Optimized deep groove ball bearing

A ball bearing and bearing technology, applied in the direction of bearing components, shafts and bearings, bearing assembly, etc., can solve the problems of inconvenient installation of bearings, installation methods, single angles, and inability for non-technical personnel to install bearings, etc. Retracted, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

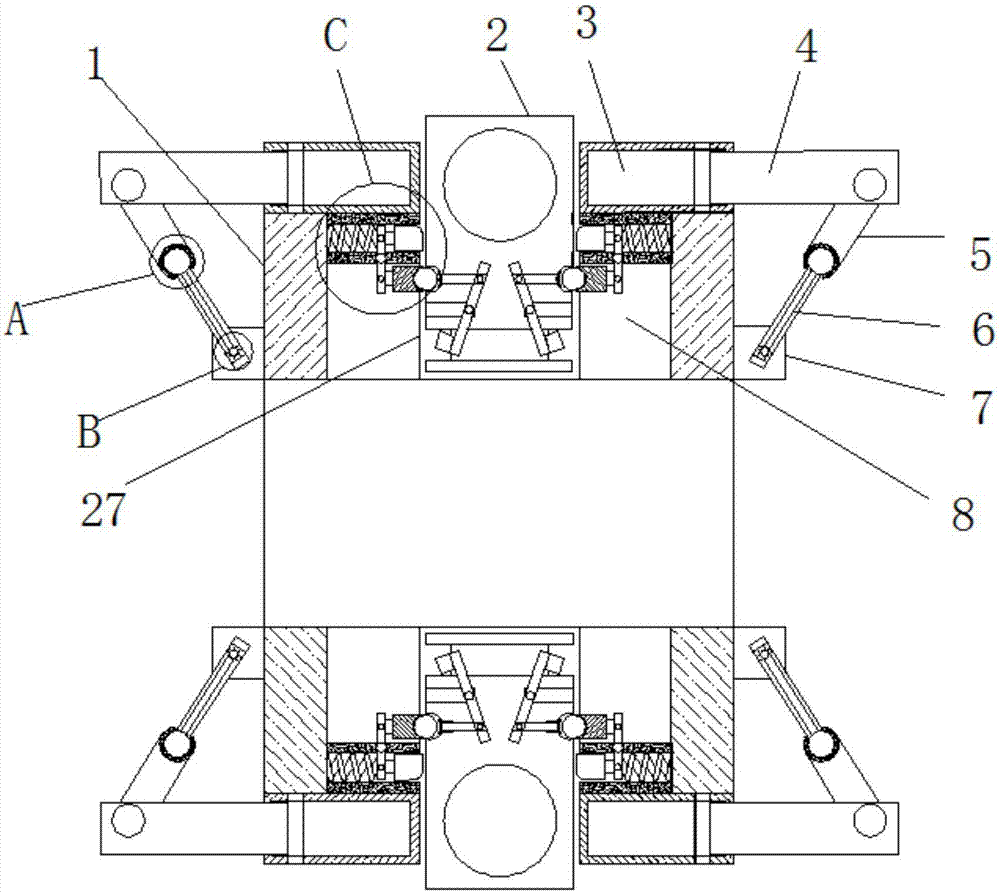

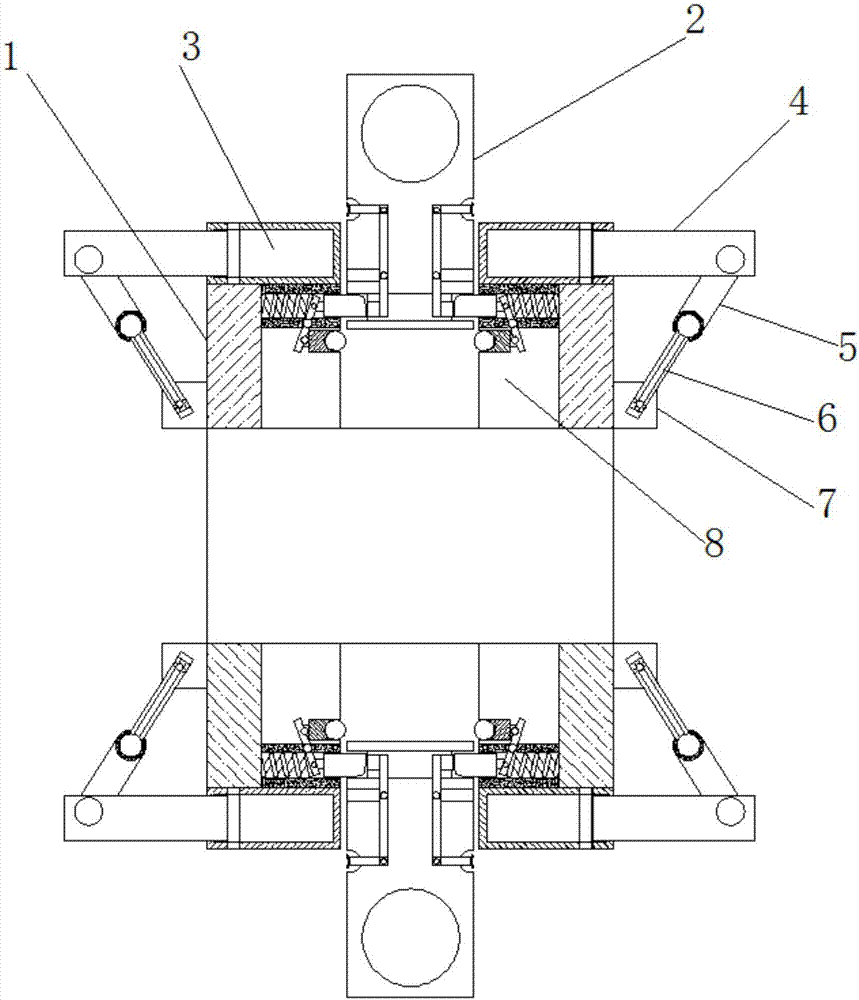

[0033] refer to Figure 1-6, an optimized deep groove ball bearing, including a bearing head 1 and a bearing inner ring. Rolling bodies are arranged on the sides of the rings that are close to each other, and fixing devices are arranged on both sides of the bearing head 1. The fixing devices include connecting kits, expansion slots 3, extension rods 4 and movable kits. The end of the bearing head 1 away from the inner ring of the bearing is provided with There are two telescopic grooves 3, and the two telescopic grooves 3 are arranged on both sides of the bearing head 1, and the ends of the telescopic grooves 3 away from each other are provided with an opening, and the opening is movably connected with a stretch rod 4, and one end of the stretch rod 4 is connected from the The opening of the telescopic groove 3 moves into the telescopic groove 3, and the other end of the extension rod 4 is provided with a connecting kit, which is composed of a live rod 5, a first circular groo...

Embodiment 2

[0036] A cavity 27 is provided in the middle position of the bearing head 1, and the cavity 27 is arranged in the middle position of the two groups of telescopic grooves 3 in the bearing head 1, and one end of the cavity 27 passes through the bearing head 1, and an opening is provided, and the