Rapid blending equipment for mortar production

A fast and equipment technology, applied in clay preparation devices, raw material supply devices for sale, mixing operation control devices, etc., can solve the problems of lack of raw material pretreatment function, sedimentation in the lower layer, and decreased mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

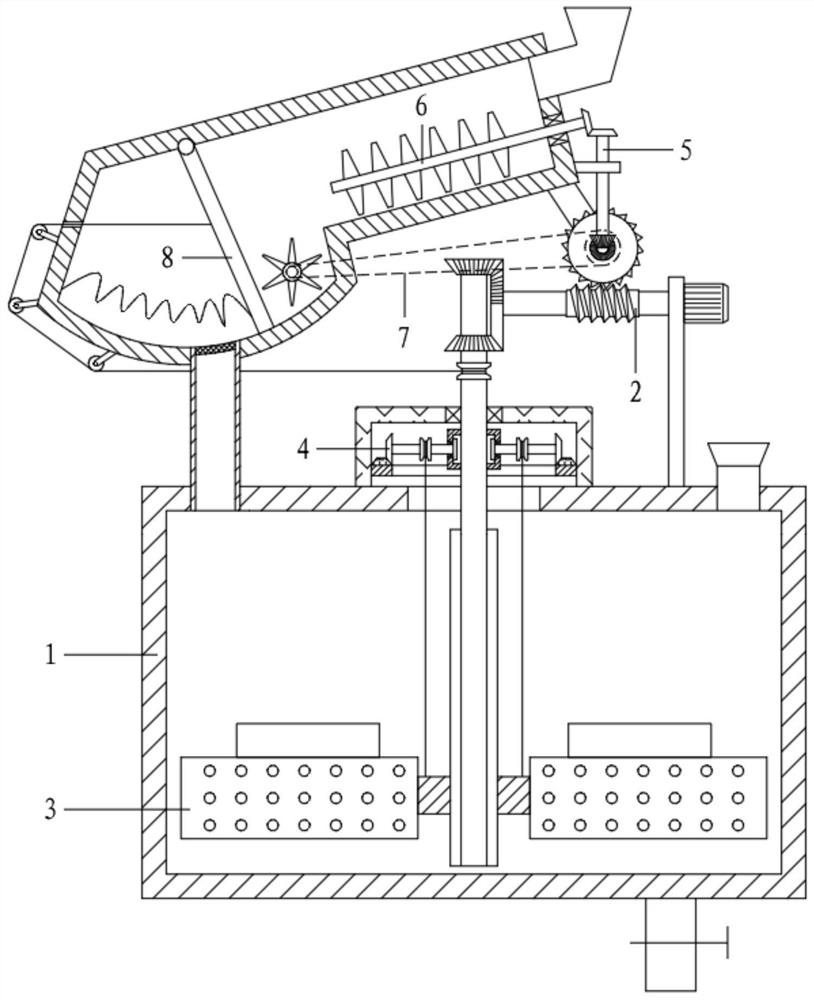

[0060] Referring to the accompanying drawings, a rapid deployment equipment for mortar production includes a frame assembly 1, a driving assembly 2, a stirring assembly 3, a lifting assembly 4, a transmission assembly 5 and a crushing assembly 6;

[0061] The frame assembly 1 includes a mixing tank 101, a slurry discharge pipe 102, a liquid feeding port 103, a feeding pipe 104, a material receiving cavity 105, a crushing cavity 106 and a feeding hopper 107; the crushing cavity 106 is arranged low on the left and high on the right. The left end of the hopper 107 is connected with a material receiving cavity 105; the mixing tank 101 is located below the material receiving cavity 105, and the bottom end of the material receiving cavity 105 is connected to the left end of the top of the mixing tank 101 through the feeding pipe 104; the right end of the mixing tank 101 is provided with a liquid filling port 103 , the bottom is connected with a slurry pipe 102, and the slurry pipe 10...

