Combustion installation

A technology for combustion devices and internal combustion furnaces, applied in heating devices, air heaters, dryers, etc., can solve the problems of difficult collection and disposal, high furnace body temperature, and high ash temperature, so as to improve the safety of use and reduce combustion Ash temperature, the effect of controlling the amount of combustion ash discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

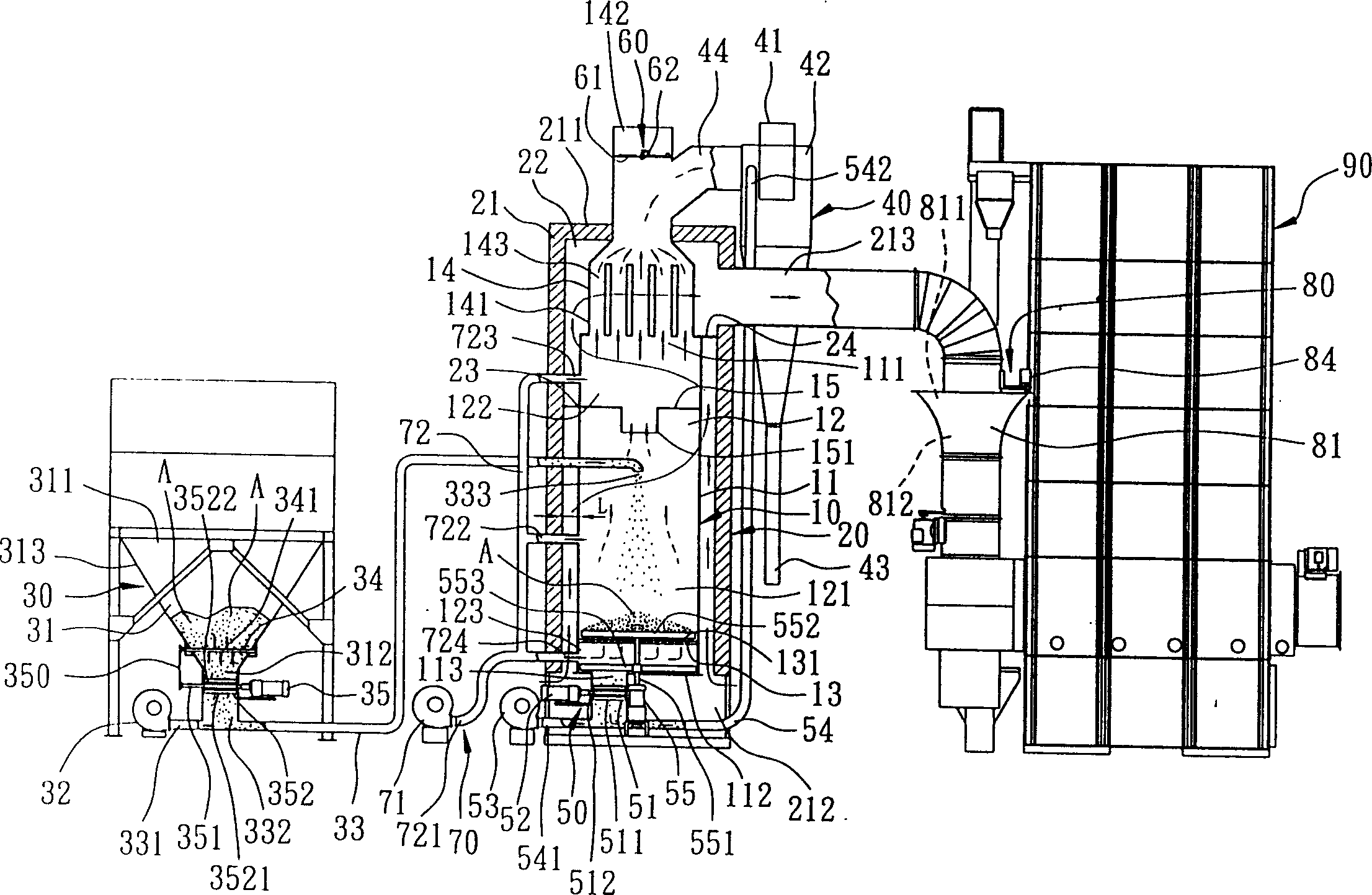

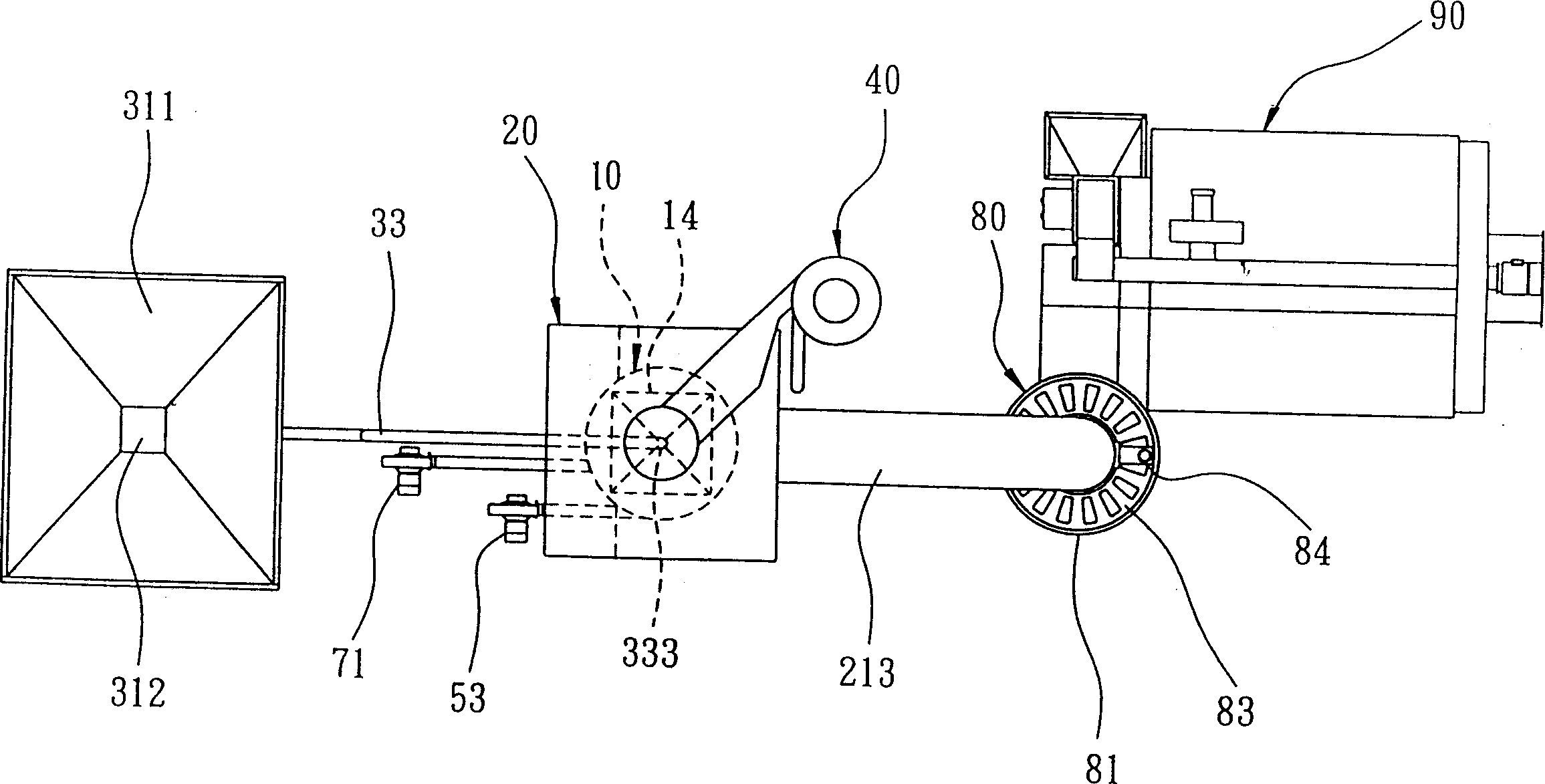

