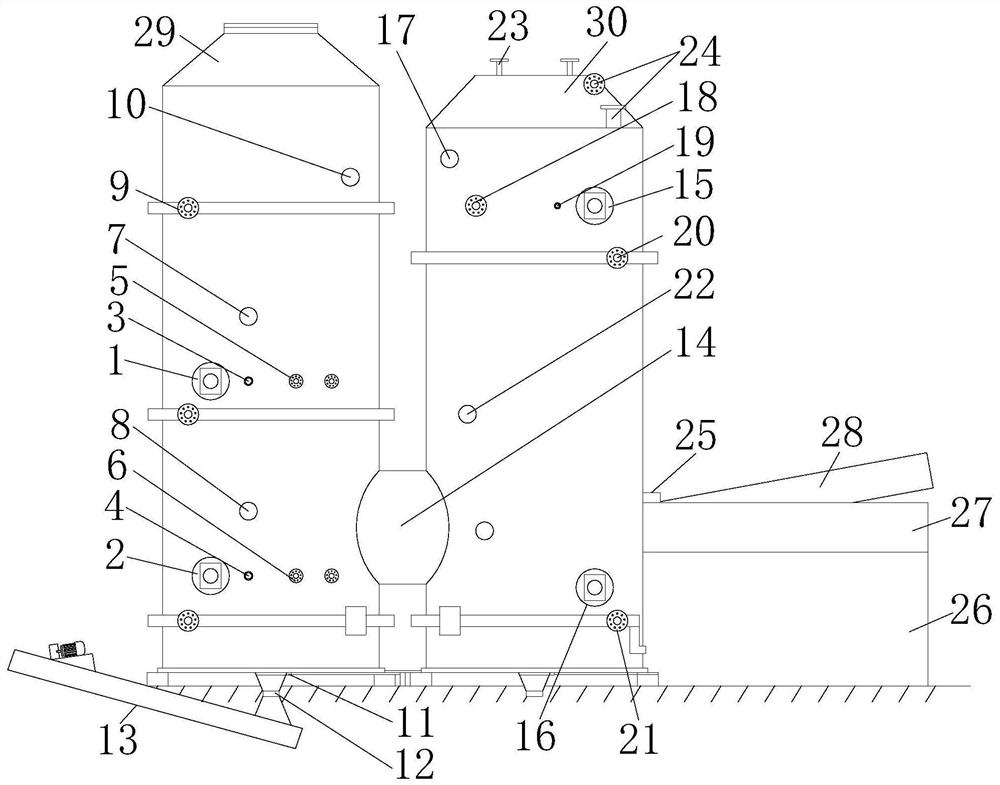

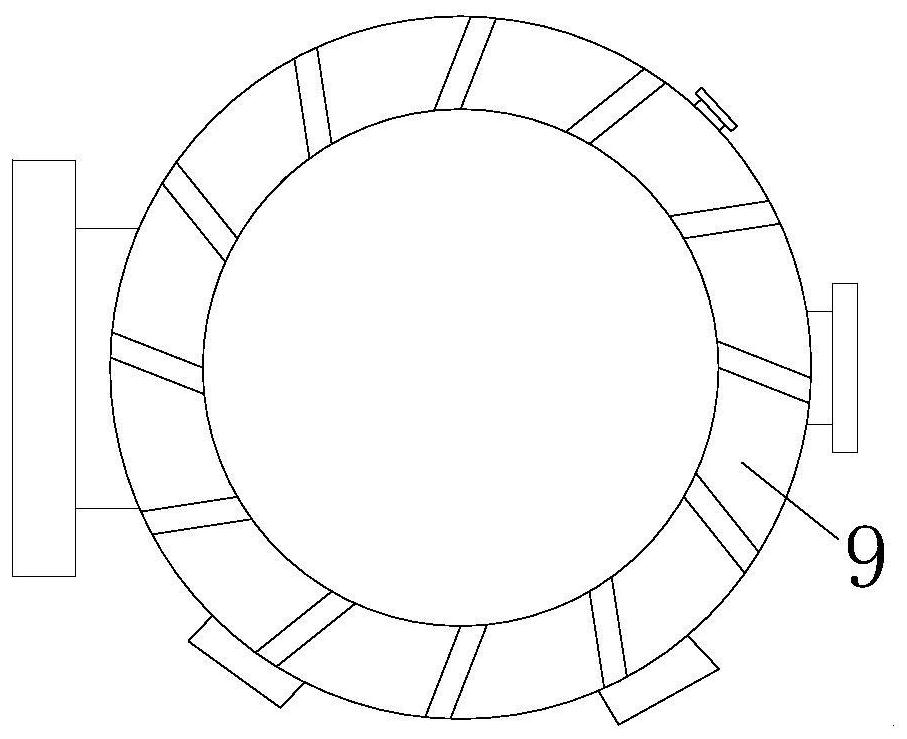

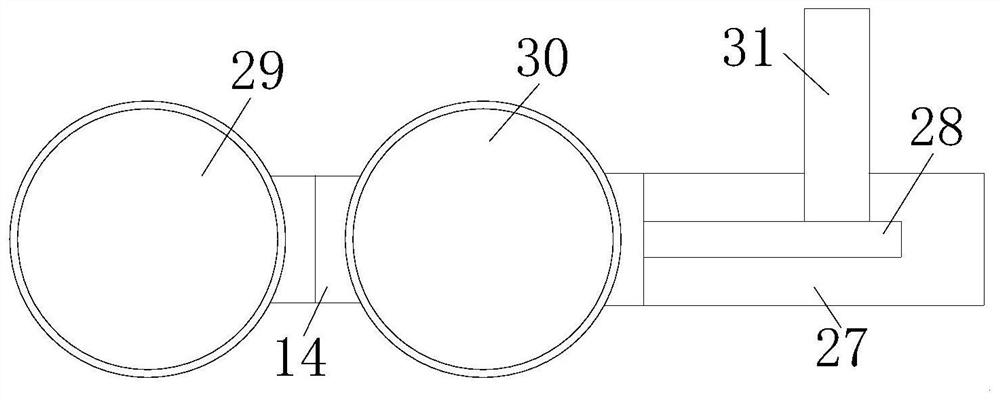

Vertical type incinerator capable of incinerating waste liquids, waste gases and solid waste simultaneously

The invention discloses a vertical type incinerator capable of incinerating waste liquids, waste gases and solid waste simultaneously. The vertical type incinerator comprises a connecting pipe, fire-observing windows, a first combustion mechanism, a second combustion mechanism, a feeding mechanism and discharging mechanisms. The first combustion mechanism comprises a second incinerator body. According to the vertical type incinerator capable of incinerating the waste liquids, waste gases and solid waste simultaneously, the discharging mechanisms are arranged on bottom positions of a first incinerator body and the second incinerator body, ash discharging is conducted by adopting a scraper slag discharging machine at the bottom, the operation is convenient, and trouble and hard work of manual labor are reduced; besides, burning ports are formed in the bottoms of the first incinerator body and the second incinerator body, solid waste can be incinerated while the waste liquids and waste gases are incinerated, and incineration diversity of the incinerator device is increased; through peculiar oxygen-supplementing wind ports, the solid waste is blown away and soars, the contact area of the solid waste and flames is increased, it is guaranteed that the solid waste combusts fully, and it is avoided that gas explosion occurs after certain concentration is reached by accumulated organicgases because of incomplete combustion of solid waste at the bottom; and the incinerator has the advantages of high-efficiency incineration and complete incineration.

