A kind of green banana starch and its preparation method and application

A green banana and starch technology, applied in the field of food processing, can solve the problems of waste, high cost, swelling and collapse of starch granules, etc., and achieve the effects of being difficult to separate, preventing swelling and collapsing, and increasing the dissolution rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A preparation method for green banana starch, comprising the following steps:

[0073] (1) Green banana pretreatment

[0074] Using defective products and leftovers from the processing line as green banana raw materials, the green bananas are sliced directly with the skin on, and then the bananas are wet-milled at a low speed with 0.2% color-protecting liquid citric acid. The color-protecting liquid citric acid is mixed with The volume ratio of bananas is 1:1, and then add a compound enzyme composed of pectinase, cellulase, and polygalacturonase to hydrolyze the cell wall, and place it at 40°C for 1 hour to obtain green banana pulp;

[0075] Pectinase, cellulase, and polygalacturonase all account for about 0.1% of banana weight;

[0076] (2) Extract green banana starch

[0077] Add extraction solvent acidic solvent and filter aid in green banana pulp, acidic solvent is the sodium bisulfite solution of 1% by mass fraction, and filter aid is the kaolin that accounts f...

Embodiment 1B

[0097] To the mensuration of the main component of green banana starch obtained in embodiment 1A, assay method is as follows:

[0098] The determination of green banana starch content refers to GB 5009.9-2016 "Determination of Starch in Food Safety National Standard Food"; the determination of amylose content refers to GB / T 15683-2008 "Determination of Rice Amylose Content"; the determination of crude protein refers to GB 5009.5-2010 "National Food Safety Standard for the Determination of Protein in Food"; for the determination of crude fat, refer to GB / T22427.3-2008 "Determination of Total Fat in Starch"; for the determination of ash content, refer to GB / T 22427.1-2008 "Determination of Starch Ash Content".

[0099] The main component of the coarse starch milk that obtains in the embodiment of table 1 and comparative example

[0100] sample Total starch (%) Amylose(%) Crude protein (%) Crude fat (%) Ash (%) Example 1 92.29 24.12 1.04 0.18 0.67 ...

Embodiment 2

[0104] Use green banana starch to make vermicelli, the specific method is as follows:

[0105] (1) Preparation of vermicelli

[0106] Get 5.0g of the green banana starch sample in Example 1A and add 20mL of water to gelatinize in boiling water, then add 25g of starch and an appropriate amount of water to make a starch dough with a total moisture content of 45%, and pour the dough into a powder with a diameter of 25cm Spread it out on an iron plate and let it stand for 5 minutes. Put it in a steamer and steam for 5 minutes, then quickly put it in cold water to cool down and take it out. Store at 4°C for 12 hours, peel off the skin and cut into vermicelli with a width of 1cm, and dry the finished product at 40°C.

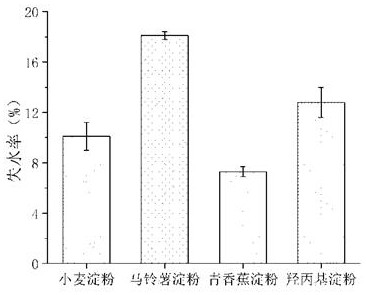

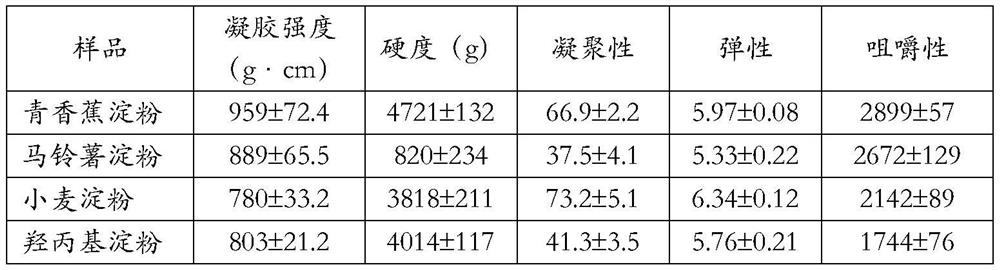

[0107] (2) Determination of Vermicelli Quality Index

[0108]①Broken rate: Boil 30 vermicelli samples with a length of 10cm in 800mL distilled water for 30min, and calculate the broken rate (%). Broken sliver rate=(broken sliver number / 20)×100%.

[0109] ②Hardnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com