Asphalt mixing equipment with heating device

An asphalt mixing and heating device technology, which is applied to mixers with rotating mixing devices, mixer accessories, transportation and packaging, etc., can solve the problems of not being able to know the remaining asphalt, not having a weighing function, and slow asphalt mixing speed, etc., to achieve Improve uniformity and modification efficiency, simple structure, avoid the effect of asphalt solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

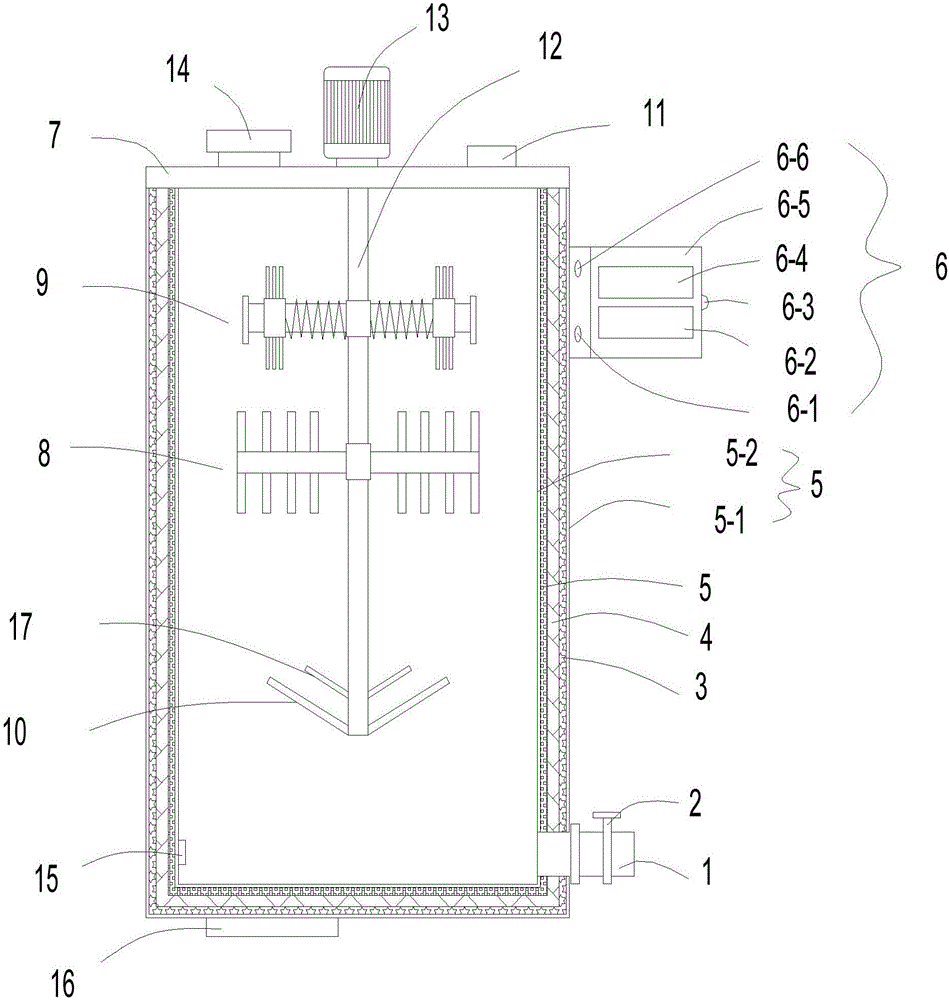

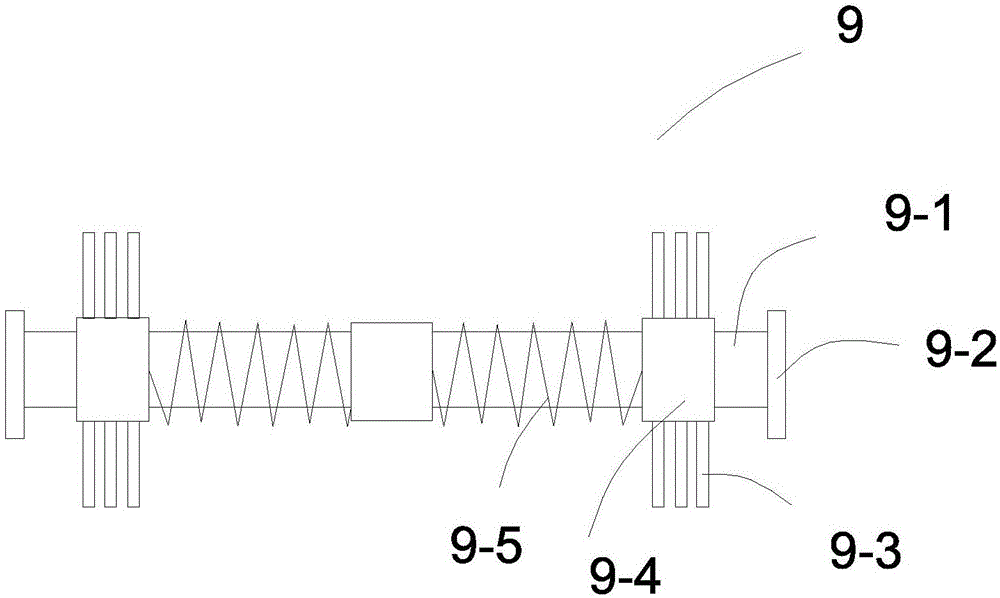

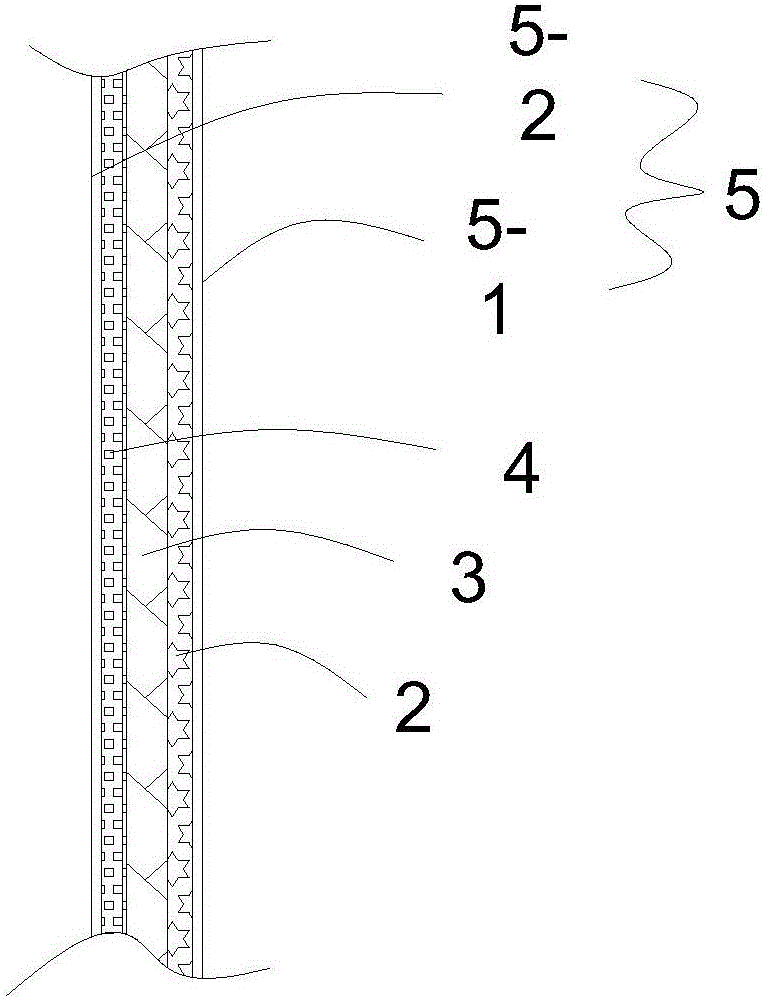

[0026] Such as Figures 1 to 4 As shown, this embodiment provides a kind of asphalt mixing equipment with a heating device, including a tank body 5 and a cover 7 that seals the tank body 5, and it is characterized in that the cover 7 is provided with a device that communicates with the inside of the tank body 5 The feed port 14 of the tank body 1 is provided with a discharge port 1 on one side of the bottom end of the tank body 1, and the stirring shaft 12 located inside the tank body 5 is arranged under the cover 7, and the stirring shaft 12 is sequentially provided with a stirring assembly A9, Stirring assembly B8, a pair of long stirring pieces 10 and a pair of short stirring pieces 17, the tank body 5 includes an inner shell 5-2 and an outer shell 5-1, an inner shell 5-2 and an outer shell 5-1 A cavity structure is formed, and a heat insulating layer 4 , an isolation layer 3 and a heating layer 2 are sequentially arranged in the cavity structure from outside to inside.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com