Owner:宜兴市华瑞焚烧炉科技发展有限公司

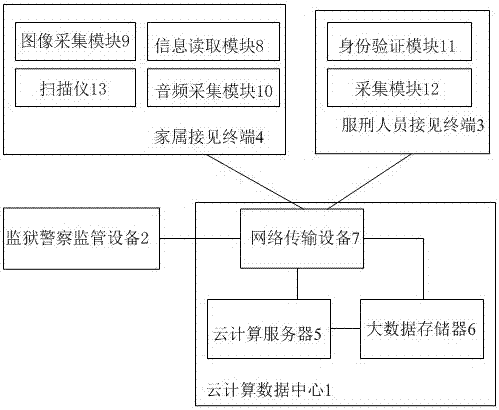

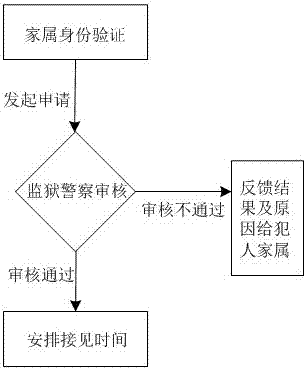

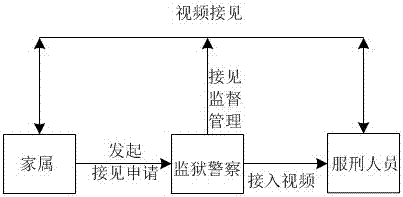

Prison video reception system based on cloud computing

InactiveCN107465894AReduce hard workSave manpower and material resourcesClosed circuit television systemsTwo-way working systemsData centerMaterial resources

The invention relates to a prison prisoner video reception system based on cloud computing. The prison prisoner video reception system is characterized by comprising a cloud computing data center, a prison police supervision device, a prisoner reception terminal and a family member reception terminal, wherein he prisoner reception terminal, the family member reception terminal and the prison police supervision device are connected with the cloud computing data center. Intelligent management is adopted, a prisoner reception process is accomplished by a video call, thereby reducing manpower and material resources, reducing the management cost, meanwhile omitting the hard work of long-distance travel of the family members of prisoners, and meanwhile video reception greatly helps the improvement of the prisoners.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

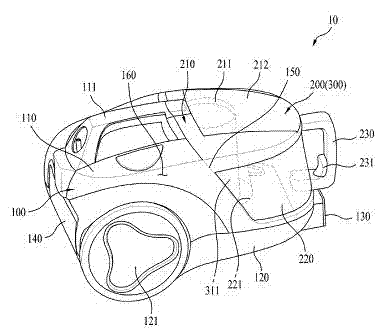

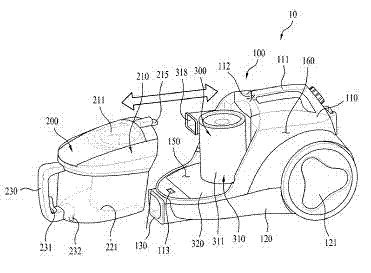

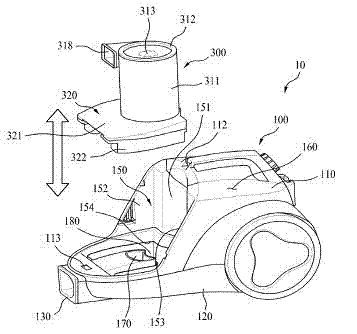

Vacuum cleaner

The invention relates to a vacuum cleaner, in particular to a vacuum cleaner with a dust storing portion having a dust storing function and a dust separating portion having a dust separating function. According to an embodiment of the invention, the vacuum cleaner comprises a main body, the dust separating portion and a dust storing portion, wherein the main body comprises a fan arrangement portion which is provided with a driving fan; the dust separating portion is arranged on one side of the fan arrangement portion, sucks air by using the suction force of the fan, and separates dust in the air by using a cyclone principle; and the dust storing portion stores dust separated by the dust separating portion, and can be separated from the external of the dust separating portion.

