Composite membrane with air-adjusting fresh-keeping and microwave heating automatic pressure-adjusting package device and its production method

A technology of microwave heating and automatic pressure regulation, applied in the direction of layered products, etc., can solve the problems of not too high elongation, easy drop of inorganic powder, excessive extension and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

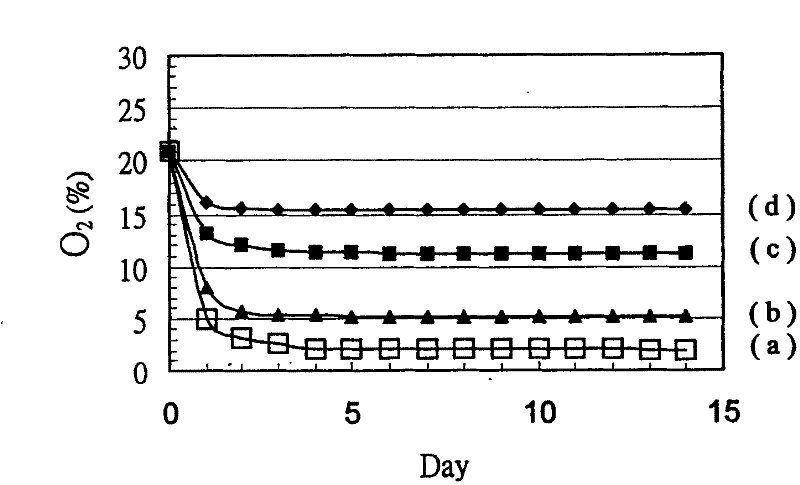

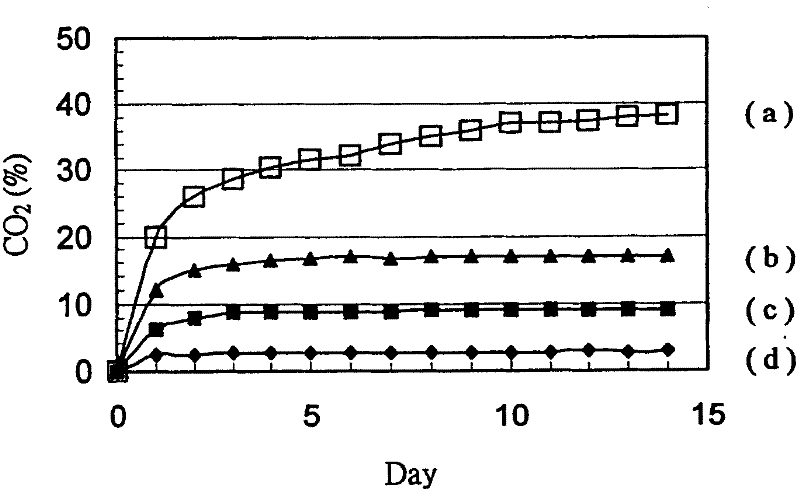

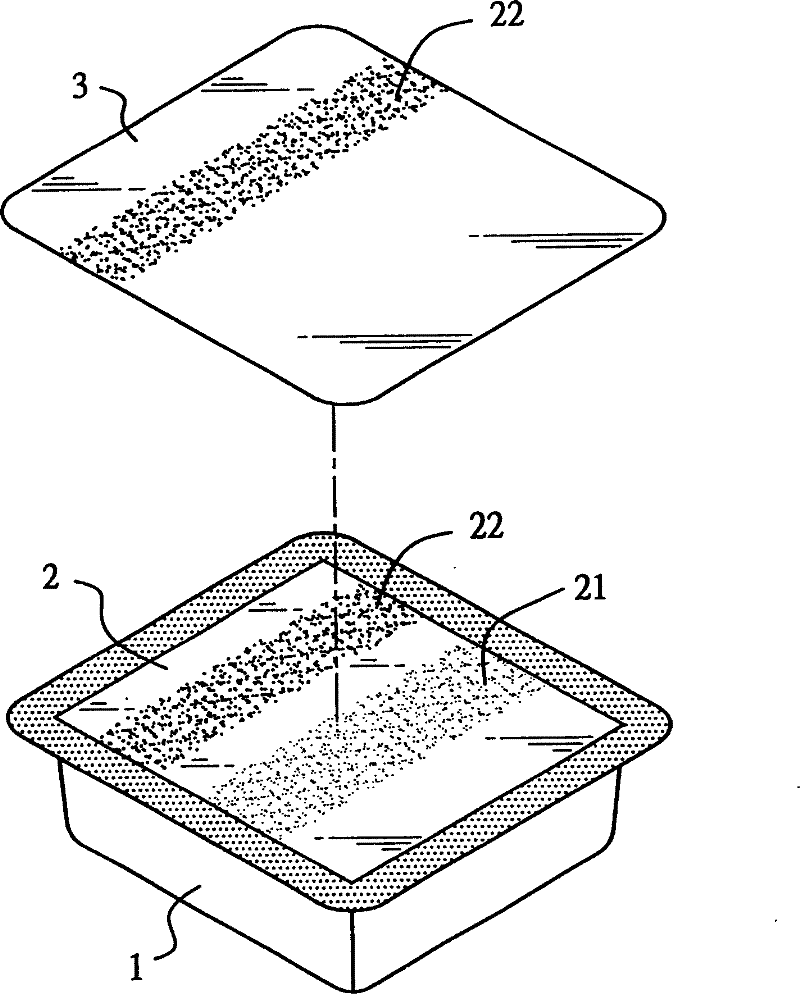

[0041] The present invention provides a composite film with modified atmosphere preservation and microwave heating automatic pressure regulation packaging device, such as Figure 3 ~ Figure 5 As shown, a substrate film layer 2 is included, and the substrate film layer 2 has a first group of multiple microscopic gap structure regions 21, the microscopic gap structures arranged thereon can be in various geometric shapes, and the average size of each microscopic gap structure The size is between 0.1 μm and 3 mm, and the vicinity of the edge of the microscopic gap structure region 21 is physically in close contact with each other. Another sealing film layer 3 covers the side with a plurality of microscopic gap structure regions 21, and the sealing film layer 3 is connected to the substrate film having a first group of multiple microscopic gap structure regions 21 through another adhesive layer 4 Layer 2, and then on the composite film with the sealing film layer 3, the adhesive la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com