System for preparing semi-coke from low-rank coal and method for preparing semi-coke

A low-rank coal and semi-coke technology, which is applied in the field of coal resource optimization, can solve the problems of low pulverized coal forming rate, low pellet strength, and serious gas explosion, so as to increase pelleting rate and pellet strength, and increase pulverized coal Ball forming rate and effect of reducing ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

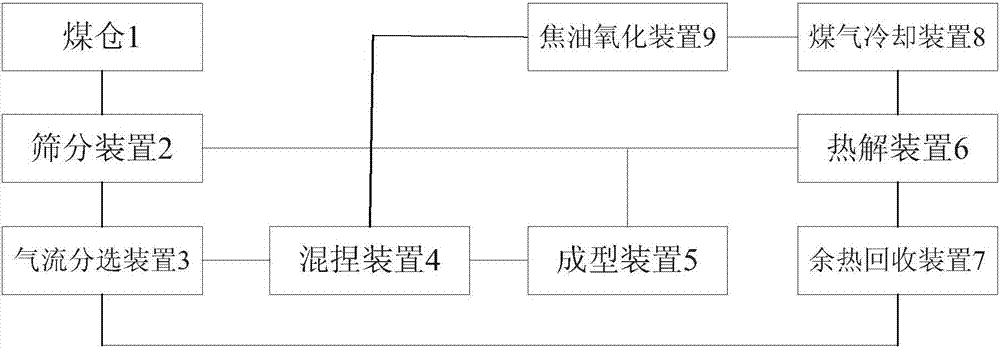

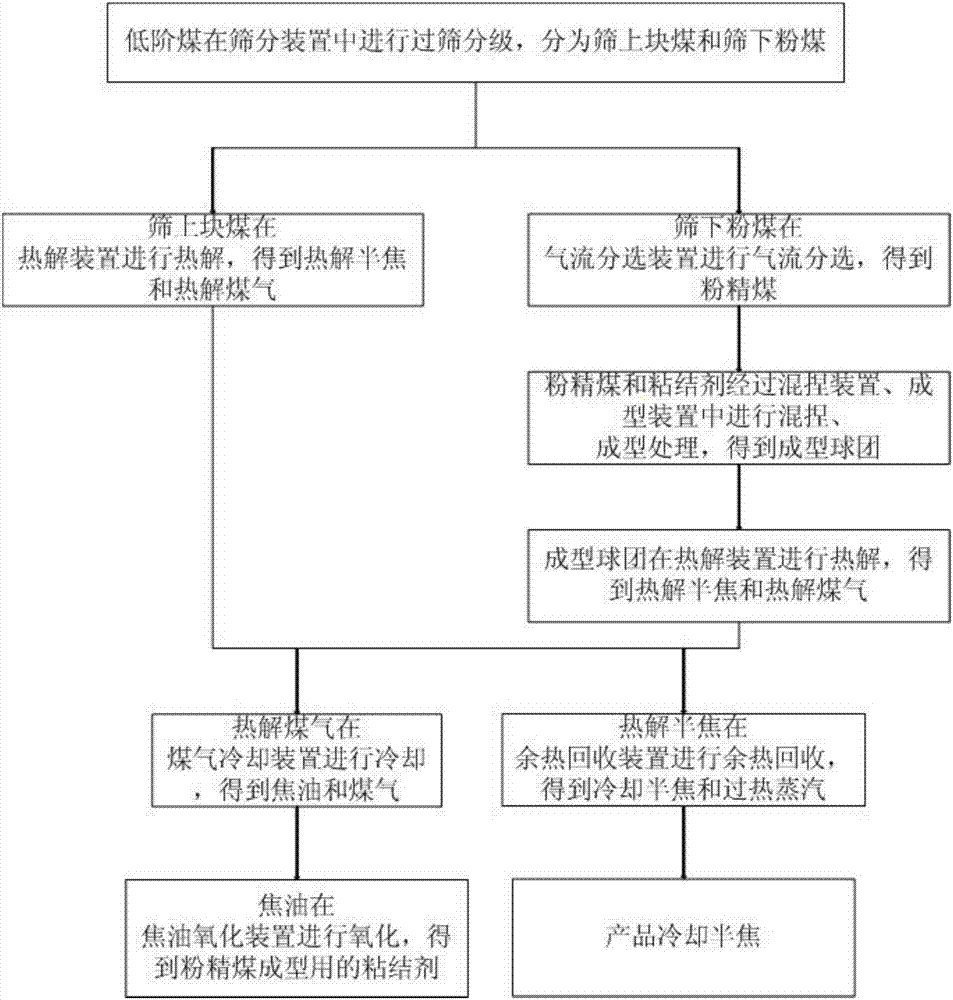

[0056] Such as figure 2 As shown, the method for preparing semi-coke using the above-mentioned system comprises the following steps:

[0057] The low-rank coal is sent from the coal bunker 1 through the bucket elevator to the low-rank coal inlet and enters the screening device 2 for sieving and classification. The screening device 2 has an aperture of 5mm and is divided into lump coal on the screen and pulverized coal under the screen. ;The lump coal on the screen is discharged from the lump coal outlet on the screen, and the pulverized coal under the screen is discharged from the pulverized coal outlet under the screen;

[0058] The pulverized coal is transported to the airflow sorting device 3 through the pulverized coal inlet under the sieve for airflow separation, and the airflow velocity of the sorted airflow is 8m / s to obtain fine coal;

[0059] The pulverized clean coal and binding agent obtained above are carried out in kneading device 4 according to the mass ratio o...

Embodiment 2

[0068] Such as figure 2 As shown, the method for preparing semi-coke using the above-mentioned system comprises the following steps:

[0069] The low-rank coal is sent from the coal bunker 1 through the bucket elevator to the low-rank coal inlet and enters the screening device 2 for sieving and classification. The screening device 2 has an aperture of 5mm and is divided into lump coal on the screen and pulverized coal under the screen. ;The lump coal on the screen is discharged from the lump coal outlet on the screen, and the pulverized coal under the screen is discharged from the pulverized coal outlet under the screen;

[0070] The pulverized coal is transported to the airflow sorting device 3 through the pulverized coal inlet under the sieve for airflow separation, and the airflow velocity of the sorted airflow is 4m / s to obtain fine coal;

[0071] The pulverized clean coal and binding agent obtained above are carried out in the kneading device 4 according to the mass rat...

Embodiment 3

[0080] Such as figure 2 As shown, the method for preparing semi-coke using the above-mentioned system comprises the following steps:

[0081] The low-rank coal is sent from the coal bunker 1 through the bucket elevator to the low-rank coal inlet and enters the screening device 2 for sieving and classification. The screening device 2 has an aperture of 5mm and is divided into lump coal on the screen and pulverized coal under the screen. ;The lump coal on the screen is discharged from the lump coal outlet on the screen, and the pulverized coal under the screen is discharged from the pulverized coal outlet under the screen;

[0082] The pulverized coal is transported to the airflow separation device 3 through the pulverized coal inlet under the sieve for airflow separation, the airflow velocity of the sorted airflow is 11m / s, and the fine coal is obtained;

[0083] The pulverized clean coal and binder obtained above are carried out in the kneading device 4 according to the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com