Owner:NANJING LG PANDA APPLIANCES

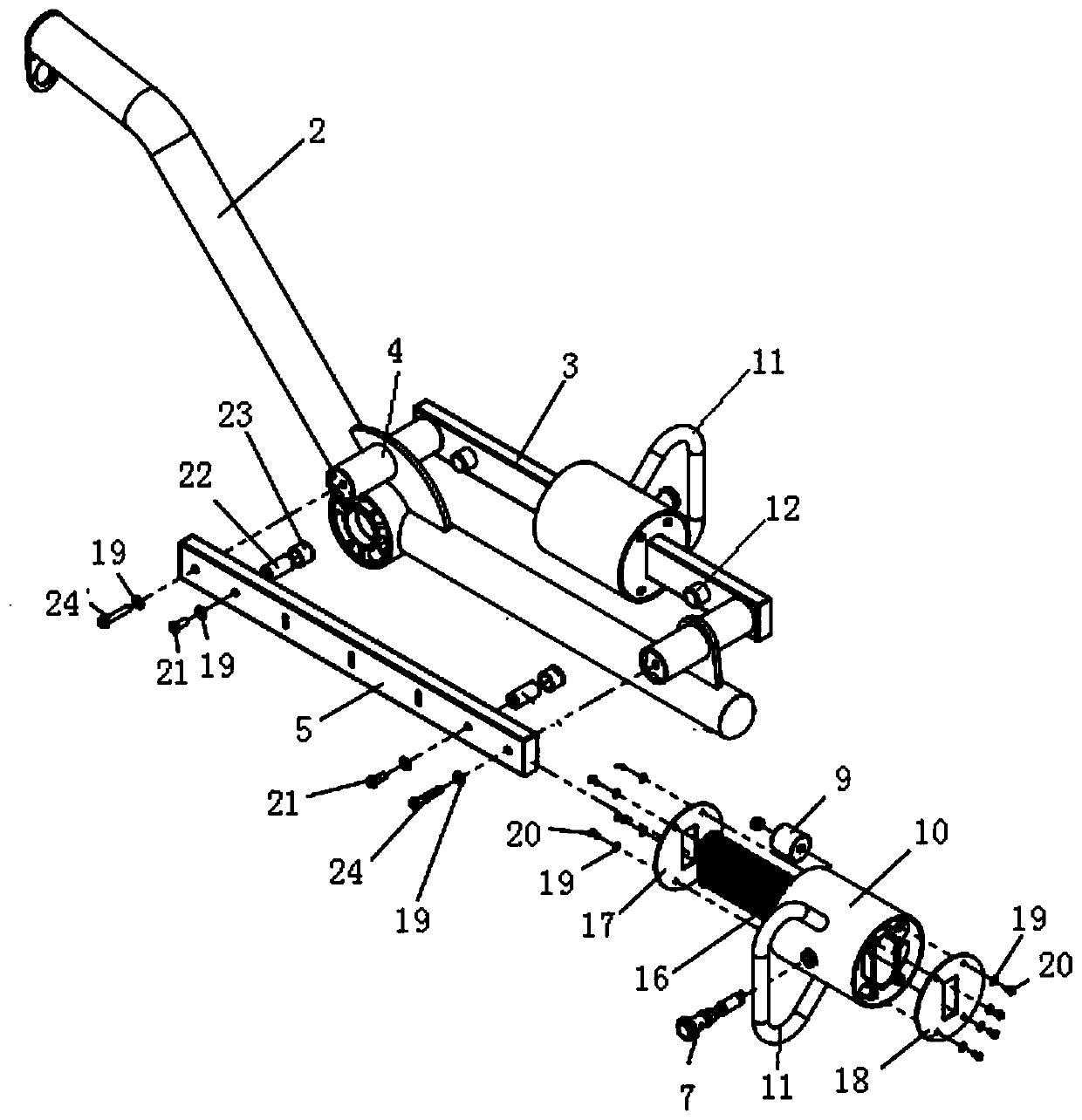

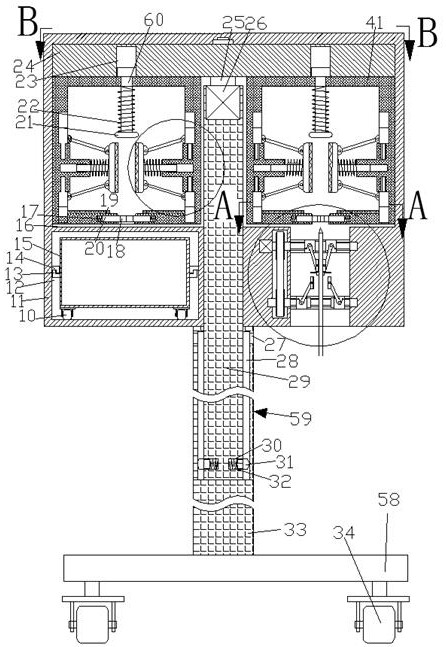

Counterweight-adjustable Lat machine with mid row

PendingCN110860076AImprove protectionProtect the jointsMuscle exercising devicesMachineControl theory

The invention discloses a counterweight-adjustable Lat machine with mid row. The counterweight-adjustable Lat machine with mid row comprises a base, an underframe, a V-shaped Lat machine frame and counterweight-adjustable mechanisms symmetrically arranged on two sides of the V-shaped Lat machine frame, wherein the top of the underframe is rotatably connected with the corner of the V-shaped Lat machine frame; a support is fixed on one inclined rod of the V-shaped Lat machine frame, and the upper surface of the inclined rod is fixedly connected with the counterweight-adjustable mechanisms on thetwo sides through the support; each counterweight-adjustable mechanism comprises a sliding rail and a counterweight assembly arranged outside the corresponding sliding rail in a sleeving mode, each counterweight assembly can slide back and forth along the corresponding sliding rail, the sliding rails and the counterweight assemblies are fixed through elastic bolts, and the counterweight is adjusted by changing the distances from the elastic bolts to the corner of the V-shaped Lat machine support. The counterweight-adjustable Lat machine with mid row belongs to indoor and outdoor general products, is not easy to cause damage during use, and is close to the movement mode of a human body under a dynamic state.

