Agitated reactor without dead angle

A reactor and agitator technology, which is applied to chemical instruments and methods, dissolution, mixers, etc., can solve problems such as unfavorable cleaning, high power consumption, and low stirring efficiency, so as to facilitate maintenance and cleaning, reduce power consumption, and improve Effect of Stirring Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

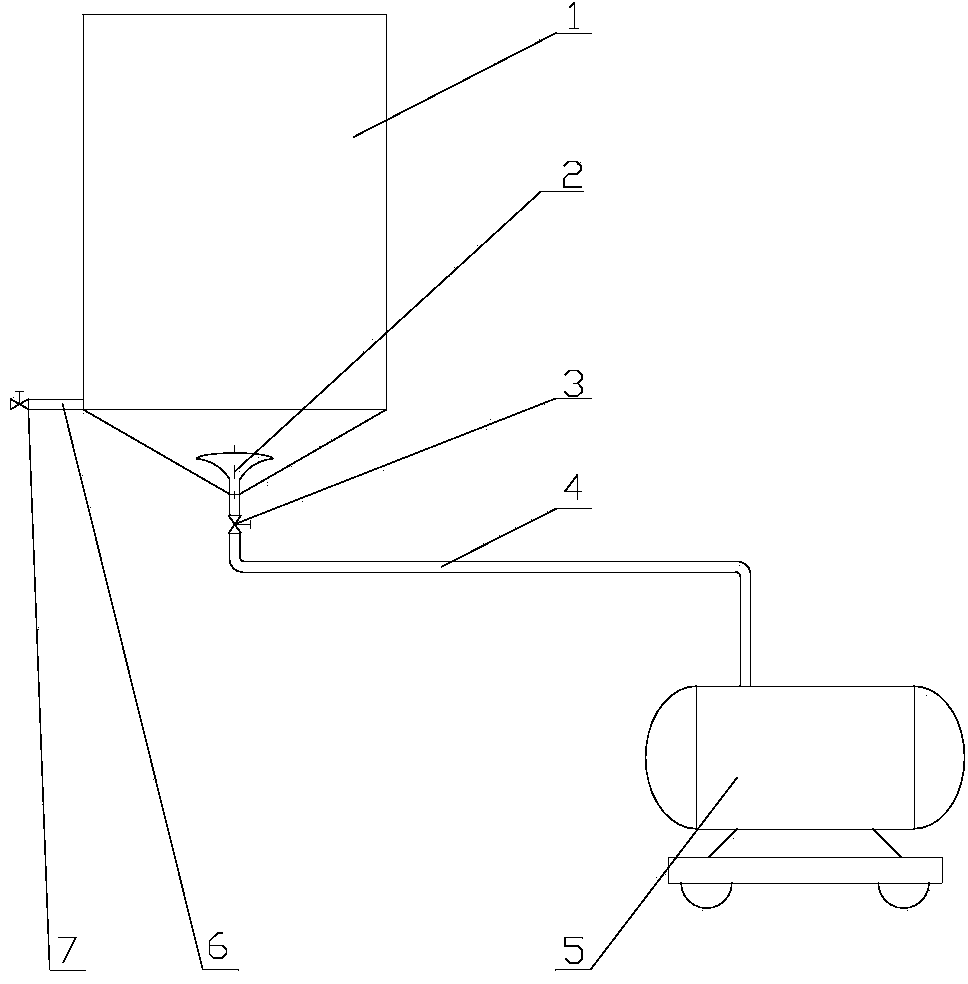

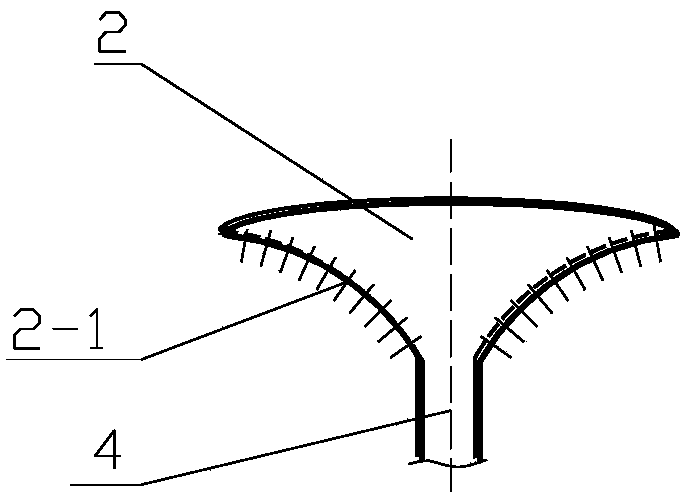

[0018] 1. A stirred reactor without dead ends includes a reactor 1, a bubble stirrer 2, an air inlet valve 3, an air inlet pipe 4, an air compressor 5, a discharge pipe 6, a discharge valve 7, and a bubble overflow hole 2-1, It is characterized in that: the reactor 1 is a cone-bottom reactor, the bubble stirrer 2 is an inverted conical shape, there is an overflow hole 2-1 on the side of the cone of the bubble stirrer 2, and the bubble stirrer 2 is located at the bottom of the reactor 1 , The bubble stirrer 2 conical tops are connected to the air inlet pipe 4, the air inlet pipe 4 is equipped with an air inlet valve 3, and the air inlet valve 3 is connected to the air compressor 5.

[0019] 2. A stirred reactor without dead ends, characterized in that: a discharge pipe 6 is installed on the bottom side of the reactor, and a discharge valve 7 is installed on the discharge pipe 6 .

[0020] 3. A stirred reactor without dead angle, characterized in that: the conical side of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com