Mixing device for whitening cream processing

A technology of mixing device and whitening cream, which is applied in the direction of mixer, transportation, packaging, dissolving, etc., can solve the problems of material stirring dead angle, large floor area, high procurement cost, etc., to eliminate stirring dead angle, reduce floor space, improve The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

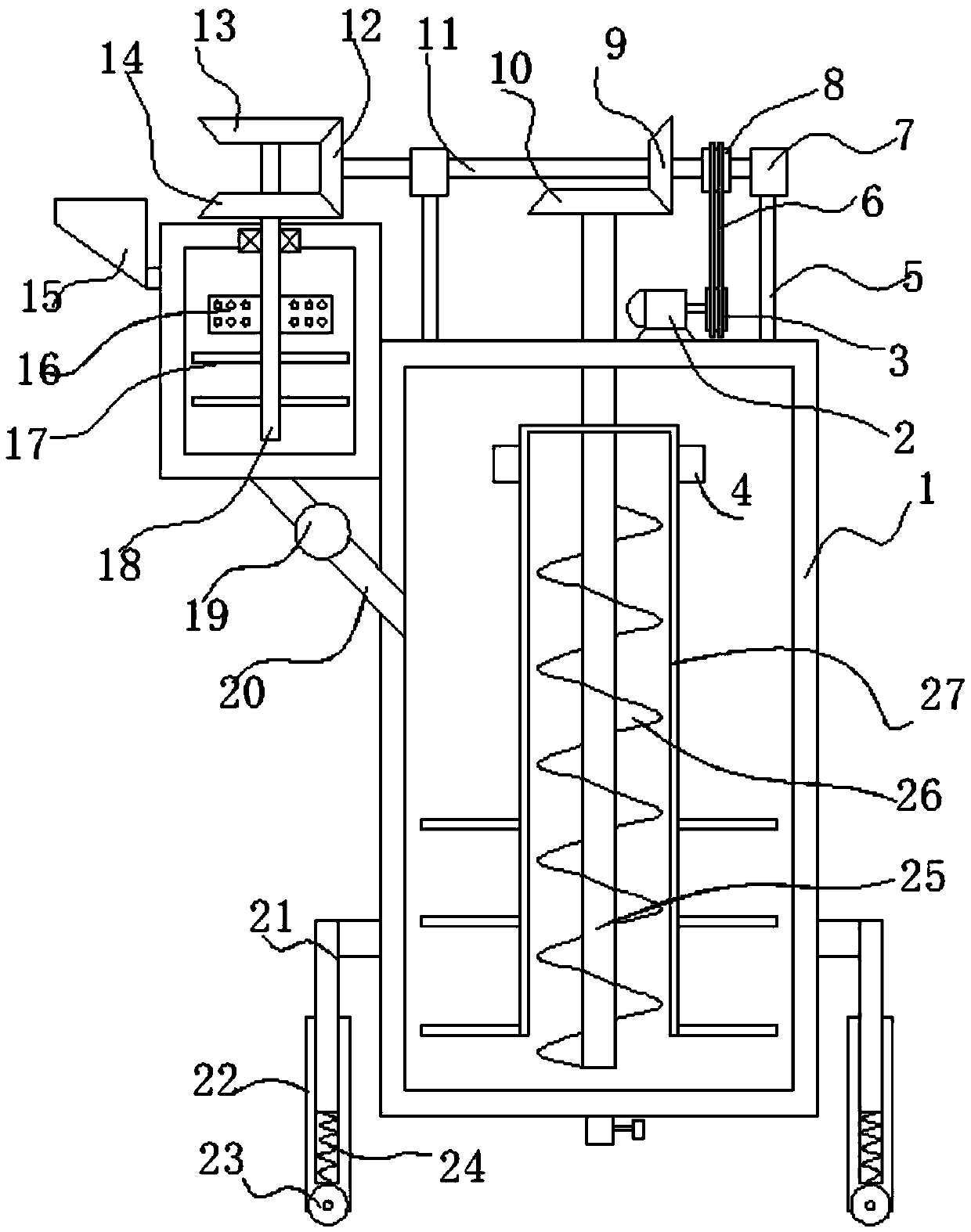

[0019] see Figure 1~3 , in an embodiment of the present invention, a mixing device for whitening cream processing includes a box body 1, a discharge pipe and a discharge valve located on the discharge pipe are provided at the lower end of the box body 1, and the upper left side of the box body 1 A pretreatment box is provided to stir the materials, and the feed end of the pretreatment box is provided with a hopper 15, and the discharge end of the lower end of the pretreatment box is connected to the feed end on the left side of the box body 1 through a connecting pipe 20, so that The connecting pipe 20 is provided with a throttle valve 19 .

