Solar slurry stirring device

A stirring device and solar energy technology, which is applied to mixers with rotating stirring devices, mixer accessories, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as low stirring efficiency, complex structure, and slow stirring speed. Achieve the effect of improving the uniformity of stirring, the overall structure is simple, and the effect of eliminating dead corners of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

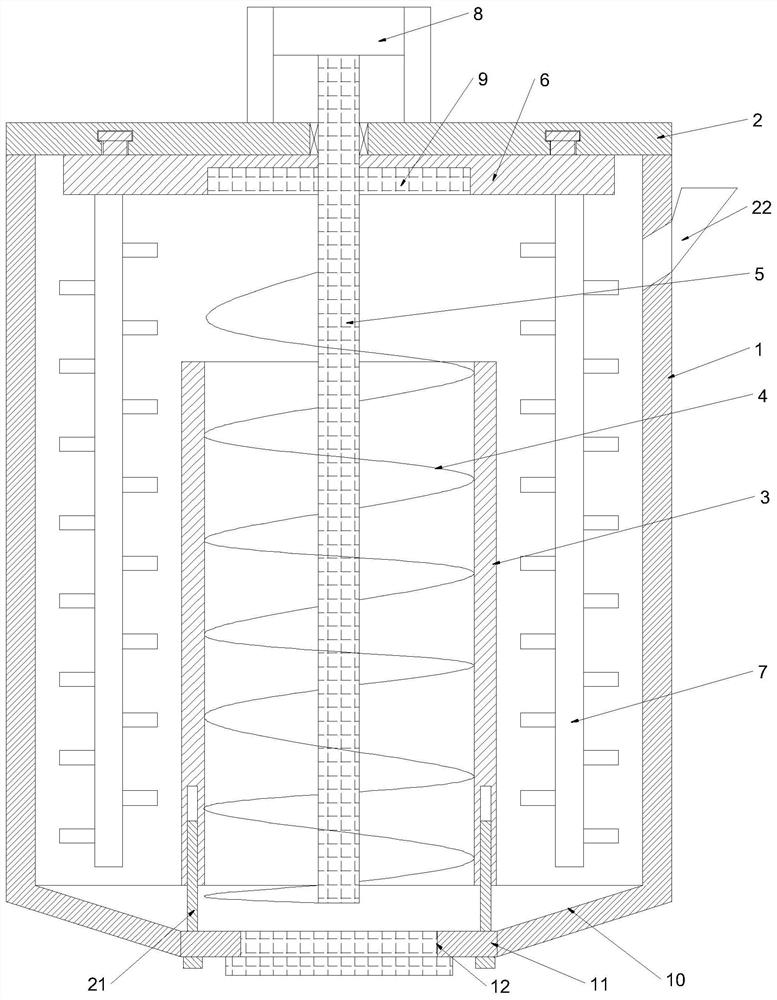

[0028] Such as figure 1 A stirring device for solar slurry shown in this embodiment includes a mixing tank 1, a barrel cover 2, a spiral riser pipe 3, a spiral lift blade 4, a central shaft 5, a rotating disc 6, a stirring rod 7, a stirring Motor 8 and driving block 9; The side wall of mixing bucket 1 is provided with feed inlet 22; The discharge opening 12 places are connected with sealing plug; The bottom of mixing bucket 1 is provided with tapered sliding surface 10, and the bottom of The bottom end is provided with a platform surface 11, the middle part of the platform surface 11 is provided with a discharge port 12, and the top of the discharge port 12 is provided with a spiral riser pipe 3, and the bottom end of the spiral riser pipe 3 is fixed on the platform surface 11 by an adjustment rod 21; The spiral riser 3 is provided with a central axis 5, and the spiral lifter blade 4 is fixed outside the central axis 5. The spiral lifter blade 4 is used to lift the solar slurr...

