Efficient dry-type anaerobic fermentation equipment for organic solid waste

A dry anaerobic fermentation, organic solid waste technology, applied in the fields of biochemical equipment and methods, waste fuel, biochemical instruments, etc., can solve the problems of wasting water, poor thermal insulation effect, scattered buildings, etc., to achieve convenient management and maintenance, The effect of avoiding biogas residue crusting and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

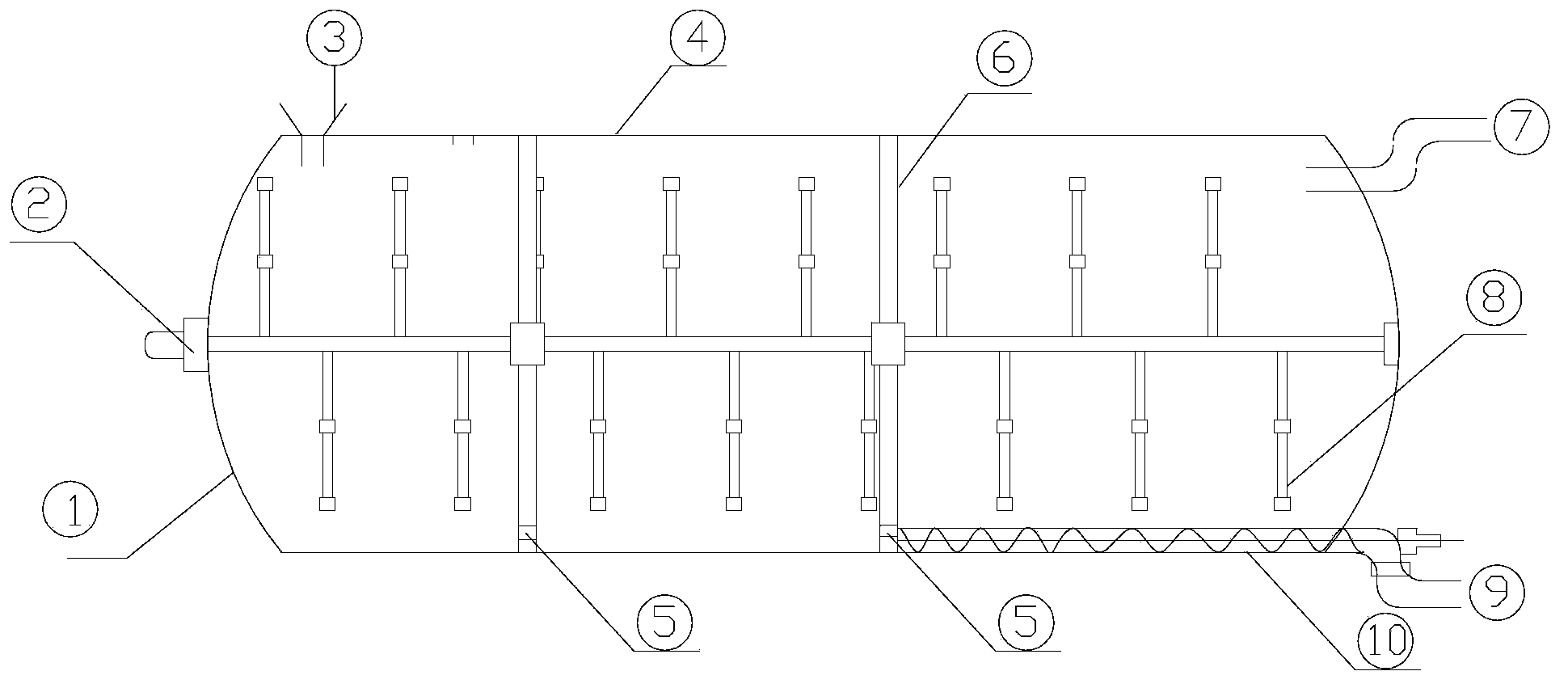

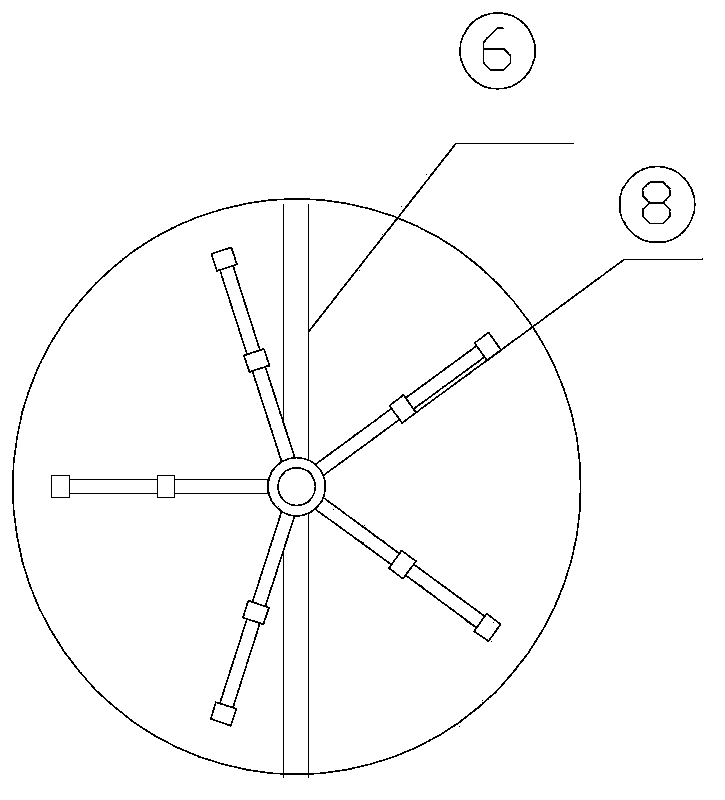

[0016] As shown in the figure: a high-efficiency dry-type anaerobic fermentation equipment for organic solid waste. The horizontal main tank ① has a feed inlet ③ and an air outlet ④ on the top, and the horizontal main tank ① has a slag outlet ⑨ on the bottom. The horizontal main tank ① has a liquid outlet ⑦ on the side; the interior of the main tank is divided into three fermentation chambers by two partitions ⑥, and the agitator ② is inserted horizontally from the center of the main tank, and the agitator ② is fixed on the top. There are stirring blades ⑧, and the bottom of the main tank is equipped with a biogas discharge device ⑩, which communicates with the slag outlet ⑨; the bottom of the partition has a communication hole ⑤. The stirring rod of the above-mentioned agitator runs through the inside of the whole main tank body. The opening of the above-mentioned feed inlet is vertically upward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com