opening is arranged in On the end of the bearing head 1 away from the inner ring of the bearing, an adjustment cavity 8 is provided on both sides of the inner cavity 27 of the bearing head 1, and a limit fixing mechanism is arranged on the side of the adjustment cavity 8 close to the telescopic groove 3. The limit fixing mechanism includes The fixed frame 21, the second balance bar 20, the spring 22, the locking block 19 and the rotation limiting mechanism, the fixed frame 21 is fixedly arranged on the side away from the bearing inner ring on the adjustment chamber 8, and the fixed frame 21 is close to the cavity 27 One side is provided with an opening, the opening passes through the cavi...

Embodiment 3

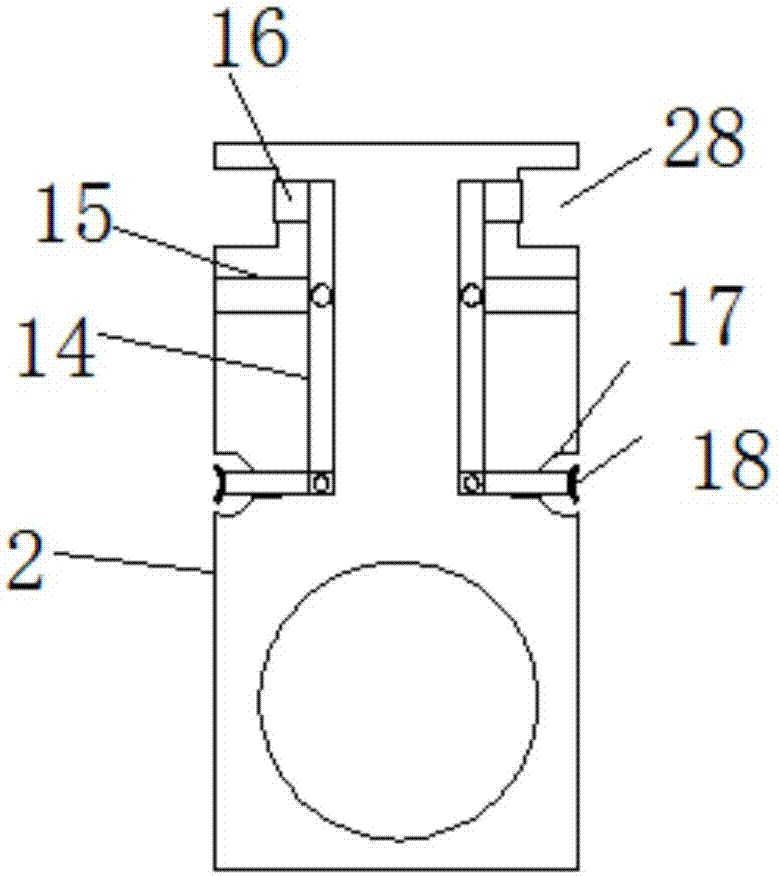

[0039] The cavity 27 is provided with a movable fixing part 2, and the both sides of the fixing part 2 are provided with a limiting groove 17 and a locking groove 28, and the fixing part 2 is provided with a fixed through hole on the side away from the limiting groove 17, and the fixed part The through hole is arranged on the end of the fixing part 2 away from the cavity 27, and one side of the fixing part 2 is provided with a locking groove 28, and the locking groove 28 is arranged on both sides of the end of the fixing part 2 extending into the cavity 27, limiting The position groove 17 is opened in the middle position of the fixing part 2, and the side of the limit groove 17 close to each other is movably provided with a limit plate 18, and the limit plate 18 moves through the limit groove 17, and the limit groove in the fix part 2 17 and the locking groove 28 is provided with a first balance bar 14, and the middle position of the first balance bar 14 is movably connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com