Permanent magnet filter stick and method for preparing permanent magnet material thereof

A technology of permanent magnet materials and permanent magnets, which is applied in the direction of magnetic materials, filtration and separation, magnetic objects, etc., and can solve problems such as difficult manufacturing processes and complex equipment structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

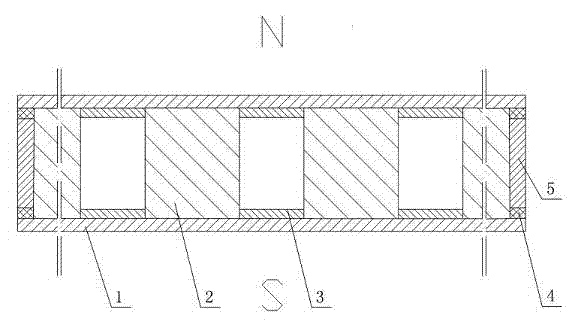

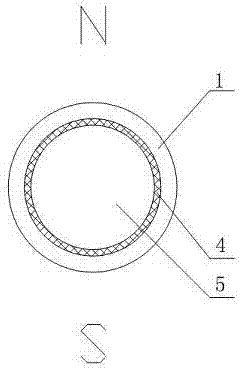

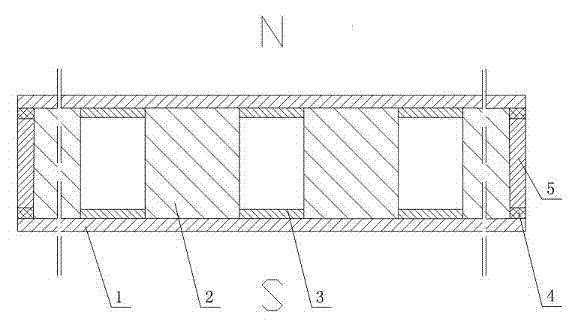

[0024] like figure 1 , 2 As shown, the present invention comprises an outer sleeve 1 and a segmented permanent magnet rod 2 installed in the outer sleeve 1, and each section of the permanent magnet rod 2 is isolated by an ordinary steel pipe section 3; the outer sleeve 1 and the segmented permanent magnet There is a gap between the rod 2 and the ordinary steel pipe section 3 in the radial direction; the two end faces of the outer casing are respectively closed by iron sheets 5 and sealed by a sealing ring 4 .

[0025] Among them: the outer casing 1 is a SUS316L stainless steel pipe; the number of segments of the permanent magnet rod 2 is 16 segments; the length of the permanent magnet rod 2 is 41 mm, and the diameter is 20 mm; the two magnetic poles of each segment of the permanent magnet rod are respectively located in the radial direction of the permanent magnet rod 2 ; The length of the ordinary steel pipe 3 is 9mm and the diameter is 20mm; the thickness of the iron sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com