Hanging arm sludge mixing device

A technology of stirring device and suspension arm, which is applied to mixers with rotary stirring devices, accessories of mixers, chemical/physical/physical-chemical stationary reactors, etc., can solve the problem that sludge cannot be effectively stirred, sludge hardness increases, Increase the motor load and other problems, to achieve the effect of improving the chemical reaction efficiency, easy cleaning, and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

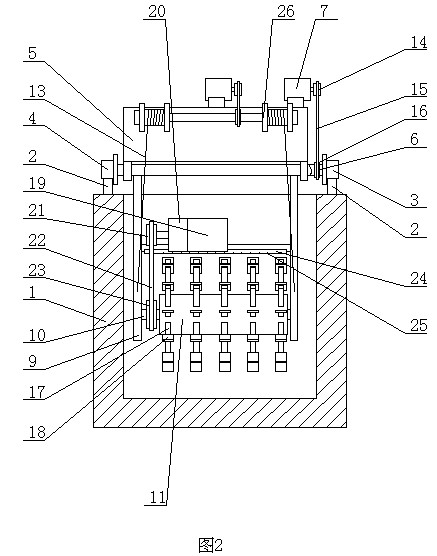

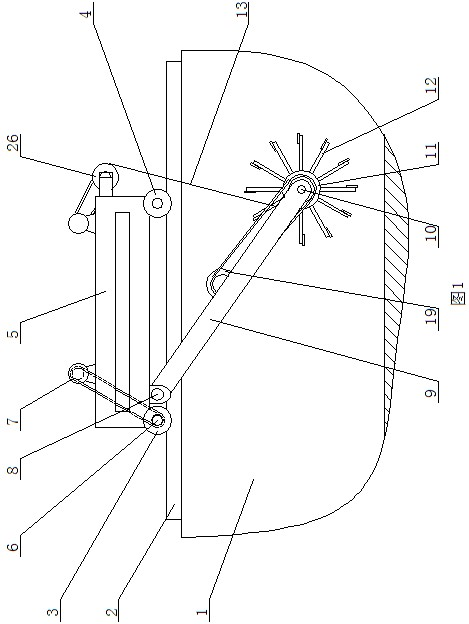

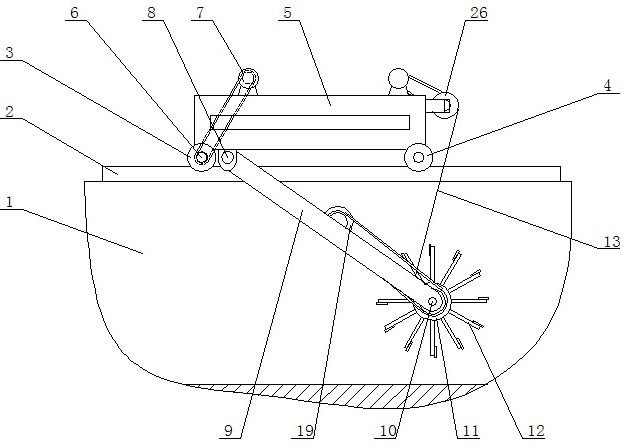

[0007] The hanging arm type sludge stirring device of the present invention comprises a stirring tank 1, guide rails 2 are arranged on both sides of the top of the stirring tank 1, a driving wheel 3 and a driven wheel 4 are installed on the guide rail 2, and the driven wheel 4 is installed on a walking frame 5, and the driving The wheels 3 are connected through the drive shaft 6, the drive shaft 6 is connected with the travel motor 7 through the travel transmission device, the hinge shaft 8 is installed at the bottom of the travel frame 5, the two sides of the hinge shaft are hinged with the upper end of the cantilever 9, and the stirring shaft is installed at the lower end of the cantilever 9 10. The stirring roller 11 is installed on the stirring shaft 10, the stirring teeth 12 are arranged on the stirring roller 11, the stirring motor 19 is installed on the cantilever 9, the stirring motor 19 is connected with the stirring shaft 10 through the stirring transmission device, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com