Spray dryer for pea protein powder production

A spray dryer and pea protein powder technology, applied in spray evaporation, evaporator accessories, etc., can solve the problems of water retention, protein powder pores, affecting the quality of protein powder, etc., to eliminate the dead angle of stirring, assist the drying process, improve The effect of the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

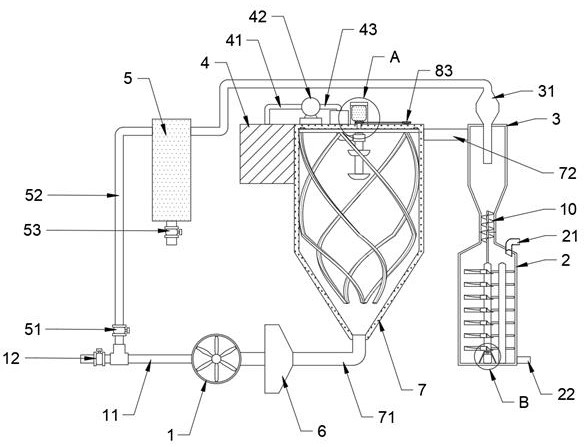

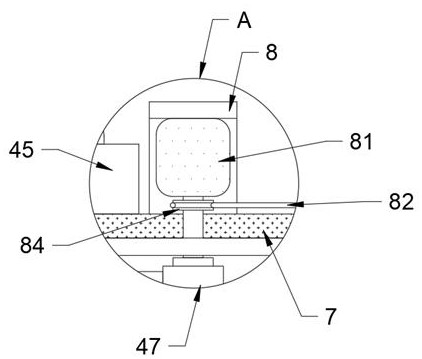

[0036] Specifically, the scraping component includes the ring groove opened on the inner wall of the top 7 of the dryer body 7.There are many spiral scrape 86 distributed in the circular array, and the outer wall of the output shaft of the motor 281 is fixed with a belt wheel 84, the top of the dryer body 7 runs through and is connected to the short shaft through the bearing.Fixed installation with a belt wheel two 83 and gear 88, the outer wall of the belt 1 84 and the belt wheel 2 83, there are the same belt 82, the inner wall of the fixed ring 85 inner wall is opened with a meshing of the gear 88.84. The transmission of the belt 2 83 and the belt 82 drives the gear 88 rotation, which in turn drives the low -speed rotation of the fixed ring 85 and the spiral scraper 86.The effective cleaning of the inner wall of the dryer body 7 is to prevent the aggregate from bonding the liquid on the inner wall of the dryer body 7.

[0037] Specifically, the recycling mechanism includes a sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com