Electric control system for crane

An electrical control system and crane technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of large, sometimes falling down, huge lifting control cabinet structure, large control cabinet volume, etc. Achieve the effect of low board cost, low power consumption and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Further explain below in conjunction with accompanying drawing:

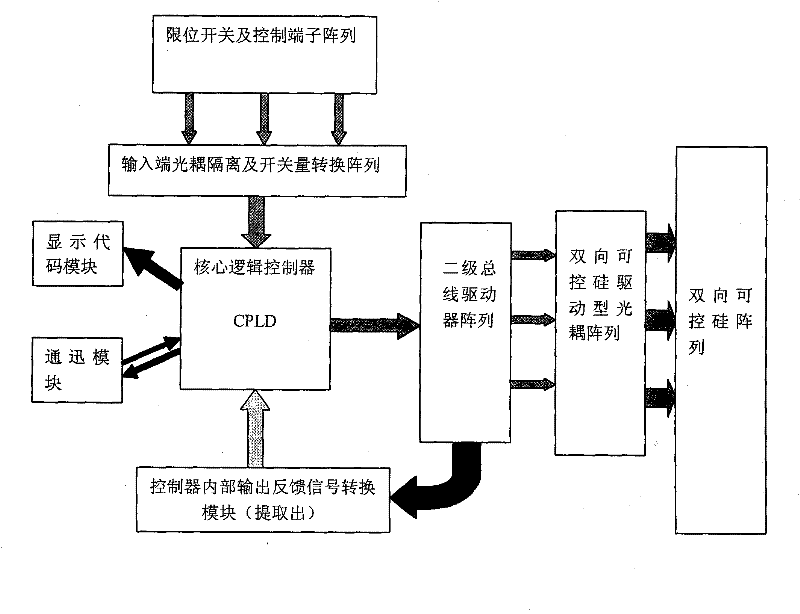

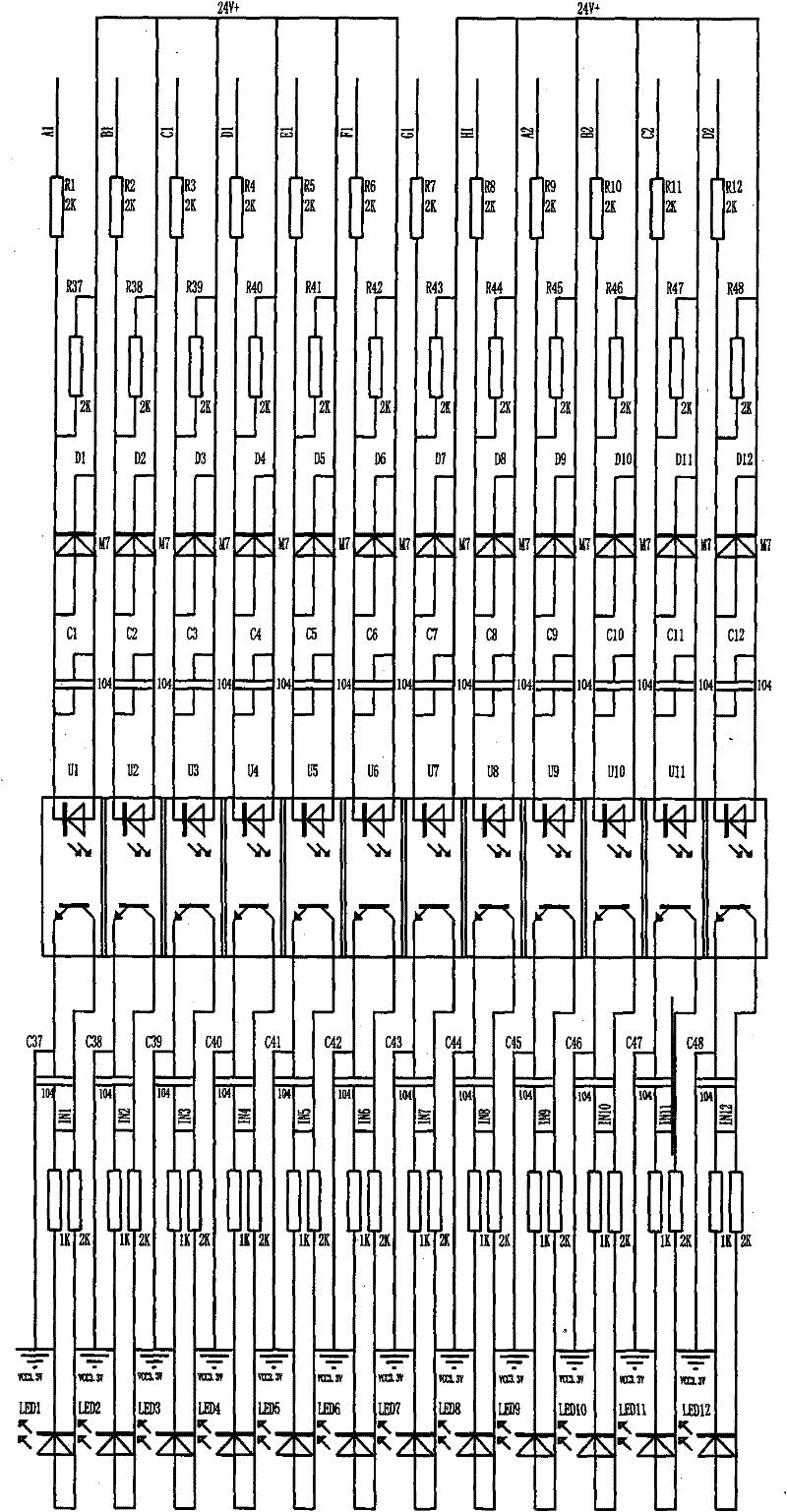

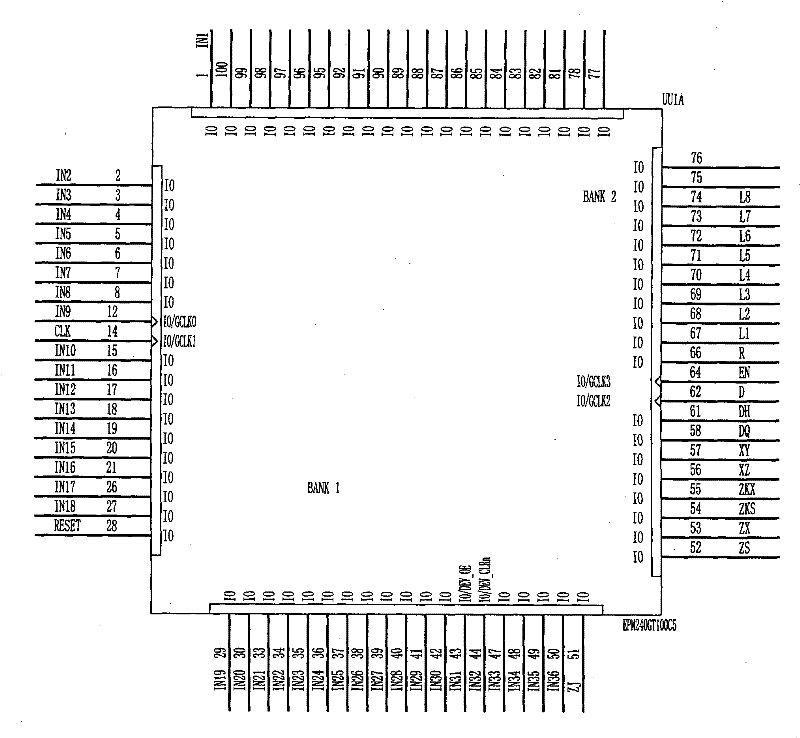

[0056] As shown in 1, the crane electrical control system includes limit switches and control terminal arrays, input optocoupler isolation and switching value conversion arrays, core logic controllers, controller internal output feedback signal conversion modules, output strong and weak current isolation And secondary bus drive module, terminal solid state relay drive array, contactor coil control terminal access terminal; limit switch and control terminal array are connected to the core logic controller through the input end optocoupler isolation and switch value conversion array, and the core logic controller They are respectively connected to the controller's internal output feedback signal conversion module, output strong and weak current isolation and secondary bus drive module, the controller's internal output feedback signal conversion module is connected to the output strong and weak current isolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com