A device and method for improving coagulation effect of isoprene rubber

An isoprene rubber and agglomeration kettle technology, applied in the field of synthetic rubber, can solve the problems of high foam in the system, sticky glue, and high steam consumption in the coagulation unit, and achieves the advantages of eliminating the dead angle of stirring, reducing the surface tension and reducing the steam consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The rare earth isoprene rubber hexane solution used is obtained by polymerizing isoprene with hexane as a solvent under the action of a rare earth catalyst. The rubber content is 12%, and the 1,4-cis content of rare earth isoprene rubber is 96%. The molecular weight distribution was 2.5, and the Mooney viscosity was 85. The specific operation steps are as follows:

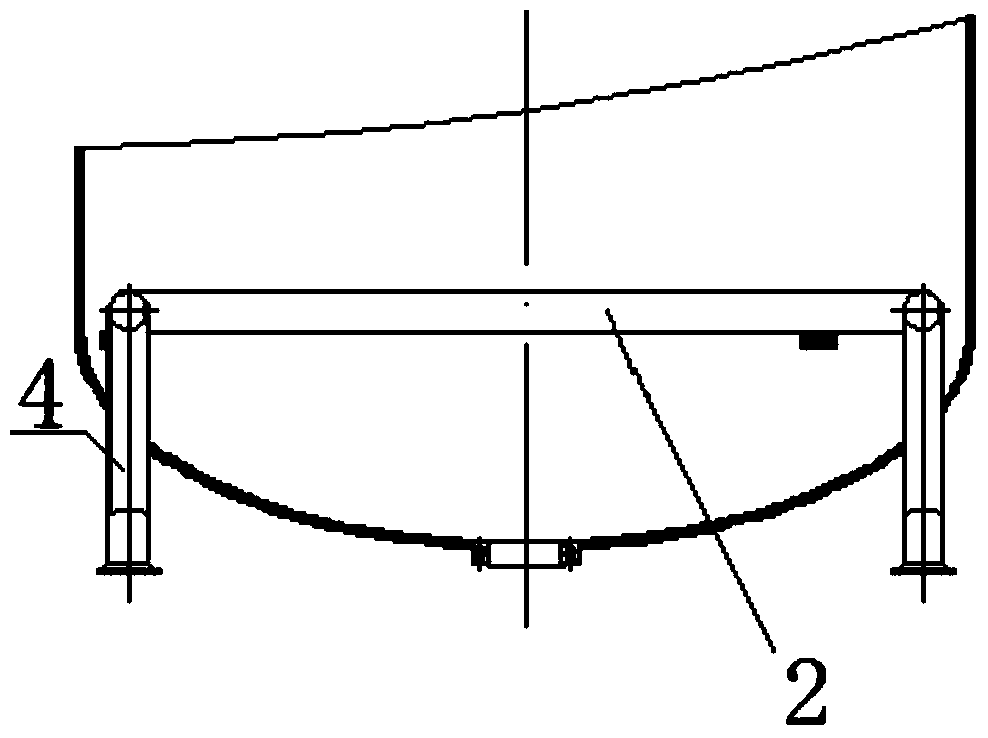

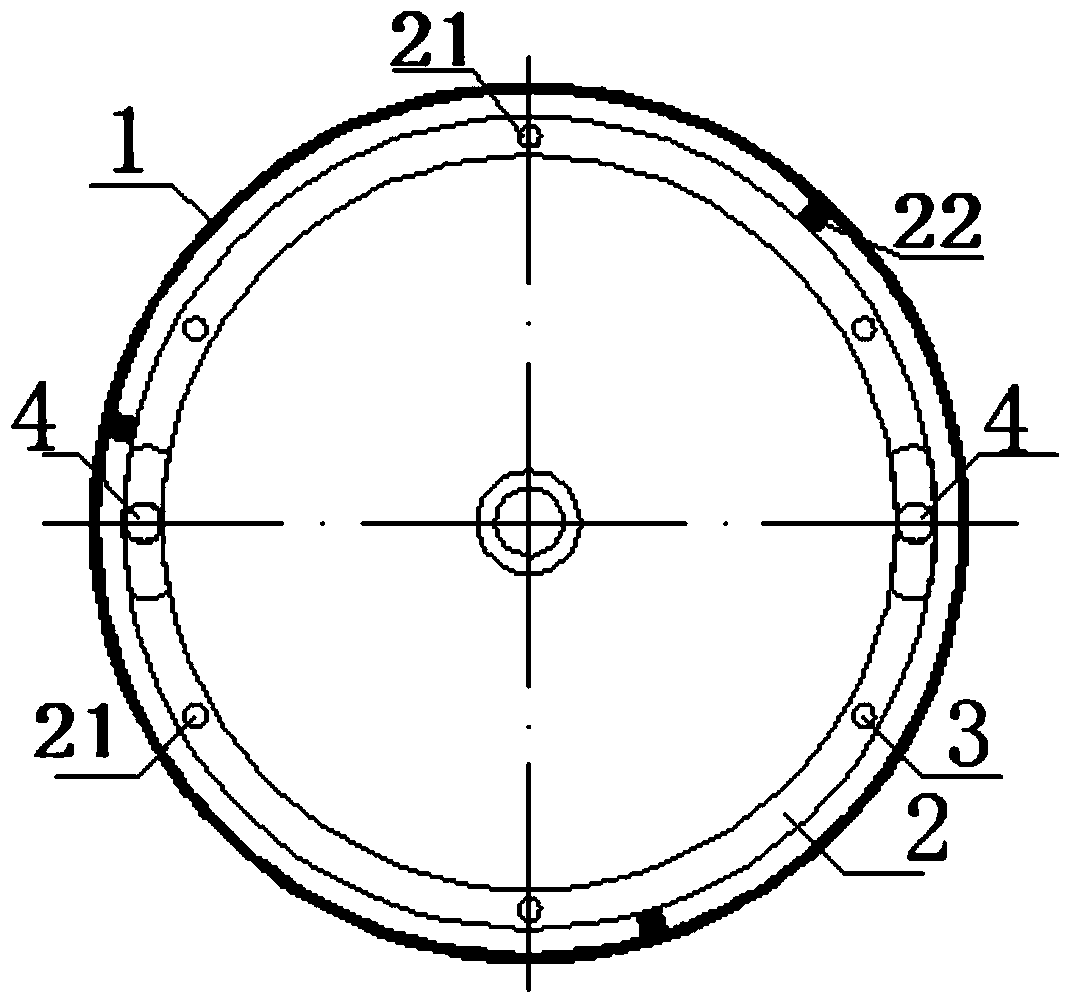

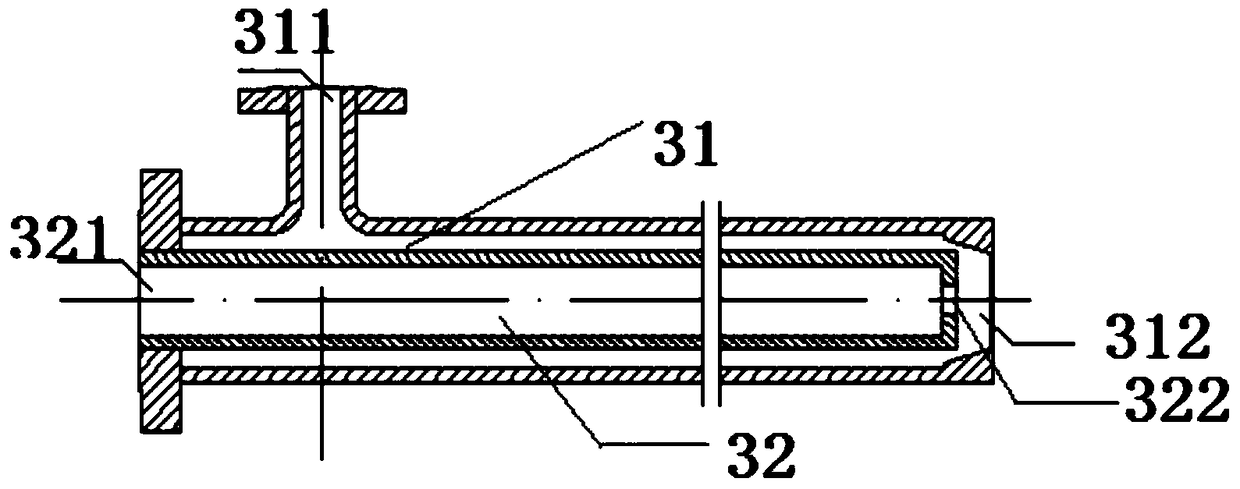

[0060] Rare earth isoprene rubber is sprayed 3 into the coagulation kettle 1 through a dual-fluid nozzle. A ring of compressed air pipelines with holes are arranged on the inner wall of the first coagulation kettle and the second coagulation kettle. Each pipeline has 3 openings and 3 openings. The holes are evenly distributed on the annular compressed air pipeline, and the compressed air outlet is parallel to the wall of the coagulation kettle 1. The specific operating conditions are: the compressed air from the compressed air supply device and the rare earth isoprene rubber from the glue supply device are p...

Embodiment 2

[0062] Glue used is with embodiment 1, and concrete operation steps are as follows:

