Aided flowing device of storage silo

A technology of storage bin and micro-orifice plate is applied in the field of flow-assisting device of storage bin, which can solve the problems of poor fluidity of powder materials, inconvenient use, and large occupied area, so as to avoid accumulation, uniform fluidization, and eliminate the The effect of stirring dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

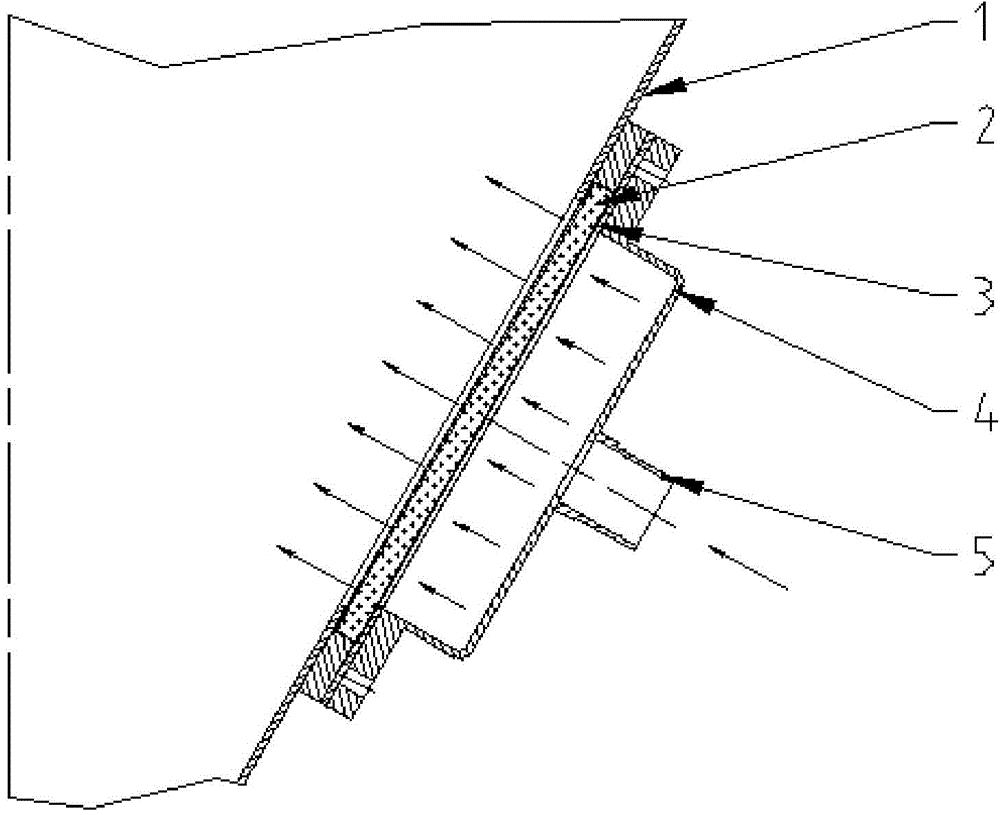

[0018] A flow-aid device for a storage bin, installed on the side of the storage bin 1 and communicated with the storage bin 1, its structure is as follows figure 1 As shown, the flow aid device includes a microporous plate 2 , a compression washer 3 , an inflatable frame 4 and a trachea connector 5 .

[0019] The side of the storage bin 1 is provided with an opening at the fitting position of the microporous plate 2, the microporous plate 2 is connected with the storage bin 1 through the opening, the microporous plate 2 is fixed by the compression gasket 3, and the inflatable frame 4 is erected On the outer surface of the microporous plate 2 and fixed by the compression gasket 3 , the outer surface of the inflatable frame 4 is connected with a trachea joint 5 .

[0020] Open a hole on the storage bin 1 and weld the flange side, put the microporous plate 2 into the flange side of the storage bin 1, add a compression gasket 3 and an inflatable frame 4, and fix the inflatable fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com