Semiconductor package device with layer-increasing structure and making method thereof

A layer-building structure and packaging technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, semiconductor/solid-state device parts, etc., can solve the problems of inability to improve the reliability of finished products, chip 70 cracks, colloidal warping, etc. Problems, to achieve the effect of perfect protection, avoid gas explosion, not easy to absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

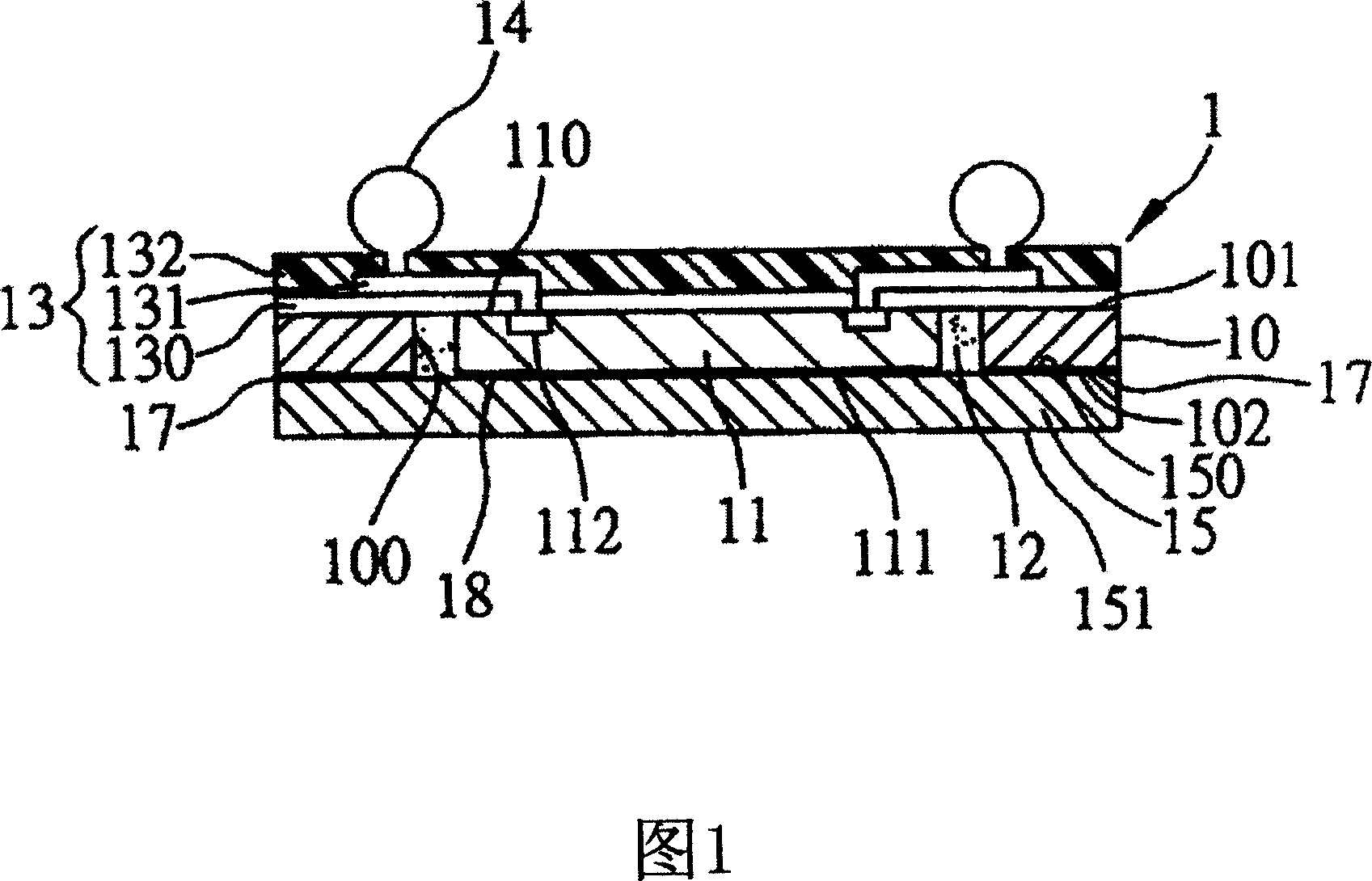

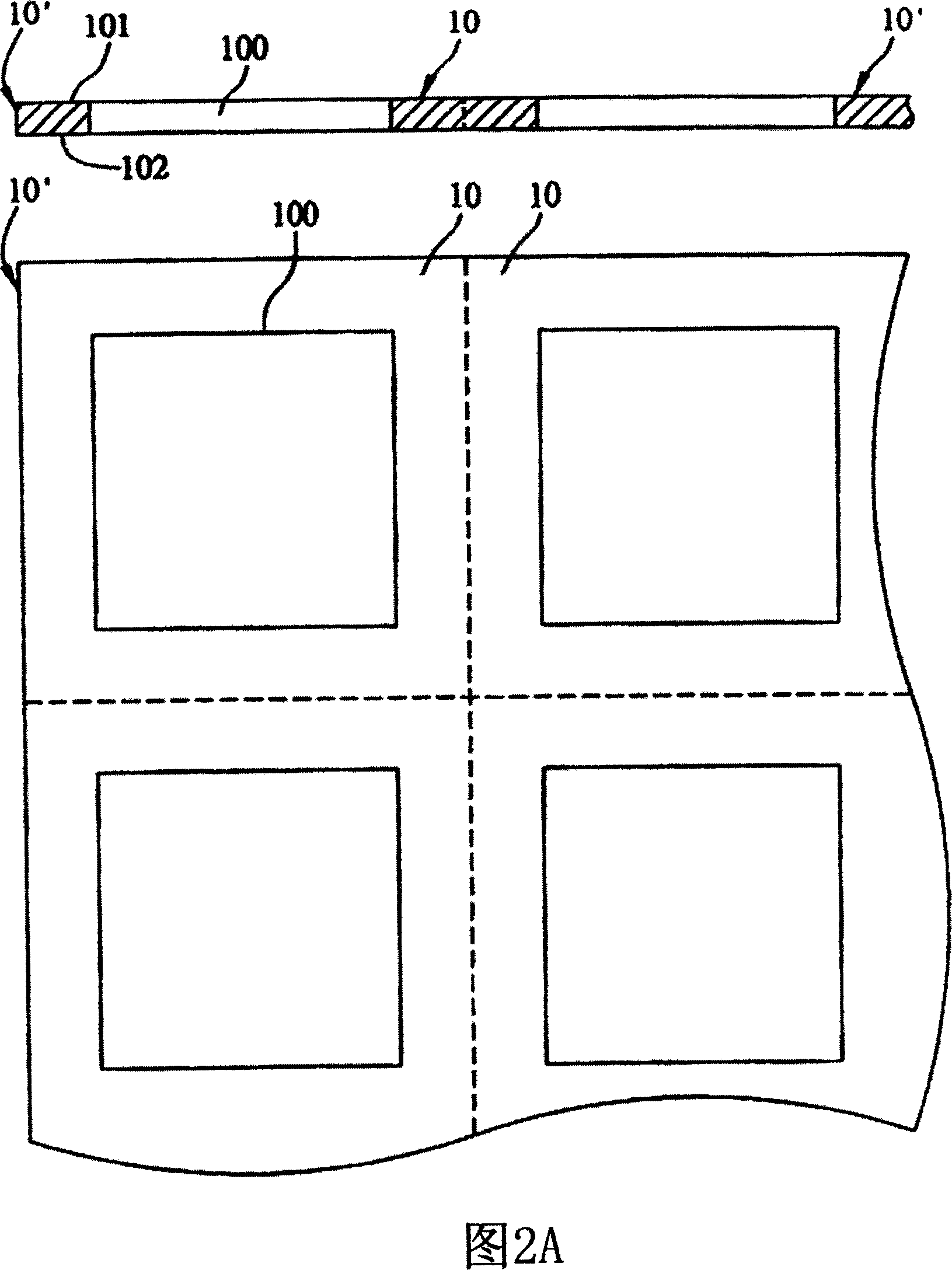

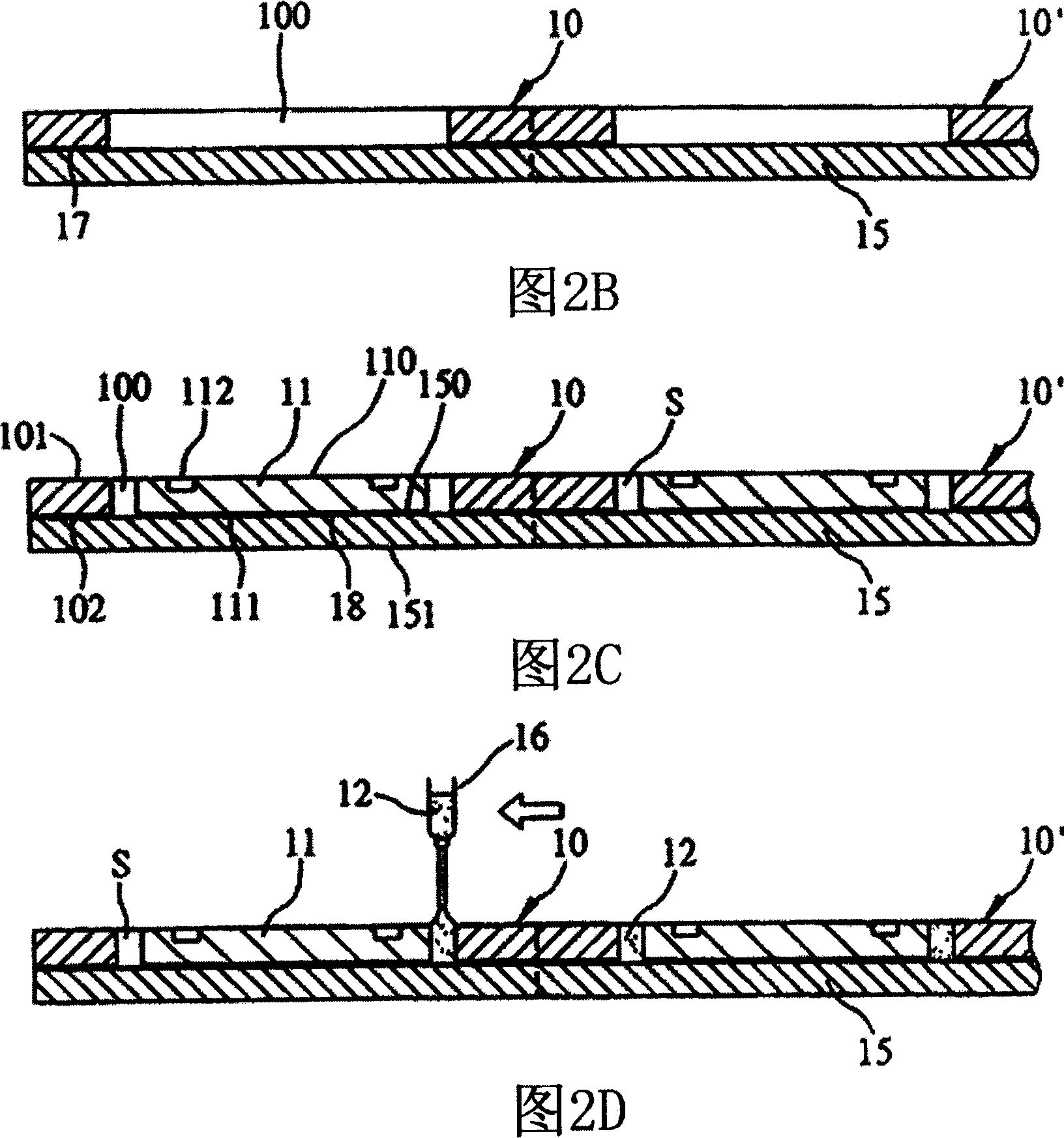

[0029]As shown in FIG. 1 , the wafer-level semiconductor package 1 with a build-up structure of the present invention mainly consists of a hard base 15, a hard frame 10 with a through hole 100, and is accommodated in the through hole 100 of the hard frame 10. The chip 11, the resin material 12 filled between the rigid frame 10 and the chip 11, the build-up structure 13 formed on the rigid frame 10 and the chip 11, and a plurality of solders implanted on the build-up structure 13 The ball (ie, the above-mentioned conductive component) 14 constitutes.