[0063] The rare earth isoprene rubber is sprayed 3 into the coagulation kettle 1 through a two-fluid nozzle. The first coagulation kettle and the inner wall of the first coagulation kettle are not equipped with a compressed air pipeline 2 with holes. The specific operating conditions are: the compressed air from the compressed air supply device And the rare earth isoprene rubber from the glue supply device is injected into the coagulation kettle 1 through the two-fluid nozzle 3, and the rare earth isoprene rubber injected into the coagulation kettle 1 through the two-fluid nozzle has a glue feeding speed of 1m 3 / h, the pressure of the compressed air injected into the dual-fluid nozzle 3 is 0.6MPa, the amount of release agent should be kept at 0.05kg / t glue, the temperature of the first coagulation tank is 83°C, the stirring speed is 280 rpm, the second The temperature of the coagulation kett...

Embodiment 3

[0065] Glue used is with embodiment 1, and concrete operation steps are as follows:

[0066] A ring of compressed air pipelines 2 with holes are arranged on the wall of the first condensation kettle and the second condensation kettle, and each pipeline 2 is provided with 6 compressed air outlets, and the 6 openings are evenly distributed on the ring-shaped compressed air pipeline 2 , the compressed air outlet is parallel to the wall of the coagulation kettle, and the specific operating conditions are: the compressed air from the compressed air supply device and the rare earth isoprene rubber from the glue supply device are injected into the coagulation kettle through the two-fluid nozzle 3, and at the same time, the The compressed air line 2 is injected with compressed air, and the rare earth isoprene rubber injected into the coagulation kettle through a two-fluid nozzle is fed at a speed of 1m 3 / h, the pressure of the compressed air injected into the dual-fluid nozzle 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com