Lake asphalt melting and stirring system

A mixing system and lake asphalt technology, which is applied in the field of lake asphalt melting and mixing system, can solve the problems of serious energy consumption, damage, low output, etc., and achieve the effects of reducing labor intensity, easy manufacturing, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

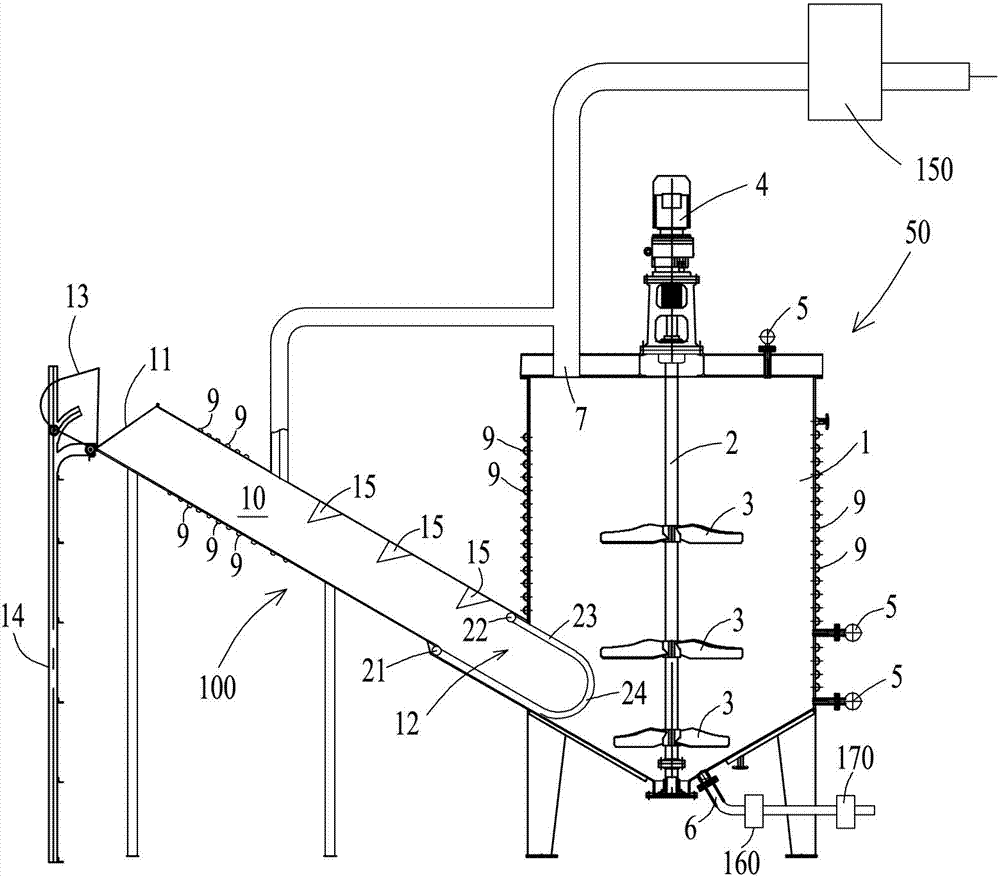

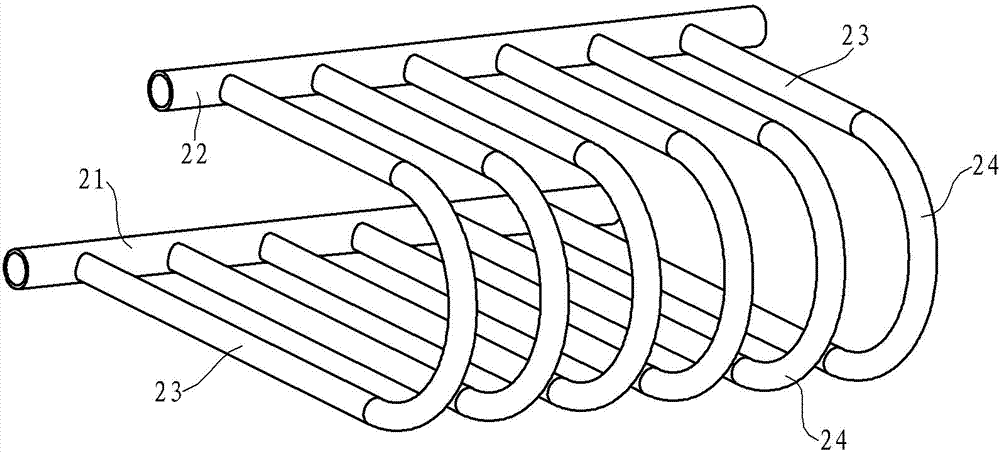

[0027] Such as figure 1 and figure 2 As shown, the lake asphalt melting system according to the embodiment of the present invention includes a thermal insulation mixing tank 50 with an insulation layer on the outer wall and a melting device 100 , and the melting device 100 communicates with the thermal insulation mixing tank 50 . The massive lake asphalt is first melted into a liquid state in the melting device 100 , then flows into the heat preservation mixing tank 50 to be fully stirred, and is taken out for use after the stirring is completed.

[0028] The thermal insulation mixing tank 50 has a closed tank body 1, and a vertical stirring shaft 2 is installed inside the tank body 1, and stirring blades 3 are installed in groups on the stirring shaft 2, and at least one set of stirring blades 3 needs to be installed. , in order to fully stir, the present embodiment is provided with three groups altogether. The motor 4 that drives stirring shaft 2 to rotate is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com