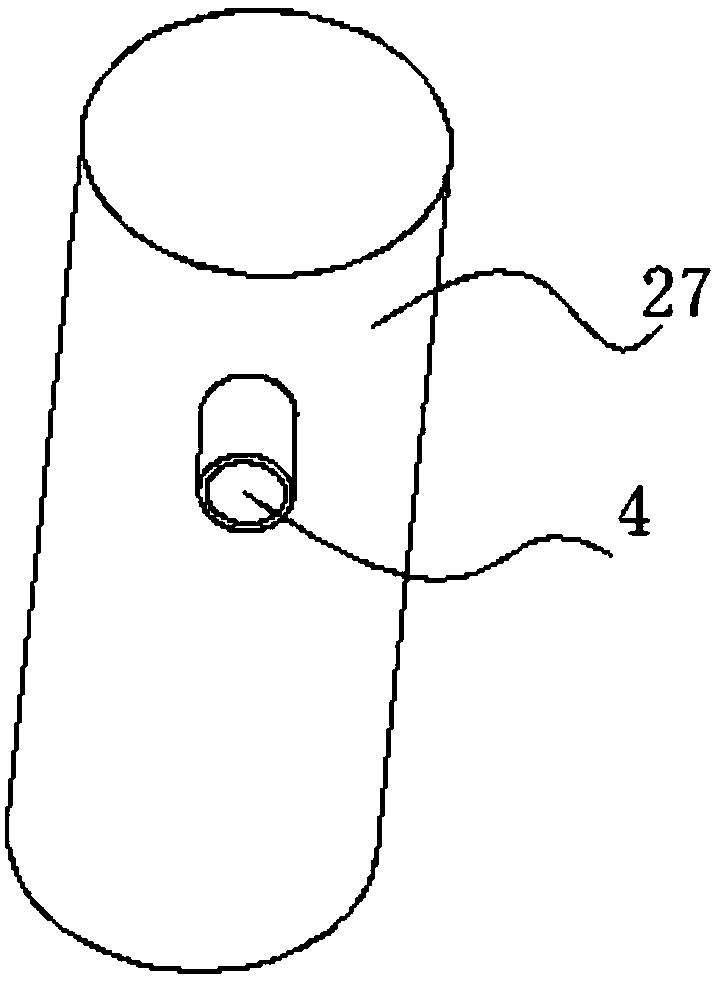

[0020] The box body 1 is a vertically arranged cylindrical barrel, and the inside of the box body 1 is provided with a stirring mechanism for convective stirring of materials, and the convective stirring mechanism includes a rotating rod 25 that is installed on the top of the box body 1, so that The rotating rod 25 and the box body 1 ar...

Embodiment 2

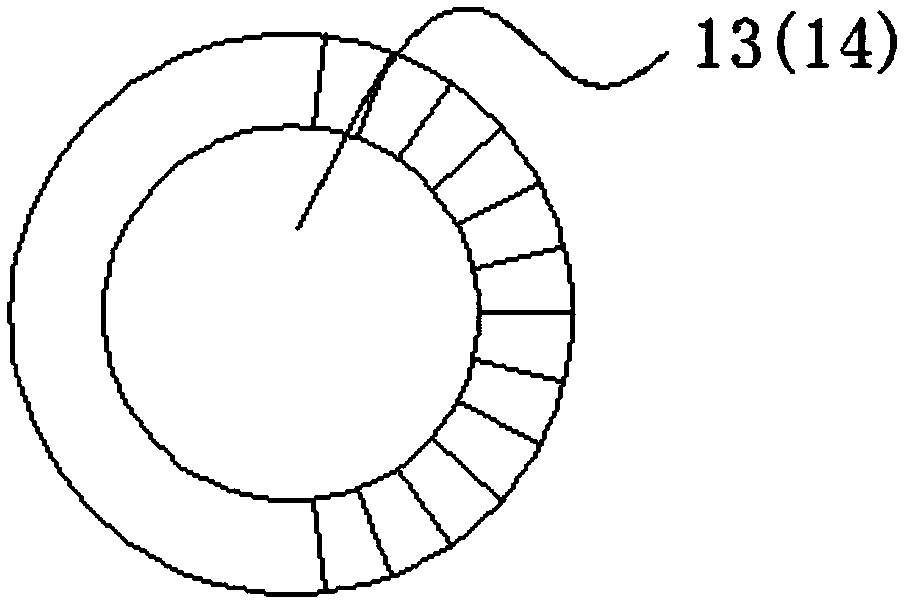

[0023] The difference from Embodiment 1 is that a pretreatment mechanism is provided in the pretreatment box, and the pretreatment mechanism includes a stirring shaft 18 that is installed on the top of the pretreatment box, and the lower end of the stirring shaft 18 is symmetrically arranged on both sides. Stirring bar 17 and stirring plate 16, described stirring plate 16 is provided with several split holes, and described stirring shaft 18 upper end is provided with coaxially and is provided with No. 2 gear 13 and No. 3 gear 14, No. 2 gear 13 and No. 3 gear. No. gear 14 meshes with the transmission gear 12 at the right end of transmission rod 11, and said No. two gear 13 and No. three gear 14 are all incomplete gears, and No. two gear 13 and No. three gear 14 are staggered and meshed with transmission gear 12, so that Under the transmission of No. 2 gear 13, No. 3 gear 14 and transmission gear 12, the stirring shaft 18 rotates forward and reverse intermittently, thereby avoidi...

Embodiment 3

[0025] The difference from Embodiment 1 is that the lower end of the box body 1 is symmetrically provided with outriggers 21 on both sides, the lower end of the outrigger 21 is slidingly provided with a support sleeve 22, and the inside of the support sleeve 22 is provided with a buffer spring 24, The buffer spring 24 connects and fixes the support sleeve 22 with the supporting leg 21, and the lower end of the support sleeve 22 is provided with a roller 23 for easy device handling, and the roller 23 is a self-locking roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com