Combined stirring means and apparatus in high solid anaerobic digestion biogas production

A technology of anaerobic digestion and stirring method, which is applied in the direction of biochemical cleaning equipment, biochemical equipment and methods, enzymology/microbiology equipment, etc. Low material utilization rate and other issues, to achieve the effect of reducing damage, saving energy consumption, and avoiding material crusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

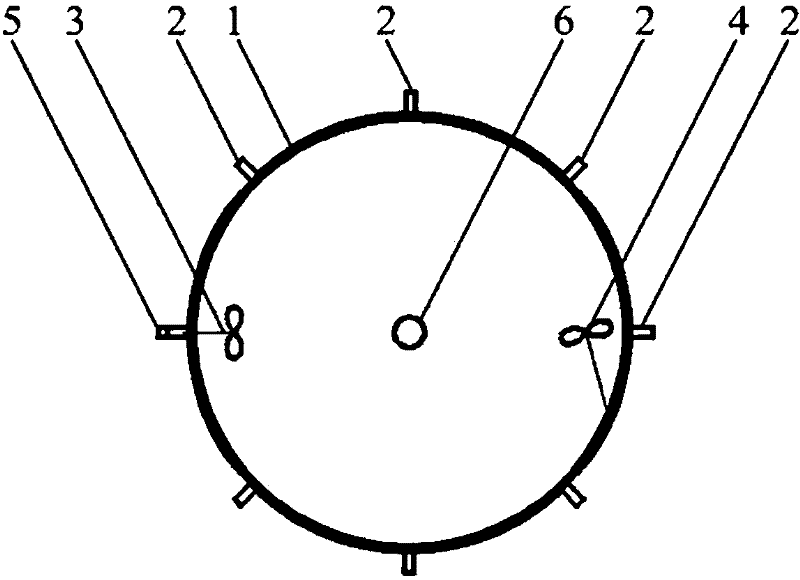

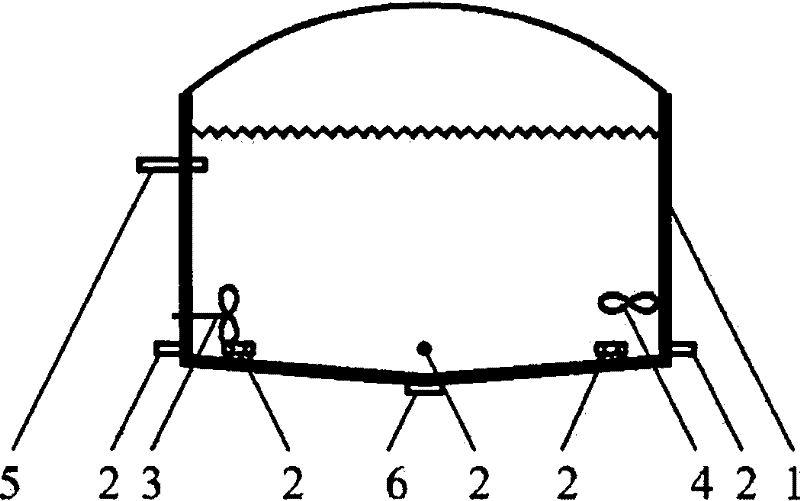

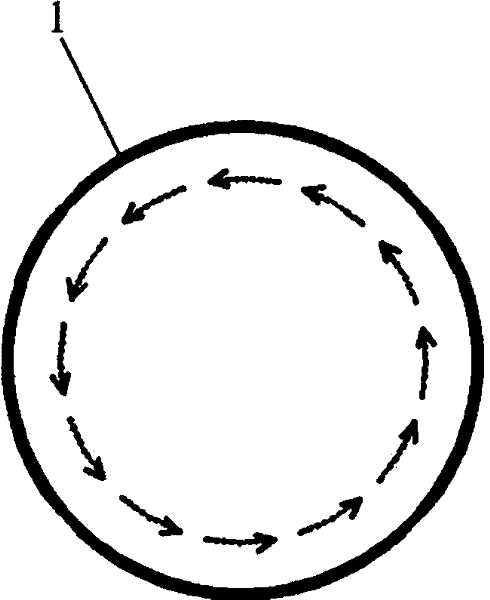

[0025] Reactor 1 has a wall height of 10 meters and a bottom diameter of 20 meters. The radial agitator 3 and the tangential agitator 4 are both 15 kW axial flow propeller agitators. The vertical distance between the shaft and the bottom surface of the reactor 1 is twice the length of the propeller. , the shaft extends into the reactor 1 for 0.5 to 1 meter, the sand discharge pipe 2 is set to 8, the inner diameter is 10 cm, the inner diameter of the feeding pipe 5 is 20 cm, and the distance from the top of the reactor 1 wall is 2 meters. The inner diameter of the large discharge pipe 6 It is 50 cm and is located in the middle of the bottom surface of reactor 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com