Shrimp head remover

A shrimp head machine and shrimp head technology, applied in shrimp/lobster processing, crustacean processing, slaughtering, etc., to achieve the effect of high shrimp body meat yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

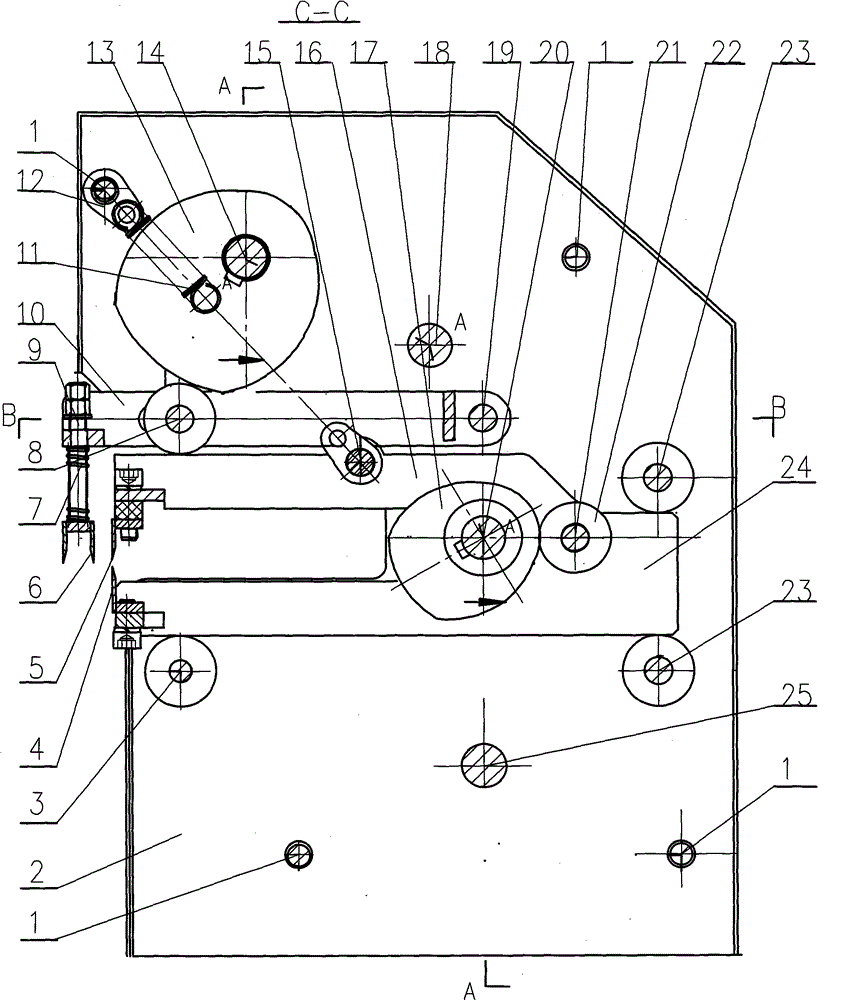

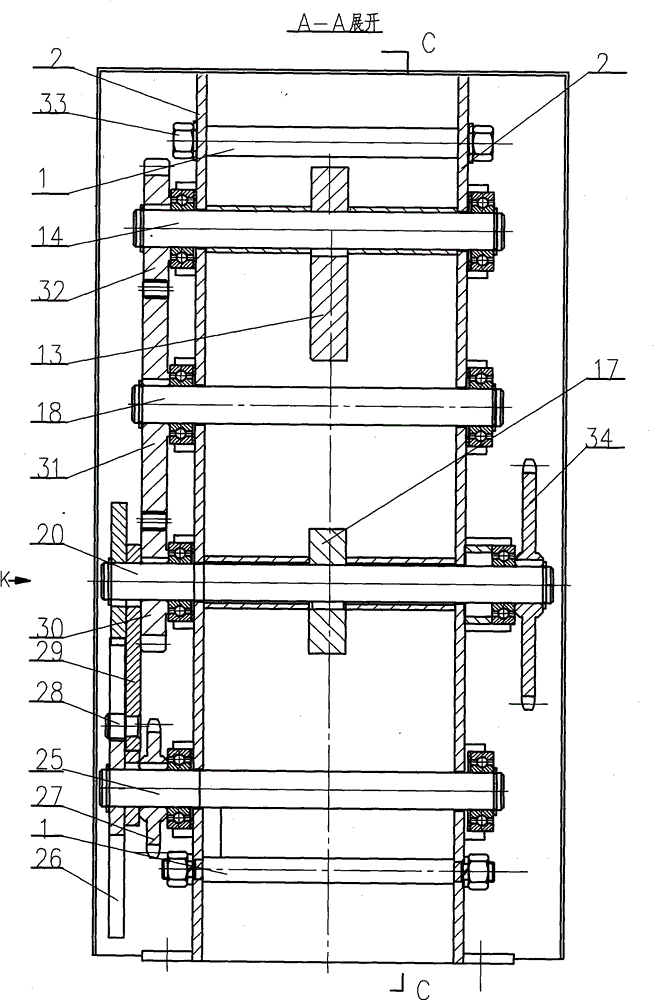

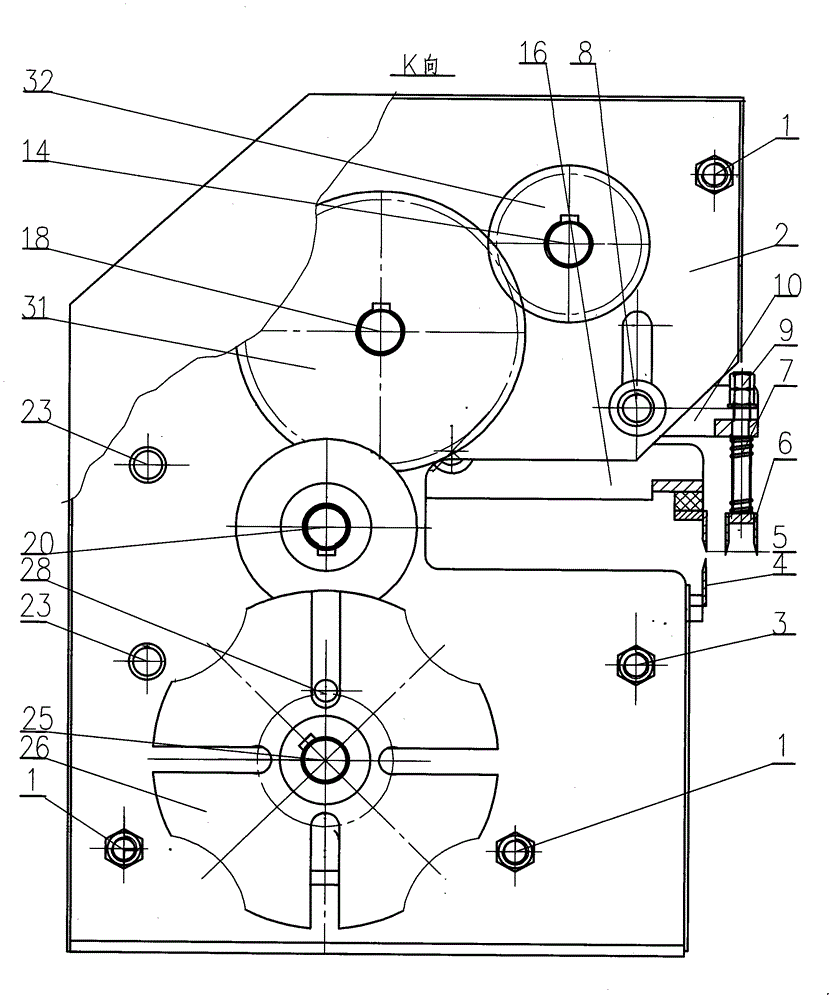

[0016] The details of the structure of the shrimp head removing machine of the present invention are given below in conjunction with the description of the embodiments of the accompanying drawings. The present invention mainly is made up of reduction motor, lower frame, upper frame, shrimp head removing machine main frame, rotary workbench, hopper and unloading baffle plate etc. The reduction motor 40 that motor sprocket wheel 39 is housed, the shrimp head machine main frame 42, upper frame 44 and rotary table 46 and its drive mechanism all are contained on the lower frame 38. Chain 141 is connected motor sprocket wheel 39 and is contained in the large sprocket wheel 34 on the lower camshaft 20 in the shrimp head machine main frame 42. The power of motor 40 is transmitted to the shrimp head machine main frame 42. Chain II45 connects the small sprocket wheel I27 that is installed on the sheave shaft 25 in the shrimp head machine main frame 42 and the small sprocket wheel II52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com