Laser 3D printing method for in-situ synthesized alumina particle reinforced nickel base composite

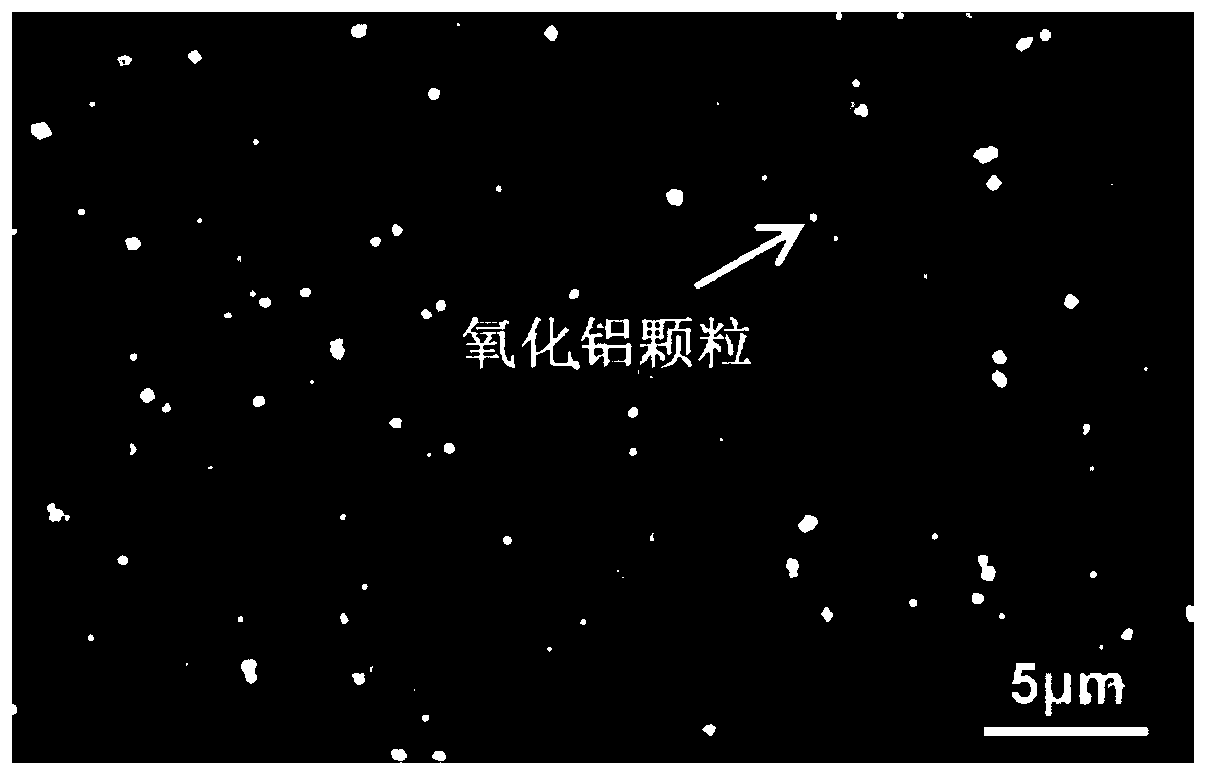

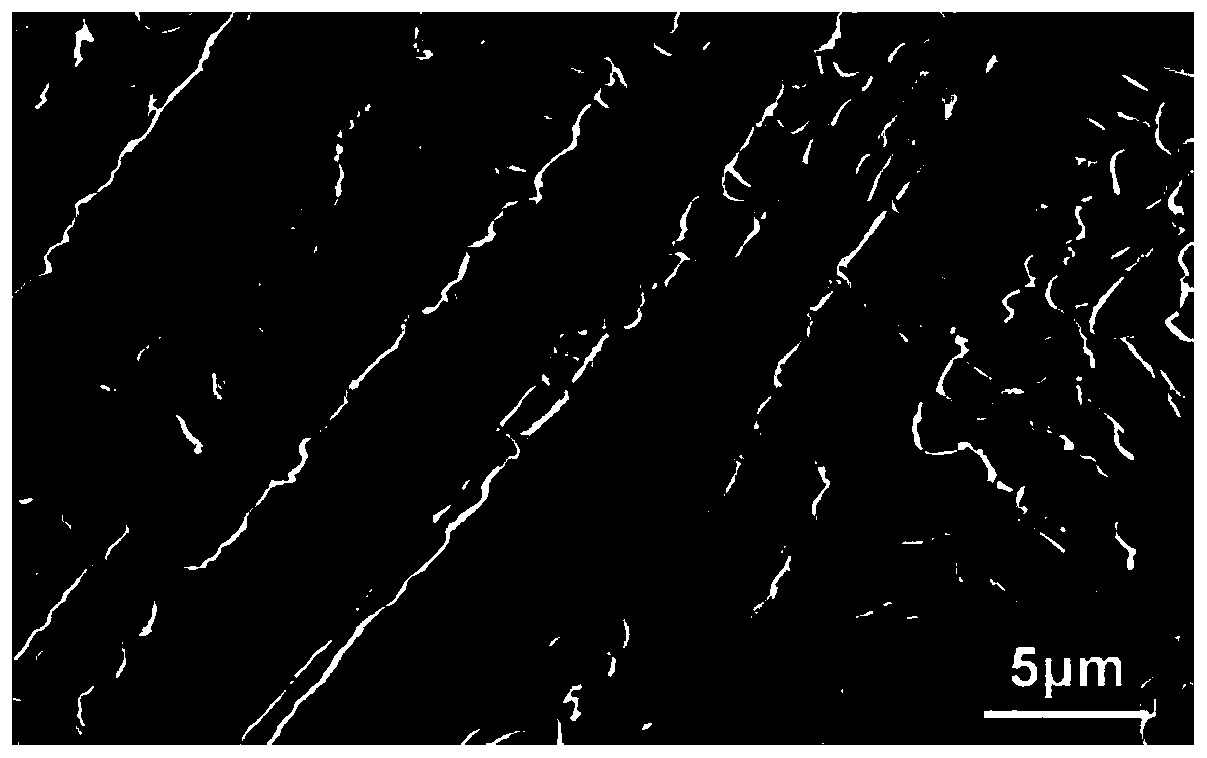

A kind of aluminum oxide particles, 3D printing technology, applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problems of poor distribution uniformity, poor matrix interface bonding, coarse particles, etc., to achieve good interface bonding, fine particles good, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A laser 3D printing method for in-situ synthesis of alumina particles reinforced nickel-based composite materials, comprising the following steps:

[0021] Step 1: Mix nickel-based alloy powder with pure aluminum powder, the mass percentage of pure aluminum powder is 2%, and then mechanically ball mill for 10 hours, and screen out powder with a particle size of 50 μm to 120 μm after ball milling;

[0022] Step 2: Preliminary optimization of the laser 3D printing process window to obtain the following preliminary optimization parameters: laser output power of 700-1300W, defocus amount of -2.5mm, laser spot diameter of 2-3.5mm, and scanning speed of 6-15mm / s , the powder delivery rate is 12-18g / min;

[0023] Step 3: use a colorimetric pyrometer to record the temperature change curve of the molten pool during the laser 3D printing process at fixed points, extract and calculate the average peak temperature T of the temperature change curve, the intercept t of the nickel-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com