Embodiment 2

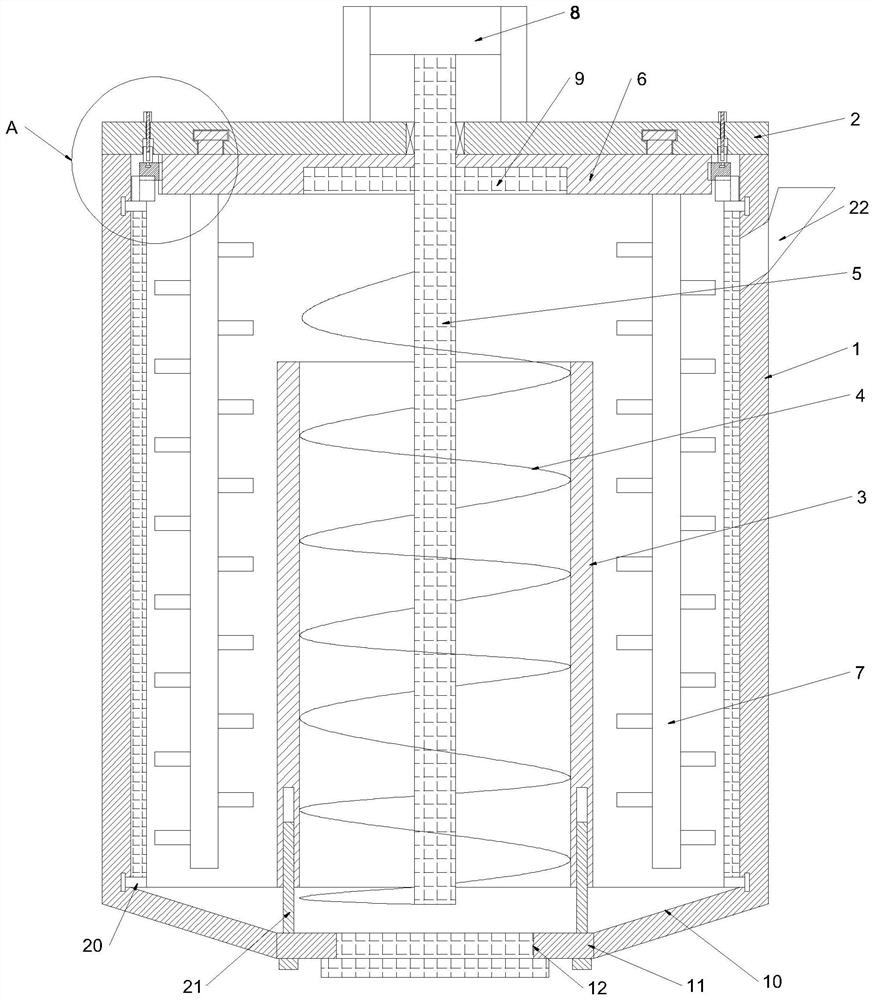

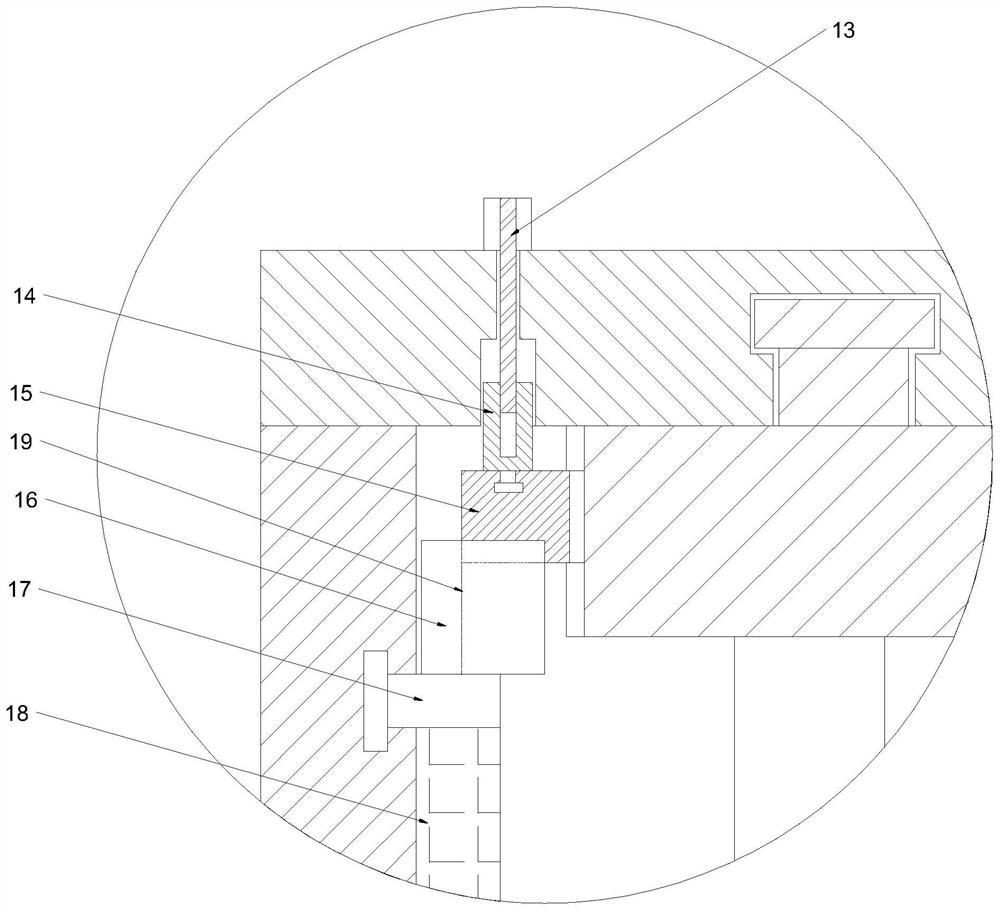

[0030] combine Figure 2 to Figure 3 The stirring device for solar slurry shown in this embodiment is different from Embodiment 1 in that it also includes a push rod 13, a top plate 14, a matching block 15, a drive plate 16, and a first swivel ring 17. The second swivel 20 and the scraper 18; at least one set of mating block 15 is provided, and is longitudinally slidably connected to the periphery of the rotating disk 6, and the top side of the mating block 15 is provided with an arc-shaped chute connected to the top disk 14 in rotation , and the top of the top plate 14 is provided with a threaded notch, the internal thread of the threaded notch is connected with a push rod 13, and the top of the push rod 13 passing through the bung 2 is also provided with a limit block; The matching block 15 is inserted into the matching groove 19, the bottom end of the drive plate 16 is fixed with a first swivel 17, and the bottom side of the first swivel 17 is provided with at least one set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com