Owner:JINAN LISHENG SPORTS GOODS CO LTD

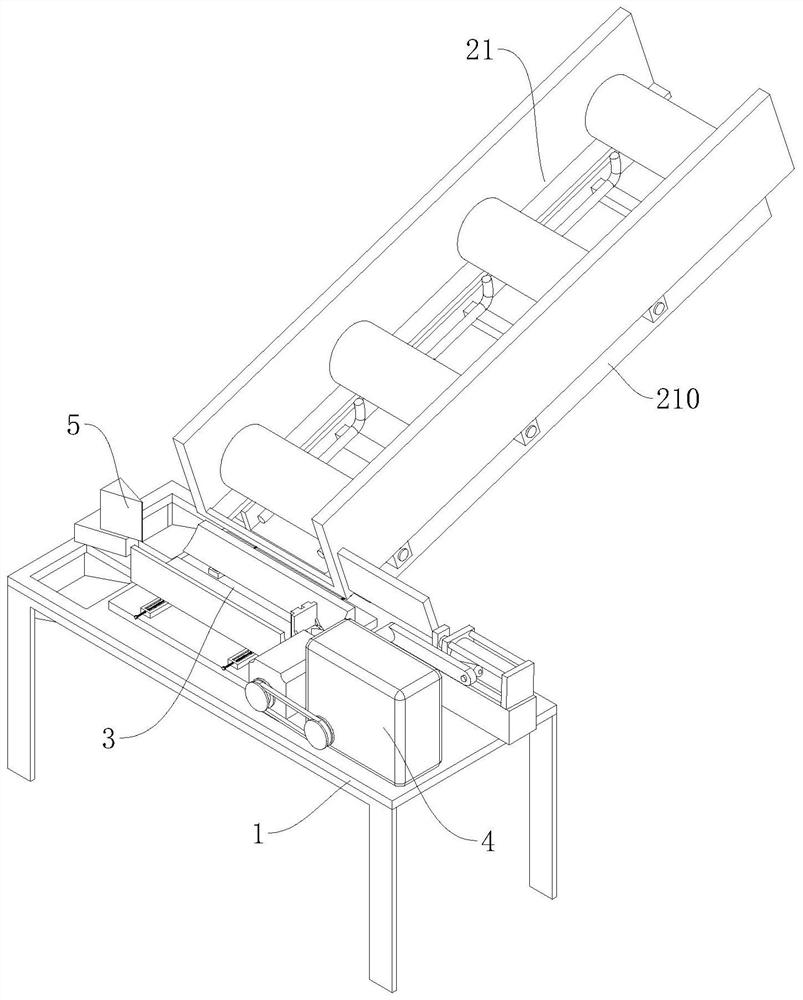

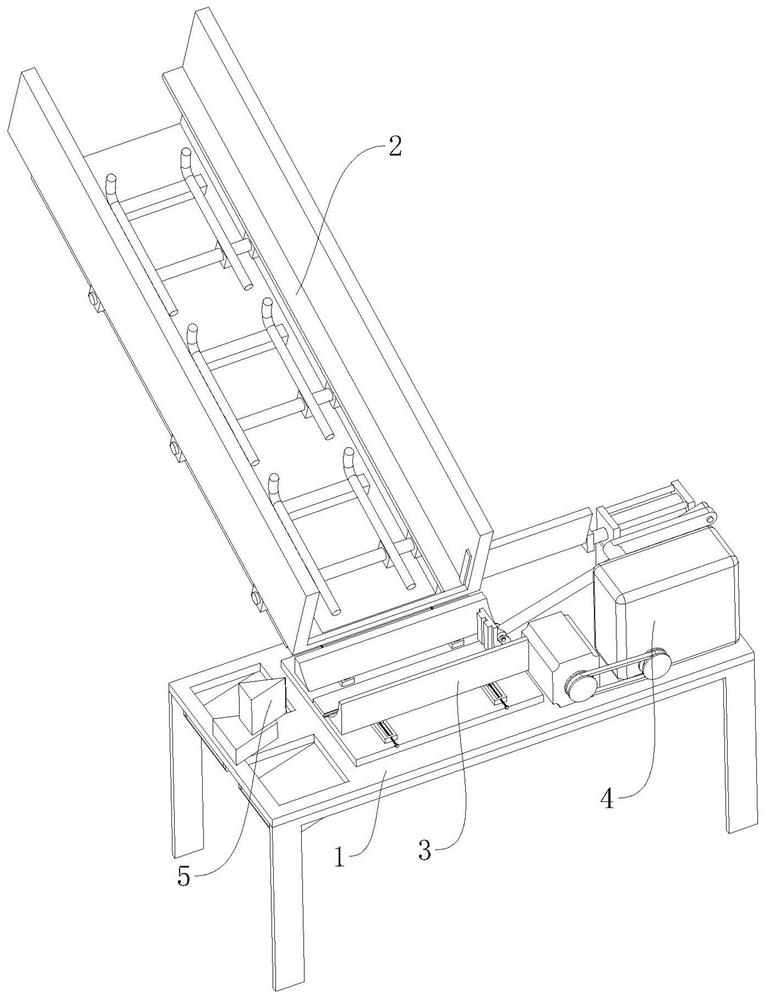

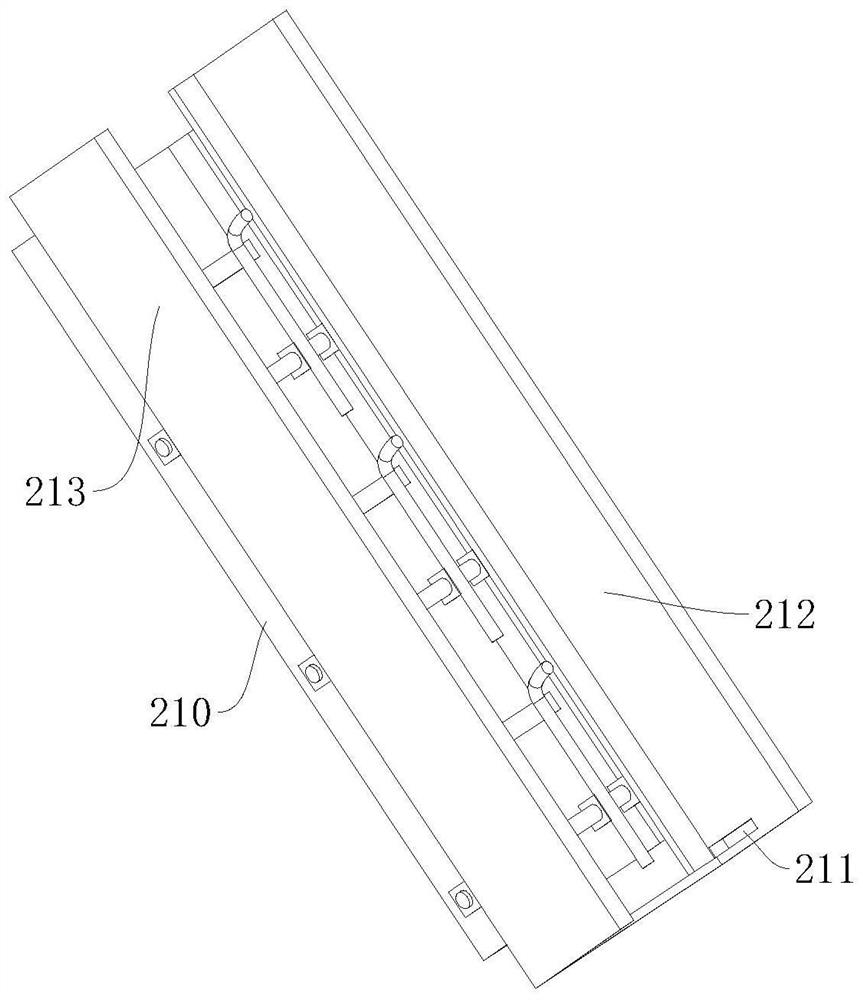

A continuous automatic log splitter

ActiveCN109500957BImprove continuityReduce hard workWood splittingAgricultural engineeringWood splitting

The invention relates to the technical field of agricultural machinery, in particular to an automatic continuous wood splitting machine. The automatic continuous wood splitting machine comprises a workbench, a discharging device, a pushing device and a driving device. The pushing device is arranged at the top end of the workbench, a wood splitting cutter used for splitting wood is arranged at thetop end of the workbench, and the driving device is disposed at the top end of the workbench. The pushing device comprises a bearing bottom plate, a first limiting assembly, a second limiting assemblyand a pushing assembly, the bearing bottom plate is installed at the top of the workbench, the first limiting assembly and the second limiting assembly are separately mounted on one side of the top end of the bearing bottom plate, and the pushing assembly is disposed between the first limiting assembly and the second limiting assembly. The discharging device is disposed on the side of the workbench, and the discharging device and the first limiting assembly are arranged on the same side. The wood splitting operation with higher continuity is completed by the cooperation work between the discharging device, the pushing device and the driving device, the labor of personnel is reduced, and the efficiency is improved.