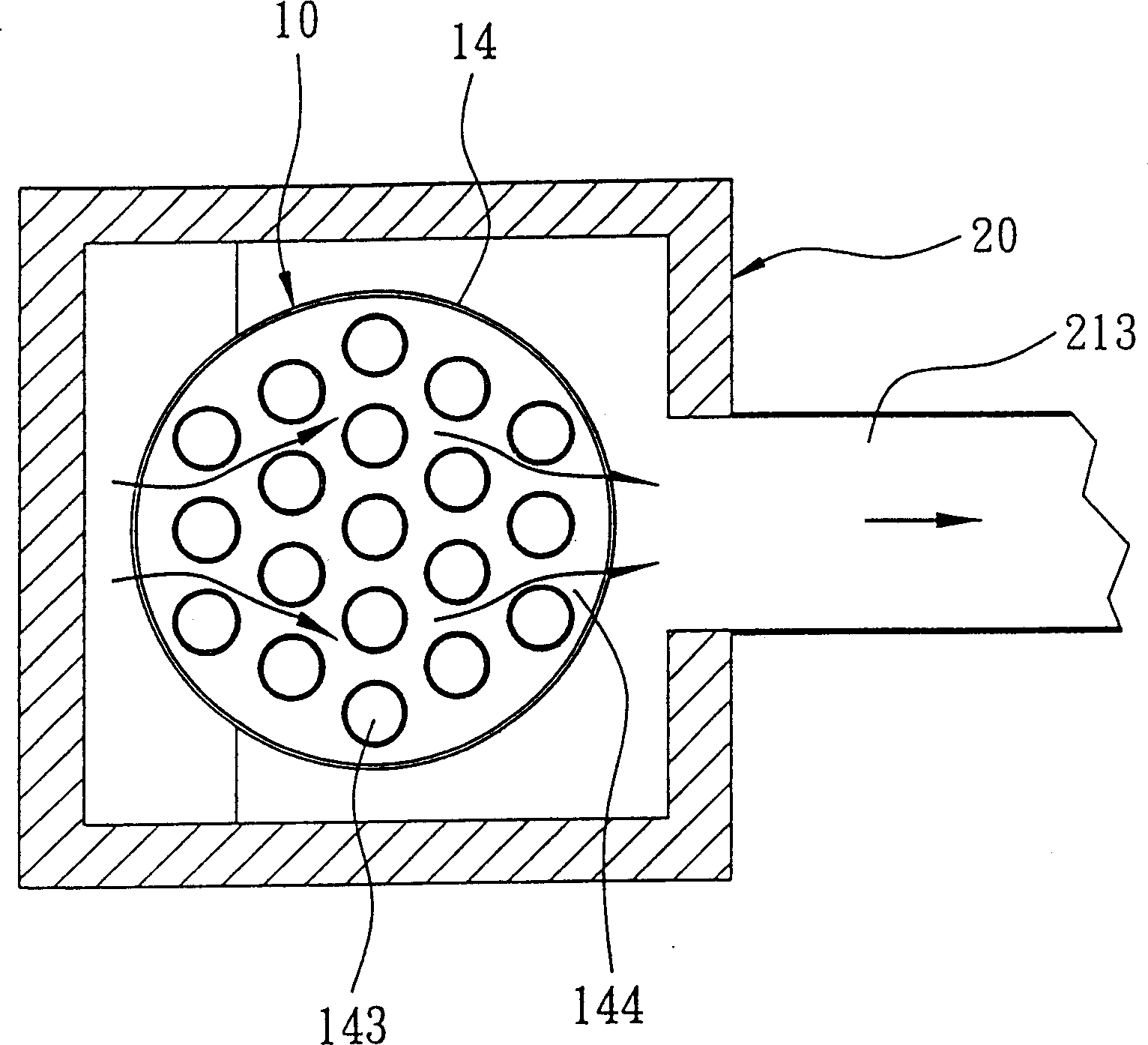

[0021] Example 1, see figure 1 The preferred embodiment of the combustion device of the present invention includes: an internal combustion furnace 10, an isolation cylinder 20, a material supplier 30, a dust collector 40, a residual material distributor 50, an explosion-proof device 60, an air supply device 70 and an air volume automatic adjustment device 80 . The internal combustion furnace 10 has an annular wall 11 , a combustion space 12 defined in the annular wall 11 , a support plate 13 that can store materials, a heat exchanger 14 , and a baffle plate 15 . The upper end of the ring wall 11 is an open end 111 and the lower end is a bottom plate 112 and an ash discharge port 113 passing through the bottom plate 112 . The carrier plate 13 is transversely blocked between the ring walls 11 above the bottom plate 112 , and has a plurality of through holes 131 from top to bottom. One end 141 of the heat exchanger 14 is connected to the open end 111 of the ring wall 11 , the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com