[0030] The hard base 15 and the hard frame 10 are made of glass material, metal material (such as copper metal, etc.), thermosetting material (such as polyimide resin (Polyimide Resin), BT resin (BismaleimideTriazine Resin) and FR-4, etc.) material, the hard base 15 and the hard frame 10 will not be warped and deformed under high temperature environment or temperature cycle in the manufacturing process, so it is used as the prima...

Embodiment 2

[0045] The manufacturing method to be disclosed in Embodiment 2 of the present invention is substantially the same as that in Embodiment 1 above, so only the differences will be described in detail with reference to the accompanying drawings, and the similarities will not be described again. In FIGS. 3A to 3B , the same or similar components as those in FIGS. 2A to 2F are denoted by the same reference numerals.

[0046] Referring to Fig. 3A, prepare the module board 10 ' that is made of a plurality of hard frames 10 that are arranged in an array, each hard frame 10 has a rectangular through hole 100, a first surface 101 and an opposite second surface 102; meanwhile, prepare The hard base 15 has a first surface 150 and a second surface 151 , and a plurality of chips 21 are fixed at predetermined positions on the hard base 15 . The fixing method is to apply bonding glue 18 on at least one surface of the first surface 150 of the hard base 15 and the non-active surface 111 of the ...

Embodiment 3

[0051]The structure of the wafer-level semiconductor package 4 to be disclosed in Embodiment 3 of the present invention is roughly the same as in Embodiment 1. The difference is shown in FIG. .

[0052] The manufacturing method of the semiconductor package 4 is to prepare a hard base 25, the hard base 25 has a first surface 250, a second surface 251 and at least one through hole 252, and the opening position of each of the through holes is in each corresponding The center of the chip preset position. Next, as in the first embodiment, the rigid frame 20 is fixed on the rigid base 25 with the adhesive material 27 . Then chip 21 is placed on the hard base 25, the chip 21 is placed in such a way that the non-active surface 211 of the chip 21 faces down to the through hole 252 of the hard base 25, and the gap between the chip 21 and the hard frame 20 A gap S is formed. After the chips 21 are loaded on the hard base 25 , the air is sucked out through the through holes 252 , so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com