Owner:FENGHUA NANFANG MACHINERY MANUFACTORY

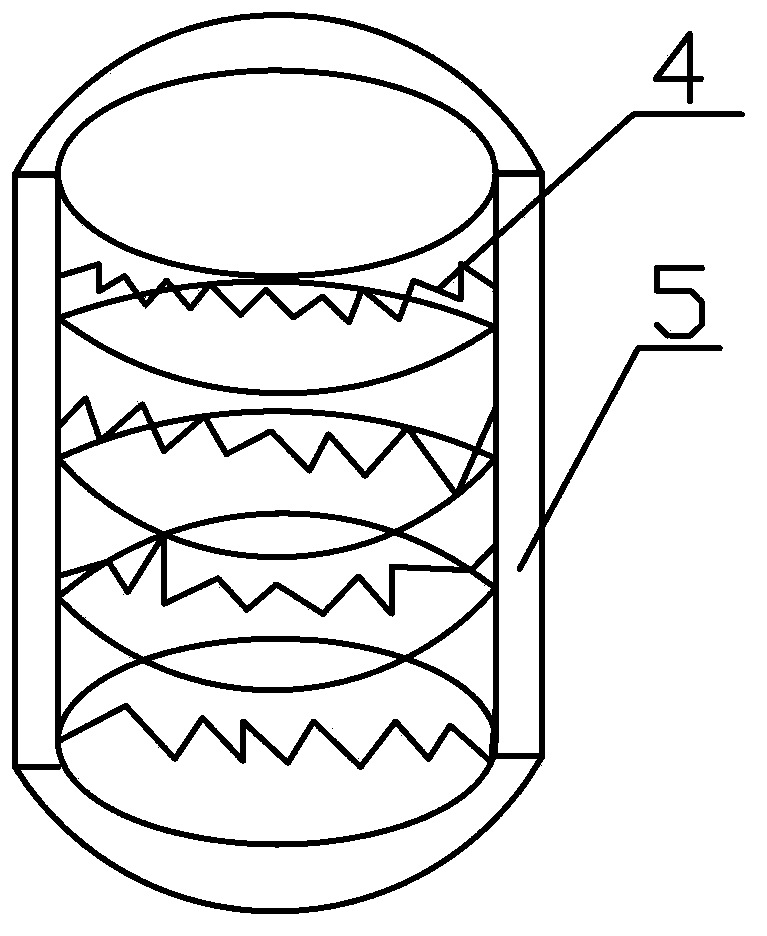

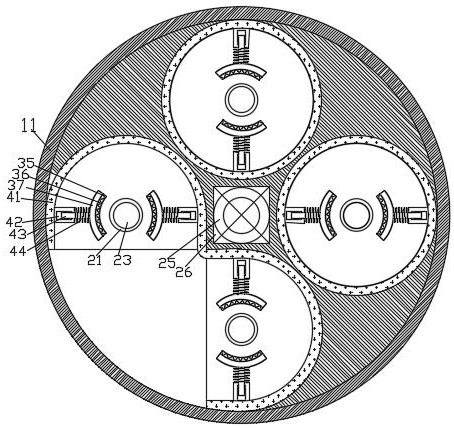

An automatic replacement device for infusion bottles used in hospital treatment

ActiveCN111359052BReduce work intensityReduce hard workMedical devicesFlow monitorsEngineeringMechanical engineering

The invention discloses an automatic replacement device for infusion bottles for hospital treatment, which comprises a cylindrical body. The top wall of the cylindrical body is provided with a circular turntable fixedly installed on the first shaft. The bottle clamping device is installed symmetrically on the left and right. A round hole is provided at the center of the top wall of the bottle clamping device. There is a storage space in the body of the cylinder. The present invention provides a convenient and reliable infusion device for the sick, and there is no need to worry about the danger that the medicine in the infusion bottle will not be found after dripping out, which reduces the work of the nurses. Intensity, but also reduce the hard work of the family to accompany the bed, no longer need to always pay attention to the changes in the liquid medicine in the infusion bottle, convenient and reliable.

Owner:鄂东医疗集团市中心医院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com