Embodiment 2

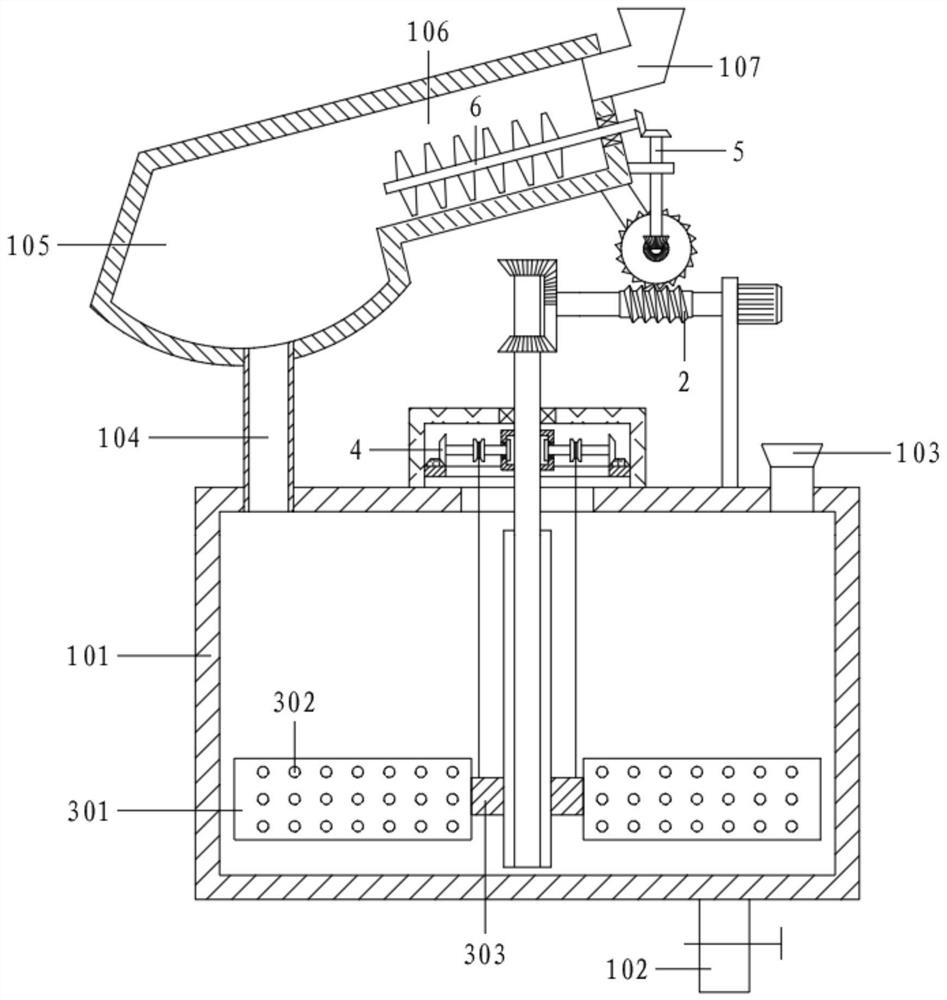

[0064] Referring to the accompanying drawings, a rapid deployment equipment for mortar production includes a frame assembly 1, a driving assembly 2, a stirring assembly 3, a lifting assembly 4, a transmission assembly 5 and a crushing assembly 6;

[0065] The frame assembly 1 includes a mixing tank 101, a slurry discharge pipe 102, a liquid feeding port 103, a feeding pipe 104, a material receiving cavity 105, a crushing cavity 106 and a feeding hopper 107; the crushing cavity 106 is arranged low on the left and high on the right. The left end of the hopper 107 is connected with a material receiving cavity 105; the mixing tank 101 is located below the material receiving cavity 105, and the bottom end of the material receiving cavity 105 is connected to the left end of the top of the mixing tank 101 through the feeding pipe 104; the right end of the mixing tank 101 is provided with a liquid filling port 103 , the bottom is connected with a slurry pipe 102, and the slurry pipe 10...

Embodiment 3

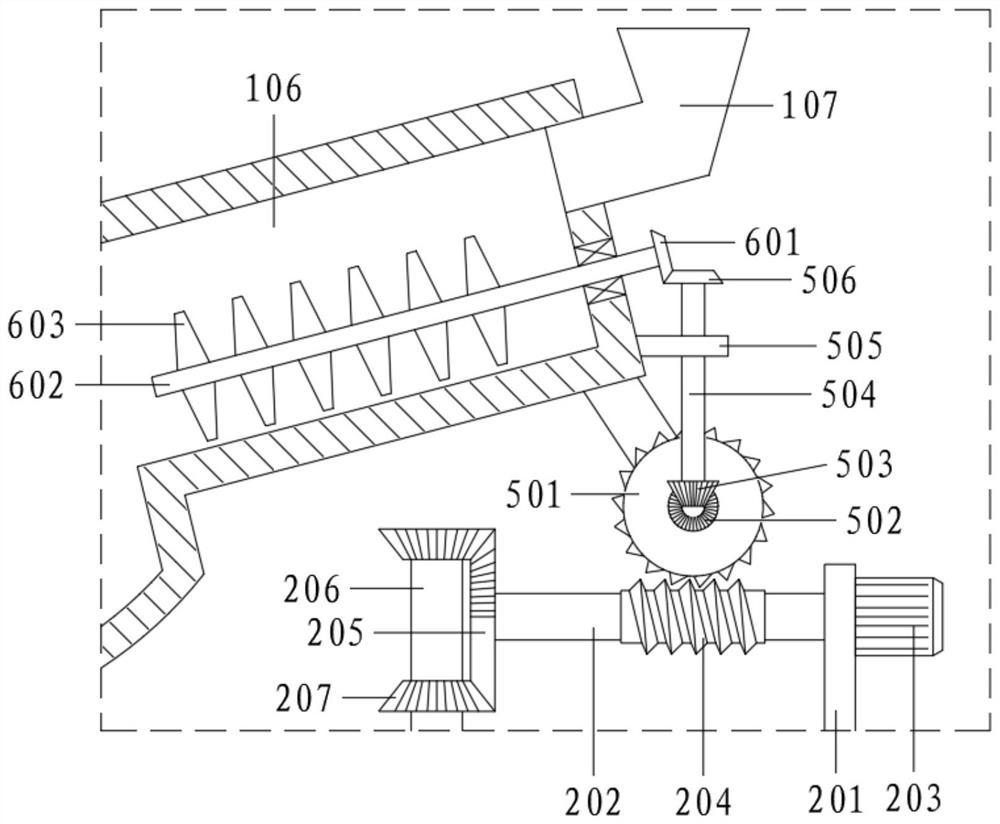

[0085] On the basis of Example 2,

[0086]It also includes a pulverizing assembly 7; the pulverizing assembly 7 is located on the right side of the feeding tube 104, and includes the No. 1 transmission wheel 701, the transmission belt 702, the No. 2 transmission wheel 703, the installation shaft 704 and the crushing knife 705;

[0087] The installation shaft 704 is installed in the material receiving chamber 105, and the front and rear ends are rotatably connected to the inner wall of the material receiving chamber 105; the installation shaft 704 is evenly installed with a crushing knife 705; The No. 1 transmission wheel 701 is connected, and the No. 1 transmission wheel 701 and the No. 2 transmission wheel 703 are connected through a transmission belt 702.

[0088] Specifically, when the worm wheel 501 rotates, it also drives its coaxial No. 1 transmission wheel 701 to rotate; It rotates and produces a pulverizing effect; the mortar raw material falling into the receiving ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com