Device for producing liquid cement grinding aid

A technology of cement grinding aid and production device, which is applied to mixers, dissolvers, mixers and other directions with rotary stirring devices, can solve the problems of uneven mixing of raw materials, poor product quality, and dead ends in mixing, and achieve no mixing. Dead angle, improve product quality, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

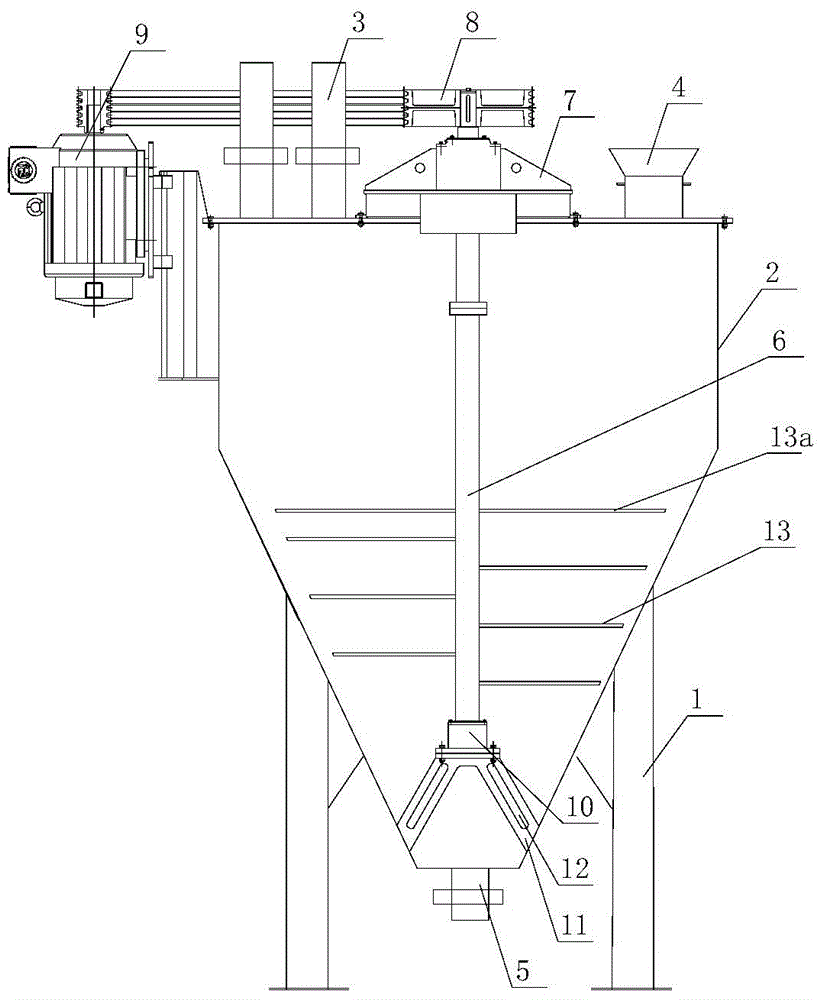

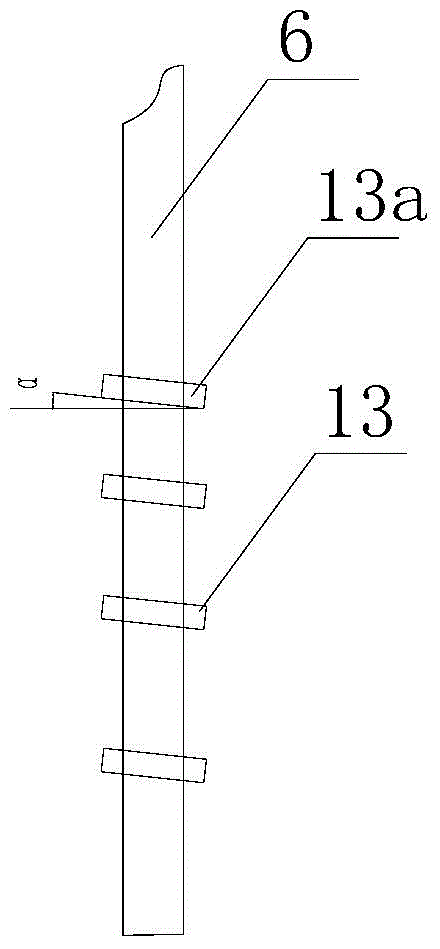

[0016] see figure 1 and figure 2 , a production device for producing liquid cement grinding aids, comprising a frame 1 and a tank body 2 fixed on the frame, the top of the tank body 2 is provided with a feed inlet. There are multiple feed ports, including a liquid feed port 3 and a solid feed port 4 . The liquid feed port is equipped with a solenoid valve and an automatic metering device. The controller controls the solenoid valve to open or close the liquid feed port. The automatic metering device realizes the automatic metering of materials and realizes the automatic production of cement grinding aids. The upper part of the tank body is cylindrical, the lower part of the tank body is in the shape of a conical barrel, the lower end of the cone is provided with a discharge port 5, the discharge port is provided with a solenoid valve, and a rotating shaft 6 is vertically arranged in the tank body. The upper end of the rotating shaft 6 is rotatably supported in a support seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com